LaserSpeed 8000-3 Instruction Handbook

Appendix E: Troubleshooting Guide

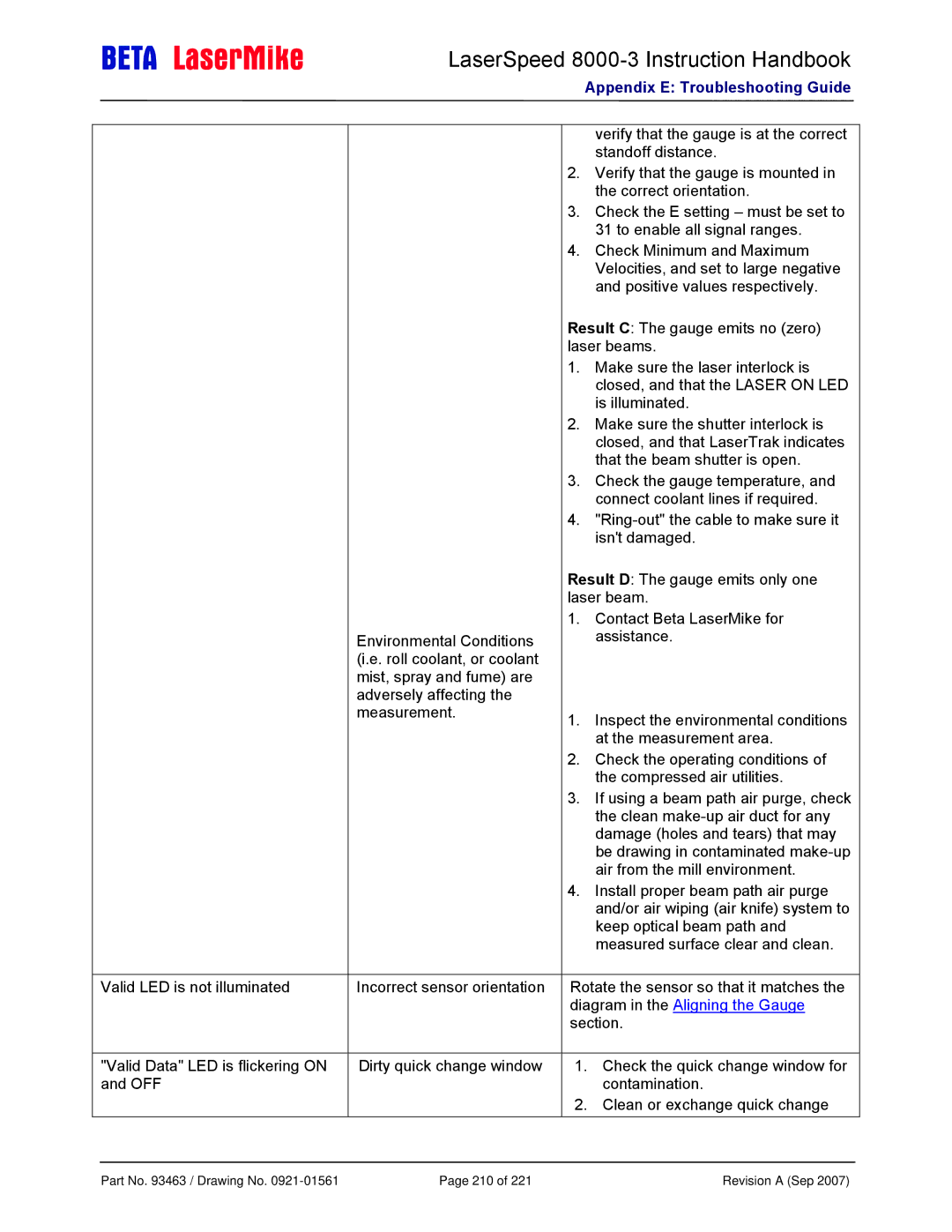

Environmental Conditions (i.e. roll coolant, or coolant mist, spray and fume) are adversely affecting the measurement.

Valid LED is not illuminated | Incorrect sensor orientation |

"Valid Data" LED is flickering ON | Dirty quick change window |

and OFF |

|

verify that the gauge is at the correct standoff distance.

2.Verify that the gauge is mounted in the correct orientation.

3.Check the E setting – must be set to 31 to enable all signal ranges.

4.Check Minimum and Maximum Velocities, and set to large negative and positive values respectively.

Result C: The gauge emits no (zero) laser beams.

1.Make sure the laser interlock is closed, and that the LASER ON LED is illuminated.

2.Make sure the shutter interlock is closed, and that LaserTrak indicates that the beam shutter is open.

3.Check the gauge temperature, and connect coolant lines if required.

4.

Result D: The gauge emits only one laser beam.

1.Contact Beta LaserMike for assistance.

1.Inspect the environmental conditions at the measurement area.

2.Check the operating conditions of the compressed air utilities.

3.If using a beam path air purge, check the clean

4.Install proper beam path air purge and/or air wiping (air knife) system to keep optical beam path and measured surface clear and clean.

Rotate the sensor so that it matches the diagram in the Aligning the Gauge section.

1.Check the quick change window for contamination.

2.Clean or exchange quick change

Part No. 93463 / Drawing No. | Page 210 of 221 | Revision A (Sep 2007) |