LaserSpeed

Installing the System

coolant is blown off in the same direction the material is moving, the air velocity can add or subtract from the material’s velocity; this too may cause erroneous measurements.

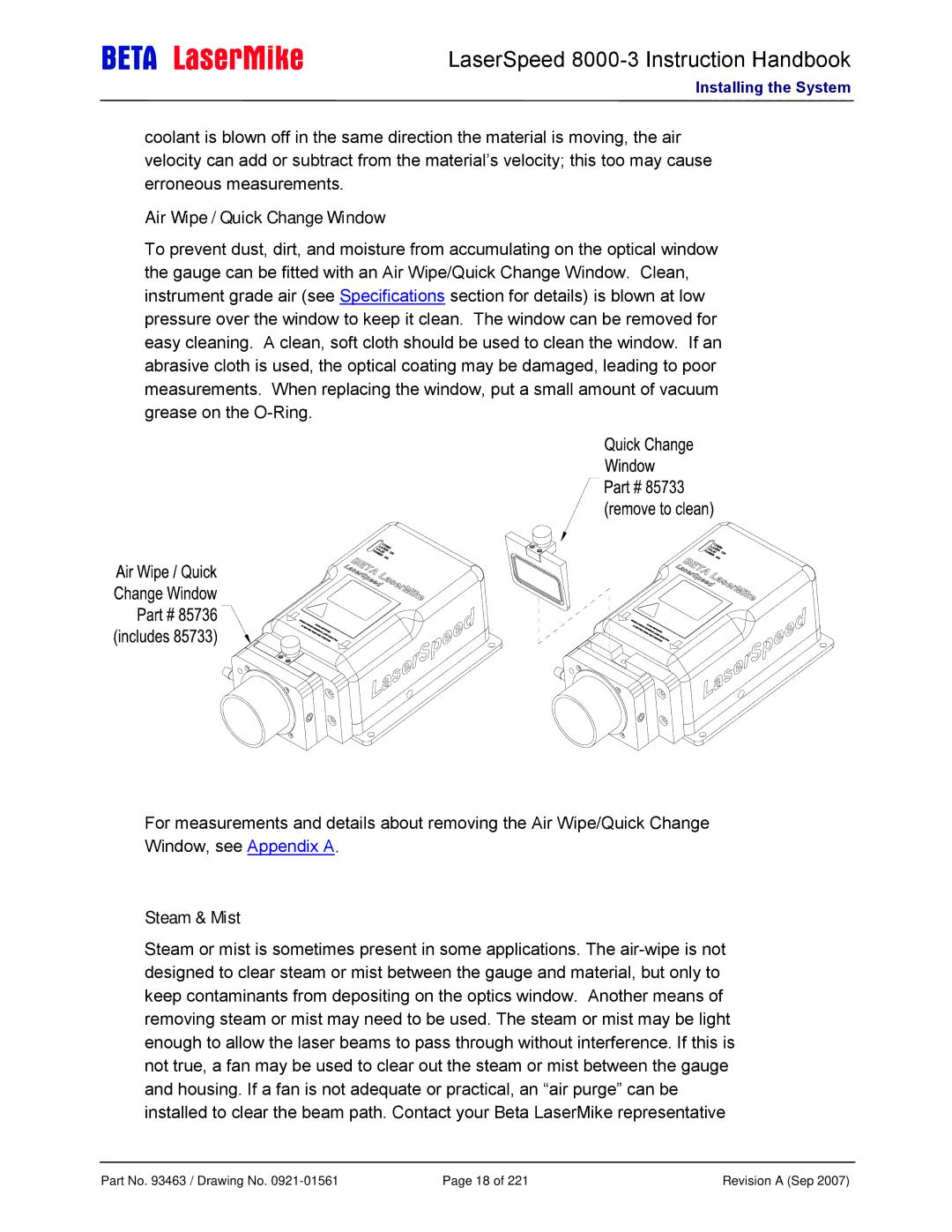

Air Wipe / Quick Change Window

To prevent dust, dirt, and moisture from accumulating on the optical window the gauge can be fitted with an Air Wipe/Quick Change Window. Clean, instrument grade air (see Specifications section for details) is blown at low pressure over the window to keep it clean. The window can be removed for easy cleaning. A clean, soft cloth should be used to clean the window. If an abrasive cloth is used, the optical coating may be damaged, leading to poor measurements. When replacing the window, put a small amount of vacuum grease on the

For measurements and details about removing the Air Wipe/Quick Change Window, see Appendix A.

Steam & Mist

Steam or mist is sometimes present in some applications. The

Part No. 93463 / Drawing No. | Page 18 of 221 | Revision A (Sep 2007) |