Cisco 7500 Series Installation and Configuration Guide

Corporate Headquarters

Cisco 7500 Series Installation and Configuration Guide

N T E N T S

Iii

RSP Asynchronous Serial Ports-Console and Auxiliary

Installing a Cisco 7500 Series Router

Checking the Settings

Copying Files Between RSP Memory and a Flash Memory Card

Vii

Viii

Exchanging the Eeprom Devices

Bits 0-3 A-2

OL-5008-03 B0

Audience

Organization

Related Documentation

Chapter Title Description

Xii

Conventions

Convention Description

Xiii

Xiv

Safety Warnings

Waarschuwing Belangrijke Veiligheidsinstructies

Warnung Wichtige Sicherheitsanweisungen

Hinweis Bewahren SIE Diese Sicherheitsanweisungen AUF

Figyelem! Fontos Biztonsági Elõírások

Megjegyzés Õrizze MEG Ezeket AZ Utasításokat

Aviso Instruções Importantes DE Segurança

Xvii

Restricted Area Warning

Xviii

Obtaining Documentation

Xix

Documentation Feedback

Obtaining Technical Assistance

Cisco.com

Ordering Documentation

Submitting a Service Request

Definitions of Service Request Severity

Cisco Technical Support Website

Xxi

Obtaining Additional Publications and Information

Xxii

Cisco 7500 Series Product Overview

Terms and Acronyms

Cisco 7505 Overview

Cisco 7505 CyBus Backplane

Cisco 7505 Front View

Cisco 7505 System Specifications

Description Specification

Cisco 7507 Overview

Cisco 7507 Front View

Lower Power supply

Cisco 7507 Dual CyBus Backplane

Dual CyBus Backplane in the Cisco

Cisco 7507 System Specifications

Cisco 7507-MX Overview

Cisco 7507-MX Front View

Cisco 7507-MX Dual CyBus Backplane

Cisco 7507-MX Rear View

Dual CyBus Backplane in the Cisco 7507-MX

Cisco 7507-MX System Specifications

Cisco 7513 Overview

10 Cisco 7513 Front View

Cisco 7513 Dual CyBus Backplane

Receptacles

12 Dual CyBus Backplane in the Cisco

Cisco 7513 System Specifications

Cisco 7513-MX Overview

13 Cisco 7513-MX Front View

Cisco 7513-MX Dual CyBus Backplane

14 Cisco 7513-MX Rear View

15 Dual CyBus Backplane in the Cisco 7513-MX

Cisco 7513-MX System Specifications

Cisco 7576 Overview

16 Cisco 7576 Front View

Cisco 7576 Dual CyBus Backplane

Receptacles

18shows the details of the dual CyBus backplane

Identifying Cisco 7576 Independent Routers and CyBuses

CyBus Slot Number Assignments

Cisco 7576 System Specifications

Route Switch Processor Overview

RSP-Specific Hardware Features

RSP2-Cisco

Route Switch Processor RSP2

RSP4/4+-Cisco 7507, Cisco 7513, and Cisco

Type

Quantity Description Location

U13 U10

OL-5008-03 B0

RSP8-Cisco 7507-MX and Cisco 7513-MX

Type Size Quantity Description Location

U15 U12

