Laserjet Enterprise 500 Color

Page

HP LaserJet Enterprise 500 color M551 Printers

Copyright and License

Conventions used in this guide

Conventions used in this guide

Table of contents

Removal and replacement

Vii

Enww

Enww

Solve problems 237

Enww

395

Xiii

Upgrade not performed error reading upgrade 435

Enww

457

Xvii

Appendix a Service and support 575

Parts and diagrams 525

Appendix C Regulatory information 589

Appendix B Product specifications 587

Index 601

List of tables

484

Xxiii

Xxiv

List of figures

Xxvi

22 Remove the pickup roller Tray 1 2

70 Remove the right front cover 1 118

104 Remove the residual toner feed motor 6 141

145 Remove the developing disengagement motor 2 171

186 Reinstall the PGC actuators 2 199

233 Remove the drawer connector optional paper feeder 236

35 Component locations 5 290

Xxxiv

Theory of operation

1Relationship between the main product systems

Basic operation

Period Duration Description

Sequence of operation

1Sequence of operation

2Engine control system

Engine control system

DC controller

3DC controller block diagram

Solenoids

Switches

Clutches

Component abbreviation Component name

Motors and fans

Sensors

Abbreviation Name Purpose Type Failure detection

Motors

Abbreviation Name Cooling area Type Speed

6Motors

Circuit Description

High voltage power supply

8High voltage power supply circuits

Paper

5Low voltage power-supply circuit

Low voltage power supply

Main DC voltage Sub-voltage Behavior

9Converted DC voltages

Sleep powersave mode

Safety

Power supply voltage detection

Low voltage power supply failure

Fuser control

Power off condition

10Fuser components

Type of component Abbreviation Name Function

7Fuser temperature control circuit

Fuser temperature control circuit

Fuser over temperature protection

Fuser failure detection

8Laser/scanner system

Laser/scanner system

Enww

9Image formation system

Image formation system

Functional block Steps Description

Image formation process

11Image formation process

Primary charging

Pre-exposure

Development

Laser-beam exposure

Secondary transfer

Primary transfer

Separation

Fusing

Print cartridge

ITB cleaning

Drum cleaning

Enww

22Developing-roller engagement and disengagement control

Developing roller engagement and disengagement

Enww

23 ITB unit

Intermediate transfer belt ITB unit

12Primary-transfer-roller engagement states

Primary-transfer-roller engagement and disengagement

Roller state Product state

Enww

25ITB cleaning process

Color misregistration control

Calibration

Image stabilization control Description

Image stabilization control

13Image-stabilization controls

Abbreviation Component

Pickup, feed, and delivery system

SR10

Fuser motor

30Three main units of the pickup, feed, and delivery system

31Pick feed mechanism Theory of operation

Pickup-and-feed unit

32Cassette-pickup mechanism

Cassette pickup

33Cassette presence sensor Theory of operation

Cassette presence detection

34Cassette lift mechanism

Cassette lift operation

35Paper level detection mechanism Theory of operation

Cassette paper presence detection

36Cassette media width detection

Cassette media width detection

37Multifeed prevention

Multifeed prevention

38Multipurpose tray pickup mechanism

