LaserSpeed

Installing the System

for more details. When mounting the gauge, be aware of the environment in which the gauge is operating. Steam, mist, coolant on the material, ambient temperature, scale and slag may all affect the performance of the gauge.

These environmental conditions may need to be modified as mentioned above in order to maximize the performance of the gauge.

Mounting Location

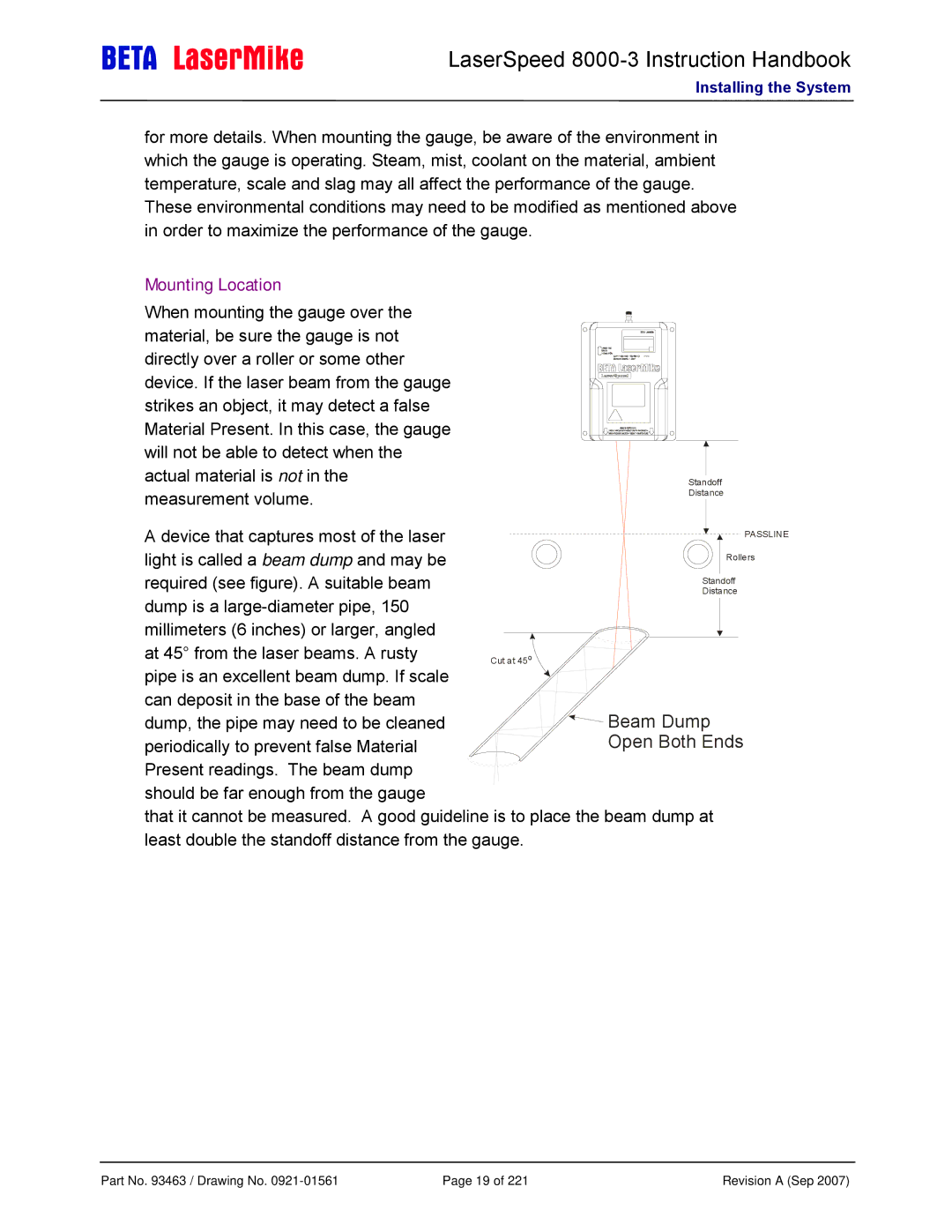

When mounting the gauge over the |

|

material, be sure the gauge is not |

|

directly over a roller or some other |

|

device. If the laser beam from the gauge |

|

strikes an object, it may detect a false |

|

Material Present. In this case, the gauge |

|

will not be able to detect when the |

|

actual material is not in the | Standoff |

measurement volume. | Distance |

| |

A device that captures most of the laser | PASSLINE |

| |

light is called a beam dump and may be | Rollers |

| |

required (see figure). A suitable beam | Standoff |

Distance | |

dump is a |

|

millimeters (6 inches) or larger, angled |

|

at 45° from the laser beams. A rusty | Cut at 45º |

pipe is an excellent beam dump. If scale |

|

can deposit in the base of the beam | Beam Dump |

dump, the pipe may need to be cleaned | |

periodically to prevent false Material | Open Both Ends |

Present readings. The beam dump |

|

should be far enough from the gauge

that it cannot be measured. A good guideline is to place the beam dump at least double the standoff distance from the gauge.

Part No. 93463 / Drawing No. | Page 19 of 221 | Revision A (Sep 2007) |