LaserSpeed 8000-3 Instruction Handbook

C | Calibration Trim |

C<CR> Read

Response Format: <N>

C<N><CR> Set

<N> is a number between 5000 and 20000, corresponding to 50% to 200%. This allows the calibration number to be adjusted by the values from 0.5000 to 1.9999. The factory calibration will adjusted by (Calibration Trim/10000).

This value should normally be left at 10000 (100%). Do not change this setting unless you know exactly how it will affect your process. LaserSpeed gauges are permanently factory calibrated to a NIST standard, and should not require trimming.

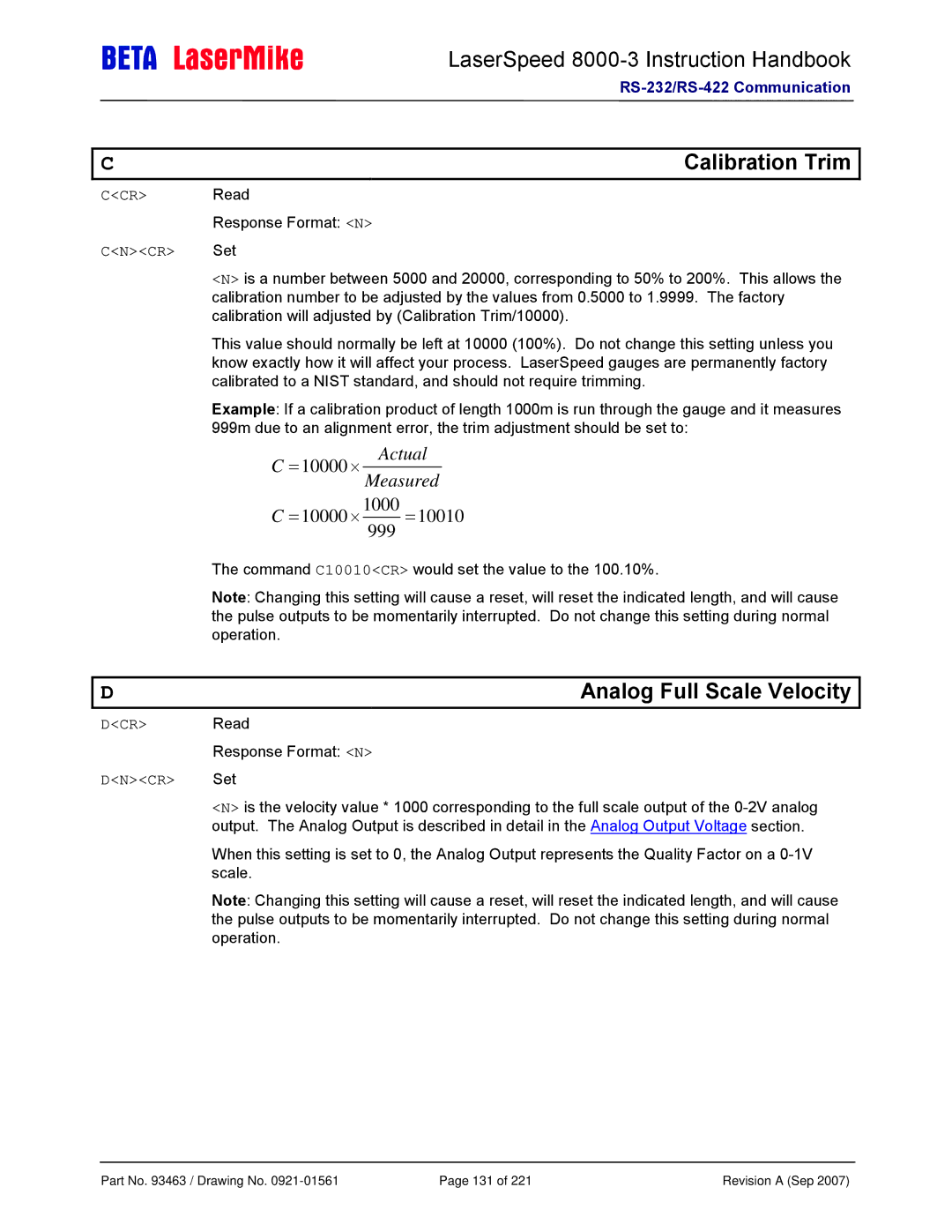

Example: If a calibration product of length 1000m is run through the gauge and it measures

999m due to an alignment error, the trim adjustment should be set to:

=⋅ Actual

C 10000 Measured

C= 10000 ⋅ 1000999 = 10010

The command C10010<CR> would set the value to the 100.10%.

Note: Changing this setting will cause a reset, will reset the indicated length, and will cause the pulse outputs to be momentarily interrupted. Do not change this setting during normal operation.

D | Analog Full Scale Velocity |

D<CR> Read

Response Format: <N>

D<N><CR> Set

<N> is the velocity value * 1000 corresponding to the full scale output of the

When this setting is set to 0, the Analog Output represents the Quality Factor on a

Note: Changing this setting will cause a reset, will reset the indicated length, and will cause the pulse outputs to be momentarily interrupted. Do not change this setting during normal operation.

Part No. 93463 / Drawing No. | Page 131 of 221 | Revision A (Sep 2007) |