Multipurpose tray pickup

39Paper-feed mechanism Theory of operation

Paper feed

40Skew-feed prevention

Skew-feed prevention

OHT detection

Fusing and delivery unit

42Loop-control mechanism

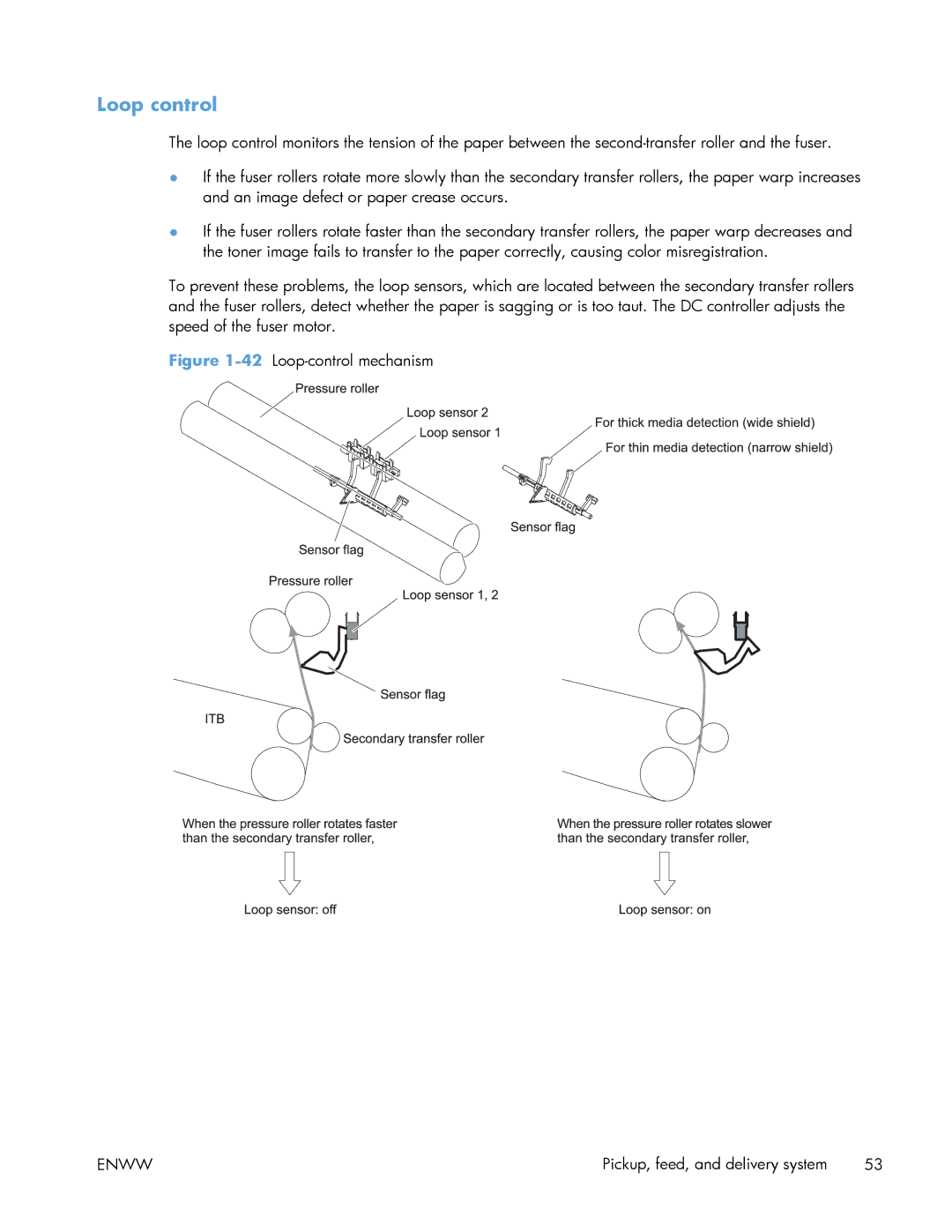

Loop control

Fuser motor

Pressure-roller pressurization control

44Duplexing unit

Duplexing unit duplex models

Duplex pickup operation

Duplexing reverse and feed control

Jam Description

Jam detection

17Jams that the product detects

Fuser delivery delay jam

Optional paper feeder

Component Abbreviation Component name Type

18Electrical components for the paper feeder

48Paper-feeder pickup and feed operation

Paper-feeder pickup and feed operation

Paper size detection

Paper size detection and cassette presence detection

19Paper size detection

50Paper-feeder cassette lift Theory of operation

Paper feeder cassette lift operation

Enww

Paper feeder presence detection

51Paper-feeder multiple feed prevention

Paper-feeder multiple feed prevention

Paper feeder jam detection

Removal and replacement

Introduction

Removal and replacement strategy

Electrostatic discharge

Required tools

Before performing service

Service approach

After performing service

Post service test

SSD

Parts removal order

3Parts removal order 2

Print cartridges

Customer self repair CSR components

5Remove the print cartridge 2

Duplex reverse guide

7Remove the duplex reverse guide 2 Removal and replacement

9Remove the toner collection unit 2

Toner collection unit

10Remove the toner collection unit 3

ESD sensitive component

Formatter PCA

Before proceeding, remove the following components

Disk drives

Remove the HDD

14Remove the HDD 2

Remove the SSM

Reload the firmware

Install a replacement hard drive

Tray cassette

Fuser

Pickup roller Tray

Pickup roller Tray

26Remove the pickup roller Tray 2 4 Removal and replacement

27Remove the Pickup and feed rollers Tray 3 1

Pickup and feed rollers Tray

Enww

Separation roller Tray

Secondary transfer roller

33Reinstall the transfer roller

Reinstall the transfer roller

Secondary transfer assembly

37Reinstall the secondary transfer assembly

Reinstall the secondary transfer assembly

Intermediate transfer belt ITB

Enww

Right door optional paper feeder

43Remove the right door optional paper feeder 3

Identification and location

Covers

Cover on

Front door assembly

46Remove the front door assembly 2 Removal and replacement

48Remove the right door assembly 2

Right door assembly

50Remove the right door assembly 4 Removal and replacement

52Remove the right door assembly 6

54Remove the right door assembly 8 Removal and replacement

Right rear cover

Enww

Remove the left cover

Left cover

61Remove the left cover 4 Removal and replacement

Remove the left bottom cover

Left bottom cover

Remove the left bottom handle

Left bottom handle

Hardware integration pocket HIP dn and xh models only

Control panel assembly

Enww

Remove the right front cover

Right front cover

Enww

74Remove the right front cover 5 Removal and replacement

75Reinstall the power button

Reinstall the power button

Remove the front top cover

Front top cover

Enww

Remove the rear cover and upper rear cover

Rear cover and upper rear cover

