NS9215 Hardware Reference

90000847C Release date 10 April

Page

Page

Page

Contents

A p t e r 3 W o r k i n g w i t h t h e C P U

102

105

A p t e r 4 S y s t e m C o n t r o l M o d u l e 137

141

A p t e r 5 M e m o r y C o n t r o l l e r 203

Sram

Bit wide configuration 228 229

Hardware Reference NS9215

HT1

315

A p t e r 7 E x t e r n a l D M a 339

Hardware Reference NS9215

A p t e r 9 I / O H u b M o d u l e 363

Hardware Reference NS9215

A p t e r 1 1 S e r i a l C o n t r o l D u l e H D L C 415

Hardware Reference NS9215

A p t e r 1 4 R e a l T i m e C l o c k M o d u l e 459

A p t e r 1 6 T i m i n g 479

A p t e r 1 7 P a c k a g i n g 513

Hardware Reference NS9215

Pinout

Heading Description

Pin Signal Description

M o r y b u s i n t e r f a c e

N O U T 2 6

Pin Signal

H e r n e t i n t e r f a c e M a C

Sdram RAS

Sdram CAS

N e r a l p u r p o s e I / O G P I O

DCD Uart a

CTS Uart a

DSR Uart a

RXD Uart a

DCD / TXC Uart C

CTS Uart C

I2C SCL

Picdbgdataini

DCD Uart B

CTS Uart B

DSR Uart B

RXD Uart B

DSR Uart D

RXD Uart D

RI Uart D

TXC / DTR Uart D

Pin Signal Description

PIC1CLKI

PIC1CLKO

Pin Signal Description

PIC0CLKI

PIC0CLKO

Pin Signal Description

Pin Signal Description

Pin Signal Description

S t e m c l o c k

I/O OD

System clock drawing

RTC clock and battery backup drawing

S t e m m o d e

Sysmode2 Sysmode1 Sysmode0 Description

S t e m r e s e t

SPI YES

A G T e s t

Adcvss

R a n d b a t t e r y b a c k e d l o g i c

POR VSS

W e r a n d g r o u n d

GND

Power and ground

Address Description Access Reset value

N t r o l a n d S t a t u s r e g i s t e r s

System memory bus I/O control

Register address Map

Control and Status registers

I O C o n f i g u r a t i o n r e g i s t e r s

Gpio configuration options

Bits Mnemonic Description

Configuration Register #0

Configuration Register #1

Bits Access Mnemonic Reset Description

Address A0902000

Configuration Register #2

Configuration Register #3

Address A0902008

Address A090200C

Configuration Register #4

Configuration Register #5

Address A0902010

Address A0902014

Configuration Register #6

Configuration Register #7

Address A0902018

Address A090201C

Configuration Register #8

Configuration Register #9

Address A0902020

Address A0902024

Configuration Register #10

Configuration Register #11

Address A0902028

Address A090202C

Configuration Register #12

Configuration Register #13

Address A0902030

Address A0902034

Configuration Register #14

Configuration Register #15

Address A0902038

Address A090203C

Configuration Register #16

Configuration Register #17

Address A0902040

Address A0902044

Configuration Register #18

Configuration Register #19

Address A0902048

Address A090204C

Configuration Register #20

Configuration Register #21

Address A0902050

Address A0902054

Configuration Register #22

Configuration Register #23

Address A0902058

Address A090205C

Configuration Register #24

Configuration Register #25

Address A0902060

GPIOAddress A0902064

Configuration Register #26

Address A0902068

Gpio Control

I O C o n t r o l r e g i s t e r s

Address A090206C

Address A0902070

Address A0902074

Address A0902078

Gpio Status

I O S t a t u s r e g i s t e r s

Address A0902080

Address A0902084

Address A0902088

M o r y B u s C o n f i g u r a t i o n r e g i s t e r

Address A090208C

CS0

CS1

CS2

CS3

High data bus pullup control

Apudis

Memory Bus Configuration register

Working with the CPU

About the processor

Process block Diagram

S t r u c t i o n s e t s

Arm926EJ-S

ARM instruction set Thumb instruction set

Java instruction set

Accessing CP15 registers

ARM926EJ-S system addresses Address manipulation example

Terms and abbreviations

Mnemonics for these instructions are

Term Abbreviation Description

For reads

Be ZERO, does not cause any physical damage to the chip

Register summary

Register Reads Writes

TLB

This is the contents of the ID code register

Writing to register R0 is Unpredictable

R0 ID code

Any value other than 1 or 2. Note this example

Cache type register and field description

Dsize and Isize fields

Field contains these bits

Field Description

O n t r o l r e g i s t e r

Size field Cache size

Assoc field Associativity

Len field Cache line length

Bit functionality

Control register

Bits Name Function

ICache

DCache behavior

