DVW-707/707P DVW-709WS/709WSP DVW-790WS/790WSP

Warnung

Recycling NICKEL-CADMIUM Batteries

Page

Table of Contents

Audio IN, Audio OUT CH1, CH2, DC IN, DC OUT

Mechanical Deck Parts Replacement

VTR System Alignment

Tape Path Adjustment

DVW-790WS/709WS/707

Camera System Electrical Alignment Only for DVW-707/707P

Page

Purpose of this manual

Contents

Related manuals

Fixtures and Adjustment Equipment

Fixtures

Illust No. Part No Description Usage

Illust No Description Usage

Equipment Model Name

Adjustment Equipment

Board to be Extension board Reference Checked

Using the Extension Boards

Using the EX-655 and EX-656 Boards

Procedure

When extending the DCP board assembly

Using the EX-657 and EX-658 Boards

Using the EX-667 Board

SV-210 Board

DC-DC Converter

DIF-75 Board Optional Board BKDW-702

CN2

CN2CN22

IC Link

Disconnecting/Reconnecting Flexible Card Wires

Disconnecting

Reconnecting

Description on EEPROM/NV-RAM Data

Spare CCD Units

Description on CCD Block Number

Ref. No. Address Data stored

Setting/Adjustment After Board Replacement

Adjusting After Eeprom Replacement

Eeprom on the ES-23 Board

DC Fans Precaution

Setting/Adjusting After Board Replacements

Board Setting/Adjusting after Replacement

Page

Data Structure

Service Mode

About the Setup Card

How to Enter the Service Mode

Fundamental Operation of the Setup Menu

Contents of Setup Menu

High

White Preset

Master Gain LOW

MID

Write Protect

Setup Card Read →CAM

Write →CARD

ID Edit

FIX

VTR Mode

Function 2/2 DCC Function FIX/DCC/ADP.K

SEL DCC

Zebra Select

VF Setting Zebra 1 Detect

Zebra 1 Aperture

Zebra 2 Detect

Level Skin Tone DTL

Burst Phase

RGB Setup LVL

ENC Setup LVL

Level Gamma Table

Level Black

Flare

Test OUT ENC/R/G/B

Iris Weight

Level Phase

SC Phase

Iris Mode

Para

Adjustment

Shading G

SAW

WARM-COOLA

Preset WHT

Offset WHT

Offset Whitea

LOW Light Level

Battery

Operation B-G SEL

LOW Light

Operation AWB Level Gate

Delay

Data Reset

Service

Marker 2/3

Menu SEL Setup Card

VF Setting

Menu SEL Marker 1/3

Sensitivity

Resolution

Measurement

Modulation

VTR ADJ EQ Adjustment

AD Gain AD Clock Phase

Clock Phase

ND Comp ND Detection OFF/EXEC/RESET

Display Description

ROM

DP DIAG.STATUS

MPX

DTL

Setup Menu List

Turbo YES

Setup C RM-P9 RM-B150 SET C-SET Remark

Shutter EVS YES CLS

Setup C

VTR Mode YES OFF REC Inhibit CCU Assignable SW

Remark

SET Remark

ENC Y Level YES Black Flare Test OUT

YES Level

SC 0/180 SEL

RM-B150 SET C-SET Remark

FRM Shutter FRM Shutter Unit YES OFF

Preset WHT Color Temp P YES

Delay YES

REC Tally YES Upper Time Code Disp OFF Loop Recording

YES Function 1/2 OFF Function 2/2 VF Setting Wide Screen

YES OFF Level 143DTL Level 243DTL Menu SEL

YES OFF Level 11SC-H

BC COMP.ADJ FIELD/FRAME YES Field Test OUT ENC Vsub