80Remove the rear cover and upper rear cover 3

Enww

Remove the rear top cover

Rear top cover

83Remove the rear top cover 2 Removal and replacement

Remove the right bottom handle

Right bottom handle

Remove the rear bottom handle

Rear bottom handle

Delivery fan, cartridge fan, and environmental sensor

Internal assemblies

Disconnect five connectors callout

Enww

Enww

Release one tab callout

Remove the toner collection sensor

Toner collection sensor

97Remove the toner collection sensor 3

Remove the residual toner feed motor

Residual toner feed motor

101Remove the residual toner feed motor 3

Enww

105Remove the residual toner feed motor 7

Reinstall the residual toner collection door

Remove the RD sensor assembly

Registration density RD sensor assembly

109Remove the RD sensor assembly 3 Removal and replacement

111Remove the RD sensor assembly 5

112Remove the RD sensor assembly 6 Removal and replacement

Remove the power supply fan and fan duct

Power supply fan and fan duct

115Remove the power supply fan 3 Removal and replacement

116Remove the power supply fan 4

Remove the registration assembly

Registration assembly

119Remove the registration assembly 3

Remove three screws callout

123Remove the registration assembly 7

Enww

Remove the lower pickup guide

Lower pickup guide

Enww

Reinstall the lower pickup guide

Remove the ICB

Interconnect board ICB

Enww

ESD sensitive part

DC controller PCA and tray

Remove the DC controller PCA

Enww

Enww

132Remove the low voltage power supply 1

Remove the low voltage power supply

Enww

Remove two screws callout

Remove the assembly

Remove the high voltage power supply lower

High voltage power supply lower HVPS-D

Enww

Reinstall the high voltage power supply lower

142Remove the high voltage power supply lower 4

Remove the developing disengagement motor

Developing disengagement motor

145Remove the developing disengagement motor 2

Remove the pickup motor

Pickup motor

Remove the lifter drive assembly

Lifter drive assembly

Enww

Remove the automatic close assembly

Automatic close assembly

Remove the cassette pickup drive assembly

Cassette pickup drive assembly

152Remove the cassette pickup drive assembly 3

Enww

156Remove the cassette pickup drive assembly 7

Enww

Reinstall the cassette pickup drive assembly

159Remove the cassette pickup drive assembly 10

Make sure that the spring callout 1 is correctly installed

Cassette pickup assembly

Remove the cassette pickup assembly

165Remove the cassette pickup assembly 3

Remove the laser/scanner assembly Y/M

Laser/scanner assembly Y/M

Enww

Enww

172Remove the laser/scanner assembly Y/M 7

Enww

176Remove the laser/scanner assembly Y/M 11

Enww

Laser/scanner assembly C/Bk

Remove the laser/scanner assembly C/Bk

Enww

Enww

183Remove the laser/scanner assembly C/Bk 6

Reinstall the protective glass cleaner PGC actuators

184Remove the laser/scanner assembly C/Bk 7

187Reinstall the PGC actuators 3

189Reinstall the PGC actuators 5 Removal and replacement

High voltage power supply upper HVPS-T

Remove the high voltage power supply upper

193Remove the high voltage power supply upper 4

Enww

195Reinstall the high voltage power supply upper

Reinstall the high voltage power supply upper

Drum motor

Remove the drum motor