Cache

Behavior

CRm and opcode2 fields should be Zero when writing to R2

Access permissions and instructions

R a n s l a t i o n T a b l e B a s e r e g i s t e r

O m a i n a c c e s s C o n t r o l r e g i s t e r

Fault S t a t u s r e g i s t e r s

Access instructions

E g i s t e r

Register bits

Status and domain fields

Fault a d d r e s s r e g i s t e r

Priority Source Size Status Domain

A c h e O p e r a t i o n s r e g i s t e r

Function Description

Function/operation Data format Instruction

Cache operation functions

MVA

Set/Way example Test and clean DCache instructions

Modified virtual address format MVA Set/Way format

Test, clean, and invalidate DCache instruction

L B O p e r a t i o n s r e g i s t e r

Unpredictable

Operation Data Instruction

A c h e L o c k d o w n r e g i s t e r

Modified virtual address format MVA

Cache ways

That allows you to control each cache way independently

Access

Instruction or data lockdown register

Instructions

Modifying the Cache Lockdown register Register format

For each of the cache lines to be locked down in cache way

Cache unlock procedure

0 T L B L o c k d o w n r e g i s t e r

Bit

Which region the TLB entry is placed

1 a n d R 1 2 r e g i s t e r s

3 P r o c e s s I D r e g i s t e r

Programming instructions Sample code sequence

Use these instructions to program the TLB Lockdown register

Fcse PID register Access instructions

Performing a fast context switch

Register format This is the format of the Fcse PID register

Function Data ARM instruction

Context ID register Access instructions

Accessing reading or writing this register is reserved

4 r e g i s t e r

5 T e s t a n d d e b u g r e g i s t e r

MMU Features

M o r y M a n a g e m e n t U n i t M M U

State space servo control

Protection scheme

Access permissions and domains Translated entries

MMU program accessible registers Address translation

Register Bits Description

Translation table base

TTB register Format

Table walk process

First-level fetch

First-level descriptor

First-level fetch concatenation and address

Table descriptors

Bits Section Coarse Fine Description

Section descriptor Format

Value Meaning Description

Section descriptor Bit description

Fine page table

Descriptor

Bits Description

113

Second-level descriptor Second-level descriptor format

Second-level descriptor pages

Second-level descriptor least significant bits

Second-level descriptor bit assignments

Bits Large Small Tiny Description

Translation sequence for large page references

Translating sequence for small page references

Translation Sequence for tiny

References

Level descriptor

More information

U Fault s a n d C P U a b o r t s

Priority encoding table Fault Address register FAR

Domain Fault Address register

FAR values for Multi-word

Transfers

Compatibility issues

Specifying access permissions

Interpreting access permission bits

M a i n a c c e s s c o n t r o l

Fault c h e c k i n g s e q u e n c e

Privileged permissions User permissions

No access 00 Reserved Check domain status

Fault checking sequence

A b l i n g a n d d i s a b l i n g t h e M M U

T e r n a l a b o r t s

Enabling

B s t r u c t u r e

Disabling

Cache features

C h e s a n d w r i t e b u f f e r

Write buffer Enabling the caches

Bit settings

Settings

R1 register C and M bits for DCache

DCache

C h e M V a a n d S e t / W a y f o r m a t s

Description ARM926EJ-S behavior Table C Table B Bit

Generic, virtually indexed, virtually addressed cache

ARM926EJ-S

Cache format

N c a c h a b l e i n s t r u c t i o n f e t c h e s

This figure

For example, with a 4-way cache a =

Self-modifying code

AHB behavior Instruction Memory Barrier

Sample IMB sequences

Noncachable instruction fetches

Features

S i n t e r c o n n e c t i o n

S t e m b u s a r b i t e r

Ownership

Until the transaction completes

Master will not occupy the system bus

Locked bus sequence Relinquishing the bus

Split transfers Arbiter configuration example

D r e s s d e c o d i n g

Address range Size System functions

O g r a m m a b l e t i m e r s

Software watchdog timer

Master Name Hmaster30 assignment

N e r a l p u r p o s e t i m e r s / c o u n t e r s

Gptc characteristics Control field

Source clock frequency

Bit mode options

S i c P W M f u n c t i o n

A d r a t u r e d e code r f u n c t i o n

