Connection

Basic Parameters Extended

Peripheral Units

Limited applications

Precautions

Symbols Meaning

Marking

Handling in general

Transportation・Installation

Wiring

About operation

About disposal of inverters

When selecting the retry mode Applicable to inverters

About inspection and maintenance

Sticking warning labels

Features

Ⅱ. Preface

Package Name plate

Type Form Specification code

200V-3.7kW

Special

Panel description

Panel indication

Indication number

Indication alphabet

Page

VFA7-2185P, 2220P VFA7-4185P, 4220P

Grounding terminal

VFA7-2300P, 4300P VFA7-4370P1~4550P1

Page

Page

Detaching the terminal board front cover

P24

Operation in low speed ranges

Comparison with commercial power operation

Adjustment of overload protection level

High-speed operation at a frequency of 60 Hz or over

Braking of a motor after power shutoff

Load producing negative torque

Motor with a braking system

Inverter capacity

Power factor improving capacitor

Over-current protective function

Use of an inverter at a voltage other than the rated one

Power supply Inverter

Influences of leakage currents and measures against it

Measures to be taken

Power supply

Installation environment

Resistor

Installation

Installation place

Applicable Calorific value

Heat radiation area Required Motor Inverter

For closed-type

Page

Heat-sink going out attachmentsimple type

Normal attachment Heat-sink going out attachment Simple type

Connection