Drum motor 2 or drum motor

197Remove the drum motor 2 or drum motor

Remove the drum motor 2 or drum motor

Fuser motor

198Remove the fuser motor

Remove the fuser motor

Main drive assembly

Remove the main drive assembly

Enww

204Remove the main drive assembly 6

205Remove the main drive assembly 7 Removal and replacement

206Reinstall the main drive assembly 1

Reinstall the main drive assembly

Slowly rotate the shaft near the black cam

210Reinstall the main drive assembly 5

Enww

214Reinstall the main drive assembly 9

Enww

Fuser drive assembly

Remove the fuser drive assembly

Enww

222Remove the fuser drive assembly 6 Removal and replacement

223Reinstall the fuser drive assembly

Reinstall the fuser drive assembly

Delivery assembly

225Remove the delivery assembly 2

Remove the delivery assembly

227Remove the delivery assembly 4 Removal and replacement

228Remove the delivery assembly 5

Reinstall the delivery assembly

Duplex drive assembly

Remove the duplex drive assembly

Drawer connector

Optional paper feeder assembly Tray

Remove one connector callout

Solve problems

Solve problems checklist

Solve problems checklist

Print the menu maps

Menu map

Print the current settings pages

Current settings pages

Cold reset using the Preboot menu

Preboot menu options

Access the Preboot menu

Determine the problem source

Troubleshooting process

Troubleshooting flowchart

1Troubleshooting flowchart

Power-on troubleshooting overview

Power subsystem

Power-on checks

Enww

Individual component diagnostics

Tools for troubleshooting

LED diagnostics

Understand lights on the formatter

2Heartbeat LED, product initialization

Formatter to control panel communication interruptions

Heartbeat LED, product initialization

49.XX.YY error or

Preboot menu

3Heartbeat LED, product operational

Connectivity LED, product operating

Connectivity LED, product initialization

Connectivity LED

4Connectivity LED, product initialization

If the error persists, perform a firmware upgrade

5Connectivity LED, product operational

HP Jetdirect LEDs

Defeating interlocks

Engine diagnostics

2Diagnostic test 2

Administration Troubleshooting Diagnostic Tests

Disable cartridge check

4Engine-test button

Engine test button

Paper path sensors test

Paper path test

Sensor name Sensor number

6Paper-path sensors diagnostic tests

Manual sensor test

7Manual sensor diagnostic tests

Sensor or switch name Sensor or switch number

Registration sensor

Fuser loop sensors

Fuser output sensor

Open the right door Lower the secondary transfer assembly

Duplexer refeed sensor

Output-bin full sensor

Fuser pressure-release sensor

ITB alienation sensor

Enww

Right- and front-door interlock switches

Enww

Tray/bin manual sensor test

8Manual sensor test 2 diagnostic tests

Tray 1 paper sensor

Tray 2 paper sensor

Tray 2 cassette sensor

Tray 2 cassette lifter sensor

Tray 3 empty sensor

Tray 3 media feed sensor

Tray 3 stack surface sensor

Tray 3 media size sensors

Print/stop test

9Component test details

Component tests

Component test special-mode test

Alienation Motor

Fuser Pressure Release Motor

ITB Contact/Alienation

TCU Motor

Block diagrams

Diagrams

10Sensors

DC controller PCA

Location of connectors

30Paper feeder driver PCA