H a n c e d P W M f u n c t i o n

Sample enhanced PWM waveform

Input signals

NC No change CW Clockwise CCW Counter clockwise Err Error

Quadrature Encoding truth

CCW

Testing signals

Timer support

Monitors how far the encoder has moved Typical application

Digital filter

T e r r u p t c o n t r o l l e r

FIQ interrupts

IRQ interrupts

Vector

IRQ characteristics Interrupt sources

IRQ FIQ

Interrupt sources are assigned as shown

Interrupt ID Interrupt source

N f i g u r a b l e s y s t e m a t t r i b u t e s

L c o n f i g u r a t i o n

Configuring the powerup settings

PLL configuration and control system block diagram

O t s t r a p i n i t i a l i z a t i o n

Pin name Configuration bits

S t e m c o n f i g u r a t i o n r e g i s t e r s

Offset 3124 2316 158

155

Isaddr

System Memory Chip Select 0 Dynamic Memory Mask

N e r a l a r b i t e r C o n t r o l r e g i s t e r

C 0 , B R C 1 , B R C 2 , a n d B R C 3 r e g i s t e r s

Address A090

Register

B Error D e t e c t S t a t u s

Channel enable bit

Channel allocation Register Register bit assignment

This is how the channels are assigned in the four registers

Address A090 001C

EDS1

Not reset CPU instruction error

Not reset CPU data error

Not reset AHB error response

Transaction type write or read

AHB Error Interrupt Clear

AHB Slave Error Response Detect Config

M e r M a s t e r C o n t r o l r e g i s t e r

EIC

Timer 9 reload step enable

Timer 9 low step enable

Timer 9 high step enable

Timer 8 reload step enable

M e r 0 4 C o n t r o l r e g i s t e r s

Addresses A090 0190 / 0194 / 0198 / 019C / 01A0

Timer enable

Capture and compare mode functions

Debug mode

Timer clock select

M e r 5 C o n t r o l r e g i s t e r

Address A090 01A4

Reload mode

TM2

M e r 6 9 C o n t r o l r e g i s t e r s

Addresses A090 01A8 / 01AC / 01B0 / 01B4

D3118 Reserved D1716

M e r 6 9 H i g h r e g i s t e r s

M e r 6 9 L o w r e g i s t e r s

M e r 6 9 H i g h a n d L o w S t e p r e g i s t e r s

M e r 6 9 R e l o a d S t e p r e g i s t e r s

High step direction

High step

Reload step direction

Reload step

M e r 0 9 R e a d a n d C a p t u r e r e g i s t e r

Interrupt Vector Address register

Individual register mapping

Register 3124 2316 1508 0700

Interrupt enable

A D D R r e g i s t e r

Invert

Interrupt type

Interrupt service routine address

T e r r u p t S t a t u s a c t i v e

Interrupt status active

ISA

T e r r u p t S t a t u s R a w

F t w a r e W a t c h d o g C o n f i g u r a t i o n

Address A090 016C

Israw

Software watchdog enable

Software watchdog timer clock select

F t w a r e W a t c h d o g T i m e r

Software watchdog interrupt clear

O c k C o n f i g u r a t i o n r e g i s t e r

Watchdog timer

Address A090 017C

Clock scale control

Max clock scale control

CPU clock select

Memory clock out

IO hub

D u l e R e s e t r e g i s t e r

Ethernet MAC

Module Reset register resets each module on the AHB bus

Reset status

RST Stat

I2C

Miscellaneous System Configuration and Status register

Boot mode

Endian mode

Misaligned bus address response mode

Internal register access mode bit

PLL frequency formula Register Register bit assignment

L C o n f i g u r a t i o n r e g i s t e r

PLL bypass

W e r M a n a g e m e n t

Address A090 018C

Intid

Interrupt ID

Deprecated Chip sleep enable

New designs should not use this bit

Hardware clock scale control

Sdram self refresh control

CPU wake interrupt clear

RTC wakeup

I2C wakeup

SPI wakeup

Address A090 022C

B B u s a c t i v i t y S t a t u s

Addresses A090 01D0 / 01D4

Chip select 0 disable

Registers

Addresses A090 01D8 / 01DC

Chip select 0 base

Addresses A090 01E0 / 01E4

Chip select 1disable

Chip select 1 base

Addresses A090 01E8 / 01EC

Chip select 2 disable

Chip select 2 base

Addresses A090 01F0 / 01F4

Chip select 3 disable

Chip select 3 base

Addresses A09001F8 / 01FC

Chip select 0 mask

Chip select 1 disable

Addresses A090 0200

Addresses A090 0208 / 020C

N I D r e g i s t e r

Genid

STS

Status

CLR

RTC standby mode status

C M o d u l e C o n t r o l r e g i s t e r

RTC Module Control register controls the RTC module

Polarity

RTC standby mode

RTC clock ready interrupt status

RTC module interrupt status

RTC clock ready interrupt clear

RTC Module Control register

Memory controller provides these features

