Simovert

Edition AB

Page

Contents

10-1

11-1

12-1

13-1

14-1

15-1

16-1

17-1

17.1

17-2

Definitions and Warnings

Definitions and Warnings 01.2004

Sitting

Standing Standing / Sitting

Installation

Maintenance and servicing

Keep these safety instructions in a safe place

General

Description

DC link voltage

Operating range

Description 01.2004

Configuration Operation and control options

Initial Start-Up

Energizing the power and the unit

Persons and equipment can occur by

You are advised to only connect

Invertors after completing the basic

Transport, Storage, Unpacking

Transport Storage Unpacking Scope of delivery type G

Scope of delivery type J

Box options

Installation

Installing the units

Point of installation

Clearances

Mounting dimensions and dimension sheets

AFE basic mains module with CleanPower filter

Mounting dimensions of AFE reactor

Current Voltage

AFE inverter construction type G

Door/roof openings

An arcing short-circuit must be prevented by the provision

Partitions

Opening cross sections

Filters

Following filter mat is approved for use

Fibroidelastov made by DELBAG-Luftfilter Gmbh

Technical filter data in accordance with DIN

Water cooling

Built-in components

Roof section

AFE inverter construction type J

Appendix

Masterdrives VC inverters

01.2004 Installation

Filters

Fan, flow rate, opening cross- sections

Mlfb

Implementation

DC auxiliary

Supply

Installing the optional boards

Opened until at least after this delay time

Boards may only be replaced by qualified personnel

Slot 2 can be used for technology boards T100, T300, TSY

Installation 01.2004

Installation in Conformance with EMC Regulations

Connecting-Up and Wiring

AFE basic mains module and CleanPower filter

X3 connector terminal

Connection overviews

AFE reactor connection

U2/T1 V2/T2 W2/T3

Fan

+ D/L

Electronics box for boards Cusa X9 connector

DC connection

Fan connection 230 V 1 AC

210 a 3NE1 227-0 250 a 3NA3 144 250 a

Example configuration -7 for construction type J shows a

Control transformer must be protected by a 6 a fuse

Directly from the plant

Mains

Typical circuit for AFE chassis unit, construction type J

Power connections

AFE inverter and AFE reactor

Auxiliary power supply, precharging

Protective conductor connection

X9 external DC 24 V supply, precharging contactor control

Fan supply

Connectors for

Control terminals

Standard connections of the AFE inverter

Control terminal

View of Cusa

Connecting up control cables

Terminal assignments

X100 control

Terminal strip

X101 control

Terminal Name Function Range

X102 control

Possible cross- .5 mm 2 AWG

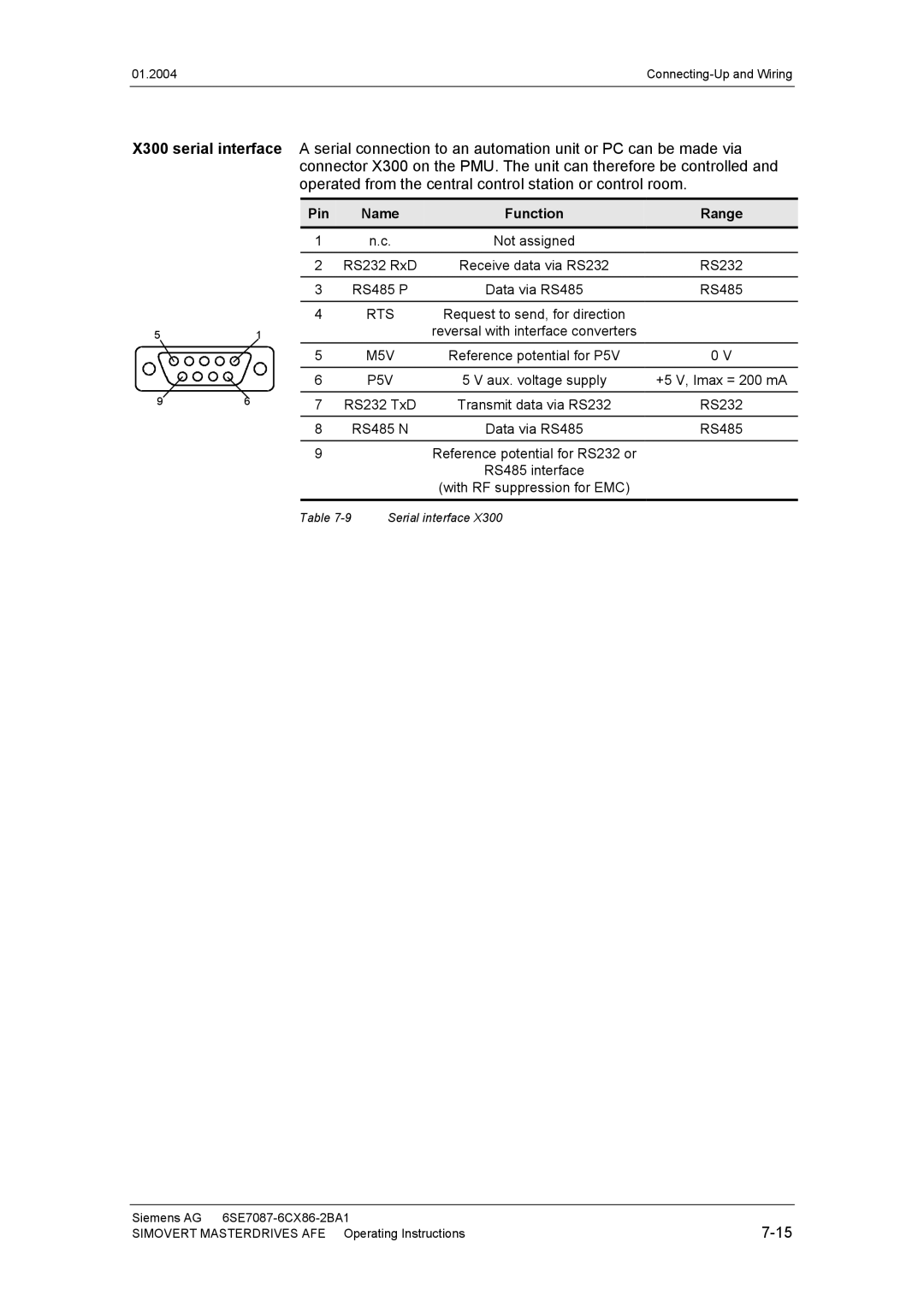

X300 serial interface

Pin Name Function Range

Factory setting

Digital inputs/outputs

Connection

Digital outputs

Only one of the above possible connections may be used

Dual-port Ram DPR for SCB, TSY, CB, TB

Voltage Sensing Board VSB

View of option board VSB

Connector assignments

VSB

Basic Function Check

Commissioning of the equipment

Please check

