LaserSpeed 8000-3 Instruction Handbook

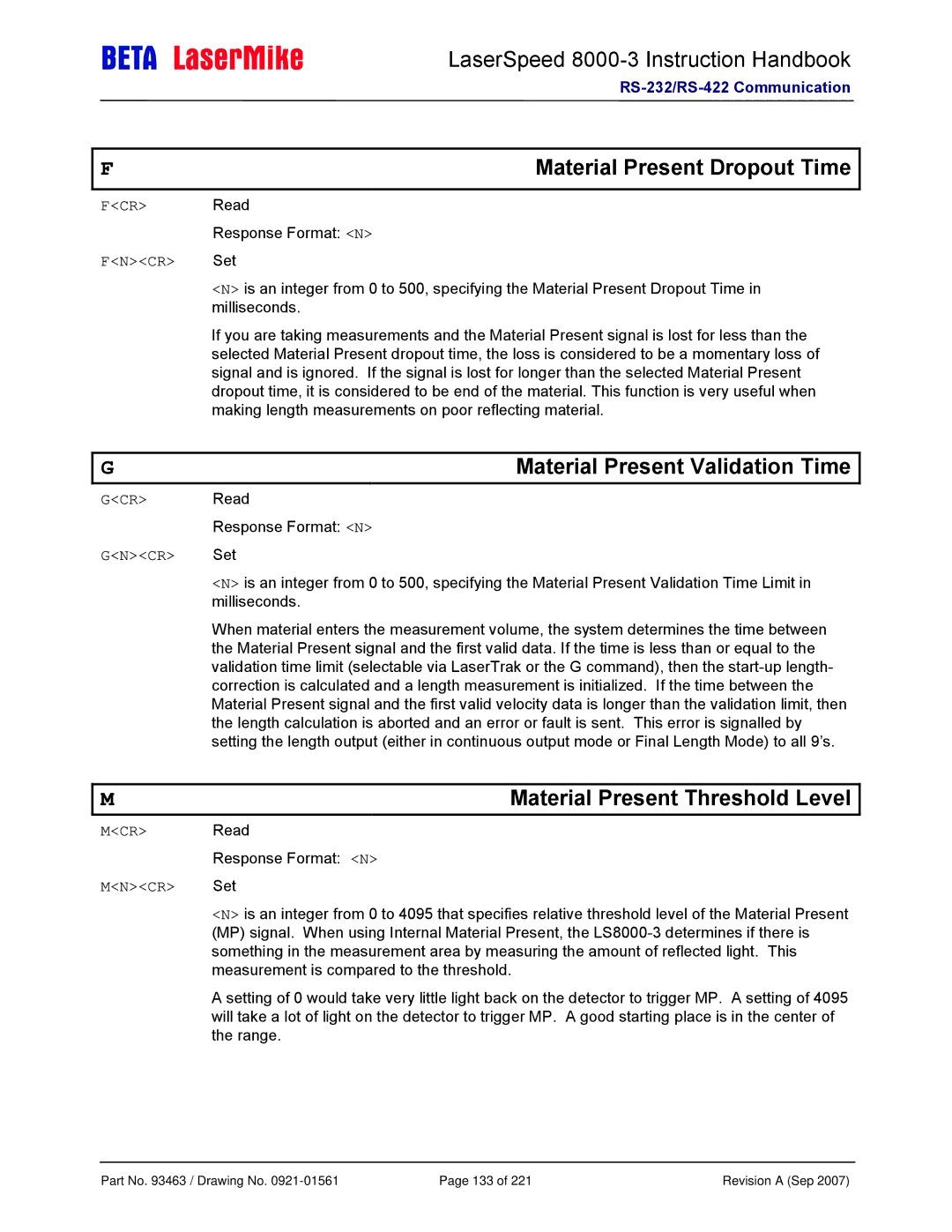

F | Material Present Dropout Time |

F<CR> Read

Response Format: <N>

F<N><CR> Set

<N> is an integer from 0 to 500, specifying the Material Present Dropout Time in milliseconds.

If you are taking measurements and the Material Present signal is lost for less than the selected Material Present dropout time, the loss is considered to be a momentary loss of signal and is ignored. If the signal is lost for longer than the selected Material Present dropout time, it is considered to be end of the material. This function is very useful when making length measurements on poor reflecting material.

G | Material Present Validation Time |

G<CR> Read

Response Format: <N>

G<N><CR> Set

<N> is an integer from 0 to 500, specifying the Material Present Validation Time Limit in milliseconds.

When material enters the measurement volume, the system determines the time between the Material Present signal and the first valid data. If the time is less than or equal to the validation time limit (selectable via LaserTrak or the G command), then the

M | Material Present Threshold Level |

M<CR> Read

Response Format: <N>

M<N><CR> Set

<N> is an integer from 0 to 4095 that specifies relative threshold level of the Material Present (MP) signal. When using Internal Material Present, the

A setting of 0 would take very little light back on the detector to trigger MP. A setting of 4095 will take a lot of light on the detector to trigger MP. A good starting place is in the center of the range.

Part No. 93463 / Drawing No. | Page 133 of 221 | Revision A (Sep 2007) |