SJ700-2 Series

Page

Installation

Safety Instructions

! Warning

Wiring

Operation

Maintenance, inspection, and parts replacement

Precautions Concerning Electromagnetic Compatibility EMC

Model No Required torque N-m Wire range AWG

Or 1/0

13.7

60 a

Model No Fuse/circuit breaker a Type Rating

30 a

40 a

Contents

Contents

Running time over and power-on time over signals RNT and ONT

Contents

Xii

Error Codes

Xiii

Index

Overview

Page

Specification label

Inspection of the Purchased Product

Inspecting the product

Method of inquiry

Method of Inquiry and Product Warranty

Product warranty

Warranty Terms

Exterior Views and Names of Parts

Installation and Wiring

Page

Installation and Wiring

Inverter

Precautions for installation

Loss with 100% load W

Ventilation fan

Inverter AcceptableUnacceptable

Inverter capacity kW 18.5 Loss with 70% load W

Backing plate Rubber bushing

Joint Section to be cut off

Wiring

Hitachi

Phase power supply

Explanation of control circuit terminals

Explanation of main circuit terminals

AL0

SW1

OFF on

Wiring of the main circuit

Inverter Grounding bolt prepared by user

Terminal layout Inverter model

Charge lump

Terminal layout

Terminal layout Inverter model Charge lump

Applicable peripheral equipment

100

Inverter Motor

50/60 Hz ±5%

200 to 240 V +10%, -15%

50/60 Hz ±5% 282 to 339 VDC

380 to 480 V +10%, -15%

CM1 15 CM2 12 AL0 AL2

TH FW 8 CM1

PL CM1 7 6

FW 8 CM1 14 13 11 AL1

Source logic

When using the internal interface power supply

When using an external power supply

Sink logic

BRD

Operation

Page

! Warning

Operating Methods

Frequency-setting command

Input device control Device switch

Control circuit terminal block

How To Operate the Digital Operator OPE-S

Monitor Power lamp Digit LED display

Names and functions of components

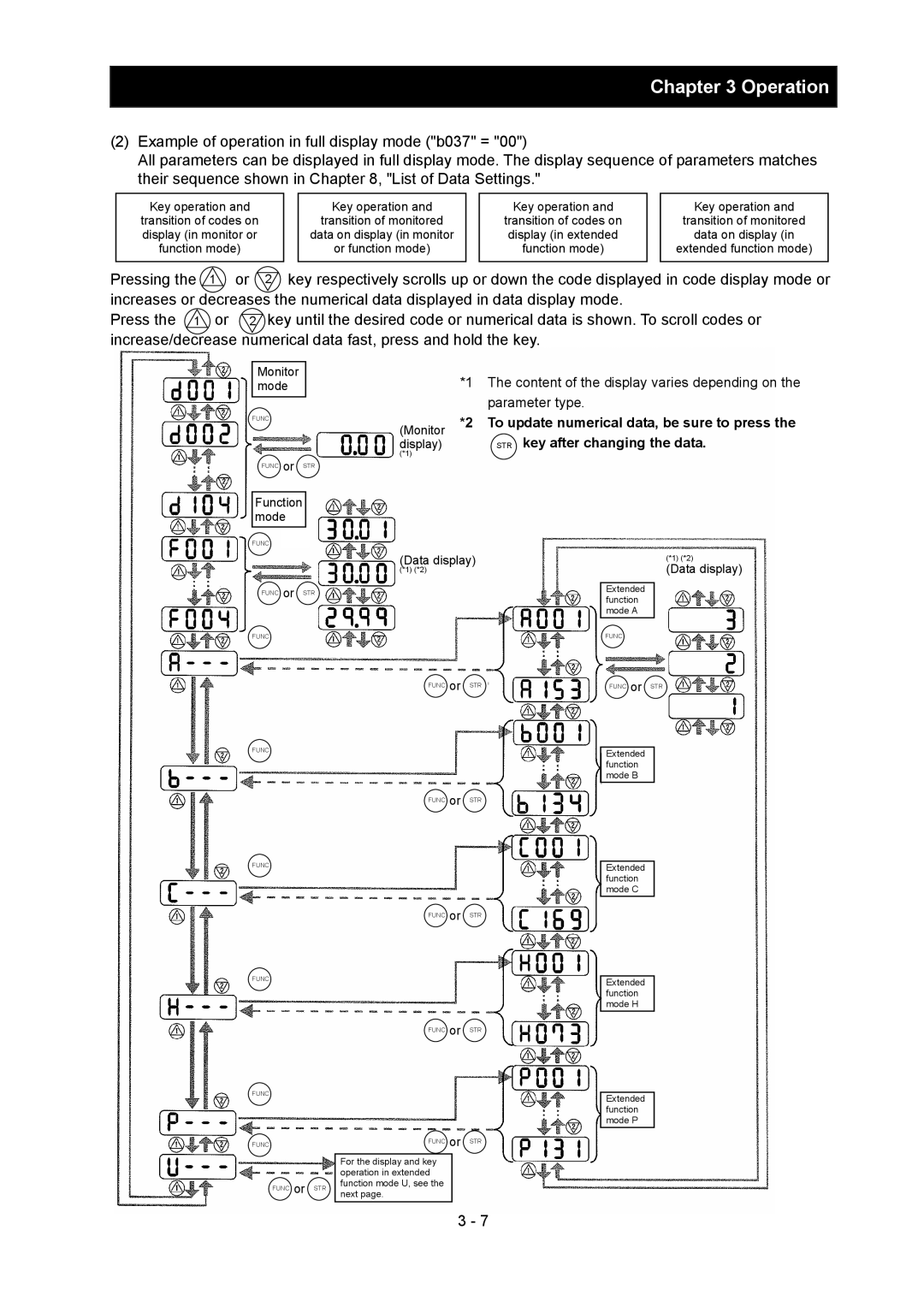

Code display system and key operations

Operation

Corresponding to the function code. Data display *1*2

STR key after changing the data

Parameter type

Pressing the STR key

Display the monitor mode code. d001 is displayed

ELB

How To Make a Test Run

Key to decelerate or stop the motor

Key to start the motor RUN lamp green LED goes on Press

CM1 PLC

This chapter describes the functions of the inverter

Explanation of Functions

Page

Rotation direction monitoring

Monitor Mode

Output frequency monitoring

Output current monitoring

Intelligent input terminal status

Intelligent output terminal status

Scaled output frequency monitoring

Torque bias monitoring

Torque command monitoring

Power monitoring

Actual-frequency monitoring

Motor temperature monitoring

Cumulative power monitoring

Cumulative power-on time monitoring

Heat sink temperature monitoring

Program number monitoring easy sequence function

Current position monitor in absolute position control mode

Life-check monitoring

Program counter display easy sequence function

BRD load factor monitoring

Programming error monitoring

Trip monitoring 1 to

DC voltage monitoring

Rotational direction restriction

Function Mode

Output frequency setting

Keypad Run key routing

Active state C011 to C018 NC contact

Frequency source setting

Run command source setting

No contact

Stop key enable

Stop mode selection

Deceleration time tB

Acceleration/deceleration time setting

Maximum frequency setting

Base frequency setting

External analog input setting O, OI, and O2

+fO2 + fO2

Frequency operation function

Frequency addition function

Start/end frequency setting for external analog input

External analog input O/OI/O2 filter setting

16 V/f gain setting

Start/end frequency settings for the O2-L terminal

VPf

17 V/F characteristic curve selection

To free-setting V/f frequency 6 Hz

Free-setting V/f frequency

To 400.Hz Free-setting V/f frequency

To free-setting V/f frequency 7 Hz

Torque boost setting

