Section 1: Introduction

Correct signals initiates print head activity.

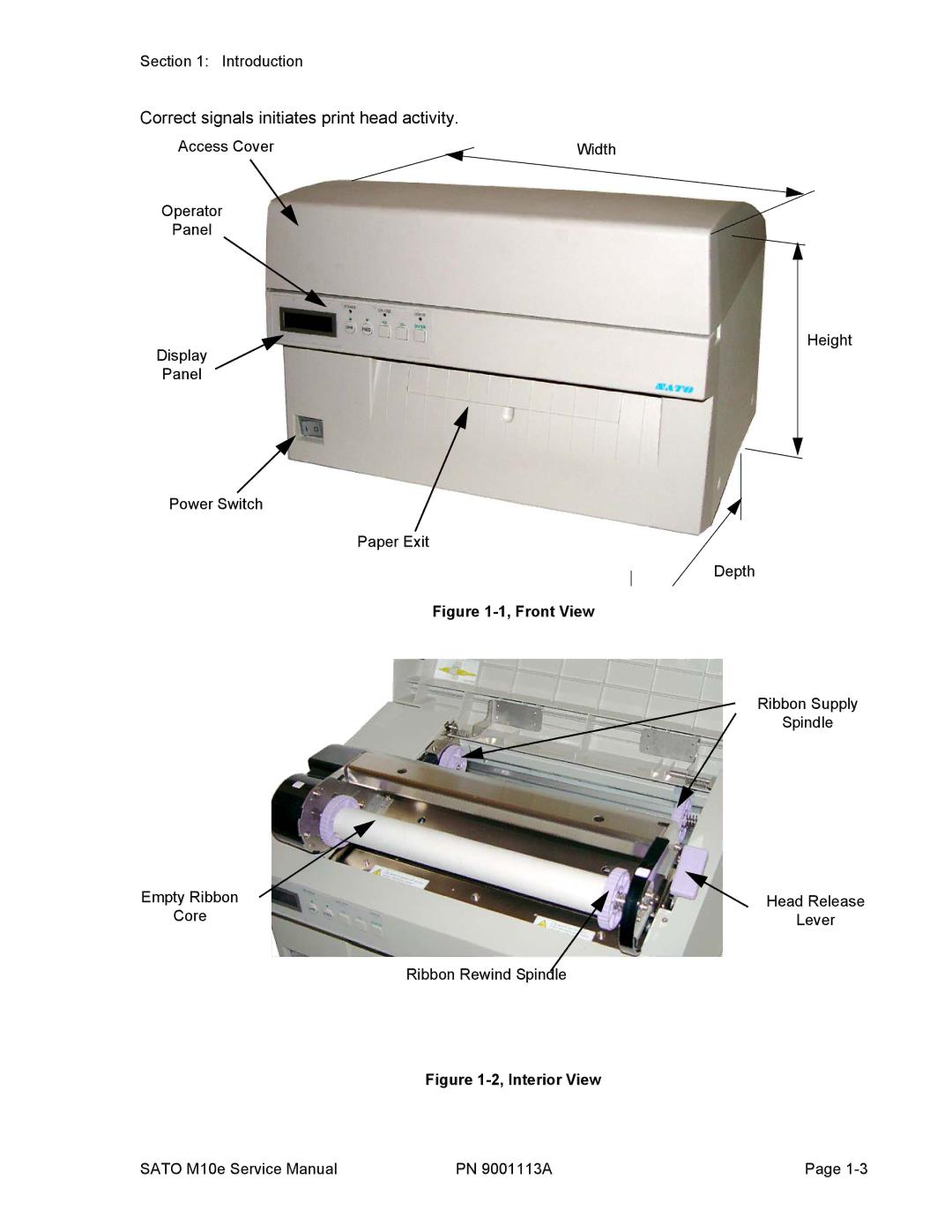

Access Cover | Width |

Operator

Panel

Display

Panel

Power Switch

Paper Exit

Depth

Figure 1-1, Front View

Height

Ribbon Supply

Spindle

Empty Ribbon | Head Release |

Core | Lever |

| Ribbon Rewind Spindle |

Figure 1-2, Interior View

SATO M10e Service Manual | PN 9001113A | Page |