LaserSpeed 8000-3 Instruction Handbook

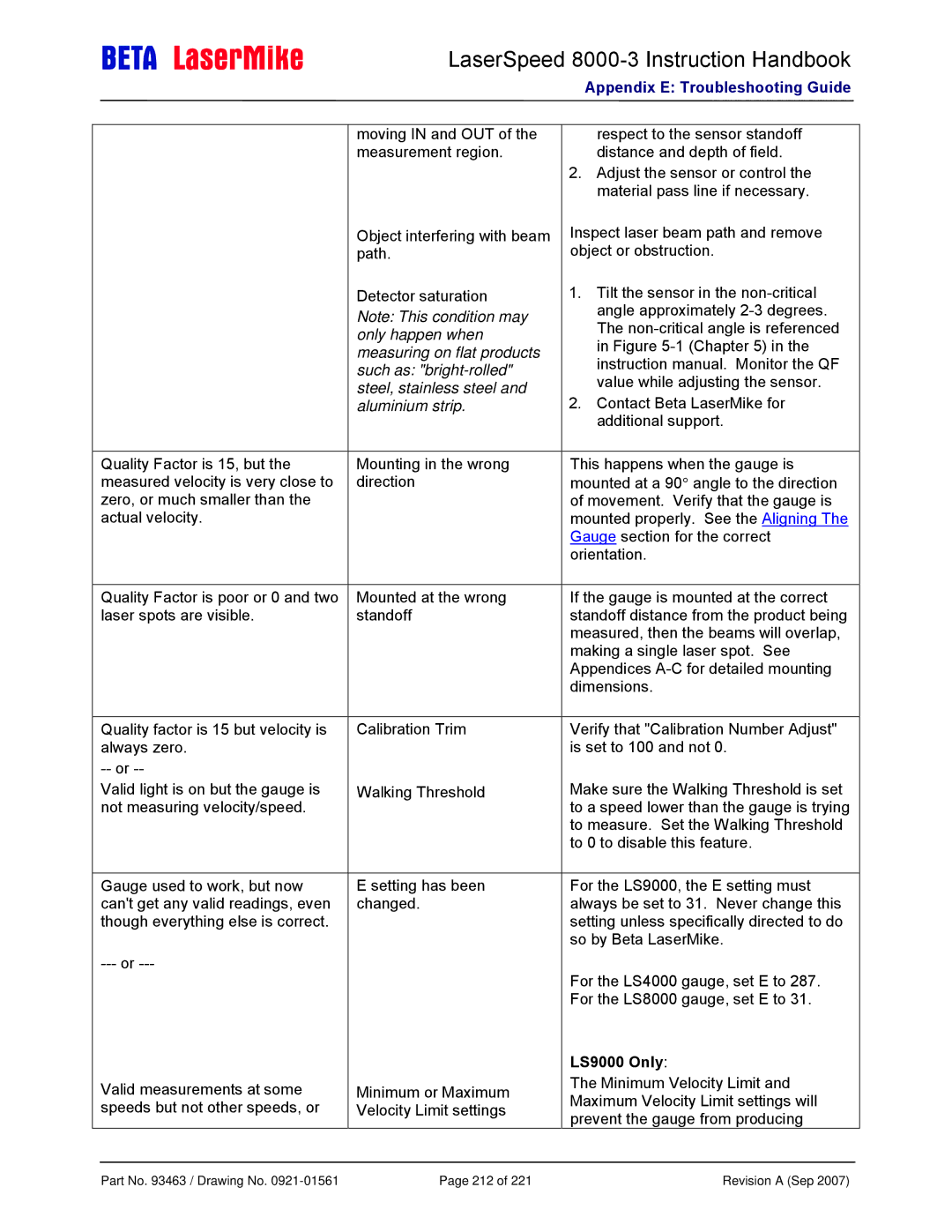

Appendix E: Troubleshooting Guide

| moving IN and OUT of the |

| measurement region. |

| Object interfering with beam |

| path. |

| Detector saturation |

| Note: This condition may |

| only happen when |

| measuring on flat products |

| such as: |

| steel, stainless steel and |

| aluminium strip. |

|

|

Quality Factor is 15, but the | Mounting in the wrong |

measured velocity is very close to | direction |

zero, or much smaller than the |

|

actual velocity. |

|

|

|

Quality Factor is poor or 0 and two | Mounted at the wrong |

laser spots are visible. | standoff |

Quality factor is 15 but velocity is | Calibration Trim |

always zero. |

|

| |

Valid light is on but the gauge is | Walking Threshold |

not measuring velocity/speed. |

|

Gauge used to work, but now | E setting has been |

can't get any valid readings, even | changed. |

though everything else is correct. |

|

|

Valid measurements at some | Minimum or Maximum |

speeds but not other speeds, or | Velocity Limit settings |

respect to the sensor standoff distance and depth of field.

2.Adjust the sensor or control the material pass line if necessary.

Inspect laser beam path and remove object or obstruction.

1.Tilt the sensor in the

2.Contact Beta LaserMike for additional support.

This happens when the gauge is mounted at a 90° angle to the direction of movement. Verify that the gauge is mounted properly. See the Aligning The Gauge section for the correct orientation.

If the gauge is mounted at the correct standoff distance from the product being measured, then the beams will overlap, making a single laser spot. See Appendices

Verify that "Calibration Number Adjust" is set to 100 and not 0.

Make sure the Walking Threshold is set to a speed lower than the gauge is trying to measure. Set the Walking Threshold to 0 to disable this feature.

For the LS9000, the E setting must always be set to 31. Never change this setting unless specifically directed to do so by Beta LaserMike.

For the LS4000 gauge, set E to 287. For the LS8000 gauge, set E to 31.

LS9000 Only:

The Minimum Velocity Limit and Maximum Velocity Limit settings will prevent the gauge from producing

Part No. 93463 / Drawing No. | Page 212 of 221 | Revision A (Sep 2007) |