B083

DC braking DB setting

Example 3-a Example 3-b

Edge mode A056

Example 1-a Example 1-b

Example 2-a Example 2-b

Ii Example 6-a when the stop command is input

Ii Example 5-a when the stop command is input

Edge mode

Example 7-a

Example 7-b

Frequency upper limit setting

When the O-L or OI-L terminal is used

When the O2-L terminal is used

Frequency setting Acceleration

Acceleration stop frequency setting

Setting of 0 Hz disables the jump frequency function

Setting of the length of time to stop

PID function

Operation targets are the inputs To the OI and O terminals

OI-L + O2

OI + O2

Operation targets include + O2 Input to the OI terminal

01 %

FW on OFF FBV Onoff

Two-stage acceleration/deceleration function 2CH

Use functions A097 and A098 to select acceleration

Acceleration/deceleration curve selection

You can set different patterns of motor acceleration

Inverter

Energy saving mode tuning A086

Energy-saver operation

Accuracy

Retry or trip after instantaneous power failure

Power supply Inverter output Motor speed

Example 8 b00400

Example 5 b00400

Example 6 b00401

Example 7 b00402

Disabling the protection

Phase loss power input protection

Function code Data Description Phase loss detection

Enable Enabling the protection

Electronic thermal protection

Constant-torque characteristic

Characteristic

Free setting of electronic thermal characteristic

Disabling the electronic thermal protection

Setting of the current at each breakpoint

Setting of the threshold level to output

Thermal warning signal

Overload restriction/overload notice

Overcurrent restraint

Over voltage supression during deceleration

Reduced voltage start function

Start frequency setting

Class

Carrier frequency setting

Automatic carrier frequency reduction

Function code Range of data Description Automatic carrier

00/01 Invalid, 01 valid Frequency reduction

Dynamic braking BRD function

Cooling-fan operation setting

Intelligent input terminal setting

Input terminal a/b NO/NC selection

If two or more input terminals are turned on at the same

Bit operation mode

By setting multispeeds 1 to 7 A021 to A027

Make multispeed s 0 to 7 available for selection

Jog stop mode

Jogging JG command setting

43 2nd/3rd motor control function SET and SET3

Forcible-operation from terminal F-TM function

Software lock SFT function

Free-run stop FRS function

Commercial power source switching CS function

Reset RS function

Example 4 Restarting with active matching frequency

Unattended start protection USP function

Remote control function UP and DWN

External trip EXT function

53 3-wire interface operation function STA, STP, and F/R

55 P/PI switching function PPI

Control gain switching function CAS

Synchronous rotation speed at base frequency

Analog command holding function AHD

Speed error at rated torque a

Intelligent pulse counter Pcnt and PCC

Intelligent output terminal setting

Intelligent output terminal a/b NO/NC selection

Example of operation as an alarm output terminal

Disabling the output of frequency

C042/C045 043/C046

63 0 Hz speed detection signal ZS

Alarm code output function AC0 to AC3

Over-torque signal OTQ

Logical output signal operation function LOG1 to LOG6

Communication line disconnection signal NDc

Capacitor life warning signal WAC

Cooling-fan speed drop signal WAF

Starting contact signal FR

Heat sink overheat warning signal OHF

FWR Forward rotation signal

Low-current indication LOC signal

Forward rotation signal FWR

Irdy Inverter ready signal

MJA Major failure signal

Reverse rotation signal RVR

Major failure signal MJA

RVR Reverse rotation signal

WCO/WCOI/WCO2

Output signal delay/hold function

Input terminal response time

External thermistor function TH

Function code Range of data Description

FM terminal

Pulse output terminal

FM siginal selection

AM and AMI terminals