Cisco 7500 Series Installation and Configuration Guide

SRAM3

Memd Data Asic

Location See

Type Size Quantity Description

Common RSP Hardware Features

RSP LEDs

Dram Description

RSP Flash Memory

Sram Description

RSP Eeprom

RSP Asynchronous Serial Ports-Console and Auxiliary

Pin Signal Direction Signal Description

Signal Pin Direction Signal Description

AC-Input and DC-Input Power Supply Overview

Female End DB-25 Pins Male End DB-25 Pins Description

24 AC-Input Power Supply Cisco

26 AC-Input Power Supply Cisco 7507 and Cisco 7507-MX

H3030

Arbiter Overview

Chassis Interface Overview

Fan Tray and Blower Assembly Overview

30 7500 Series Chassis Interface

Cisco 7505 Fan Tray Assembly

Cisco 7507 and Cisco 7507-MX Blower Assembly

32 Blower Assembly Cisco 7507 and Cisco 7507-MX

34 Blower Module Assembly Rear View

Interface Processor Overview

OL-5008-03 B0

System Software Overview

Preparing for Installation

Tools and Parts You Need

Safety Recommendations

Safety with Electricity

Chassis Lifting Guidelines

Lifting Safely Cisco 7507 Shown

Correct Way to Lift the Cisco 7513, Cisco 7513-MX, or Cisco

Preventing Electrostatic Discharge Damage

AC-Input and DC-Input Power Guidelines

Cisco 7505 Power Considerations

Cisco 7507 and Cisco 7507-MX Power Considerations

Page

Plant Wiring Guidelines

Interference Considerations with Cabling

Distance Limitations of Interface Cabling

Minimum Maximum

Specifications Minimum Maximum

Cisco 7505 Airflow Considerations

Cisco 7507 and Cisco 7507-MX Airflow Considerations

Chassis

Equipment Rack-Mounting Guidelines

General Equipment Rack Ventilation Considerations

Cisco 7505 Rack-Mount Considerations

Noninterface processor end

Cisco 7507 and Cisco 7507-MX Rack-Mount Considerations

Power supply/interface processor end

Cisco 7500 Series Installation and Configuration Guide

Panel end

Cisco 7500 Series Installation and Configuration Guide

Cisco 7500 Series Environmental Monitoring

Cisco 7500 Series Temperature and Voltage Thresholds

Cisco 7505 Temperature and Voltage Thresholds

Parameter Normal Critical Shutdown

Parameter Critical Normal

Parameter Normal High Warning High Critical Shutdown

Parameter Normal Low Critical Low Warning

Power supply 75C Restart 40C

Cisco 7500 Series Environmental Reports

Cisco 7505 Environmental show Command Examples

Router# show env last

Router# show env table

Airflow Temperature Measured

RSP3 Inlet 44C/111F 50C/122F

0123456 Dbus slots XX Inlet Hotpoint

At 32C

+24V 20.00 23.80V 28.00

Airflow

Cisco 7576 Environmental show Command Examples

LowCritical