Gain TMP MOD.BAL. TMP SAW/REC Test Level Test SAW OFF

Preknee KS on Test OUT ENC Test SAW OFF

YET

AD ADJ AD Gain AD Clock Phase ND Comp ND Detection OFF

MPX DTL ROM SV1 SV2 WSH

Setup C RM-P9 RM-B150 F-SET

Page

Replacing Boards

Section Parts Replacement

MB-810 Board

Replacing the MB-810 and MB-811 Boards

MB-811 Board

Replacing the HN-260 Board

Removal

Replacing the CI-20 and CI-21 Boards

Replacing Boards

Reinstallation Required tools

Replacing the CCD Unit

Replacement

Adjustments after replacement

Replacing the CCD Unit and Its Components

CN1 CN2

Removal Removing the Front Assembly

DVW-790WS/790WSP/709WS/709WSP

Removing the ND Filter Knob

Removing the CC Filter Knob DVW-790WS/790WSP/709WS/709WSP

Removing the CCD Unit

DVW-707

Reinstallation Reinstalling the CCD Unit

Reinstalling the ND Filter Knob

DVW-790WS/709WS

Reinstalling the Front Assembly

Adjustment After Replacement Tape Running Adjustment

Electrical Alignment

Reinstallation

Adjustment After Replacement

CN3

Replacing the Boards Inside the CCD Unit

790WS/790WSP

CN5 CN2

CN3 CN1 CN6

CN7 CN4

Replacing the External Connectors/Switches

CH2, DC IN, DC OUT Connectors

Removing the Connector Box Assembly

Removing the CNB-11 Board

Removing the CNB Stay

Removing the RM-180 Board

DC OUT connector

Removing the Connector

Audio IN/AUDIO OUT connector

DC in connector

VF Connector

Power Switch, MIC in Connector

Power Switch

MIC in Connector

Shutter Switch

Replacing the Rotary Encoder

Upper DC Fan

Replacing the DC Fans

Lower DC Fan

Replacing the Camera SW Ornamental Plate

CP-329 board

Camera SW ornamental plate Mm or less Inside panel

Removal Required tool

Replacing the Card Door Assembly

Replacing the 40-pin Fitting Assembly

Reinstallation Required tool

General Information for Parts Replacement and Adjustment

About Cleaning Blade Tape Cleaner depending on model

About Tools

Selection Procedure into the Unthreading End Mode

Threading End/Unthreading End Mode

Threading End Mode

Unthreading End Mode

Installation

Manual Eject Assembly Removal/Installation

Part Name Section

Index

About stop washer

About screwdriver and torque reading

About oil and grease

Overviews

Upper Drum Assembly Replacement

Basic information

Preparations

Tools

Removal Brush Cover Removal

Brush Assembly Removal

Upper Drum Assembly Removal

Desoldering the Leads of Slip Ring Assembly

Installation Cleaning of Contact Surfaces

Upper Drum Assembly Installation

Upper Drum Eccentricity Adjustment Tool Installation

Upper Drum Eccentricity Adjustment Tool Removal

Upper Drum Eccentricity Adjustment

Cleaning of Video Heads and Tape Running Surfaces

Soldering the Leads of Slip Ring Assembly

Brush Assembly Installation

Brush Cover Installation