With and without asynchronous page mode

Static memory features, such as

Amba 32-bit AHB compliancy

W p o w e r o p e r a t i o n

Power-on reset memory map

M o r y m a p

Example Boot from flash Sdram remapped after boot

Device Write protect Mode Buffer

A t i c m e m o r y c o n t r o l l e r

ROM

Sram

Write protection Extended wait transfers

Be aware

A t i c m e m o r y i n i t i a l i z a t i o n

Access sequencing and memory width Wait state generation

Memory mapped peripherals

Programmable enable

Output enable programmable delay

A t i c m e m o r y r e a d c o n t r o l

ROM, SRAM, and Flash

External memory read transfer with zero wait states

External memory read transfer with two wait states

Timing parameter Value

WAITRD2 WAITOEN0 WAITPAGEN/A WAITWRN/A

External memory read transfers with zero wait states

WAITENN/A WAITTURNN/A

Burst of zero wait states with fixed length

Burst of two wait states with fixed length

External memory page mode read transfer

Y n c h r o n o u s p a g e m o d e r e a d

External memory 32-bit burst read from 8-bit memory

WAITRD2 WAITOEN0 WAITPAGE1 WAITWRN/A WAITWENN/A WAITTURNN/A

Timing parameters Value

WAITRD0 WAITOEN0 WAITPAGE0 WAITWRN/A WAITWENN/A WAITTURNN/A

Write enable programming delay

A t i c m e m o r y w r i t e c o n t r o l

Wait states added between external read and write transfers

External memory write transfer with zero wait states

External memory write transfer with two wait states

WAITRDN/A WAITOENN/A WAITPAGEN/A WAITWR0 WAITWEN0 WAITTURN0

S t u r n a r o u n d

S t u r n a r o u n d T i m i n g a n d p a r a m e t e r s

Read followed by write with no turnaround

WAITRD0 WAITOEN0 WAITPAGEN/A WAITWR0 WAITWEN0 WAITTURN0

Write followed by a read with no turnaround

Read followed by a write with two turnaround cycles

T e l a n e c o n t r o l

WAITRD0 WAITOEN0 WAITPAGEN/A WAITWR0 WAITWEN0 WAITTURN2

D r e s s c o n n e c t i v i t y

Memory banks constructed from 16-or 32-bit memory devices

Memory banks constructed from 16-bit memory

2Mx32 ROM

N a m i c m e m o r y c o n t r o l l e r

Access sequencing and memory width

R a M I n i t i a l i z a t i o n

Left-shift value -bit wide data bus Sdram RBC

Device size Configuration Load Mode register left shift

Bit Parameter Parameter description

256M 8M x 16M x 32M x 512M 64M x

Bit wide Configuration

Signal 16M device 64M device 128M 256M 512M

Device Signal

Left-shift value -bit wide data bus Sdram BRC

BA0

BA1

G i s t e r s

Register map

Only. Bursting is not allowed

Address Register Description

TRWL, tRDL

N t r o l r e g i s t e r

Reset values

Address A070

Bits Access Mnemonic Description

Low-power mode

Memory controller enable

Address mirror

A t u s r e g i s t e r

N f i g u r a t i o n r e g i s t e r

Self-refresh acknowledge Srefack

Write buffer status

N a m i c M e m o r y C o n t r o l r e g i s t e r

END

Sync/Flash reset/power down signal dypwrn

Dynamic memory clock enable

Sdram initialization

Self-refresh request Srefreq

Refresh timer

Refresh

Read data strategy

Active to precharge command period tRAS

Precharge command period tRP

RAS

Srex

Address A070 003C

Self-refresh exit time tSREX

Last-data-out to active command time tAPR

APR

Data-in to active command tDAL or tAPW

DAL

Active to active command period tRC

Address A070 004C

RFC

Auto-refresh period and auto-refresh to active command

Period

Exit self-refresh to active time command

XSR

Load mode register to Active Command Time

RRD

Active Bank a to Active Bank B

MRD

External wait timeout

A t i c M e m o r y E x t e n d e d W a i t r e g i s t e r

Example

Address A070 0100 / 0120 / 0140

Write protect

Bdmc

Address mapping

AM1

Memory Configuration

Address mapping

For the Dynamic

119 Description

Address A070 0104 / 0124 / 0144

For a chip select connected to Select this mapping

RAS latency active to read/write delay

CAS

CAS latency

Do not modify

Buffer enable

Psmc

Bsmc

Extended wait

Chip select polarity

Byte lane state

Mode

Bmode

Burst mode

Memory width

Wait write enable Waitwen

Wait output enable Waitoen

Address A070 0208 / 0228 / 0248

Wwen

Nonpage mode read wait states or asynchronous page mode

Read first access wait state Waitrd

A t i c M e m o r y R e a d D e l a y 0 3 r e g i s t e r s

Wtrd

Asynchronous page mode read after the first wait state

Wtpg

Wtwr

