LaserSpeed 8000-3 Instruction Handbook

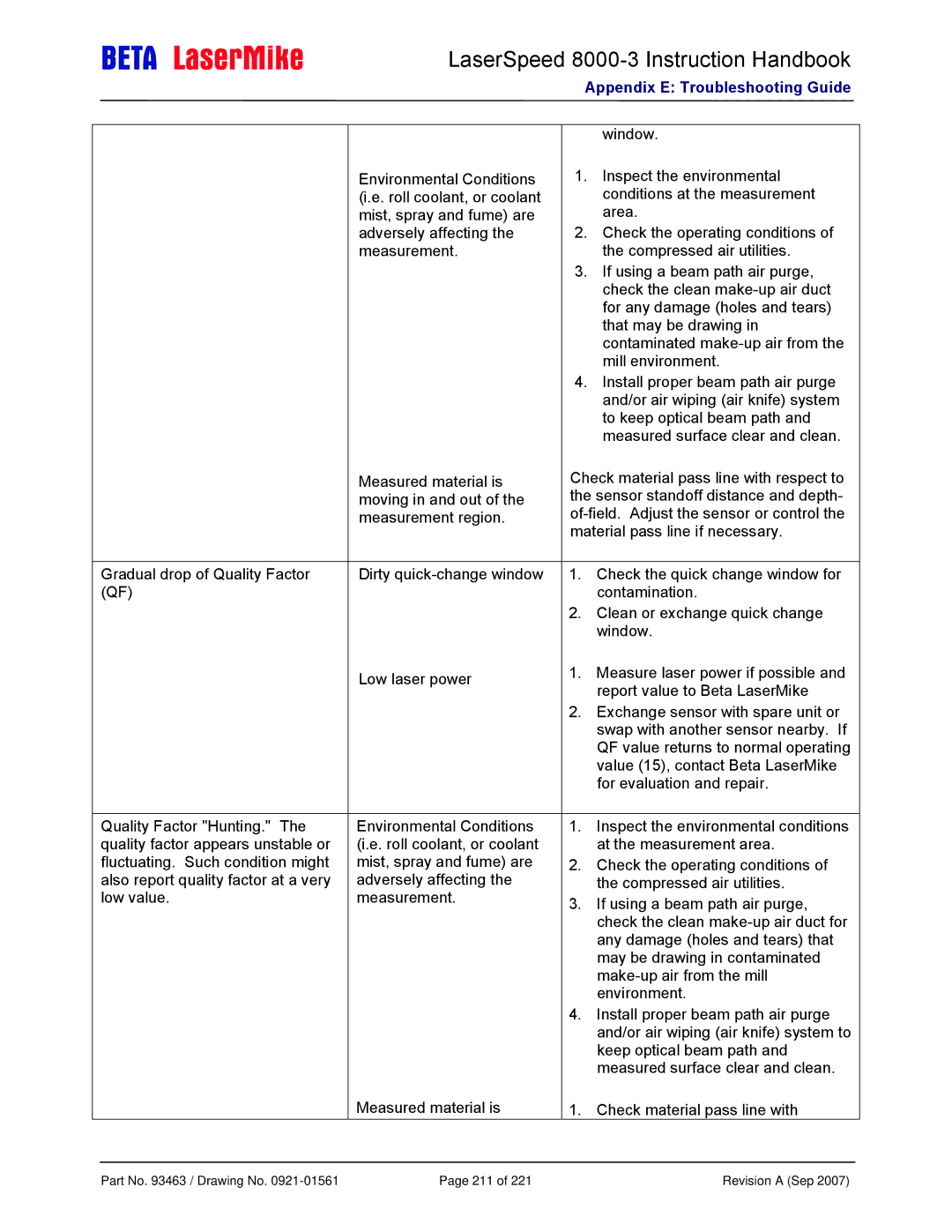

Appendix E: Troubleshooting Guide

Environmental Conditions (i.e. roll coolant, or coolant mist, spray and fume) are adversely affecting the measurement.

| Measured material is |

| moving in and out of the |

| measurement region. |

|

|

Gradual drop of Quality Factor | Dirty |

(QF) |

|

Low laser power

Quality Factor "Hunting." The | Environmental Conditions |

quality factor appears unstable or | (i.e. roll coolant, or coolant |

fluctuating. Such condition might | mist, spray and fume) are |

also report quality factor at a very | adversely affecting the |

low value. | measurement. |

Measured material is

window.

1.Inspect the environmental conditions at the measurement area.

2.Check the operating conditions of the compressed air utilities.

3.If using a beam path air purge, check the clean

4.Install proper beam path air purge and/or air wiping (air knife) system to keep optical beam path and measured surface clear and clean.

Check material pass line with respect to the sensor standoff distance and depth-

1.Check the quick change window for contamination.

2.Clean or exchange quick change window.

1.Measure laser power if possible and report value to Beta LaserMike

2.Exchange sensor with spare unit or swap with another sensor nearby. If QF value returns to normal operating value (15), contact Beta LaserMike for evaluation and repair.

1.Inspect the environmental conditions at the measurement area.

2.Check the operating conditions of the compressed air utilities.

3.If using a beam path air purge, check the clean

4.Install proper beam path air purge and/or air wiping (air knife) system to keep optical beam path and measured surface clear and clean.

1. Check material pass line with

Part No. 93463 / Drawing No. | Page 211 of 221 | Revision A (Sep 2007) |