CTL Head Position Adjustment

Adjustments After Replacement Tape Running Adjustment

Video Tracking Adjustment

CTL Head Height Adjustment

Brush Assembly Replacement for Slip Ring

2x2 Brush assembly Brush cover Connector

Installation Brush Assembly Installation

Slip Ring Assembly Replacement

Remove this screw first

Slip Ring Assembly Removal

Installation Slip Ring Assembly Installation

Blue

Brush Assembly Installation

Drum Assembly Replacement

Disconnection of the Brush Assembly Connector

Removal Video Head Cleaner Removal

CN2 CN3

Drum Assembly Removal

Cleaning Drum assembly Positioning pins

Cleaning of Video Heads and Tape Running Surface

Drum Assembly Installation

Connection of the Brush Assembly Connector

Video Head Cleaner Installation

Video System Adjustment

CUE Head Height Adjustment

Pinch Roller Replacement

Removal Pinch Roller Removal

Installation Install Shaft Cleaning

Pinch Roller Installation

Pinch Roller Cleaning

HC Roller Assembly Replacement for Video Heads

VH Cleaner Assembly Removal

Removal Mode Selection

Installation HC Roller Replacement

VH Cleaner Assembly Installation

Operation Ceck

Manual Eject Assembly Removal

CUE Brush Replacement for CUE Head

Installation CUE Brush Replacement

Manual Eject Assembly Installation

Operation Check

Brake Band Assembly Replacement

Removal Band Holder Removal

Brake Band Assembly Removal

Brake Band Assembly Installation

Installation Reel Table Cleaning

FWD Back Tension Adjustment

Band Holder Installation

Adjustment after replacement

Soft Brake Assembly Replacement

Removal Soft Brake Assembly Removal

Adjustment After Replacement Brake Torque Check

Soft Brake Assembly Installation

10. S/T Idler Assembly Replacement

Or T Idler Assembly Removal

Installation Cleaning of the Installation Shaft

Or T Idler Assembly Installation

4x2.5

Swing Gear Assembly Replacement

Removal Removal of the Swing Gear Assembly Fixing Screw

Mechanical Deck Assembly Removal

Installation Swing Gear Assembly Installation

Swing Gear Assembly Removal

Mechanical Deck Assembly Installation

Adjustment After Replacement Belt Tension Adjustment

Swing Gear Assembly Fixation

Timing Belt Replacement

Removal Mechanical Deck Assembly Removal

Installation Cleaning of the Pulleys

Timing Belt Installation

Timing Belt Removal

HN hole

Capstan Motor Replacement

Removal Manual Eject Assembly Removal

Capstan Motor Removal

Installation Capstan Motor Installation

With drop-safe Pin of the chassis

Adjustments After Replacement Belt Tension Adjustment

CTL Head Replacement

Removal Entrance Head Assembly Removal

Installation CTL Head Replacement

Entrance Head Assembly Installation

Entrance Head Assembly Cleaning

Adjustments After Replacement Tape Running Adjustment

CUE Head Replacement

Cassette Compartment Removal

