FR-S500

This section is specifically about safety matters

Electric Shock Prevention

Transportation and installation

Fire Prevention

Injury Prevention

Additional Instructions

Wiring

Trial run

Operation

Maintenance, inspection and parts replacement

Emergency stop

Disposing of the inverter

Treat as industrial waste

Standard connection diagram and terminal specifications

How to use the control circuit terminals

Main circuit terminals

Input terminals

Handling of the RS-485 connector

Connection to the Stand-Alone Option

Design information

Maintenance parameters 122

Output terminal function parameters

Current detection function parameters

Display function parameters

Parameter unit FR-PU04 setting 151

Errors Alarms 156

Troubleshooting 166

Calibration parameters 126

Specification list 170

Outline drawings 175

180

Inverter

FR-S500

Chapter

Standard connection diagram and terminal specifications

Standard connection diagram

Three-phase 200V power input Three-phase 400V power input

NFB MC

Single-phase 100V power input

Explanation of main circuit terminals

Main circuit

Control circuit

Symbol Terminal Name Definition

Alarm output

Signals

Indicator

1Three-phase 200V power input

Main circuit terminals

Terminal block layout

3Single-phase 100V power input FR-S510WE-0.1K, 0.2K, 0.4K-NA

FR-S510WE-0.75K-NA

Cables, wiring length, and crimping terminals

FR-S520E-0.1K

To 0.75K-NA FR-S520E 5K, 2.2K-NA 7K-NA

FR-S540E-0.4K

Wiring instructions

Selection of peripheral devices

Select the NFB according to the inverter power

Supply capacity Install one NFB per inverter

NFB *1, 4 or

To-ground leakage currents

Line-to-line leakage currents

Path during commercial Power supply operation

∆n ≥ 10 × lg1+Ign+lg2+lgm

Standard breaker

∆n ≥ 10 × lg1+lgn+3 × lg2+lgm

Main circuit terminals

Power-off and magnetic contactor MC

Inverter input side magnetic contactor MC

Handling of output side magnetic contactor

Inverter Start/Stop Circuit Example

NFB FR-BAL-H

Regarding noise and the installation of a noise filter

General countermeasures

BSF01

FR-BIF

Grounding precautions

Power supply harmonics

Inverter-driven 400V class motor

Rectifying the motor insulation

Suppressing the surge voltage on the inverter side

How to use the control circuit terminals

Bar Terminal Model Wire Size mm2

With Insulation Without Insulation Sleeve

Terminal Screw Size

Changing the control logic

STF STR

RUN 24VDC

STR R

RUN

Two-wire type connection STF, STR

Two-wire type connection is shown on the right

Input terminals

Run start and stop STF, STR, Stop

Three-wire type connection STF, STR, Stop

DC Injection Brake and Coasting to Stop Functionality

Start/Stop Timing Chart for two-wire type

Forward-Reverse Rotation Switch-Over Timing Chart

STF-SD

STR-SD

Voltage input 10, 2

Manual-Automatic Switching

External frequency selection REX, RH, RM, RL

Current input 4, 5, AU

AU-SD

Multi-Speed Setting

Multi-Speed Operation Connection Example

Indicator connection and adjustment AM

Frequency of 90Hz, set 90Hz in Pr . Factory setting 50Hz