Paper feeder driver PCA

Base product

Plug/jack locations

Locations of major components

32Component locations 2

33Component locations 3 Solve problems

34Component locations 4

2219

Location Connector Component Component name Abbreviation

PCAs, motors, fans, switches, solenoids, and clutches

13PCAs, motors, fans, switches, solenoids, and clutches

500 paper feeder

Location Connector Component abbreviation Component name

Timing chart

General timing chart

Inter

Circuit diagrams

40 Paper feeder circuit diagram

Internal print-quality test pages

Print quality troubleshooting pages

Yellow Green

44Black print-quality troubleshooting

Print quality assessment

Enww

Set up an auto cleaning

Cleaning

Process a cleaning

Configuration

Configuration

45Configuration

HP embedded Jetdirect

Security Settings information

14Important information on the configuration pages

Finding important information on the configuration pages

Accessories and internal storage

Diagnostics menu

Color band test

Repetitive defects ruler

Print quality troubleshooting tools

Calibrate the product

15Sign In menu

Control panel menus

Sign In menu

Retrieve Job From USB menu

Cancel

Retrieve Job From USB menu

Select a File or Folder

All Jobs With PIN Menu options include

Retrieve Job From Device Memory menu

Retrieve Job From Device Memory menu

Copies

17Retrieve Job From Device Memory menu

Delete is

Copies field

Delete Select

Delete Enter Pin to

Print Copies

Job without

Delete Delete All

Jobs

18Supplies menu

Supplies menu

Low Threshold

Settings

Color Cartridges Very Low Stop Settings Prompt to Continue

Yellow Cartridge

Settings Magenta Low Threshold Cartridge

Low Threshold Cyan Cartridge

Settings Specify

Color/Black Mix Mostly Black

Settings Prompt to

Pages Color Pages if

Mostly Color

Level Gauge

Reset Supplies New Fuser Kit Yes

Off Messages menu to

Enww

Manage Trays Use Requested Tray Exclusively First

Trays menu

First level Second level Values

19Trays menu

Mode Enabled

Disabled

Alternative Letterhead Disabled

Alternate

Image Rotation Standard

Tray 1 Type

Tray 1 Size

Tray 2 Size

Tray 2 Type

20Reports menu

Administration menu

Reports menu

Guide for matching printed colors

General Settings menu

General Settings menu

Wake/Auto On All Events Network port Power button Only

21General Settings menu

First level Second level Third level Fourth level Values

After

Enww

Midtones are the middle-range color- values in an image

Restore Color

Registration

X1 Shift Mm to Y1 Shift X2 Shift Default = Y2 Shift

Print Mode

Adjust Paper

Transparency

Sensing

Down

Humidity Mode Normal High

Pre-Rotation Off Mode

Reduced

Paper Curl Mode Normal

Smooth

Smooth setting

Standard.

Heavy Paper Standard

Background Normal Alternate

Low Voltage

Tray Normal Alternate

Alternate 2 setting

Alternate 1 setting

Alternate 3 setting

Alternate 2 settings

Fuser Temp Normal Alternate

Enww

Jam Recovery Auto Off

Default Folder

Held Timeout Hour

Manage Stored Quick Copy Job

Manage Stored

Enww

General Print Settings menu

Retrieve From USB Settings menu

Retrieve From USB Settings menu

General Print Settings menu

23General Print Settings menu

Factory default setting is

Setting is 0.44 to 99.99.