Address A070 0218 / 0238 / 0258

Write wait states Waitwr

Wttn

Bus turnaround cycles Waitturn

StaticMemory Turn Round Delay 0-3 registers

Features Common acronyms

Ethernet Communication Module

H e r n e t M a C

Ethernet communications module

MAC module block diagram Features

Feature Description

A t i o n a d d r e s s l o g i c S a L

PHY interface mappings

Station address logic

Media Independent Interface

A t i s t i c s m o d u l e

MAC receiver

Ethernet front- end module EFE

H e r n e t f r o n t e n d m o d u l e

Receive packet processor

C e i v e p a c k e t p r o c e s s o r

Transmit packet processor

Receive buffer descriptor format

Transferring a frame to system memory

Receive buffer descriptor format description

A n s m i t p a c k e t p r o c e s s o r

Receive buffer descriptor field definitions

Transmit buffer Descriptor field

Transmit buffer descriptor format

Definitions

Transmitting a frame

Frame

Transmitted

Successfully

Unsuccessfully

T e r r u p t s

H e r n e t s l a v e i n t e r f a c e

Interrupt condition Description

S e t s

Bit field Register Active Default Modules reset State

Status bits

L t i c a s t a d d r e s s f i l t e r i n g

Filter entries

Multicast address Filter registers

Multicast address filtering example

O c k s y n c h r o n i z a t i o n

Multicast address

Filtering example

Writing to other registers

Register address Filter

Rxdptr

Eintr

Eintren

Txptr

H e r n e t G e n e r a l C o n t r o l R e g i s t e r #

Address A060

Enable RX packet processing

Enable receive DMA

Enable TX packet processing

Accept short 64 receive frames

Enable transmit DMA

Enable initialization of RX buffer descriptors

Etxdma

Erxinit

MAC host interface soft reset

RX Fifo RAM access

Align RX data

Insert transmit source address

H e r n e t G e n e r a l S t a t u s r e g i s t e r

Rxinit

H e r n e t T r a n s m i t S t a t u s r e g i s t e r

RX initialization complete

Frame transmitted OK

Broadcast frame transmitted

Multicast frame transmitted

TX abort late collision

H e r n e t R e c e i v e S t a t u s r e g i s t e r

Address A060 001C

Receive frame size in bytes

Receive frame OK

Receive broadcast frame

Receive multicast frame

C C o n f i g u r a t i o n R e g i s t e r #

Receive enable

Bits Access Mnemonic Reset Definition

Internal loopback

Excess deferral

Auto detect pad enable

Vlan pad enable

Pad/CRC enable

CRC enable

C k t o B a c k I n t e r P a c k e t G a p r e g i s t e r

PAD operation Table for transmit

Frames

Type

Full-duplex mode

Half-duplex mode

Address A060 040C

Back-to-back inter-packet-gap

L l i s i o n W i n d o w / R e t r y r e g i s t e r

Address A060

IPGR1

Non back-to-back inter-packet-gap part

X i m u m F r a m e r e g i s t e r

Cwin

Collision window

Retx

Maximum frame length

Reset MII management block

Rmiim

Clocks field Settings

I M a n a g e m e n t C o m m a n d r e g i s t e r

Clock select

Suppress preamble

I M a n a g e m e n t a d d r e s s r e g i s t e r

Register bit

If both Scan and Read are set, Scan takes precedence

Automatically scan for read data

I M a n a g e m e n t R e a d D a t a r e g i s t e r

I M a n a g e m e n t W r i t e D a t a r e g i s t e r

Address A060 042C

I M a n a g e m e n t I n d i c a t o r s r e g i s t e r

MII read data

Miilf

MII link failure

A t i o n a d d r e s s r e g i s t e r s

Read data not valid

Nvalid

Automatically scan for read data in progress

A t i o n a d d r e s s F i l t e r r e g i s t e r

Register bit assignments for all three registers

Station Address Register #1

Station Address Register #2

G i s t e r H a s h T a b l e s

PRO

PRM

PRA

Address Register Transmit and receive counters

A t i s t i c s r e g i s t e r s

TR1K

Receive statistics Counters address

Receive byte counter A060 069C

Receive packet counter A060 06A0

Address Register Receive counters

Receive FCS error counter A060 06A4

Receive multicast packet counter A060 06A8

Receive broadcast packet counter A060 06AC

Rbuo

Receive alignment error counter A060 06BC

Receive code error counter A060 06C4

Receive carrier sense error counter A060 06C8

Receive undersize packet counter A060 06CC

Receive jabber counter A060 06D8

Transmit statistics counters address map

Transmit byte counter A060 06E0

Address Register Transmit counters

Transmit packet counter A060 06E4