Refer to page 126 for the procedure of indicator adjustment

Terminal AM Output Circuit

Signal inputs by contactless switches

Control circuit common terminals SD, 5, SE

Multi-speed setting RL, RM, RH, REX signals

Remote setting RL, RM, RH signals

Second function selection RT signal Pr to Pr setting

Current input selection AU signal Pr to Pr setting

Start self-holding selection Stop signal Pr to Pr

Output shut-off MRS signal Pr to Pr setting

External thermal relay input Pr to Pr setting

Jog operation JOG signal Pr to Pr setting

Jog operation using external signals

STF STR-SD

PID control valid terminal Pr to Pr setting

PU operation/external operation switchover Pr to Pr

Related parameters

Connection to the Stand-Alone Option

Connection of the brake unit BU type

Connection of the high power factor converter FR-HC

Connection of the power regeneration common converter FR-CV

NFB MC1

Handling of the RS-485 connector

Connection of the parameter unit FR-PU04

Wiring of RS-485 communication

Model

Product Model Maker

Product Model

Maker

Wiring methods

Wiring of one RS-485 computer and one inverter

Switchover

Design information

MC1

MC2

Memo

101

120

122

126

Indica Name Setting

Function Parameter list

Factory

Cus

Func- Para- Indica Name Setting Range

Setting To

Factory Refer

Tion meter tion

Func Para Indica Name Setting Range

Tion

Name Setting Range

Func- Para- Indica- tion meter tion

Remote Setting function

THM, THT, BE, GF

OHT, OLT, PE, OPT

PWM

Name Setting Range Minimum Factory

PID

Maintenance parameters

Parameter for manufacturer setting

Additional parameters

Indi Name Setting Range

Calibration parameters

Func

ECL

Indica Name Setting Range

Communication Parameters

Func Parame- Indica Name Setting Range

Is valid

Ter Tion

List of parameters classified by purpose of use

List of parameters classified by purpose of use

Setting

Explanation of functions parameters

Torque boost Pr

Increase this value for use when

Name Factory Setting Setting Range

Maximum and minimum frequency Pr

Used to adjust the inverter

Base frequency, base frequency voltage Pr.3 , Pr.19 , Pr.47

Motor rating Outputs voltage, frequency to

Name Factory

Name Factory Setting Remarks Range

Multi-speed operation Pr , Pr , Pr Pr to Pr , Pr to Pr

Acceleration/deceleration time Pr , Pr , Pr , Pr , Pr

Pr.3

Acceleration 120 Deceleration time s

Use an external thermal relay

Para Name Factory

H7 setting

Function Relay Function Applied Additional

Can be adjusted according to the load

Install a mechanical brake. No holding torque is provided

DC injection brake Pr , Pr , Pr

Changed to 4%

Starting frequency Pr

Remarks Setting Range

Load pattern selection Pr

Using the FWD or REV

Jog operation Pr.15 , Pr.16

RUN key rotation direction selection Pr.17

Stall prevention function and current limit function Pr

Explanation of functions parameters

Stall prevention Pr , Pr , Pr

To Refer to to

Acceleration/deceleration pattern Pr

Set the acceleration/deceleration pattern

Function Description

Extended function display selection Pr

Frequency jump Pr To Pr

Speed display Pr