Font Point Size Range 4.00 Default =

Symbol Set

24Default Print Options menu

Default Print Options menu

Enww

Jobs. If Book-style

Edge to Edge Enabled Disabled

Flip-style

Display Settings menu

Display Settings menu

26Manage Supplies menu

25Display Settings menu

Manage Supplies menu

Stop The product stops until you replace the print cartridge

Enww

Different percentage for each color

Cause an error

Unit Settings Prompt to

Low. Continuing to

Print without

Settings Color/Black Mix Auto

Supply Messages Low Message Off

Reset Supplies New Fuser Kit

Pages Black Pages if

27Manage Trays menu

Manage Trays menu

Blank Pages Auto Yes Override A4/Letter

First level Values Description Use Another Tray Enabled

Alternative Letterhead Mode Disabled

Jetdirect Menu

Network Settings menu

28Network Settings menu

Manual Settings menu to configure TCP/ IPv4 parameters

IPv4 Settings Config Bootp Method

29Jetdirect Menu

Auto IP

Enww

Primary DNS

Dhcp Renew Yes

Xxx.xxx.xx.x

Secondary

Enww

Unavailable

Router Policy Specified

Router

Unavailable If

Proxy Port

Idle Timeout

802.1x Reset

Disable IPSec

Security Required

Optional

Reset Security Yes

TCP/IP

Diagnostics Embedded LAN HW Test Yes Tests

Data Path Test Yes

Http Test Yes

Snmp Test Yes

Execute Yes

Execution

Time

Dest IPv4

IPv6

127.0.0.1 Dest IPv6

Packet Size

Ping Results Packets Sent

Print Results Yes Execute

Packets

Received

RTT Average

RTT Min

RTT Max

Enww

10T Half is set

100TX Half or

10T Half

10T Full

Exit Troubleshooting Print Event Log

Troubleshooting menu

30Troubleshooting menu

Print Paper Path Print Quality Print PQ

Pages Troubleshooting

Print Diagnostic

Select Print Test

Paper Path Start Test

Check

Sensors

Paper Path Test Print Test

Manual Sensor

Number of Copies Range 1 Default =

Test

Manual Tray/Bin

Repeat Off Print/Stop Test

Backup/Restore menu

Device Maintenance menu

Calibrate/Cleaning menu

31Backup/Restore menu

Product automatically

First level Second level Values Description Full Calibration

Delay Calibration at Yes Wake/Power On

USB Firmware Upgrade menu

Label missing

10.0X.Y0 Supply memory error

Memory error

10.22.51

10.22.50

10.22.52

10.23.50

10.23.52

10.23.51

10.23.60

Printing past very low

10.XX.34 Used supply in use

10.XX.40 Genuine HP supplies installed

10.XX.70 Printing past very low

10.XX.41 Unsupported supply in use

10.YY.25 Wrong cartridge in color slot

10.YY.15 Install supply

10.YY.35 Incompatible supply

13.00.00

YY Internal clock error

13.A3.D3

13.A3.FF

13.B2.A2

13.B2.A1

13.B2.A3

13.B2.D1

13.WX.FF

13.D3.DZ

13.WX.EE

13.WX.YZ Fuser area jam

13.WX.YZ Fuser wrap jam

13.WX.YZ Jam in middle right door

13.WX.YZ Jam below control panel

13.WX.YZ Jam in Tray

13.WX.YZ Jam in right door

Too complex

Insufficient memory To continue, press OK

32.1C.XX

32.08.XX

Enww

Recommended action

Enww

32.21.00

33.XX.YY Used board/disk

Error

33.XX.YY

YZ Unexpected type in tray

YZ Unexpected size in tray

LBP OHT

YZ Error To continue, press OK

Enww

47.00.XX

42.XX.YY

47.01.XX

47.02.XX

47.03.XX

47.WX.YZ Printer calibration error To continue, press OK

47.04.XX

47.05.00

47.FC.23

49.XX.YY To continue, turn off then on

50.WX.YZ Fuser error To continue, turn off then on

Enww

Enww

XX To continue, turn off then on

YY Error

Recommended action 54.00.03

54.XX.YY Error

54.0X.0D or 54.0X.0E

YY Error To continue, turn off then on

YY DC controller error To continue, turn off then on

55.0X.YY DC controller error To continue, turn off then on

58.00.04

57.00.0Y Error To continue, turn off then on

Recommended action 59.00.04 or

59.05.XX

59.05.08 or

60.00.0Y Tray Y lifting error

No system To continue, turn off then on

Error To continue, turn off then on

61.00.01

Corrupt data in firmware volume

81.0X.YY Embedded JetDirect error

Corrupt data in configuration volume

Corrupt data in solutions volume

Corrupt data in job data volume

Upgrade not performed file is corrupt

Upgrade not performed error writing to disk

Upgrade not performed timeout during receive

Upgrade canceled by user

Upgrade not performed error reading upgrade

Upgrade not performed the file is invalid

99.00.2X

Unknown disk

Unsupported disk

Incorrect disk

Disk malfunction

No disk data installed

Disk data error

Disk is not bootable please download firmware