Transmit excessive collision packet counter A060

Transmit oversize frame counter A060

Transmit undersize frame counter A060

These are the General Statistics registers

Carry Register

C1MAX

C1MGV

C1RBY

C1RPK

Mask register

M1MGV

M1RBY

M1RPK

M1RFC

Address A060 073C

Mask register Register

0x00000000 RXA Buffer Descriptor Pointer

Address A060 0A04

RXB Buffer Descriptor Pointer

Address A060 0A08

Address A060 0A0C

RXC Buffer Descriptor Pointer

RXD Buffer Descriptor Pointer

H e r n e t I n t e r r u p t S t a t u s r e g i s t e r

Address A060 0A10

Rxovflstat

Rxbufc

Rxdoneb

Rxdonec

Rxdoned

Rxnobuf

H e r n e t I n t e r r u p t E n a b l e r e g i s t e r

Address A060 0A14

Address A060 0A18

Address A060 0A1C

Address A060 0A20

Address A060 0A24

Address A060 0A28

Address A060 0A2C

Address A060 0A30

Address A060 0A34

Address A060 0A38

F r e e B u f f e r r e g i s t e r

Address A060 0A3C

Rxfreed

Rxfreec

L t i c a s t a d d r e s s F i l t e r r e g i s t e r s

Address A060 0A58

Address A060 0A5C

Address A060 0A60

Address A060 0A64

L t i c a s t a d d r e s s M a s k r e g i s t e r s

Address A060 0A90

Address A060 0A94

Address A060 0A98

Address A060 0A9C

Address A060 0AB4

Address A060 0AB8

Address A060 0ABC

Address A060 0AC0

B u f f e r D e s c r i p t o r R a M

Offset+0

Offset+4

Offset+8

Offset+C

Address A060 2000 512 locations

M p l e h a s h t a b l e code

Pointer to buffer to store hash table

Pointer to hash table

337

Sample hash table code

External DMA

A t r a n s f e r s

DMA buffer descriptor diagram

A b u f f e r d e s c r i p t o r

Source address pointer Buffer length

Destination

S c r i p t o r l i s t p r o c e s s i n g

Use this equation to compute total access time

R i p h e r a l D M a r e a d a c c e s s

Determining the width of Pden Equation variables

Variable Definition

Peripheral DMA burst read access

Peripheral DMA single read access

R i p h e r a l D M a w r i t e a c c e s s

Peripheral DMA burst write access

REQ signal

REQ signal

Logic remains paused until the REQ signal is reasserted

Done signal Special circumstances

Static ram chip select configuration

A t i c R a M c h i p s e l e c t c o n f i g u r a t i o n

Register name Field Value Comment

A B u f f e r D e s c r i p t o r P o i n t e r

A C o n t r o l r e g i s t e r

Channel enable

Channel go

Source width

Destination width

Destination burst

Fly-by mode

Source address increment

State

Reset

Index

Error completion interrupt pending

Normal completion interrupt pending

Buffer not ready interrupt pending

Channel abort interrupt pending

A P e r i p h e r a l C h i p S e l e c t r e g i s t e r

SEL

Chip select

DMA Peripheral Chip Select register

AES

Processes 32 bits at a time

Is programmable for 128-, 192-, or 256-bit key lengths

Supports ECB, CBC, OFB, CTR, and CCM cipher modes

Block diagram

Key size Characteristic 128 192 256

S D M a b u f f e r d e s c r i p t o r

Data blocks

AES buffer descriptor diagram

Source address pointer

Source buffer length

Destination buffer length

AES op code

Interrupt I bit Last L bit Full F bit

C r y p t i o n

B p r o c e s s i n g

C , C F B , O F B , a n d C T R p r o c e s s i n g

CCM mode does not require an initialization vector

M m o d e

Nonce buffer

Contents

Bits

CCM mode

Hub Module

A c o n t r o l l e r

AHB slave

Interface

Servicing RX and FIFOs

Source address pointer Buffer length Control15 W

Control14

Control13 L

Control12 F

Control110

Status150

A n s m i t D M a e x a m p l e

Not applicable

Process

Pointer and Index

Visual example

System Memory

Reserved

Uart a register Address map

Uart B register Address map

Register Offset Description

Uart C register Address map

Uart D register Address map

SPI register Address map

AD register Address map

Reserved

I2C register Address map

IO Hardware Assist register

RTC register Address map

IO register Address map

Error completion interrupt pending RX

Normal completion interrupt pending RX

Buffer not ready interrupt pending RX

Channel abort interrupt pending RX

RX Fifo service request interrupt pending

Error completion interrupt pending TX

TX Fifo service request interrupt pending

RX Fifo overflow interrupt pending

D u l e D M a R X C o n t r o l

Flex I/O

Channel abort

Direct

Rxthrs

Rxbdp

RX Fifo threshold