Parameter Name Factory Setting

How to change the highest frequency

Mode indication

Flicker ... Parameter setting complete

Confirm the RUN indication and operation

Press the Mode to choose the parameter

Setting mode Turn To show

For the Pr setting method, refer to Press the SET To show

Gain and bias frequency settings are too close

Setting mode Turn To show Pr must be set to

Press the SET to set the value

Turn the to read another parameter Press

To return to

Start-time ground fault detection selection Pr

Output terminal function parameters

Up-to-frequency Pr

Output frequency detection Pr , Pr

Current detection function parameters

On OFF

When the inverters output current falls

Zero current detection Pr , Pr

Parameter

Display function parameters

Monitor display Pr , Pr

Setting dial function selection Pr

Restart setting Pr , Pr , H6

Parameter Name Factory Setting Remarks Range

Restart operation parameters

Monitoring reference Pr , Pr

Refer to the following table and set the parameters

Stfstr

Retry reset ⇒ Pr.66 to Pr.69 retry function Refer to

Remote setting function selection Pr

Additional function parameters

Pr Setting

Function E2PROM

Frequency setting storage conditions

Terminal function selection parameters

Input terminal function selection Pr , Pr , Pr , Pr

Setting Signal Functions Related Parameters Name

MRS

REX

JOG

Setting Signal Function Operation

Output terminal function selection Pr , Pr

FDN

FUP

Protective Functions Major Faults for Retries

Alarm Signal Output

Operation selection function parameters

Retry function Pr , Pr , Pr , Pr

102

Pr.70 Setting Description

Pr.72 Setting Description

PWM carrier frequency Pr , Pr

You can change the motor sound

Voltage input selection Pr

Reset selection/PU stop selection Pr

Reset Selection PU Stop Selection Setting

Input filter time constant Pr

From the operation panel PU

STR OFF

Cooling fan operation selection Pr

Parameter write disable selection Pr

Pr Setting Function

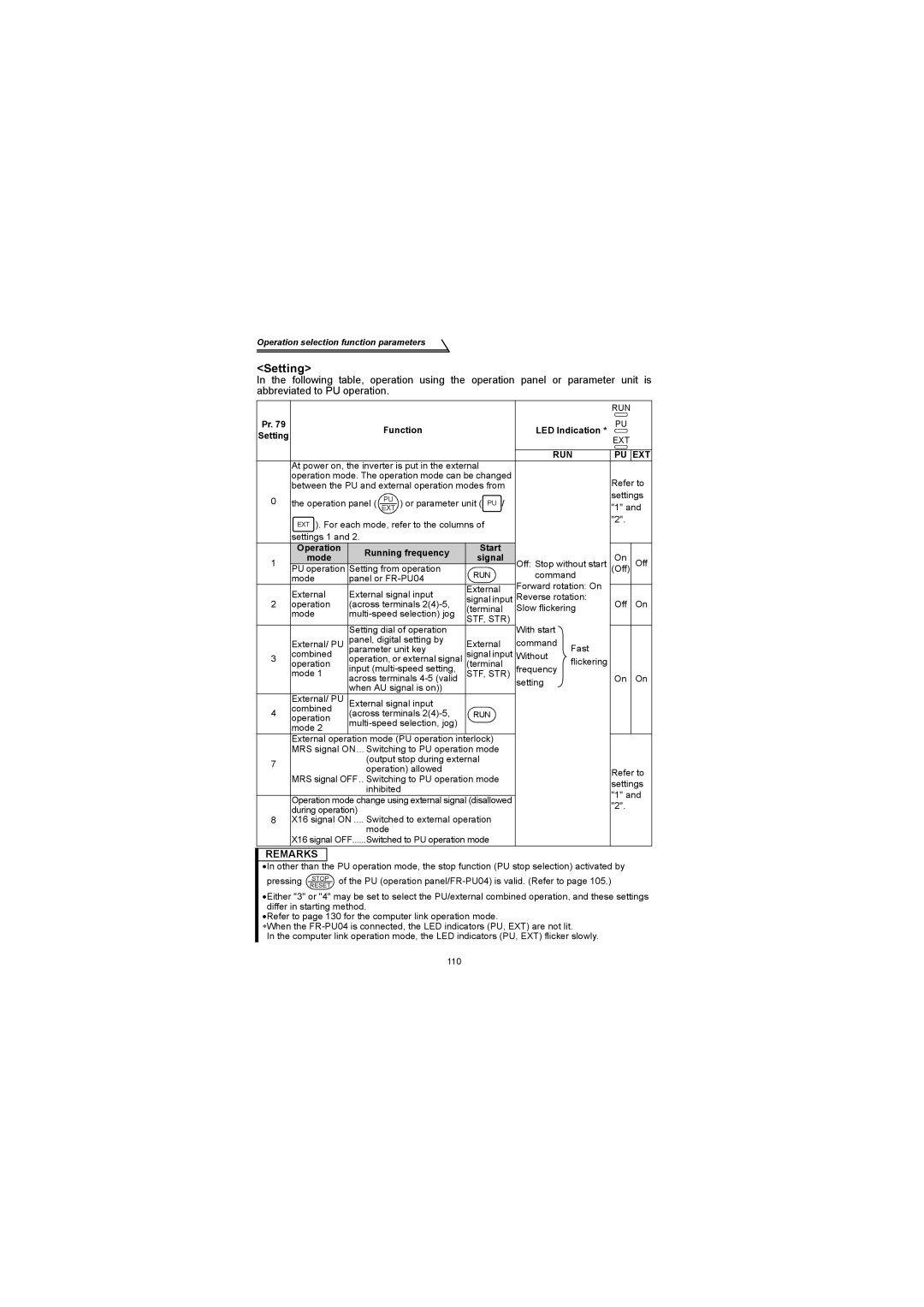

Operation mode selection Pr

Reverse rotation prevention selection Pr

Operation Running frequency Start Mode Signal

Function LED Indication

EXT

STF, STR

MRS Signal Function/Operation

PU operation interlock

Preparation

Operating Condition

Operation mode switching by external signal

X16 Signal Operation Mode

To Refer to to

Setting Basic PID control configuration

PID control Pr to Pr

PID action overview

Operation example for stepped changes of measured value

PD action

PID action

Both actions for control

Reverse action

Wiring example

Contact input signal AU Signal need not be turned on

Forward action

Pr =

O signals

Parameter setting

Entry Description

Adjustment procedure

Calibration example

Start

END

Set point input calibration

Detector output calibration

Auxiliary parameters

Slip compensation Pr , Pr , Pr

Rated slip =

×100%

Setting Description

Automatic torque boost selection Pr

Operating conditions

Maintenance parameters

Maintenance output function H1 , H2

Name Factory Setting Remarks Range

Motor primary resistance Pr