Reset is run P052 automatically returns to

P052 =

Checking actual value acquisition and precharging

P561 =

Explanation of Terminology and Functionality of the AFE

Data sets

Function Diagrams

10-1

Switchover, basic/reserve setting Basic/Resv

Switchover of reserve data set RDS

10-2

Parameterization

Examples

11-1

Setting parameters via the PMU

Key Meaning Function

Toggle key

Key

Example

Menu selection Closed-loop control settings

Start-up parameterization

Select language

Input rated supply voltage Input line frequency in Hz

Factory setting P052 = 1 Parameter reset

Function selection P052

Access level Expert Mode

Initialization Mlfb input P052 =

Function Condition Result

To change P070

Download P052 =

Select Return

Select Download

Hardware configuration P052 =

TB installed in the electronics box of the converter

007, Starting Lockout 008 or Ready for on 009 states

P051 = P090 = P091 =

Closed-loop control settings P052 =

Select Closed-loop control settings

Parameter List

Key to parameter list

12-1

General visualization parameters

R001 Operating status

R004 Output Amps

R006 DC Bus Volts

12-3

R013 Operat. hours

R030 Line volts

R032 Line frequency

P051 Access Level

General parameters

P052 Function Select

12-5

P054 OP Backlight

Drive data

12-7

R082 Line filter L/%

P083 Precharging

R089 Board Position

Hardware configuration

P091 Board Position

Closed-loop control

12-10

R139

R150 Control status

R152 Active RDS

P164 Operating mode

12-11

P160 Startmot,max

P161 Startgen,max

12-12

P325 MC switch-on del

P329 MCInvEnableDel

12-13

P308 Sampling Time

Functions

P387

P408 Forming time

P409 Line contac. del

Setpoint channel

12-16

P518 Deviation Time

Control and status bit connections

12-18

P575 Src No Ext Fault1

12-19

P572

P576 Src. ext V ok

P586 Src No ExtFault2

12-20

P587 Src.slave AFE

P588 Src No Ext Warn1

12-21

12-22

12-23

12-24

P629 DstPrechrgContEn

P631 Dst Pre-Charging

P660 SCI AnalogInConf

Analog inputs/outputs

P656 Cusa AnalogOutGain

P657 Cusa AnalogOutOffs

P662 SCI AnalogInOffs

12-26

P664 SCI AnaOutActVal

P665 SCI AnaOut Gain

Interface configuration

P682 SCB Protocol

P683 SCom/SCB BusAddr

P684 SCom/SCB Baud

12-28

P686 SCom/SCB # PrDat

P687 SCom/SCB TlgOFF

P689 SCB Peer2PeerExt

12-29

P694 CB/TB Act Values

P695 CB/TB TlgOFFTime

12-30

Diagnostic functions

R721 SW Generat.Date

R722

R723 PCB Code

12-32

R730 SCB Diagnosis

12-33

R748 Trip Time

P799 Special Access

Gating unit

Factory parameters

P927 Parameter Access

Profile parameters

P928 Src Base/Reserve

R949 Fault Value

R951 Fault Texts

12-36

12-37

12-38

12-39

12-40

Control and Status Words

Control word

Introduction

Application

Display of control word on PMU seven-segment display

Multiple connections are permitted

Control word

Factory setting applies only when P077 =

Control word 1 visualization parameter r550 or r967

Designation

Bit No. meaning

Control word 2 visualization parameter r551

Parameter No

Sources for control words 1

Table X external terminals

Table a