Installing a Cisco 7500 Series Router

Cisco 7500 Series General Installation Considerations

Providing a Ground Connection for the Chassis

V I E W D R a F T C I S CO CO N F I D E N T I a L

Wire Grounding lug Chassis grounding receptacles Screws

Installing the Cisco

Installation Flowchart Cisco

V I E W D R a F T C I S CO CO N F I D E N T I a L

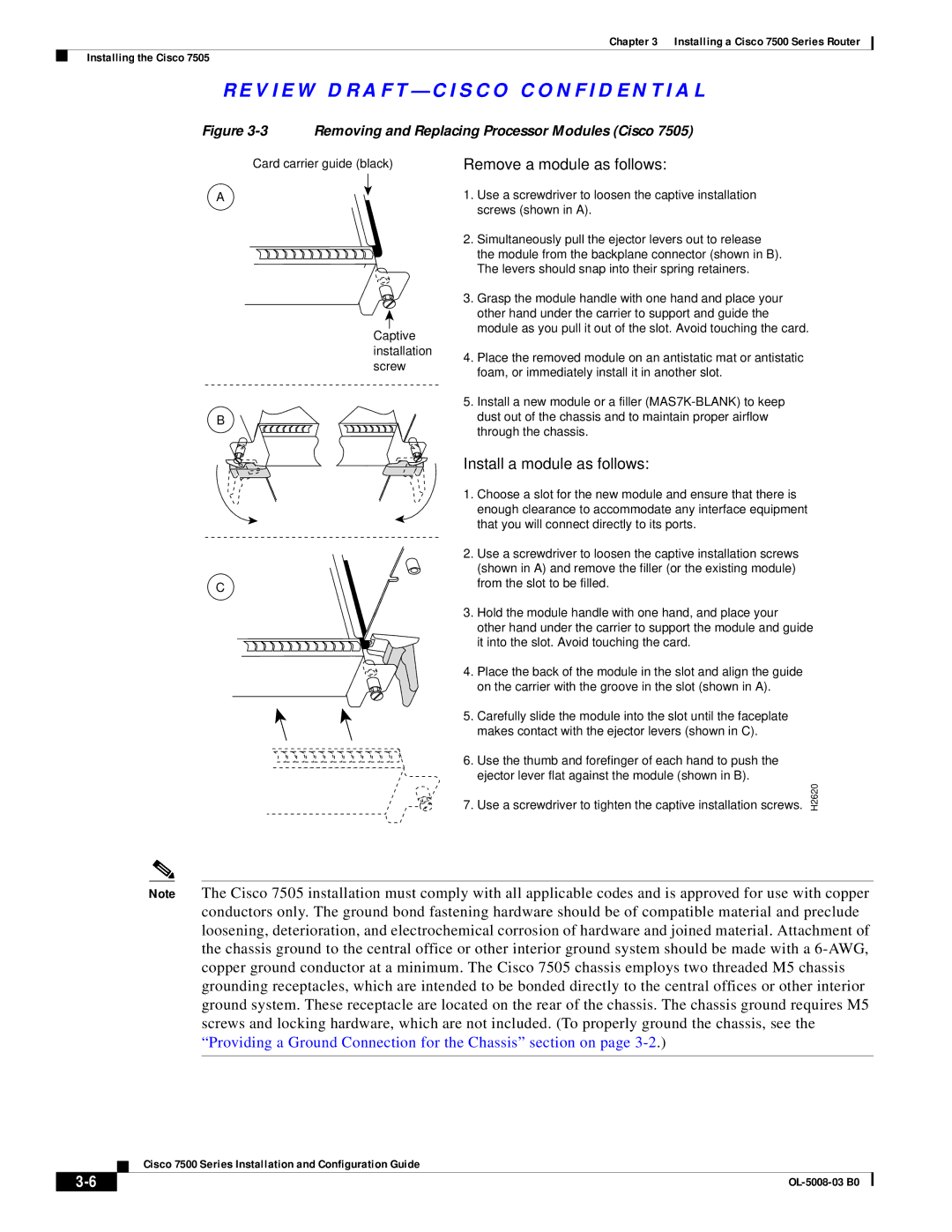

Remove a module as follows

Cisco 7505 Installation Considerations

Rack-Mounting the Cisco

Rack-mount the chassis as follows

Connecting Power to the Cisco 7505 DC-Input Power Supply

Attaching the Cisco 7505 Cable-Management Brackets

Removing the Terminal Block Cover and Attaching Power Cables

Installing the Cisco 7507 and Cisco 7507-MX

Insert power supplies Make external connections

V I E W D R a F T C I S CO CO N F I D E N T I a L

Stop

Cisco 7507 and Cisco 7507-MX Installation Considerations

Installing Cisco 7507 and Cisco 7507-MX Power Supplies

Captive installation screw

Step

Captive installation screws on terminal block cover

Terminal block cover

Installing the Cisco 7513, Cisco 7513-MX, and Cisco

Use Cisco 7513 and Cisco Unpacking Instructions

13 Temporary Storage for Removed Processor Modules

V I E W D R a F T C I S CO CO N F I D E N T I a L

Bottom ejector lever Remove a module as follows

Blower module weighs approximately 10 lb 4.55 kg

15 Lifting a Cisco 7513, Cisco 7513-MX, or Cisco

Blower module Loosen Screws 2 Bracket Card cage

V I E W D R a F T C I S CO CO N F I D E N T I a L

Captive screws

19 Power Supply Blank Cisco 7513, Cisco 7513-MX, and Cisco

Lift and remove the cover

DC-input power supply With the terminal block Cover removed

Connecting a Console Terminal to the RSP

Connecting to the Auxiliary Port

Making Cable Connections to the RSP

Using the Y-Cables for Console and Auxiliary Connections

What Do I Do Now?

V I E W D R a F T C I S CO CO N F I D E N T I a L

Performing a Basic Configuration of the System

Starting the System and Observing Initial Conditions

Performing a Basic Configuration of the System

Configuring the Software Configuration Register

Bit Number Hexadecimal Meaning

Configuration Register Bit Meanings

Boot Field Meaning

Action/Filename Bit

Bit Address net host

Changing Configuration Register Settings

Baud Bit

Booting the Cisco 7500 Series Router for the First Time

Using the Enable Secret and the Enable Password

Recovering a Lost Password

Initialize the router by entering the i command as follows

Configuring the Cisco 7500 Series System

Performing a Basic Configuration Using AutoInstall

Configuring the Global Parameters

OK?