D u l e D i r e c t M o d e R X S t a t u s F I F O

D u l e D i r e c t M o d e R X D a t a F I F O

Full flag

D u l e D M a T X C o n t r o l

Indexen

Txbdp

D u l e D i r e c t M o d e T X D a t a F I F O

TX Fifo threshold

TXD

D u l e D i r e c t M o d e T X D a t a L a s t F I F O

Txdl

384

Modem control signal support

Receive error conditions

Character gap timeout

DMA transfers to and from system memory

Example configuration

R m a l m o d e o p e r a t i o n

Uart module structure

Control register Field Value Comment

U d r a t e g e n e r a t o r

Baud rates

This table shows the baud rates achieved with CLKref set to

Divisor Baud rate

R d w a r e b a s e d f l o w c o n t r o l

R c e d c h a r a c t e r t r a n s m i s s i o n

Force character transmission procedure Collecting feedback

M w a k e u p o n c h a r a c t e r r e c o g n i t i o n

A p p e r C o n t r o l a n d S t a t u s r e g i s t e r s

Address Register

DLAB=0

DLAB=1

A p p e r C o n f i g u r a t i o n r e g i s t e r

Rtsen

RTS

Dtren

Software

Receive character-based flow control

Remote loopback

RTS control

Enable force complete

T e r r u p t E n a b l e r e g i s t e r

RS485 transceiver deassertion control

RS485 transceiver assertion control

Enable overflow error

Enable parity error

Enable frame error

Enable line break

T e r r u p t S t a t u s r e g i s t e r

Parity error

Frame error

Uart interrupt

Force complete

Ring indicator

Character match3

Character match2

Character match1

Enable receive character gap timer

Transmit idle

Receive idle

Write this field to

Enable transmit bit rate generation

C e i v e B u f f e r G a P C o n t r o l r e g i s t e r

Mask

Enable character match

Data

Flow control enable

Flowstate

Flow control state

FLOW4

FLOW2

Force transmit enable

M W a k e u p C o n t r o l r e g i s t e r

Read-only busy

Char

Enable

A n s m i t B y t e C o u n t

Address 90011034 / 90019034 / 90021034

Txcount

R T T r a n s m i t B u f f e r

R T R e c e i v e B u f f e r

Rbuff

R T B a u d R a t e D i v i s o r L S B

R T B a u d R a t e D i v i s o r M S B

Tbuff

Brdl

Enables modem status interrupt

R T I n t e r r u p t E n a b l e r e g i s t e r

Brdm

Edssi

Enables receive line status interrupt

Enables transmit holding register empty interrupt

Enables receive data available interrupt

Interrupt identification

Enable the TX and RX Fifo

R T F I F O C o n t r o l r e g i s t e r

R T L i n e C o n t r o l r e g i s t e r

Clear all bytes in the TX Fifo

Divisor latch access bit

Parity enable

Set break, if set TX data is set to

Stick parity, operates as follows

Local loopback enable bit

R T M o d e m C o n t r o l r e g i s t e r

R T L i n e S t a t u s r e g i s t e r

Automatic flow control

R T M o d e m S t a t u s r e g i s t e r

Delta DCD indicator

Trailing edge of RI indicator

Delta DSR indicator

Delta CTS indicator

Uart Modem Status register

C e i v e a n d t r a n s m i t o p e r a t i o n s

Hdlc module structure

O c k i n g

T s

Transmit operation

Transmitter underflow

T a e n c o d i n g

Last byte bit Pattern table

Encoding examples

Last byte bit pattern Valid data

Transitions

Dpll operation Adjustment ranges and output clocks

NRZ and Nrzi encoding Biphase-Level encoding

CLK

Address

Received or a buffer close event occurs, such as end

Enable Hdlc interrupt

Enable invalid CRC

Enable valid CRC

Local loopback

Enable receive abort error

Rabort

Receive abort error

Hdlc interrupt

Invalid CRC

Valid CRC

L C D a t a R e g i s t e r

Hdata

Hdata

Hmode

L C C o n t r o l R e g i s t e r

Clock source

L C C l o c k D i v i d e r L o w

Address 9002911C

L C C l o c k D i v i d e r H i g h

Divl

Clock enable

Divh

Four-wire interface RXD, TXD, CLK, CS

Programmable SPI mode 0, 1, 2, or

Master mode internal diagnostic loopback

Interface SPI module

I c o n t r o l l e r

SPI module structure

Timing modes Clocking mode diagrams

SPI mode SPI CLK Idle

I c l o c k i n g m o d e s

Capture edge Drive edge

SPI master mode SPI slave mode

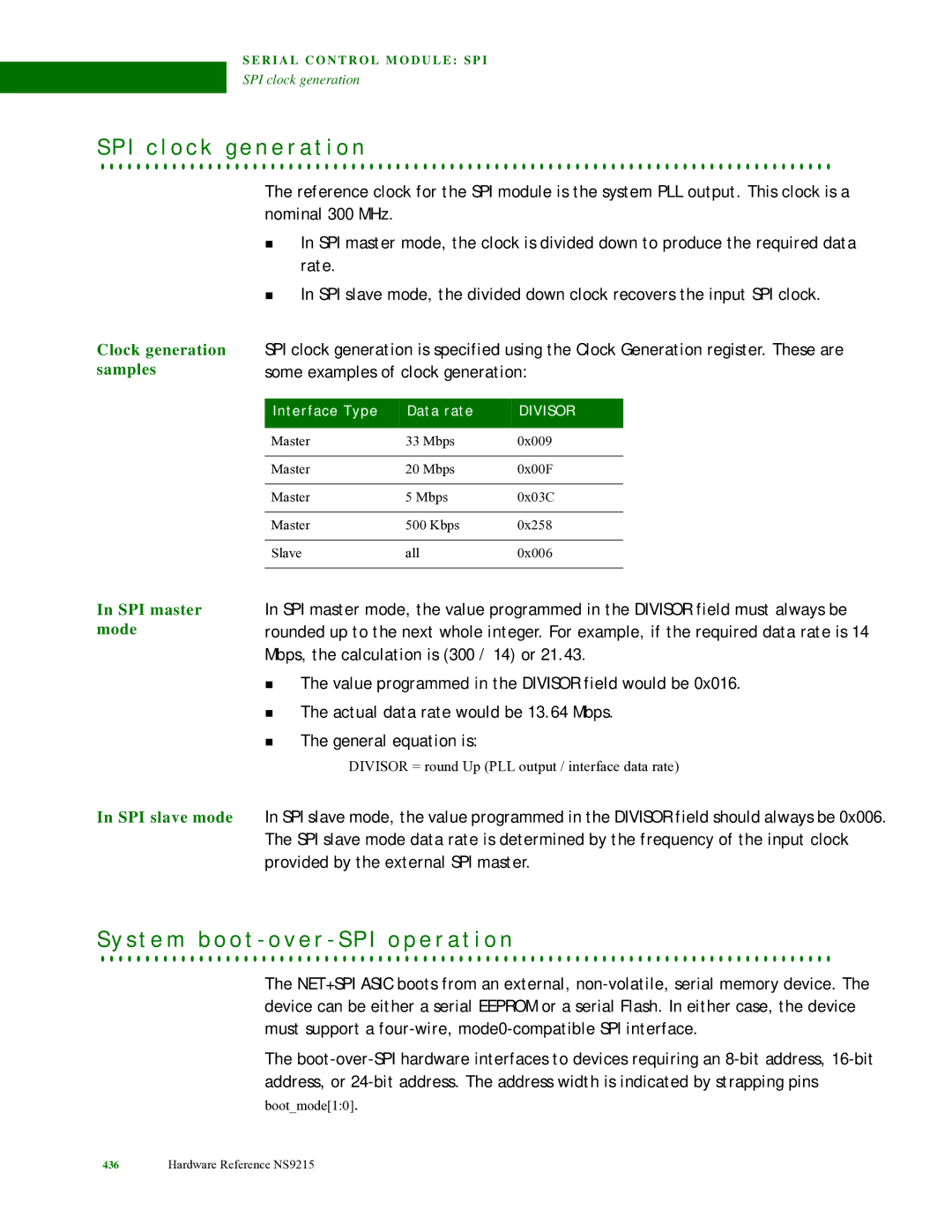

I c l o c k g e n e r a t i o n

S t e m b o o t o v e r S P I o p e r a t i o n

Clock generation samples

Bootmode10 Address width

Available Strapping options

EEPROM/FLASH header

Entry Name

Time to completion

Entry Name Description