Table B

Table C

Table D

Table E

Table F

Table G

Table H

0000 0001 2004 3004 4501 4502 4503 4504 4505

13-8

Bit 0 on / OFF1 command ↑ on / L OFF1 Condition

Bit 1 OFF2 command L OFF2 electrical Condition

Description of the control word bits

Bit 7 Acknowledge command ↑ Acknowledge Condition

Bit 8 Inching 1 on command ↑ Inching 1 on / L Inching 1 OFF

Bit 9 Inching 2 on command ↑ Inching 2 on / L Inching 2 OFF

Bit 10 Control via PLC command H Control via PLC Condition

Bit 19 Reserved Bit 20 Reserved

Bit 28 External alarm 1 command L External alarm Condition

Bit 29 External alarm 2 command L External alarm Condition

Master AFE

High signal

Setpoint channel and closed-loop control are activated

Bit 31 Reserved

13-13

Status word

Status word 1 visualization parameter r552 or r968

Destination

PMU display Status word

13-15

Bit #

= High Select = Low Destin Bit Ready for on P600.x

Destination

Status word 2 visualization parameter r553

13-17

= High Select = Low Destin

= 3

= 1 0000 1001 1002 1003

Bit 0 Ready for on signal H High signal

Bit 1 Ready to Run signal H High signal

Bit 2 Run signal H High signal

Description of the status word bits

Bit 6 Starting lockout signal H High signal

Bit 7 Alarm signal H High signal

Bit 8 Setpoint/actual value deviation signal L LOW signal

Bit 19 External fault 1 signal H High signal

Bit 20 External fault 2 signal H High signal

Bit 21 External alarm signal H High signal

Bit 22 AFE i2t alarm signal H High signal Meaning

Bit 23 AFE overtemperature fault signal H High signal

Faults and Alarms

Faults

Compare with P071 Line voltage

F003 Line overvoltage

14-2

14-3

14-4

14-5

Alarms

14-7

Fatal errors FF

Maintenance

Simovert Masterdrives units are operated at high voltages

National electrical codes VBG 4 in Germany

Personnel

CleanPower filter

Electrical components

AFE basic mains module

Position Equipment designation Brief description

AFE inverter maintenance

Replacement

Fan assembly weighs about 30 kg

Replacing the fan

Replacing the fan fuses construction type J only

Replacing the starting capacitor

Replacing the capacitor battery

Capacitor battery weighs up to 30 kg

Replacing the PMU

PMU with adapter section on the electronics box

Fuses

Fan fuses for AFE inverters

15.3.2 DC fuses

Forming

How the serial

Example A-J60147512345

Number is made up

Switch on AFE

P408 P052 = Key

End

Technical Data

CleanPower filter AFE basic mains module

17-1

AFE basic mains module and CleanPower filter

17-2

17-3

AFE reactor for construction type G

AFE reactor for construction type J

17-4

6SE703x-xES87-1FG1

AFE inverter

17-5

Derating curves

17-7

Designation Value

Environmental Friendliness

Certificates Confirmation

Equipment

Type

Order No 6SE70

Equipment Type Order No

AC drive converter

Type 6SE70 Chassis units AC-AC and DC-AC

19-3

Contents

Appendix

Appendix to

Operating manual

Page

Page

Page

SIMOVERT-MASTERDRIVES AFE Siemens AG

FKBL1-VSB1

Edition Internal Item Number A5E00243916

Chapter Changes Pages Version date

Siemens AG