Enter yes or no to accept or refuse Snmp management

Configuring Interfaces

Configuring an Ethernet Interface

Configuring a Synchronous Serial Interface

Interface Ethernet0/0

Performing a Basic Configuration Using Configuration Mode

Implementing Other Configuration Tasks

Checking the Settings

Using the Flash Memory Cards in the RSPs

Installing and Removing a Flash Memory Card in an RSP

OL-5008-03 B0

Installing and Removing a Flash Memory Card RSP2

Installing and Removing a Flash Memory Card RSP4/4+ and RSP8

Formatting a Flash Memory Card

Router# format slot0

Making a Flash Memory Card Image Bootable

Copying Files to Flash Memory

Enabling Booting from Flash Memory

Additional Commands Associated with Flash Memory

Additional Procedures Associated with Flash Memory Cards

Copying a Bootable Image into a Flash Memory Card

Copying Bootable Images Between Flash Memory Cards

Router# copy tftpnew.image slot0new.image

Router# copy slot1image.new slot0image.new

Router# copy startup-config slot0myfile2

Copying Files Between RSP Memory and a Flash Memory Card

Router# copy running-config slot0myfile2

If You Need More Configuration Information

Recovering from Locked Blocks in Flash Memory Cards

OL-5008-03 B0

OL-5008-03 B0

Maintaining Your Cisco 7505 Router

Tools Required for Maintenance Procedures

Overview of Maintenance Procedures for the Cisco

Maintenance Procedures for the Cisco

Removing and Replacing the Cisco 7505 Cover Panel

Removing and Replacing the Cisco 7505 Cover Panel

Removing and Replacing the Cisco 7505 Fan Tray

Replacing the Cisco 7505 Fan Tray

Fan Tray Tracks and Guides in the Cisco

Removing and Replacing the Cisco 7505 Power Harness Cover

Removing the Cisco 7505 Power Harness Cover

Removing and Replacing the Cisco 7505 Backplane Cover

Removing and Replacing the Cisco 7505 Backplane Cover

Removing and Replacing the Chassis Interface in the Cisco

7500 Series Chassis Interface

Removing and Replacing the CI Cisco

Removing and Replacing the Cisco 7505 Power Supply

Cisco 7505 AC-Input Power Supply-Interface Processor End

Removing and Replacing the Cisco 7505 Power Supply

OL-5008-03 B0

OL-5008-03 B0

Maintaining Your Cisco 7507 and Cisco 7507-MX Router

Tools Required for Maintenance Procedures

Maintenance Procedures for the Cisco 7507 and Cisco 7507-MX

Removing Cisco 7507 and Cisco 7507-MX Power Supplies

Should clamp both the insulation and the conductor

Breaker in the OFF position

H2530

Fail Power

Cisco 7500 Series Installation and Configuration Guide

Removing the Cisco 7507 and Cisco 7507-MX Bottom Front Panel

Removing the Cisco 7507 and Cisco 7507-MX Top Front Panel

Replacing the Cisco 7507 and Cisco 7507-MX Front Panels

OL-5008-03 B0

Replacing Cisco 7507 and Cisco 7507-MX Internal Components

Cisco 7507 and Cisco 7507-MX Internal Chassis Components

7500 Series Chassis Interface

OL-5008-03 B0

10 LED Board Cisco 7507 and Cisco 7507-MX

OL-5008-03 B0

11 Chassis Blower Cisco 7507 and Cisco 7507-MX

12 Blower Power Connection Cisco 7507 and Cisco 7507-MX

Cisco 7500 Series Installation and Configuration Guide

OL-5008-03 B0

OL-5008-03 B0

A P T E R