Inverter, or the inverter could cause a shock or a fire

Prevention of radio noise

Motor Main circuit

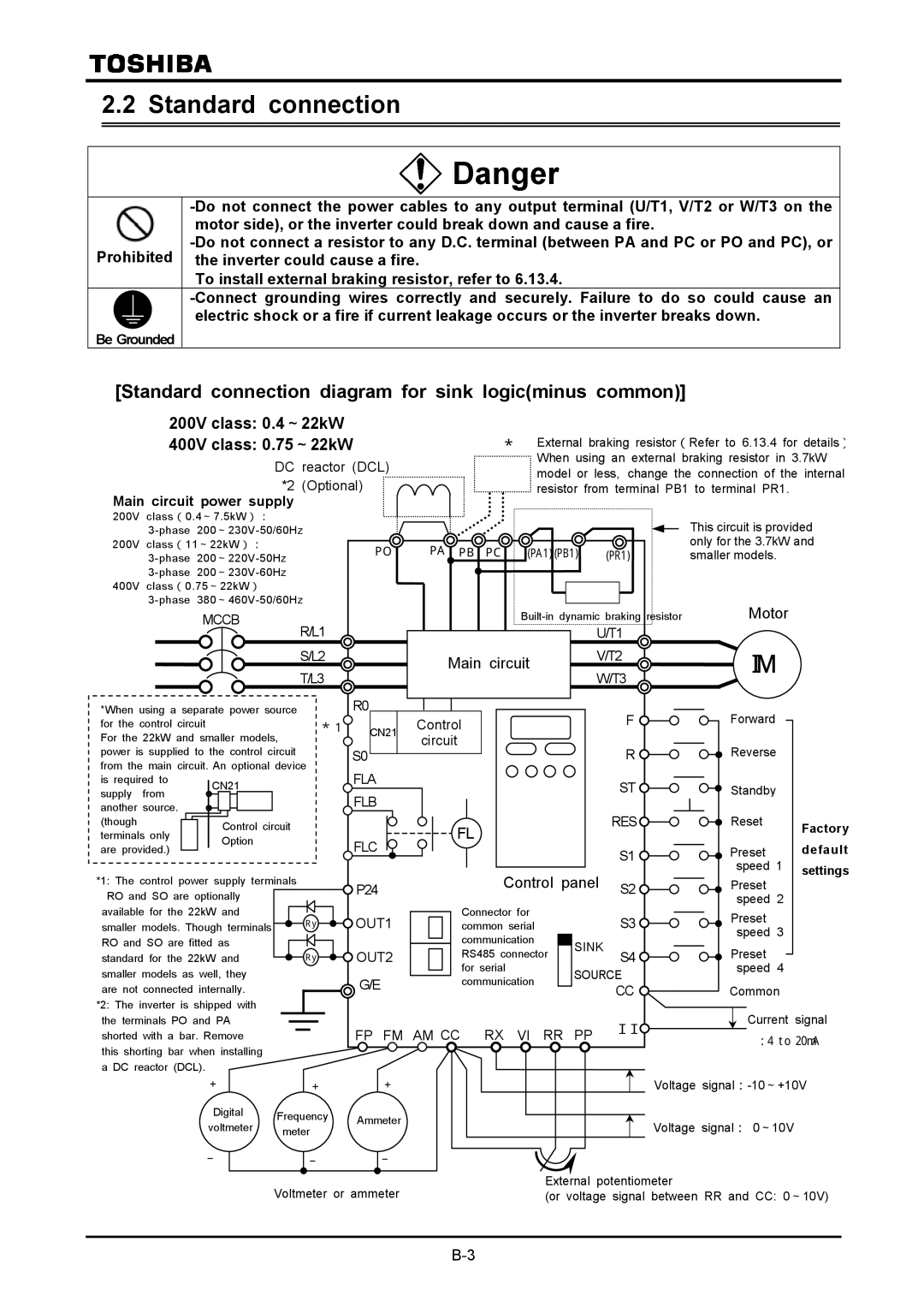

Standard connection diagram for sink logicminus common

Standard connection

Control panel

Control Circuit

R20 R46

Control

*1 R20

R46 R41

Explanation of terminals

Main circuit terminals

R0, S0 R46, R41, R20, S20

Terminal symbol

Inverter internal circuit

R20 S20 P0, PA, PB, PC, PA1,PB1,PR1

Control circuit terminals sink logicminus common

Input Function Electrical Inverter internal

Output Default setting Operation frequency command

Output Default setting Output current. Connect a 1mAdc

Connect a 1mAdc full-scale ammeter or a

Common Input

Switching logic

Input Common P24 Output Common CC

Common Programmable Inverter Controller

Serial RS485 communication connector

Motor is at a standstill, or you could get a shock

Could get a shock

Control modes of the VF-A7 inverter

Sensor vector control Optional

Simple operation of the VF-A7 1 Speed control mode

1Operation from the terminalexternal signals

Example of typical connection

)Setting the frequency by voltage signals 0 to 10

Frequency setting

Speed setting mode selection parameter at

)Setting the frequency by a current signal 4 to 20 mA

)Setting the frequency by voltage signals 0 to 10 Vdc

)Setting the frequency by voltage signals 0 to +/-10Vdc

Speed setting mode selection parameter at

Operation from the control panel [Control panel operation]