Gear Block Assembly Removal

CUE Head Block Assembly Removal

Installation CUE Head Replacement

CUE Head Block Installation

Cleaning of the Head

Cassette Compartment Installation

Gear Block AssembIy InstaIIation

Audio System Adjustment

Video Tracking Adjustmen

Reel Table Replacement

Reel table removal

Removal Reel Table Removal S reel table removal

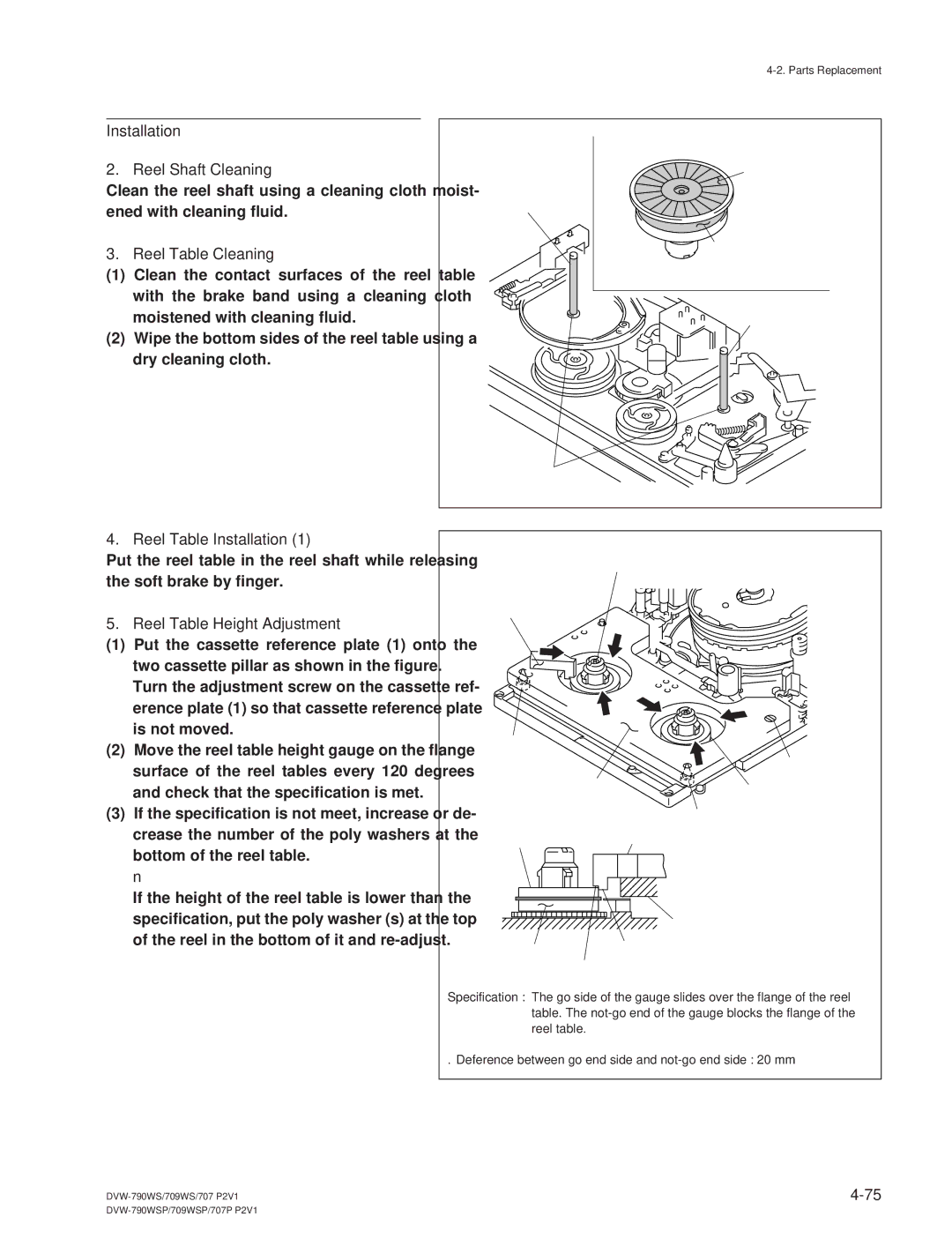

Installation Reel Shaft Cleaning

Reel Table Installation

Reel Table Height Adjustment

Put the remaining poly washer s in the step

Adjustments After Replacement FWD Back Tension Adjustment

Pinch Arm Assembly Replacement

Removal Pinch Arm Assembly Removal

Applying Oil to Installing Shafts

Installation Installing Shafts Cleaning

Pinch Eoller Cleaning

Pinch Arm Assembly Installation

Removal Sensor Cover a Removal

Sensor a Detection Pin Replacement

Sensor Cover a Installation

Installation Detection Pins Installation

Removal Sensor Cover B Removal

Sensor B Detection Pin Replacement

Sensor Cover B Installation

Tension Regulator Arm Assembly Replacement

Removal Brake Band Removal

Tension Regulator Arm Assembly Removal

Installation Tension Regulator Arm Assembly Installation

Brake Band Installation

Tension Regulator S4 Guide Cleaning

Overviews

Preparations

Removal Cassette Guide Removal

Disconnection Brush Assembly Connector

Drawing Arm Removal

Driving Gear Removal

Catcher S Removal

Threading Link Assembly Removal

Slider

Threading base

Threading gear assembly installation

Parts Replacement

Threading Link Assembly Installation

Catcher S Installation

Drawing Arm Installation

Driving Gear Installation

100

Connection the Brush Assembly Connector

Cassette Guide Installation

Cleaning of the Head and the Tape Running Surface

Replacement of Loading Motor

Motor Removal

Pinion Gear Removal

Installation Pinion Gear Installation

Gear Block Assembly Installation

Motor Installation

Replacement of FE Head

108

Remove the one screw and remove the FE head

FE Head Removal

Harness Removal

Harness Soldering

BLK GRY

Installation FE Head Installation

Replacement of Tape Cleaner

Tape Cleaner Removal

Installation Tape Cleaner Installation

Tape Guide Removal

Replacement of Tape Guide

114

Installation Tape Guide Installation

115

Adjustment After Replacement Tape Guide Height Adjustment

116

Mechanical Deck Replacement

Removing the Mechanical Deck

Attaching the Mechanical Deck

Tension Regulator Operating Position Adjustment

Mechanical Adjustment

Check Mode Selection

Tension Regulator Operating Position Check

Adjustment Position Adjustment

Point for adjustment

Mode Cancel

Tool

FWD Back Tension Adjustment

Reference of adjustment

Check REC Mode Setting

Adjustment Eject Mode Setting

Back Tension Adjustment

Brake Torque Check