Tools Required for Maintenance Procedures

Page

H5265

Removing the Card Cage Assembly

Power Supply Blank Cisco 7513, Cisco 7513-MX, and Cisco

Captive screw

Exchanging the Eeprom Devices

Eeprom B

Installing the Card Cage Assembly

Installing the Card Cage Assembly

Blower module

Cisco 7500 Series Installation and Configuration Guide

H9728

H9727

Loosen these screws

12 Cisco 7500 Series Chassis Interface

Dual arbiters Chassis B interfaces

H3099

16 Removing and Replacing the Cisco 7576 CI Cutaway View

OL-5008-03 B0

OL-5008-03 B0

Troubleshooting a Cisco 7500 Series Router

Troubleshooting Overview

Problem Solving with Cisco 7500 Series Subsystems

Troubleshooting Guidelines for the Cisco

Identifying Cisco 7505 Startup Problems

ENVM-2-FAN Fan array has failed, shutdown in 2 minutes

Cisco Systems, Inc Tasman Drive San Jose, CA

Troubleshooting the Cisco 7505 Power Subsystem

Troubleshooting the Cisco 7505 Cooling Subsystem

ENVM-2-FAN Fan array has failed, shutdown in 2 minutes

Identifying Cisco 7507 and Cisco 7507-MX Startup Problems

OL-5008-03 B0

Troubleshooting a Cisco 7500 Series Router

Subsystem Yes Fans

V I E W D R a F T C I S CO CO N F I D E N T I a L

ENVM-2-FAN Fan has failed, shutdown in 2 minutes

V I E W D R a F T C I S CO CO N F I D E N T I a L

V I E W D R a F T C I S CO CO N F I D E N T I a L

Troubleshooting Blower Operation

Troubleshooting the Cisco 7500 Series Processor Subsystem

Troubleshooting the RSP

Using Cisco 7500 Series System LEDs

Troubleshooting the Interface Processors

Using the Front-Panel System LEDs

Cisco 7507 and Cisco 7507-MX LEDs

Cisco 7513, Cisco 7513-MX, and Cisco 7576 LEDs

Using the RSP LEDs

RSP2 LEDs-Cisco 7500 Series

RSP4 and RSP8 LEDs-Cisco 7500 Series

RSP4 and RSP8 LEDs Partial Front Panel, Horizontal View

Using the Power Supply LEDs

Cisco 7505 Power Supply LED

Cisco 7507 and Cisco 7507-MX Power Supply LEDs

AC-Input Power Supply LEDs Cisco 7507 and Cisco 7507-MX

Cisco 7513, Cisco 7513-MX, and Cisco 7576 Power Supply LEDs

Additional Reference Information for Troubleshooting

Replacing Dram on the Route Switch Processor

Upgrading or Replacing Dram SIMMs on the RSP2

Quantity Dram Bank Total Dram Product Numbers

MEM-RSP-24M

Removing RSP2 SIMMs

Releasing the RSP2 Simm Spring Clips

Installing New RSP2 SIMMs

Handling an RSP2 Simm

Upgrading or Replacing Dram DIMMs on the RSP4 and RSP8

RSP4 Dram Dimm Locations

RSP8 Dram Dimm Locations

Quantity Totals Product Numbers

Removing RSP4 and RSP8 DIMMs

Installing New RSP4 or RSP8 DIMMs

Handling an RSP4 or RSP8 Dimm

Installing an RSP4 or RSP8 Dram Dimm in the Socket

OL-5008-03 B0

Configuration Bit Meanings

Bit No Hex Meaning

Bits

Bit

Action/File Name Bit

Bit 10 and Bit

Bit 11 and Bit

Bit IP Address net host

Router# show version

Setting the Configuration Register While Running Cisco IOS

Info? y/n Change

OL-5008-03 B0

Numerics

IN-1

IN-2

IN-3

RSP4

IN-4

IN-5

IN-6

Configuration

IN-7

RSP2 RSP4

IN-8

Exec

IN-9

Cisco 7507 and Cisco 7507-MX 3-14 to 3-19,6-3 to

IN-10

DC OK

IN-11

PFC

IN-12

Service Site guidelines

IN-14

RSP

IN-15

Snmp

IN-16

CPU RSP2 RSP4

IN-17

IN-18

IN-19