Initialization setting

Function code display restriction

Explanation of Functions

Last equivalent to the setting on SJ300

Automatic user-parameter setting

Stabilization constant setting

Selection of operation at option board error

Page

Brake control function

Release signal output until the release

Signal has been output until the brake is

Brake Wait Time for Mechanical delay after the release

Wait time longer than the delay after

B054 B053

B052

When using this function, follow the instructions below

Offline auto-tuning function

Normal end Abnormal end

Disabling the secondary resistance compensation

Online auto-tuning function

Automatically tuned data online auto-tuning enabled

Function code Data Description Temperature compensation

Voltage class 200 or 400

Then adjust the speed response H005/H205

Motor constants selection

Io as follows

Sensorless vector control

Zero LV starting boost current

Sensorless vector, 0 Hz domain control

Zero LV lmit

Current limiter for the low-speed range

Motor capacity selection

Torque monitoring function

Forcing function FOC

Output torque

Torque limitation function

Disabling counterrotation prevention

Enable Enabling counterrotation prevention

Reverse Run protection function

B041 B042 B044 B043

High-torque multi-motor operation

Torque LAD stop function

Personal computer Windows system

Easy sequence function

Functions requiring the SJ-FB

2 V2 control pulse setting

Vector control with encoder feedback

Torque-limited operation at

Operation Torque limiter level

Torque control function

Torque biasing function

255

Pulse train position control mode

Control block diagram

Frequency command Hz =

SBP SBP

MD1 Forward/reverse operation command with pulse train

Electronic gear function

P019 = 00 FB

P019 = 01 REF

Example of use Synchronous operation

Master inverter Slave inverter

Main motor Sub-motor

Motor gear ratio setting function

Setting of the actual pulse

Count of encoder

Home search function

10243072 2048

Absolute position control mode

Operation Output frequency Speed setting POK signal

Operation in absolute position control mode

Speed/position switching function SPD

Multistage position switching function CP1/CP2/CP3

Forward direction at the low-speed

Teaching selection P074

Position range specification function

Forward/reverse drive stop function FOT/ROT

Teaching function

SON Fwrv

Servo-on function

To +100. % Pulse train frequency limit

Block diagram for pulse train frequency input

Setting of the filter time constant for

Pulse train frequency input

Communication Functions

Communication specifications

Selection Modbus-RTU mode

Set this item when your inverter is

Communication mode

Ascii mode

Explanation of Functions

Communication in Ascii mode

STX 0101000500 BCC CR 0230 3130 3130 30 30 35 30 3030 350D

Data to be transmitted

Explanation of Functions

Response frame Frame format

Status a Status B Status C Reserved

Data

Inverter status a Inverter status B Inverter status C

Data Bytes See Note

Bytes Decimal Ascii code Output current

Data monitored at tripping

Inverter status B Bytes

Inverter status C Bytes

Station No

Station No. Command Parameter

Response frame Positive response Frame format

Data parameter number Bytes See Note

Station No. Command Parameter Data

Station No. Command

Parameter data decimal Ascii Bytes See Note Code

Data Bytes Enabling data storage

Explanation of Functions

Ii Negative response Response frame Frame format

Character data Ascii code

Transmission frame configuration Station No. Command

Reference Ascii code conversion table

This result is used as BCC

Communication in Modbus-RTU mode

Writes data to a coil

Function code Maximum number of data

Reads the coil status

Reads registers

CRC*1

Specified address is not found

Slave address Function code Exception code CRC-16