99.XX.YY

Supply low or Supplies low

Binname Full Remove all paper from bin

Supply almost full

Supply very low or Supplies very low

File System device failure To clear, press OK

Tray X lifting

File System file operation failed To clear, press OK

File System file system is full To clear, press OK

File System is write protected

File System is not initialized

Accept bad signature

Bad optional tray connection

Canceling

Calibration reset pending

Canceling... jobname

Checking engine

Chosen personality not available To continue, press OK

Cleaning do not grab paper

Clearing event log

Clearing paper path

Close front door

Creating cleaning

Close lower right door

Close upper right door

Data received To print last page, press OK

HP Secure Hard Drive disabled

EIO X disk initializing

Event log is empty

Incompatible supplies

Incompatible supply

Install Fuser Unit

Install supply

Install supply Close rear door

Internal disk not functional

Install supplies

Install Transfer Unit

Load Tray X Type, Size To use another tray, press OK

Internal disk spinning up

Load Tray X Type, Size

Moving solenoid

Manually feed Type, Size

Manually feed Type, Size To use another tray, press OK

Moving solenoid and motor

No job to cancel

Paused

Performing Color Band Test

Printing Diagnostics

Printing Configuration

Please wait

Printing Cmyk samples

Printing Event Log

Printing Engine Test

Printing File Directory

Printing Font List

Printing Help

Printing PQ Troubleshooting

Printing Menu Map

Printing Registration

Printing Usage

Printing Supplies Status

Processing duplex job Do not grab paper until job completes

Processing

Ready

Processing... copy X of Y

Ready IP Address

Remove all print cartridges

Replace supply

Remove shipping lock from Tray

Replace Supplies

Restricted from printing in color

Restore Factory Settings

Rotating color motor

Rotating motor

Supplies in wrong positions

Sleep mode on

Size mismatch in Tray

Tray X open

Tray X empty Type, Size

Unsupported drive installed To continue, press OK

Troubleshooting

Tray X overfilled

Type mismatch Tray

Unsupported USB accessory detected Remove USB accessory

Unsupported tray configuration

USB accessory not functional

Wrong cartridge in color slot

48Sample event log

Event log messages

Print an event log

Print the event log from the Administration menu

Print the event log from the Service menu

Viewing the event log from the Service menu

View an event log from the Administration menu

View an event log

Clear an event log

Common causes of jams

Product is jammed Cause Solution

Clear jams

49Jam locations

Jam locations

Clear jams in Tray

Enww

Clear jams in the output bin area

Clear jams in Tray

Clear jams in the right door

Enww

Enww

Enww

Enww

Clear jams in the lower right door Tray

33Causes and solutions for delivery delay jam

Jam causes and solutions

34Causes and solutions for fuser delivery delay jams

Jams in the output bin

37Causes and solutions for residual media jams

35Causes and solutions for wrapping jams

36Causes and solutions for fuser delivery stationary jams

PCA

38Causes and solutions for pickup delay jams

39Causes and solutions for pickup stationary jams

Jams in the duplex area duplex models

40Causes and solutions for duplexing reverse jams

41Causes and solutions for duplex repick jams

Jams in Tray 1, Tray 2 and internal paper path

42Causes and solutions for residual media jams

43Causes and solutions for pickup delay jam 1 tray pickup

45Causes and solutions for pickup delay jam 1 MP tray pickup

44Causes and solutions for pickup stationary jams

Jams in Tray

Change jam recovery

Product feeds multiple sheets Cause Solution

Solve paper handling problems

Paper does not feed automatically Cause Solution

Product feeds multiple sheets

Or, change the Manually Feed Prompt setting to Unless

Use manual print modes

Select a manual print mode

47Print modes under the Adjust Paper Types sub menu

48MP modes under the Optimize submenu

Background

Tray

Uniformity Control

Fuser Temp

Problem Sample Cause Solution

Solve image quality problems

Image defects table

Image defects table

49Image defects table

Clean the window and remove any

Replace the high-voltage power

Dirty, replace the ITB

Execute a Pressure roller clean

Set up an auto cleaning

