SECTION 2 - OPERATION

The second position, 1, prevents the control lever from entering the float position.

The final position, 1, has two functions. It will lock the lever into the neutral position to prevent accidental actuation of the lever. If the lockout lever is moved to this position while the control lever is in the retract position, the control lever is limited to travel between the float and retract positions. This position can be used for continuous flow applications.

By limiting the travel of the remote control lever from returning to the neutral position during continuous flow applications, the lockout will protect the hydraulic system from pressure spikes created by hydraulically driven implements during implement shutdown.

IMPORTANT: When shutting off hydraulically driven implements, place the remote lever in the float position to allow the implement to coast to a stop. Shut the tractor off and place the remote lever in the neutral position.

FLOW CONTROL ADJUSTMENT

Each valve spool has a flow control valve to meter oil flow to that coupler. Flow can range from a minimum of 11.4 L/min (3 GPM) to full available flow 114L/min (approximately 30 GPM).

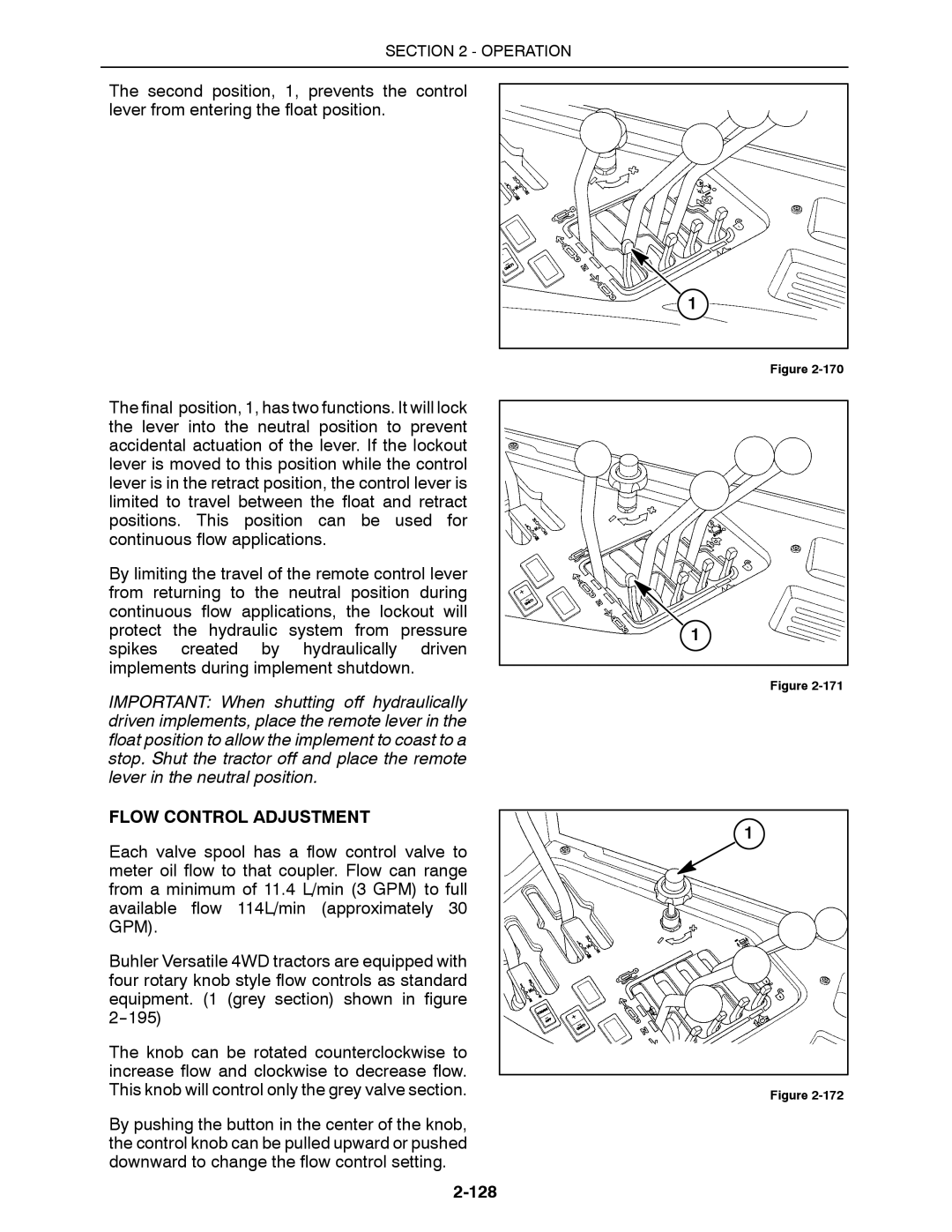

Buhler Versatile 4WD tractors are equipped with four rotary knob style flow controls as standard equipment. (1 (grey section) shown in figure

The knob can be rotated counterclockwise to increase flow and clockwise to decrease flow. This knob will control only the grey valve section.

By pushing the button in the center of the knob, the control knob can be pulled upward or pushed downward to change the flow control setting.

2-128

![]() 1

1

Figure

![]() 1

1

Figure

1

Figure