Code Description

An unsupported function is specified

Terminal status

Intelligent input terminal Coil number

Read the data received in the response as follows

Updating data lower digit

Field name Sample setting

Coil status

Updating data upper digit FFh

Intelligent input terminal

Query Response Field name Sample setting

02h Specified address is not found

Slave address Function code Exception code CRC-16 code

Exception codes

01h An unsupported function is specified

Data to be written Description

Recalculating the motor constants

Storing the register data

Coil No Setting

LOG2 logical operation result ON, 0 OFF

Ii List of registers frequency settings and trip monitoring

Register Function name Monitoring and setting items Data

Option 1 error 0 to

Option 2 error 0 to

List of inverter trip factors

Iv List of registers

Iii List of registers monitoring

List of registers function modes

Start frequency to

Monitoring and setting items Data resolution

12B4h

Failure time

Monitoring and setting items Data resolution Register

During inverter operation including 5 minutes after

EXT external trip, 13 USP unattended start

Thermal overload, 07 LAD frequency, 09 motor

C042 high

1487h Output 11 off-delay time C131

1506h

Over-speed error detection level P026 Setting

To the allowable maximum frequency

Code data

Vi List of registers 2nd control settings

2506h Motor

Ix List of registers 3rd control setting

Viii List of registers 3rd control settings

Error Codes and Troubleshooting ···················· 5

Error Codes

Page

Error Codes

Error Codes and Troubleshooting

CPU

GA.COM

Adjust

Option boards error codes

Input mode specified by switch settings

Setting of MAC ID DIP switches No to No

Baud rate Kbps DIP switch setting

= 29 hexadecimal = 41 decimal

Error code is output when the relevant program runs

Trip conditions monitoring

305 A004/A204/A304 A202/A220/A320 *2 006

DC-Bus Capacitor Life Curve

Precautions for Maintenance

Ground Resistance Test with a Megger

Method of Checking the Inverter

Page

Periodic inspection

Precautions for Maintenance and Inspection

Cleaning

Daily inspection

Ground terminals with a megger

Daily and Periodic Inspections

Withstand Voltage Test

Ground Resistance Test with a Megger

Method of Checking the Inverter and Converter Circuits

Output of Life Warning

DC-Bus Capacitor Life Curve

PfIN=

Method to measure the output voltage

Motor 2W 220kΩ

Specifications External dimensions

Specifications

Page

Common specifications of 200 V class and 400 V class models

Specifications

Specifications of the 200 V class model

Specifications of the 400 V class model

Standard

Model name type 055 075 110 150 185 220 300 370 450 550 Name

External dimensions

SJ700-055 to110LFF2/LFUF2 / HFF2/HFEF2/HFUF2

SJ700-150 to 220 LFF2/LFUF2 / HFF2/HFEF2/HFUF2

SJ700-300 LFF2/LFUF2 / HFF2/HFEF2/HFUF2

SJ700-550 LFF2/LFUF2

Monitoring Mode Function Mode Extended Function Mode

List of Data Settings

Page

Precautions for Data Setting

Function Mode

Extended Function Mode

PID

AVR

B004 Failure/under-voltage trip alarm To stop Enable

Power

Free-setting V/f voltage To 800.0

Input

Analog

C107 AMI gain adjustment To 200. %

Setting C163 Input terminal response time To 200. ¯2ms

Control

Control

RPM

Specification

List of Data Settings

Allowed or Not No/d001 to P131

Upgrading from the SJ300 Series

Appendix

Copying the parameter settings

Index

Monitor mode Motor constant

High-resolution absolute position Control 106

Instantaneous power failure

Instantaneous power failure or

Running time over / power-on time Over

Operation time over signal RNT/plug-in time over signal

Phase loss input Phase loss input protection

Remote operator Appendix-1 Reset

Torque biasing

Gain setting VP 1.7 th power

Window comparator Wiring of control circuit terminal

Thermistor