4085-001

Service Checks

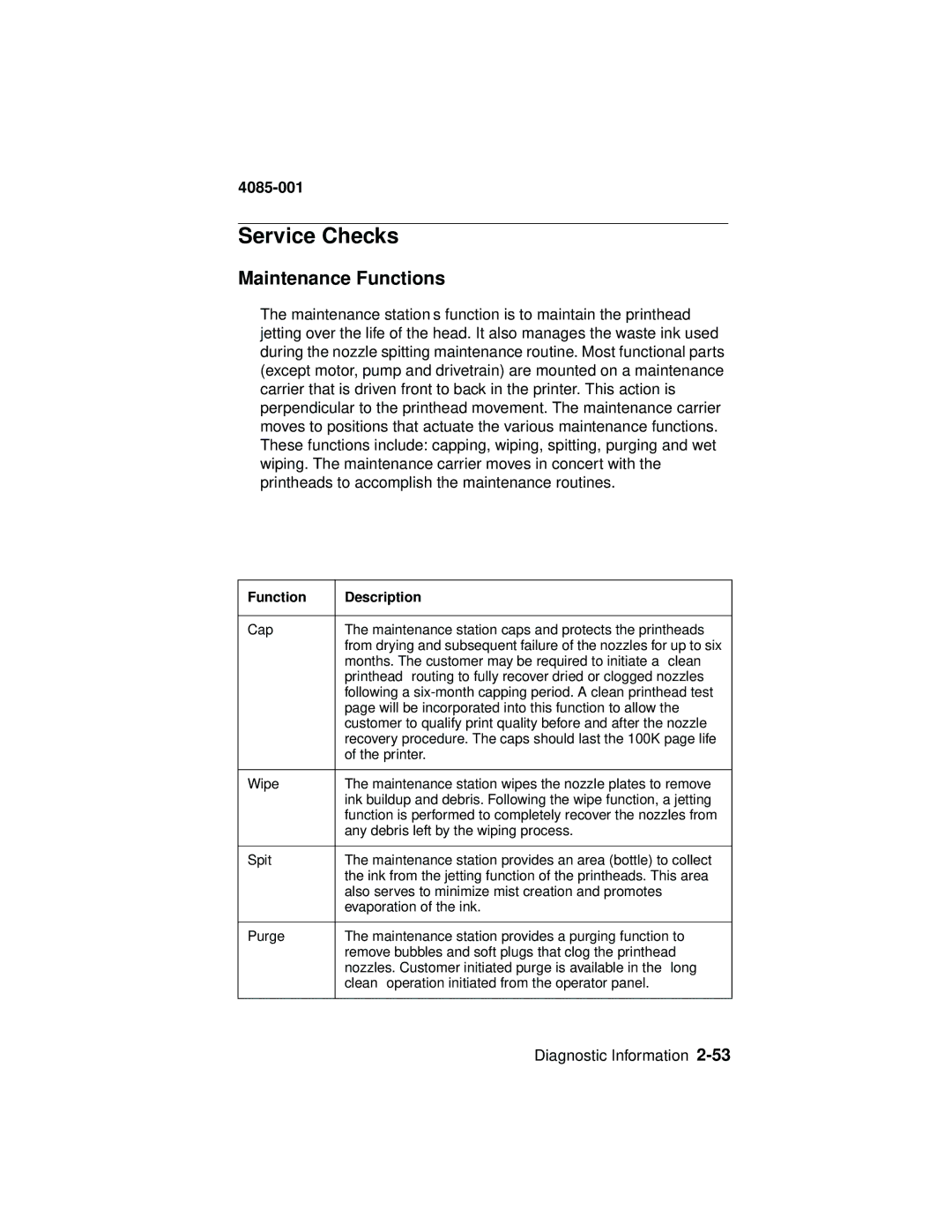

Maintenance Functions

The maintenance station’s function is to maintain the printhead jetting over the life of the head. It also manages the waste ink used during the nozzle spitting maintenance routine. Most functional parts (except motor, pump and drivetrain) are mounted on a maintenance carrier that is driven front to back in the printer. This action is perpendicular to the printhead movement. The maintenance carrier moves to positions that actuate the various maintenance functions. These functions include: capping, wiping, spitting, purging and wet wiping. The maintenance carrier moves in concert with the printheads to accomplish the maintenance routines.

Function | Description |

|

|

Cap | The maintenance station caps and protects the printheads |

| from drying and subsequent failure of the nozzles for up to six |

| months. The customer may be required to initiate a “clean |

| printhead” routing to fully recover dried or clogged nozzles |

| following a |

| page will be incorporated into this function to allow the |

| customer to qualify print quality before and after the nozzle |

| recovery procedure. The caps should last the 100K page life |

| of the printer. |

|

|

Wipe | The maintenance station wipes the nozzle plates to remove |

| ink buildup and debris. Following the wipe function, a jetting |

| function is performed to completely recover the nozzles from |

| any debris left by the wiping process. |

|

|

Spit | The maintenance station provides an area (bottle) to collect |

| the ink from the jetting function of the printheads. This area |

| also serves to minimize mist creation and promotes |

| evaporation of the ink. |

|

|

Purge | The maintenance station provides a purging function to |

| remove bubbles and soft plugs that clog the printhead |

| nozzles. Customer initiated purge is available in the “long |

| clean” operation initiated from the operator panel. |

|

|

Diagnostic Information