:Start the motor

Selecting a stop mode with the control panel

Example of control panel operation

Simple operation of the VF-A7 2 Torque control mode

Setting a control mode

When the motor is out of operation. If the monitor display

Mode setting parameter is set at Running

S4 Control mode Switching RR switching

Polarity of torque command

Torque control mode

Operation from the terminalexternal signal

Torque command

Start/stop

)Torque setting by means of voltage signals 0~10 Vdc

Torque setting by means of current signals 4 to 20 mAdc

Torque setting by means of voltage signals 0~10 Vdc

)Torque setting by means of a volume control

Others

Torque command

Setting the start and stop modes

Selecting a torque command mode

Operation from the control panel

RUN :Starts the motor

Set the torque command

Example of control panel operation

Stop :Stops the motor

Torque control mode

Setting parameters Setting monitor mode

Speed control mode

Status monitor mode Setting monitor mode

How to set basic parameters Basic parameter

Procedure for setting a basic parameter

Basic parameter list

How to set extended parameters

Procedure for setting an extended parameter

Display mode setting parameter is set at

Example of parameter setting

When the motor is out of operation.If the monitor

Running frequency

Searching for a parameter and changing its setting

Parameters that cannot be changed during operation

Basic parameters

Optional analog terminal #1 meter adjustment

FM terminal meter selection FM terminal meter adjustment

AM terminal meter adjustment

Optional analog terminal #2 meter adjustment

=

Setting the acceleration and deceleration times

Automatic acceleration/deceleration

・ Function

Acceleration/deceleration enabled by pressing key

Manually setting the acceleration and deceleration times

Change the parameter setting to automatic

Time s

Increasing starting torque/ energy-saving operation mode

:Automatic V/f mode setting

If you fail to make the setting for vector control

VF-A7 inverter has been set to this control mode by default

Selecting an operation mode

Preset speed operation

Speed setting mode

Operation command

Mode selection

Title Function Set value

Speed setting

Panel stop pattern

・Function

Setting and calibrating meters

Title Function Adjustment range

Terminal FM-related parameters

Resolution

Calibrating a meter when the inverter is out of operation

Frequency display mode.If the monitor display mode setting

By setup, before the needle of meter begins to sway

Return the parameter setting to output current display

Set the parameter at fixed output for meter

Hz standard setting =

Factory default setting

:Standard setting mode selection

Hz standard setting =

Trip clear =

Factory default setting =

Reset of user-defined parameters =

Clearing accumulating operation time =

:Forward/reverse selection

Parameter setting

Maximum frequency

:Maximum frequency

:Upper limit frequency :Lower limit frequency

Upper and lower limit frequencies

Base frequency

:Base frequency #1

Constant torque characteristic Normal way of use

Control mode selection

:Motor control mode selection

Motor control

To increase the starting torque

Setting suitable for fans and pumps

:The torque Boost rate is adjusted

Automatically

Value. Default setting Constant torque

Change the parameter setting to Sensorless vector

Control by pressing the key

※100% adjustment value 200V class 200V,400V class

To set the V/F characteristic arbitrarily

5-point setting

This control mode involves the setting of the motor constant

Speed setting

Switching between speed control and torque control

: Motor control mode selection

~

Communication add-on cassette option

Torque reference

Common serial communication option

Binary/BCD inputoptional

Manual boost ~ %

Setting the electronic thermal protective function

Parameter Title Function Adjustment range

Explanation of terms

Setting the electronic thermal protective function

Setting the motor overload protection level #1

Overload stallSoft stall

Setting of motor overload start level

Overload reduction start-up ~ Hz

×1.0 ×0.6

Inverter overload characteristic

Inverters overload protective characteristic

Motor 150%-overload time limit

Preset-speed operation 15 speeds

Setting preset-speed frequencies

Start/stop

Preset-speed #1

Forward run command

Reverse run command

Preset-speed #2

Setting the operation mode

・Output terminal setting

Frequency signals

Low-speed signal

・Function

Putting out signals of arbitrary frequencies

・Function

P24-OUT2

Standard

Selection of input signals

Changing standby signal function

Always-ON

Reverse

[ Disabled Terminal board has no priority ]

