4085-001

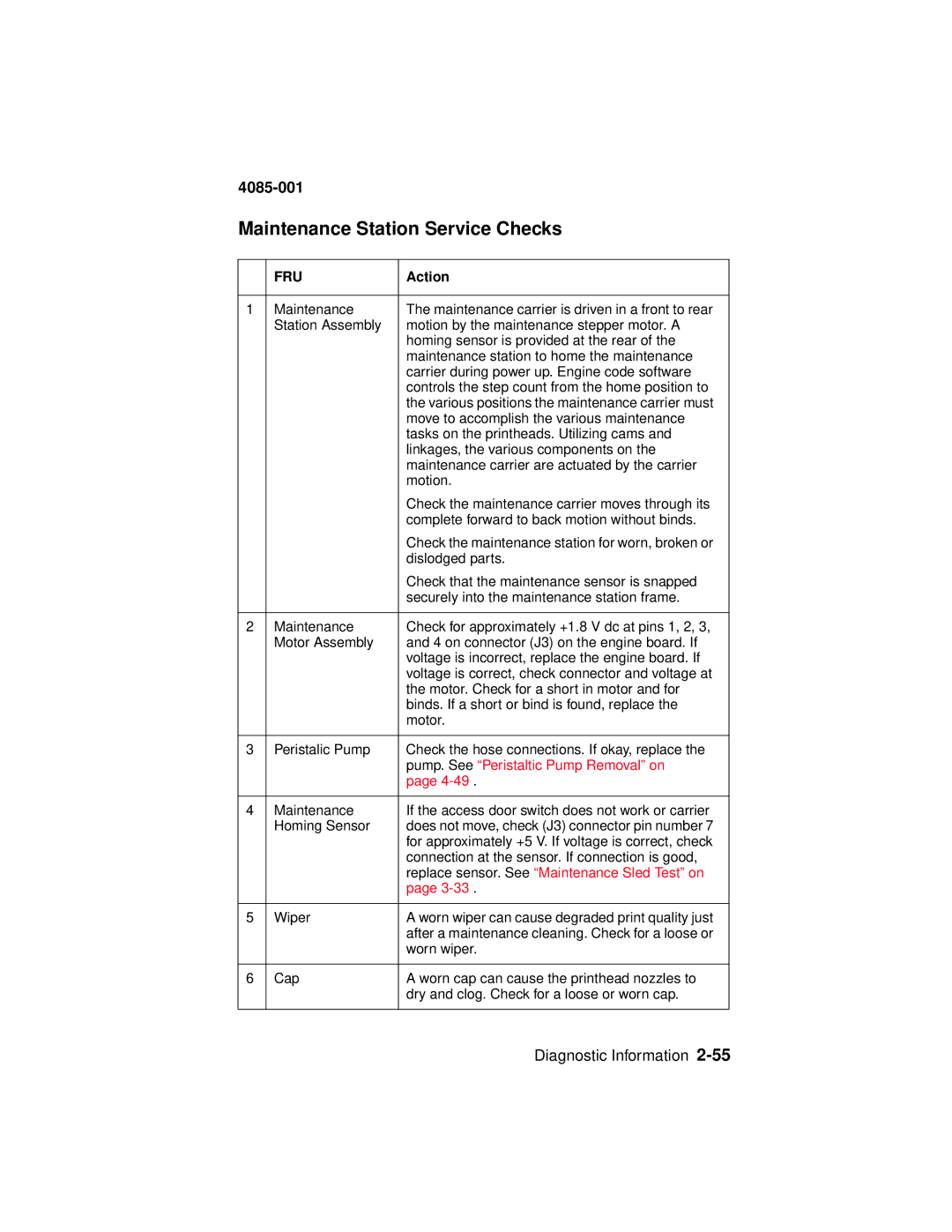

Maintenance Station Service Checks

| FRU | Action |

|

|

|

1 | Maintenance | The maintenance carrier is driven in a front to rear |

| Station Assembly | motion by the maintenance stepper motor. A |

|

| homing sensor is provided at the rear of the |

|

| maintenance station to home the maintenance |

|

| carrier during power up. Engine code software |

|

| controls the step count from the home position to |

|

| the various positions the maintenance carrier must |

|

| move to accomplish the various maintenance |

|

| tasks on the printheads. Utilizing cams and |

|

| linkages, the various components on the |

|

| maintenance carrier are actuated by the carrier |

|

| motion. |

|

| Check the maintenance carrier moves through its |

|

| complete forward to back motion without binds. |

|

| Check the maintenance station for worn, broken or |

|

| dislodged parts. |

|

| Check that the maintenance sensor is snapped |

|

| securely into the maintenance station frame. |

|

|

|

2 | Maintenance | Check for approximately +1.8 V dc at pins 1, 2, 3, |

| Motor Assembly | and 4 on connector (J3) on the engine board. If |

|

| voltage is incorrect, replace the engine board. If |

|

| voltage is correct, check connector and voltage at |

|

| the motor. Check for a short in motor and for |

|

| binds. If a short or bind is found, replace the |

|

| motor. |

|

|

|

3 | Peristalic Pump | Check the hose connections. If okay, replace the |

|

| pump. See “Peristaltic Pump Removal” on |

|

| page |

|

|

|

4 | Maintenance | If the access door switch does not work or carrier |

| Homing Sensor | does not move, check (J3) connector pin number 7 |

|

| for approximately +5 V. If voltage is correct, check |

|

| connection at the sensor. If connection is good, |

|

| replace sensor. See “Maintenance Sled Test” on |

|

| page |

|

|

|

5 | Wiper | A worn wiper can cause degraded print quality just |

|

| after a maintenance cleaning. Check for a loose or |

|

| worn wiper. |

|

|

|

6 | Cap | A worn cap can cause the printhead nozzles to |

|

| dry and clog. Check for a loose or worn cap. |

|

|

|

Diagnostic Information