LaserSpeed

Interfacing with the

When the product enters the measurement area and triggers the switch, the Material Present signal should activate. This causes the

Dual Switch Configuration

Two optical switches can be connected in parallel in order to further increase the precision of

Example:

A

In order to improve repeatability, the

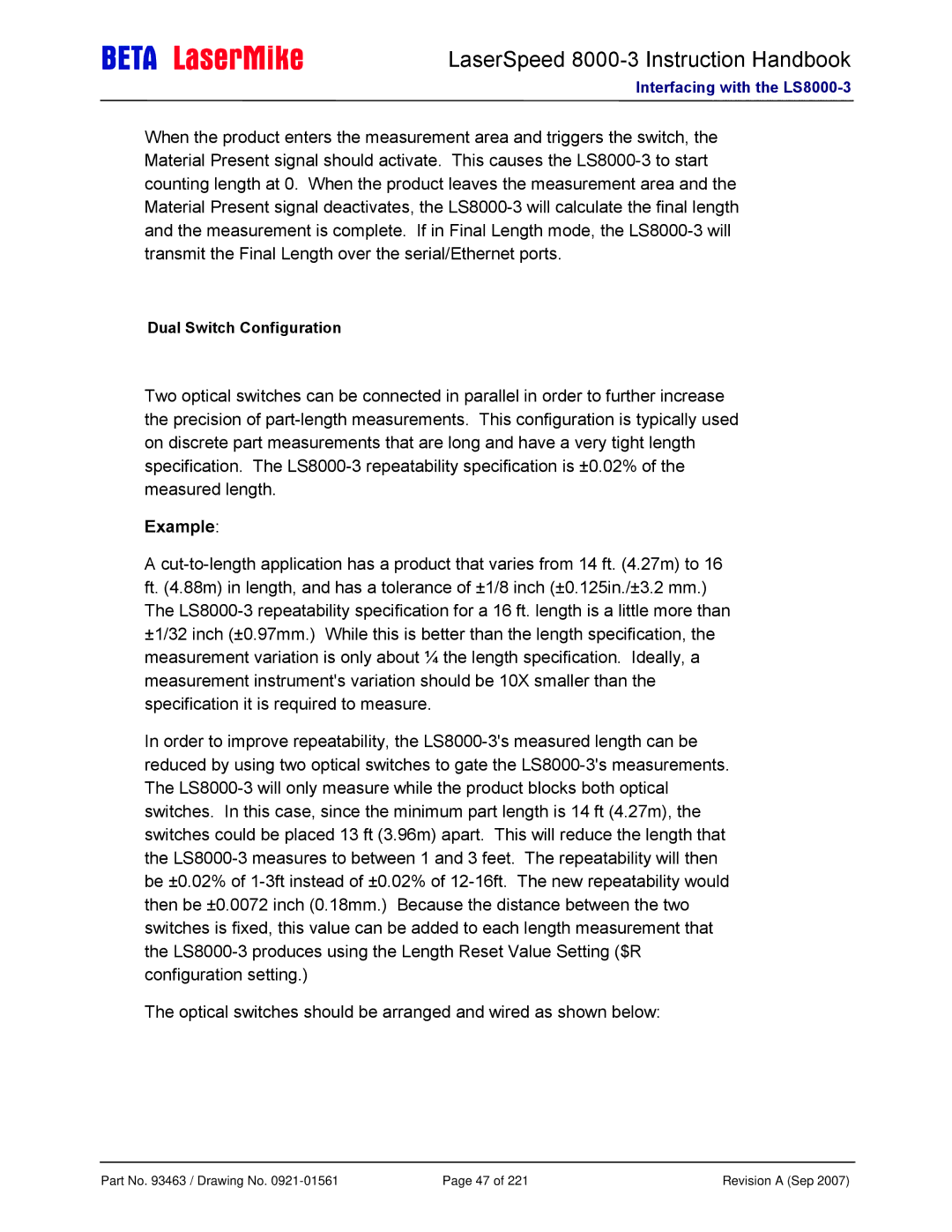

The optical switches should be arranged and wired as shown below:

Part No. 93463 / Drawing No. | Page 47 of 221 | Revision A (Sep 2007) |