Forward

=Stop

Priority command from terminal board Operation command

terminal board has priority Enabled

Setting value Jog run

Forced JOG forward rotation

Binary/BCD signal selectionExpansion TB option unit

:Binary/BCD signal selectionExpansion TB option unit

Input terminal selection #8S4

Keeping an input terminal function always active on

Signal on completion of acceleration/deceleration OUT

Selection of terminal functions

Changing input terminal functions

Refer to 7.2.2 for details

Changing output terminal functions

Response times of input/output terminals

Refer to 7.2.3 for details

Setting of switching terminals

S1:V/f switching #1 S2:V/f switching #2

Basic parameters #2

S1V/f switching #1 S2V/f switching #2 Parameters selected

OFF

has priority

Speed/torque command gain and bias

Using two types of frequency speed commands

has priority

Command selected with

Frequency reference

Setting frequency command characteristics

Setting torque reference characteristics

Start-up frequency and End frequency

Operating by means of reference signals

Operation frequency

3 0Hz dead band frequency

DC injection braking

DC injection braking

Braking under normal conditions

Motor shaft fixing control

:Motor shaft fixing control

Forward/reverse DC braking priority control =OFF

LED display lights lights

Zero-speed stop mode selection

:Zero-speed stop mode selection

~ Hz

~ Hz

Jog run

:Jog run frequency :Jog stop control

Example of jog run

Jump frequency Jumping resonant frequencies

Preset-speed #8~15

~ :Preset-speed #8~#15

Refer to 5.14 for details

:PWM carrier frequency

PWM carrier frequency

Trip-less enhancement

Set the control method of Auto-restart

Set the mode of Auto-restart

Restart after a momentary power failure

Restart of coasting motor Motor speed search function

1Case =

Adaptation for elevator applications

Case =

Regenerative power ride-through control / Deceleration stop

Set the property of Auto-restart

Case =~

Retry function

:Retry selection

Dynamic braking resistor capacity

Dynamic regenerative braking To urgently stop the motor

An internal braking resistor for 3.7kW model and smaller

~ Ω

Class Capacity kW

An external braking resistor optional

Any value

120W 70Ω 200 120W 40Ω 400 120W 150Ω 100

Supply

When using a braking resistor without thermal fuse

PBR resistor capacity

~ Ω Any value

Selection of braking resistor option and braking unit

Connectable braking resistors and their minimum resistances

Type

Adjusting the output voltage and voltage compensation

Avoiding over-voltage trip

Prohibiting the reverse operation

:Reverse-run prohibition

Dead band Frequency

Drooping control

Drooping Gain

Speed at the drooping gain ~ Hz

Commercial power/inverter switching

Function for crane/hoist

Timing chart

~ :Preset speed operation modes

PID control

Speed feedback/positioning control

Set the auto-tuning = Automatic tuning execution

Setting motor constants

Selection 1 Setting by the automatic V/f mode

Refer to 5.2 for details of this setting

Motor is out of operation. If the monitor display momde

Setting parameter is set at Running frequency

Change the parameter setting to Automatic tuning

Press the Enter key to activate the parameter

Setting the rating of the motor

Setting motor constants

①Slip frequency gain

Examples of setting auto-tuning

Inverter VFA7 2037PL Motor 7kW, 4P, 60Hz Selection

~20mAdc ⇒ II terminal

Torque control

Torque reference

~10Vdc ⇒ RR terminal

:Torque reference filter

Voltage signal 0 ~± 10Vdc

Torque reference filter

⇒ RX terminal

Setting of forward speed limit level

Speed limits in torque control mode

Setting with the control panel

Setting of reverse speed limit level

Torque bias and load sharing gain

Setting by means of external signals

Selection of external signals

―― 40 ~20mA

Voltage signals Current signals

× +

Setting of power running torque

Setting

Power running /regenerative torque limit

Setting of regenerative torque

Limiting the torque with external signals

Positive/negative torque limits

Regenerative Power running

Power running Regenerative

Torque Limit #1

RRvolume/ voltage

Positive torque limit

Negative torque limit

Torque Limit

Selection Regenerative

Motor needs to be speeded up to

Slowly in weak-field areas where it

Secondary acceleration/deceleration

Suitable for the operation

Switching of acceleration/deceleration #1, 2, 3

Selection with parameters

Output freq. Hz Setting freq

Acc/dec switching #1 Acc/dec switching #2

Acceleration/deceleration patterns

Parameter setting

Minimum acceleration/deceleration times

:Acceleration/deceleration lower limit

Pattern run

<Basic operating>

Monitor displayed during pattern run

~

Output frequency Hz Setting frequency Step trigger signal

④ :select pattern group #4 Parameter setting

Protection functions

Motor over road protection-level adjust / motor types

Setting of current stall

Inverter trip holding

Motors 150%-overload time limit

Emergency stop

Overload reduction start-up frequency

Emergency stop by terminal operation

Detection of output phase failure

Action at low currents

Over-torque trip

:Cooling fan control mode

Cooling fan control mode selection

Cumulative operation time alarm

:Cumulative operation time alarm setting

Under-voltage trip

System-supporting sequence B-timer

Over-voltage stall protection level

UV stall level

Special analog input

Over-ride

Additive over-ride

Output frequency = Reference × 1 + Over-rideVI input %

Output frequency = Reference + Over-ride VI input Hz

Output frequency = Reference + Over-rideVI input Hz

Output frequency = Reference × 1 + Over-ride %

Meter output

Setting of meter outputs

Setting of optional meter outputs

Pulse output to meters

:Current / voltage display mode

Prohibiting the change of parameter settings

:Prohibition of parameter setting

Control panel parameters

Display of the rotating speed of the motor

Display the motor speed and the load speed

:Frequency free unit magnification

Display of the speed of the load

:Selection of panel V/f1, 2, 3 or

Changing items displayed in status monitor mode

Switching basic parameters

Time 0.01 s

Selecting a control panel stop pattern

Resetting the inverter from the control panel

Panel reset function

:Panel stop pattern

Drooping control in panel operation mode

Canceling PID control in panel operation mode

Setting a torque command in panel operation mode

Override in panel operation mode

Restricting or prohibiting key operation

Setting

Canceling methods

:Panel operation prohibition

<Computer link>

Communication function RS485/common serial

Common serial optional device

<Inter-drive communication>

Terminal block enabled

Setting of operation command common serial

Operation command ~ Mode selection

Using the RS485 port fitted as standard

:Wiring :Data (Host→Inverter)

:Wiring :Data (Master→slave)

