Emissions certified models use a single electronic- controlled pressure regulator (EPR) for both fuels. A tee fitting connects both fuels together upstream of the EPR. During operation when using the secondary fuel, it is normal for a small amount of secondary fuel to seep back through the primary fuel solenoid valve. To counter this situation, one of two methods is used depending upon the generator set model: (1) a second solenoid valve (identical to the primary fuel solenoid valve) is installed in a reverse configuration on the primary fuel side or (2) a small vent line is installed between the primary fuel inlet and the air intake through a fuel solenoid valve.

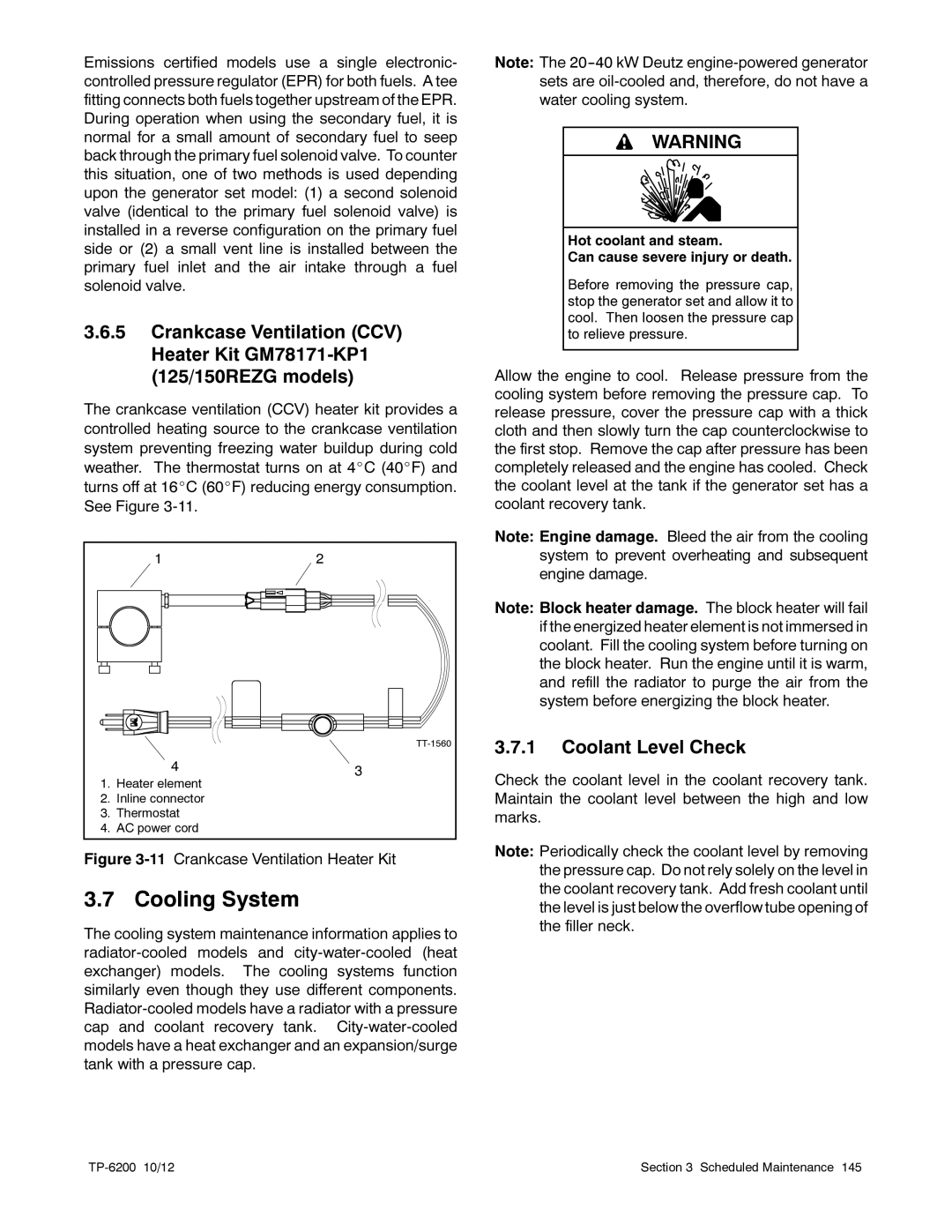

3.6.5Crankcase Ventilation (CCV) Heater Kit

The crankcase ventilation (CCV) heater kit provides a controlled heating source to the crankcase ventilation system preventing freezing water buildup during cold weather. The thermostat turns on at 4_C (40_F) and turns off at 16_C (60_F) reducing energy consumption. See Figure

| 1 | 2 | |

|

| ||

| 4 | 3 | |

1. | Heater element | ||

| |||

2. | Inline connector |

| |

3. | Thermostat |

| |

4. | AC power cord |

|

Figure 3-11 Crankcase Ventilation Heater Kit

3.7 Cooling System

The cooling system maintenance information applies to

Note: The

WARNING

Hot coolant and steam.

Can cause severe injury or death.

Before removing the pressure cap, stop the generator set and allow it to cool. Then loosen the pressure cap to relieve pressure.

Allow the engine to cool. Release pressure from the cooling system before removing the pressure cap. To release pressure, cover the pressure cap with a thick cloth and then slowly turn the cap counterclockwise to the first stop. Remove the cap after pressure has been completely released and the engine has cooled. Check the coolant level at the tank if the generator set has a coolant recovery tank.

Note: Engine damage. Bleed the air from the cooling system to prevent overheating and subsequent engine damage.

Note: Block heater damage. The block heater will fail if the energized heater element is not immersed in coolant. Fill the cooling system before turning on the block heater. Run the engine until it is warm, and refill the radiator to purge the air from the system before energizing the block heater.

3.7.1Coolant Level Check

Check the coolant level in the coolant recovery tank. Maintain the coolant level between the high and low marks.

Note: Periodically check the coolant level by removing the pressure cap. Do not rely solely on the level in the coolant recovery tank. Add fresh coolant until the level is just below the overflow tube opening of the filler neck.

Section 3 Scheduled Maintenance 145 |