Supplies

For optimum reliability and print quality use IBM supplies, which are engineered speci®cally for IBM printers. Use the ªIBM Supplies Worksheetº to help you order supplies for the printer before the system is delivered, and to maintain a stock of supplies for continuous operation.

When a printer runs low on a supply item, it displays a status message on the Display Touch Screen screen, sounds an alarm, and turns on an operator intervention light on top of the printer.

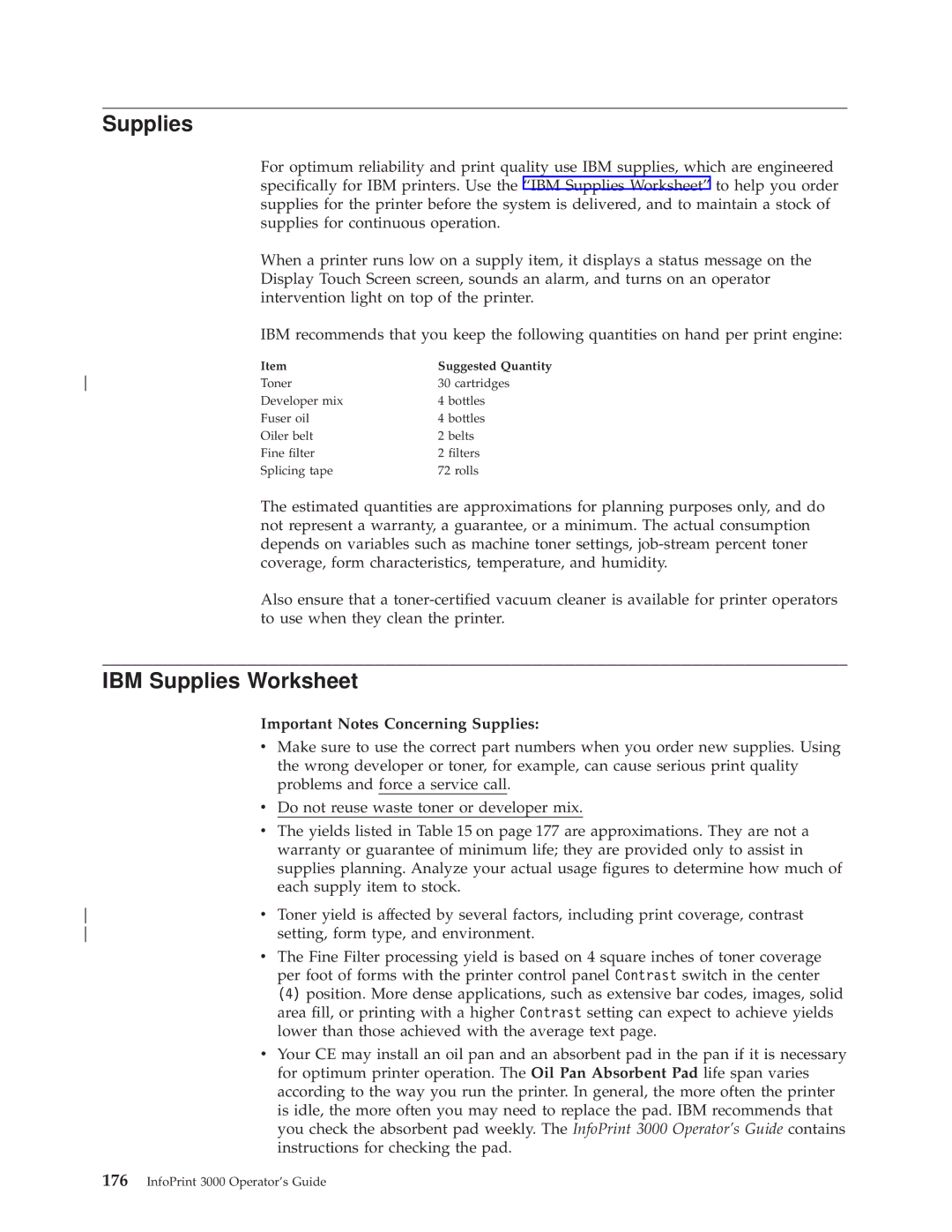

IBM recommends that you keep the following quantities on hand per print engine:

Item | Suggested Quantity | ||

Toner | 30 cartridges | ||

| Developer mix | 4 bottles | |

| Fuser oil | 4 | bottles |

| Oiler belt | 2 | belts |

| Fine ®lter | 2 | ®lters |

| Splicing tape | 72 rolls | |

The estimated quantities are approximations for planning purposes only, and do not represent a warranty, a guarantee, or a minimum. The actual consumption depends on variables such as machine toner settings,

Also ensure that a

IBM Supplies Worksheet

Important Notes Concerning Supplies:

vMake sure to use the correct part numbers when you order new supplies. Using the wrong developer or toner, for example, can cause serious print quality problems and force a service call.

vDo not reuse waste toner or developer mix.

vThe yields listed in Table 15 on page 177 are approximations. They are not a warranty or guarantee of minimum life; they are provided only to assist in supplies planning. Analyze your actual usage ®gures to determine how much of each supply item to stock.

v Toner yield is affected by several factors, including print coverage, contrast | |

setting, form type, and environment. | |

| v The Fine Filter processing yield is based on 4 square inches of toner coverage |

| per foot of forms with the printer control panel Contrast switch in the center |

| (4) position. More dense applications, such as extensive bar codes, images, solid |

| area ®ll, or printing with a higher Contrast setting can expect to achieve yields |

| lower than those achieved with the average text page. |

| v Your CE may install an oil pan and an absorbent pad in the pan if it is necessary |

| for optimum printer operation. The Oil Pan Absorbent Pad life span varies |

| according to the way you run the printer. In general, the more often the printer |

| is idle, the more often you may need to replace the pad. IBM recommends that |

| you check the absorbent pad weekly. The InfoPrint 3000 Operator's Guide contains |

| instructions for checking the pad. |