Current average value monitor signal H3 , H4 , H5

PLC

Output pulse of the Y93 signal is shown below

Setting

Pulse operation

40000h

72000h

Parameter Name Factory Setting Setting Range Remarks

Calibration parameters

Meter frequency meter calibration C1

Flicker ... Parameter setting complete

To Refer to ,

Alarm history clear ECL

Clear the alarm history

Clear parameters

Parameter clear CLr

Symbol Switching Type Switching Method

Communication parameters

Operational functions

Operation mode-based functions

Location PU operation External Computer link

Communication settings n1 to n7 , n11

Remarks Reflection Setting Range

Communication-related parameters

Computer

133

Computer programming Communication protocol

Operation Run

Ing

Data format

Reply data from inverter to computer during data write

Reply data from inverter to computer during data read

Data definitions

Waiting time

Response time

Example When communication parameter n6= 0.1 to

Error code

Sum check code

140

Setting items and set data

Data Description

HFA

H7A

H6D

H6E

E2PROM

HED

Commu Calibra Other

Nication

Data

Error Code List

Operation at alarm occurrence

Communication error

General flowchart

Program example

On COM1GOSUB*REC

If LOC1=0 then Return Printreceive Data

Operation and speed command source n8 , n9

N8 Pr operation Command source

External Remarks Location N9 Pr speed

Link startup mode selection n10

N9 Pr speed Command source

Explanation of table

External

149

15.4 E2PROM write selection n12

Parameter unit FR-PU04 setting

N13 Setting Display Language

PU display language selection n13

PU buzzer control n14

PU contrast adjustment n15

PU main display screen data selection n16

100

During stop During operation

Disconnected PU detection/PU setting lock selection n17

Monitor display and the Resetstop are valid

N17 Setting Disconnected PU Detection PU Setting Lock

154

Protective Functions

This chapter explains the protective functions of this

Errors Alarms

Error alarm definitions

Major failures

OC During Acc

Stedy Spd OC

OV During Acc

Stedy Spd OV

OV During Dec

Br. Cct. Fault

Motor Overload

Inv. Overload

Sink O/Temp

Is set to OH

CPU Fault

Minor failures

PU Leave Out

Retry No Over

Check point

FR-PU04

Write errors

Resetting the inverter

Correspondence between digital and actual characters

Pr . Refer to page 36

Actual Display

Troubleshooting

Motor remains stopped

Motor current is large

Operation mode is not changed properly

Specifications

Specification list 170 Outline drawings 175

Specification list Ratings

Three-phase 200V power supply

Three-phase 400V power supply

Single-phase 100V power supply

Common specifications

Maximum and minimum frequency settings, frequency jump

Outline drawings

Unit mm inches

Φ5 hole 118 128 Cooling fan×1

177

178

Appendix 1 Parameter Instruction Code List 180

Appendix

Appendix 1 Parameter Instruction Code List

Setting Instruction

Name Code Link Data

Tion Number Read

Operation panel display

Multi-speed setting 01Hz Speed

C4903 Voltage bias frequency 6C/EC=0 Voltage gain

Source

Revisions