Side Brake Torque Check

Check Setting

Case that the value does not meet the specification

Adjustment Mode Cancel

Adjustment Belt Tension Adjustment

Belt Tension Adjustment

Page

Index Location of Tape Path System

Contents

Drum Entrance Side Threading End Mode

Tape Running Adjustment

Checks Play Mode Playing back the tape top

Specifications

FWD Mode Fast forward at tape top

REW Mode Rewind at tape top

Play Mode Playback at tape end

REV Mode Rewind at tape end

FWD Mode Fast forward at tape end

REW Mode Rewind at tape end

CTL Head Height Check

Checks After Adjustment Video Tracking Check

Tape Running Re-check at the Drum Entrance Side

Tape Running Check at the Drum Exit Side

Drum Exit Side Checks Play Mode Playing back the tape top

REV Mode Rewind at tape end

Tape Running Check Around the Capstan Shaft

Tape Running Re-check at the Drum Exit Side

Adjustments T2 and T3 Guides Height Adjustment

Reference for adjustment

CUE Head Azimuth Adjustment

Video Tracking Adjustment

Checks Play Mode

Play Mode

RF Waveform Check

REV search mode

Drum exit side Tracking Adjustment Drum Exit Side

Video Tracking Re-check

Tape Running Check

CUE Head Height Check

CTL Head Height Adjustment

If the Level Increases When Pushing Up the Tape

Adjustments After Adjustment CTL Head Position Adjustment

Checks Play Back

CTL Head Position Adjustment

Adjustments CTL Head Position Adjustment

Adjustment After Adjustment CUE/TC Head Position Adjustment

CTL Head Position Re-check

CUE Head Height Adjustment

Play back ZR2-1/P from 00 minute to 15 minute segment

CUE Head Head-to-contact Check

Adjustments CUE Head Height Adjustments

CUE Head Azimuth Check

CUE Head Azimuth Check

CUE Head Head-to-tape Contact Adjustment

CUE Head Head-to-tape Contact Adjustment

Adjustments CUE Head Head-to-tape Contact Adjustment

CUE Head Head-to-tape Contact Check

CUE Head Head-to-tape Contact Re- check

CUE/TC Head Position Adjustment

SV REF CF

Adjustments Play Back

Adjustment

CUE/TC Head Position Re-check

Re-check according to the steps 1

Check CUE Output Level Check

CUE Output Level Check

Preparation

Check Procedure

Power System Adjustment

Battery End Detection Voltage Adjustment

Adjustment Procedure

Servo System Adjustment

Automatic Servo Adjustment

Setting upon Completion of Adjustment

Manual PG Phase Adjustment

Automatic PG Phase Adjustment

Audio System Adjustment

1. D/A Level Adjustment

GND

AGC Level Adjustment

Output Limiter Adjustment

CUE Recording Bias Adjustment

CUE Playback Level Adjustment

CUE Recording Level Adjustment

Preparation

Video System Adjustment

Confirmation Procedure

Playback Equalizer Automatic Adjustment

Precaution

Recording Current Automatic Adjustment

Page

Equipment/Fixtures

General Information for Electrical Adjustment

