LaserSpeed 8000-3 Instruction Handbook

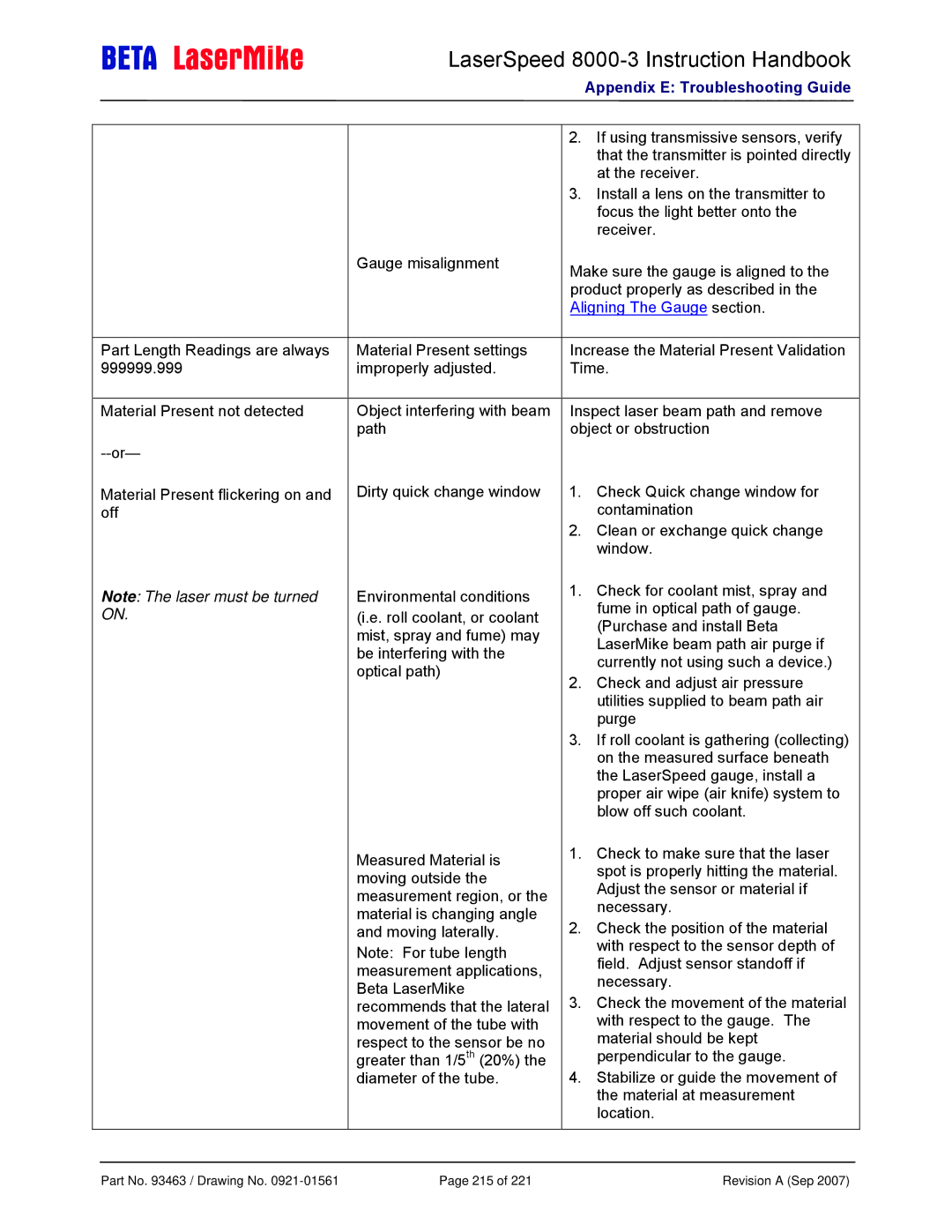

Gauge misalignment

Part Length Readings are always | Material Present settings |

999999.999 | improperly adjusted. |

|

|

Material Present not detected | Object interfering with beam |

| path |

| |

Material Present flickering on and | Dirty quick change window |

off |

|

Note: The laser must be turned | Environmental conditions |

ON. | (i.e. roll coolant, or coolant |

| mist, spray and fume) may |

| be interfering with the |

| optical path) |

Measured Material is moving outside the measurement region, or the material is changing angle and moving laterally.

Note: For tube length measurement applications, Beta LaserMike recommends that the lateral movement of the tube with respect to the sensor be no greater than 1/5th (20%) the diameter of the tube.

Appendix E: Troubleshooting Guide

2.If using transmissive sensors, verify that the transmitter is pointed directly at the receiver.

3.Install a lens on the transmitter to focus the light better onto the receiver.

Make sure the gauge is aligned to the product properly as described in the Aligning The Gauge section.

Increase the Material Present Validation Time.

Inspect laser beam path and remove object or obstruction

1.Check Quick change window for contamination

2.Clean or exchange quick change window.

1.Check for coolant mist, spray and fume in optical path of gauge. (Purchase and install Beta LaserMike beam path air purge if currently not using such a device.)

2.Check and adjust air pressure utilities supplied to beam path air purge

3.If roll coolant is gathering (collecting) on the measured surface beneath the LaserSpeed gauge, install a proper air wipe (air knife) system to blow off such coolant.

1.Check to make sure that the laser spot is properly hitting the material. Adjust the sensor or material if necessary.

2.Check the position of the material with respect to the sensor depth of field. Adjust sensor standoff if necessary.

3.Check the movement of the material with respect to the gauge. The material should be kept perpendicular to the gauge.

4.Stabilize or guide the movement of the material at measurement location.

Part No. 93463 / Drawing No. | Page 215 of 221 | Revision A (Sep 2007) |