Clean the product

Clean the paper path

Problem Cause Solution

Solve performance problems

50Solve performance problems

Solve network problems

Solve connectivity problems

Solve direct connect problems

Enww

Service menu

Service mode functions

Cold Reset Paper

Service ID

Cleaning

Clear Event Log

Restore factory-set defaults values

Product resets

Restore factory-set defaults

Active and repository firmware locations

Clean Disk and Partial Clean functions

Product cold reset

Characteristics of a Partial Clean

Partial Clean

Reasons for performing Partial Clean

Execute a Partial Clean

Execute a Clean Disk

Clean Disk

Reasons for performing Clean Disk

Enww

Sign

51Preboot menu options 1

Partial Clean

Clean Disk

Password Clear

Password

52Preboot menu options 2

External

53Preboot menu options 3

Device

54Preboot menu options 4

55Preboot menu options 5

Service Tools

56Preboot menu options 5

Reset Password

Jetdirect Off

Determine the installed revision of firmware

Product updates

Perform a firmware upgrade

Embedded Web Server

USB storage device Preboot menu

USB storage device control-panel menu

Enww

Parts and diagrams

Order parts, accessories, and supplies

Part numbers

Accessories

Print cartridges and toner collection unit

Memory

Customer self repair CSR and service kits

Simplex

Common fasteners

How to use the parts lists and diagrams

Screws

How to use the parts lists and diagrams

Simplex model Duplex model See Right-door assembly

Description Part number Qty

External covers, panels, and doors

Right-door assembly

Right-door assembly

3Internal assemblies 1

Internal assemblies 1

4Internal assemblies 1

4Internal assemblies 2

Internal assemblies 2

5Internal assemblies 2

501 25 26

Internal assemblies 3

6Internal assemblies 3

6Internal assemblies 4

Internal assemblies 4

7Internal assemblies 4

7Internal assemblies 5

Internal assemblies 5

8Internal assemblies 5

Cassette

Description Part number Qty Cassette RM1-8125-000CN

Cassette

9Paper pickup assembly

Paper pickup assembly

Paper pickup assembly

10 PCAs

PCAs

PCAs

500-sheet paper feeder

Assessories

500-sheet paper feeder

Paper feeder covers

12Paper feeder covers Parts and diagrams

Paper feeder covers

Paper feeder main body

13Paper feeder main body Parts and diagrams

Paper feeder main body

14 Cassette

Paper feeder cassette

Cassette

Paper feeder PCA

15Paper feeder PCA Parts and diagrams

RM1-5839-000CN

Paper feeder PCA

Part number Qty

Description Part number

Alphabetical parts list

17Alphabetical parts list

PCAs on

Duplexing unit cable assembly RM1-5730-000CN

Paper pickup assembly

Paper feeder PCA

Spring, compression RU6-2316-000CN

Part number Description

Numerical parts list

18Numerical parts list

RC2-5426-000CN Cover, front right

Part number Description

RM1-5696-000CN Waste toner detect assembly

RM1-6198-000CN Cassette assembly Tray

RM1-8167-000CN Right-door assembly simplex

Enww

Service and support

Hewlett-Packard limited warranty statement

Hewlett-Packard limited warranty statement

Enww

Enww

Data stored on the print cartridge

End User License Agreement

Transfer

Hewlett-Packard Development Company, L.P Rev /09

OpenSSL

Customer self-repair warranty service

Customer support

Product specifications

Table B-1Product dimensions

Physical specifications

Product Height Depth Width Weight

Product Height Depth Width

Regulatory information

FCC regulations

Environmental product stewardship program

United States and Puerto Rico

Return and recycling instructions

Multiple returns more than one cartridge

Single returns

Material restrictions

Paper

Non-U.S. returns

Residents of Alaska and Hawaii

Enww

Supplementary Information

Declaration of conformity

Energy Use

For Regulatory Topics only, contact

Boise, Idaho USA

September

Types of memory

Certificate of volatility

Volatile memory

Non-volatile memory

Laser safety

Safety statements

Vcci statement Japan Power cord instructions

Power cord statement Japan

Luokan 1 laserlaite

EMC statement Korea Laser statement for Finland

Restriction on Hazardous Substances statement Ukraine

GS statement Germany

Cables

Index

See also tests troubleshooting diagrams

See also jams fans

Pages

PCL

Registration density RD sensor

See also cassette

Power 244

Page

CF079-90942* *CF079-90942