Initial Switch Settings

Screen Mode Setting

Initial Setting

Murakami Color Research Laboratory

Maintaining the Grayscale Chart

Handling precautions

Replacement period when the chart is used as the reference

Setting Illumination when the reflective chart is used

Video GEN OUT Lock

VCO Cont Frequency Check

Test OUT → ENC

INT SC Frequency

IRE Ntsc

AD Clock Phase Adjustment

AD Clock Phase

Clock Phase

ENC Level Adjustment

ENC OUT Adjustment

Chroma Adjustment

Blanking Width

INT SC Phase Adjustment

SC Phase

Setting After Adjustment

RGB Level

Test OUT Level Adjustment

RGB Setup

RGB Sync

→ CAM/ON

Modulator Balance Adjustment

Test SAW Adjustment

Test SAW → OFF Gamma

R/B AD Gain Adjustment

Knee → OFF

AD Gain

VA Gain Adjustment

S35*PRESET WHT Color Temp P

Gamma → on

Preset White Adjustment

Shading Adjustment

Black Shading Adjustment

White Shading Adjustment

S30 *W-SHADING G

S32 *W-SHADING B

Gamma Correction Adjustment

Master Gamma

Test SAW → OFF

Setting After Aadjustment

Black Set Adjustment

Flare

Flare Adjustment

Manual Knee and White Clip Adjustments

Knee and White Clip Adjustments

DCC Pre Knee Adjustment

Gamma → OFF Test SAW

Preknee DCC

DCC Knee Adjustment

DCC Point →

DCC D Range

Detail Signal Adjustment

Crispening Adjustment

Level Depandent Adjustment

Detail Frequency Adjustment

16-4. H/V Ratio Adjustment

Ratio

APT.LVL

Detail Level Adjustment

Knee Aperture Adjustment

Knee APT

Detail Black Clip Adjustment

169/43 Mode → Select the 43 mode

17-4. H/V Ratio Adjustment

Detail LVL

DTL H B . Clip 43 Factory setting

Skin Tone Adjustment

Zebra Adjustment

Iris Weight

Automatic Iris Adjustment

Iris Mode

Iris Weight → 0 MIN

ND Detection → Exec

Adjustment After Replacing Filter Disk Unit

S06*MASTER Gain

Initial Setting for Switches

Lens

Iris → C Close

Maintaining the Grayscale Chart

Setting Illumination when the reflective chart is used

GEN SC Lock OUT

Video OUT

Spec = 40 ± 1 IRE Ntsc = 300 ± 7 mV PAL

On the setup menu, adjust as follows S40*ENC ADJ

Spec 10.9 ± 0.2 us Ntsc 12.0 ± 0.3 us PAL

Spec = 100 ± 2 IRE Ntsc = 700 ± 14 mV PAL

Spec = 100 ± 2 IRE Ntsc = 700 ± 10 mV PAL

Make sure that the carrier leakage at portion B is not

S35*PRESET WHT

Fine Whitep

S48*B-SHADING G

S50*B-SHADING B

Para

On the setup menu, adjust as follows S25 *LEVEL

Spec ± 1 IRE Ntsc ± 7 mV PAL

Spec 109 ± 2 IRE Ntsc 763 ± 14 mV PAL

Spec ± 2 IRE Ntsc

DCC Knee Adjustment

Reduce the noise at gray portion to a

16-4. H/V Ratio Adjustment

Detail Level Adjustment

On the setup menu, set as follows S12*FUNCTION 1/2

Component in the saturation detection

ZEBRA1 APT. LVL → 1 %

Adjustment Procefure

Adjustment After Replacing Filter Disk Unit

DVW-790WS/709WS/707 DVW-790WSP/709WSP/707P P2V1

Sony Corporation