Inter-drive communications

Setting of operation command RS485

Setting of speed reference RS485

Operation with External Signal

External Operation

Control terminal board

Setting of contact input terminal function

Functions of input terminals in case of sink logic

Connection method

Inverter

Example of use Push-type operation stop

Table of contact input terminal function settings

Acc/dec, V/f, torque limit #2

Acc/dec, V/f, torque limit #3

Low speed signal

Setting of output terminal functions

Symbol Title Function Adjustment Default setting

Functions of output terminals in case of sink logic

Parameter setting

OFF All the alarms above are cancelled

Or detected

Completion of positioning On Positioning has been completed

Output of the designated data in 7 bits

Over travel On Over running

OFF in positive logic

Response time setting

Setup of input/output terminal operation time

Setup of response time

Analog input filter

Setup of external speed command analog signal

Setting of analog input terminal functions

Control terminal board

Setup by analog input signals RR terminal

Title Function Adjustment range

~

Setup by analog input signals VI/II terminal

10V VI terminal

Setup by analog input signals RX terminal

Status monitor mode

Status monitor

Information on input terminals

Total accumulated operation hours

Information on output terminals

Type of connected option

Changing indication of status with power on

Changing contents of status monitor indication

Changing status monitor function

FE30 Output power

01kW

1kW

Indication in trip status

Details of indications of trip status

Examples of reading out trip data

Indication of alarm, pre-alarm, etc

Selection of wiring equipment

Failure, short-circuit or electric leak

Selection of wiring equipment

Inverter model

Installation of electromagnetic contactor

Electromagnetic contactor in the primary circuit

Installation of overload relay

Electromagnetic contactor in the secondary circuit

Application and functions of options

Sorts of separate-type options

VF-A7

Motor end surge

RS-232C ⑬ communication converter unit Model RS2001Z

RS-232C Communication Converter cable

Selection table of separate-type options

Functions of optional add-on cassettes

Optional add-on cassettes

Table of optional add-on cassettes

Table of optional add-on cassettes

②Expansion TB option unit

* In a set with SBP001Z

* In a set with SBP002Z

Table of board options

Installation of board option

Board options

Functions of board options

Before installing optional add-on cassette or board option

Case

Mandatory

Case 2-B. When PG feedback function is mot used

Case 2-A. When PG feedback function is used

Prepare for installing according to 9.7.1, 1 to

Preparation is not needed

Basic parameters 1/2

Basic parameters 2/2

Extended parameters

Frequency signal

Input signal selection

Terminal function selection 1/2

Terminal response time setup

Terminal function selection 2/2

Point Setting

Basic parameters #2

Speed/torque reference gain/bias setup 1/2

Braking

Speed/torque reference gain/bias setup 2/2

Operation frequency

Operation

Jumper frequency

Preset speed operation frequency 8- to 15-stage speed

Tripless intensification setup 1/2

PWM carrier frequency

Tripless intensification setup 2/2

Control

For lift 1/2

PID control

Commercial/inverter switching function

Functions for lift 2/2

Speed feedback/positioning control

Preset-speed operation mode

Vector control

Motor constant

Torque control

Speed/torque reference gain/bias setup #21/2

Torque limit

Speed/torque reference gain/bias setup #22/2

Secondary acceleration/deceleration

Pattern run selection Disabled, 1 Enabled

Pattern run mode Patterned operation canceled during stop

Preset-speed #1 operation time ~8000 s / min

Preset-speed #1 operation

Continuation mode

Preset-speed #2 operation time Ditto

Protection functions

Special analog input

Over-ride

Meter output 1/2

Meter output 2/2

Control Panel parameters

Communication function1/2

Communication function2/2

Reservation area

[Contents of monitor indications]

Monitor FM/AM/pulse output function selection

Input terminal function setting 1/2

104 105

[Input terminal function setting 2/2]

= = =~ =

106 107 VI/II terminal priority 108 109

[Output terminal function setting 1/2]

[Output terminal function setting 2/2]

Default settings

PWM

Standard specifications by types

Standard specifications by types large capacity types

Common specifications

Causes

Fault

Process, upper/lower limits

Digit

External dimensions and mass

External dimensions and mass

Drawing C Drawing D

Outline drawings

Drawing a Drawing B

Drawing E Drawing F

Dimensions for heat-sink going out attachmentsimple type

Also reset the

Indication Contents Expected causes Countermeasures

・ Decrease setting value

・ Extend acceleration time #1

Main RAM fault

・ Reset the inverter

Initial read-error

Main ROM fault

Presence or absence of parameter trip can be selected

・ If undervoltage is detected, set

Setting signal apart from each

Method of resetting causes of trip

~ Caution! ~

Is LED on

Is input power Input power Correct?

Make a service call

RUN/STOP key

How to check other troubles

Measures against trouble with parameter setting

Inspection method

Regular inspection

Check points

By feel touch

Points of inspection

Dealer for replacement of part

Periodical inspection

・Dont replace any component part

Replacement of expendable parts

Standard period of years to replace main component parts

When making a service call

When retaining the inverter out of operation

Warranty

Blasting during incineration

Plastics

Disposing manner