Configuration registers for the SPI module are located at

This is the primary SPI Configuration register

Enable master loopback mode

I C o n t r o l a n d S t a t u s r e g i s t e r s

SPI mode

Slave enable

O c k G e n e r a t i o n r e g i s t e r

Discard bytes

Bits Access Mnemonic Reset Divisor

Enable clock generation

Register programming steps

Use this register to define the data rate of the interface

D3102 Not used Write this field to D01

SPI master timing Parameters

I t i m i n g c h a r a c t e r i s t i c s

Parm Description Min Max Unit

SPI master timing diagram SPI slave timing parameters

SPI slave timing diagram

SPI timing characteristics

Interface timing, data structure, and error handling

Y s i c a l I 2 C b u s

I2C bus

Overview

E x t e r n a l a d d r e s s e s

Slave Description Addres Bit

Command Name Description

C o m m a n d i n t e r f a c e

R e g i s t e r s

M m a n d T r a n s m i t D a t a r e g i s t e r

Address 9005

RegisterDescription

2C Dlen port iicdlen

A t u s R e c e i v e D a t a r e g i s t e r

Provide new transmit data

S t e r a d d r e s s r e g i s t e r

Scmdl

Mcmdl

Irqcd

A v e a d d r e s s r e g i s t e r

Timing parameter for fast-mode Register

Address 9005 000C

Mask the interrupt to the ARM CPU irqdis

Master/slave interrupt codes

T e r r u p t codes

Code Name Master/slave Description

F t w a r e d r i v e r

I2C master software driver I2C slave high level driver

O w c h a r t s

Master module normal mode, 16- bit

Slave module normal mode, 16- bit

Real Time Clock Module

C G e n e r a l C o n t r o l r e g i s t e r

Address 9006

12/24 clock mode operation

2 4 H o u r r e g i s t e r

Calendar operation

Time date, hour, minute, second operation

HRT

M e r e g i s t e r

HRU

L e n d a r r e g i s t e r

Address 9006 000C

M e Alarm r e g i s t e r

L e n d a r Alarm r e g i s t e r

Alarm E n a b l e r e g i s t e r

E n t F l a g s r e g i s t e r

Address 9006 001C

Alarm event

Month event

Date event

Hour event

Alarm interrupt

Month interrupt

Date interrupt

Hour interrupt

T e r r u p t D i s a b l e r e g i s t e r

T e r r u p t E n a b l e S t a t u s r e g i s t e r

N e r a l S t a t u s r e g i s t e r

Address 9006 002C

General Status register

ADC module

Structure

C D M a p r o c e d u r e

ADC control block

C c o n t r o l a n d s t a t u s r e g i s t e r s

ADC configuration registers are located at offset

C C o n f i g u r a t i o n r e g i s t e r

Interrupt status

DMA enable

ADC channel select

C O u t p u t R e g i s t e r s 0

C C l o c k C o n f i g u r a t i o n r e g i s t e r

Wait

Dout

E c t r i c a l c h a r a c t e r i s t i c s

Parameter Symbola Rating Unit

Absolute maximum ratings

CPU / Memory clock Power

Parameter Symbol a Rating Unit

Recommended operating conditions

Inputs

E l e c t r i c a l c h a r a c t e r i s t i c s

Sym Parameter Conditiona Value Unit

Ouputs

Sym Parameter Value Unit

Manufacturer Part Number Description

NC7SP17

74LVC1G17GW

SN74LVC1G17DC

M o r y T i m i n g

Sdram burst read 16-bit

Sdram burst read 16 bit, CAS latency =

Sdram burst write 16 bit

Sdram burst read 32 bit

Sdram burst read 32 bit, CAS latency =

Sdram burst write 32-bit

Sdram load mode

Sdram refresh mode

Clock enable timing

Parm Description Min Max Unit

Static RAM read cycles with 0 wait states

Static RAM asynchronous page mode read, Wtpg =

Static RAM read cycle with configurable wait states

Static RAM sequential write cycles

Static RAM write cycle

Static write cycle with configurable wait states

Slow peripheral acknowledge timing

CPU

Slow peripheral acknowledge read

Slow peripheral acknowledge write

Ethernet timing

Ethernet MII timing

Standard Mode Fast Mode Parm Description Min Max Unit

I2C timing

SPI Timing

Parm Description Min Max Unit Mod Not

SPI master parameters

SPI slave parameters

Tbclk *8

SPI master mode 0 and 1 2-byte transfer

SPI master mode2 and 3 2-byte transfer

SPI slave mode 0 and 1 2-byte transfer

SPI slave mode 2 and 3 2-byte transfer

S e t a n d h a r d w a r e s t r a p p i n g t i m i n g

Parm Description Min Typ Unit

A G t i m i n g

O c k t i m i n g

Diagram below pertains to clock timing

System PLL reference clock Timing

Clock timing

Packaging

C k a g e

O c e s s o r D i m e n s i o n s

C K a G I N G

Processor Dimensions

V i s i o n B

V i s i o n C