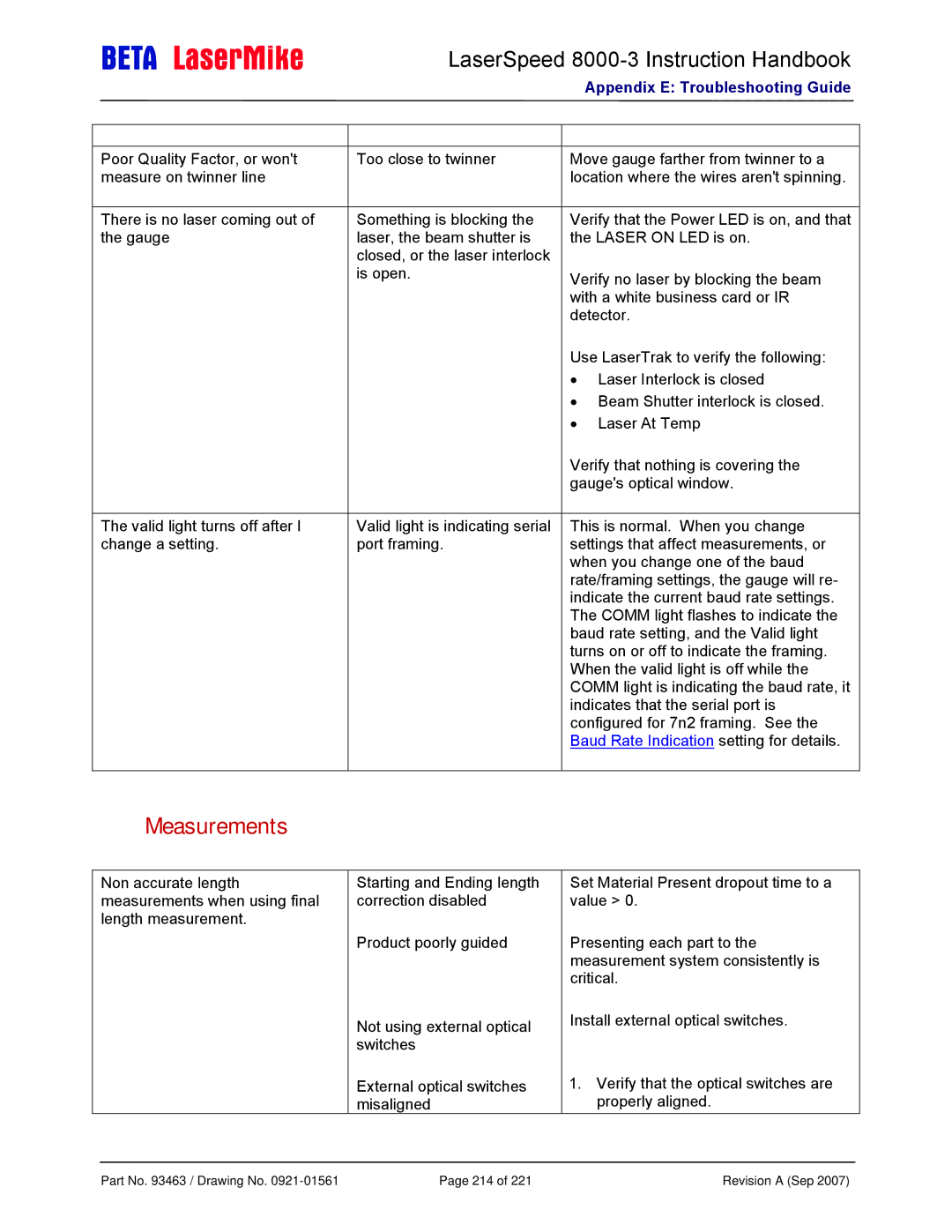

LaserSpeed 8000-3 Instruction Handbook

Appendix E: Troubleshooting Guide

Poor Quality Factor, or won't | Too close to twinner |

measure on twinner line |

|

|

|

There is no laser coming out of | Something is blocking the |

the gauge | laser, the beam shutter is |

| closed, or the laser interlock |

| is open. |

The valid light turns off after I | Valid light is indicating serial |

change a setting. | port framing. |

Move gauge farther from twinner to a location where the wires aren't spinning.

Verify that the Power LED is on, and that the LASER ON LED is on.

Verify no laser by blocking the beam with a white business card or IR detector.

Use LaserTrak to verify the following:

•Laser Interlock is closed

•Beam Shutter interlock is closed.

•Laser At Temp

Verify that nothing is covering the gauge's optical window.

This is normal. When you change settings that affect measurements, or when you change one of the baud rate/framing settings, the gauge will re- indicate the current baud rate settings. The COMM light flashes to indicate the baud rate setting, and the Valid light turns on or off to indicate the framing. When the valid light is off while the COMM light is indicating the baud rate, it indicates that the serial port is configured for 7n2 framing. See the Baud Rate Indication setting for details.

Measurements

Non accurate length measurements when using final length measurement.

Starting and Ending length correction disabled

Product poorly guided

Not using external optical switches

External optical switches misaligned

Set Material Present dropout time to a value > 0.

Presenting each part to the measurement system consistently is critical.

Install external optical switches.

1.Verify that the optical switches are properly aligned.

Part No. 93463 / Drawing No. | Page 214 of 221 | Revision A (Sep 2007) |