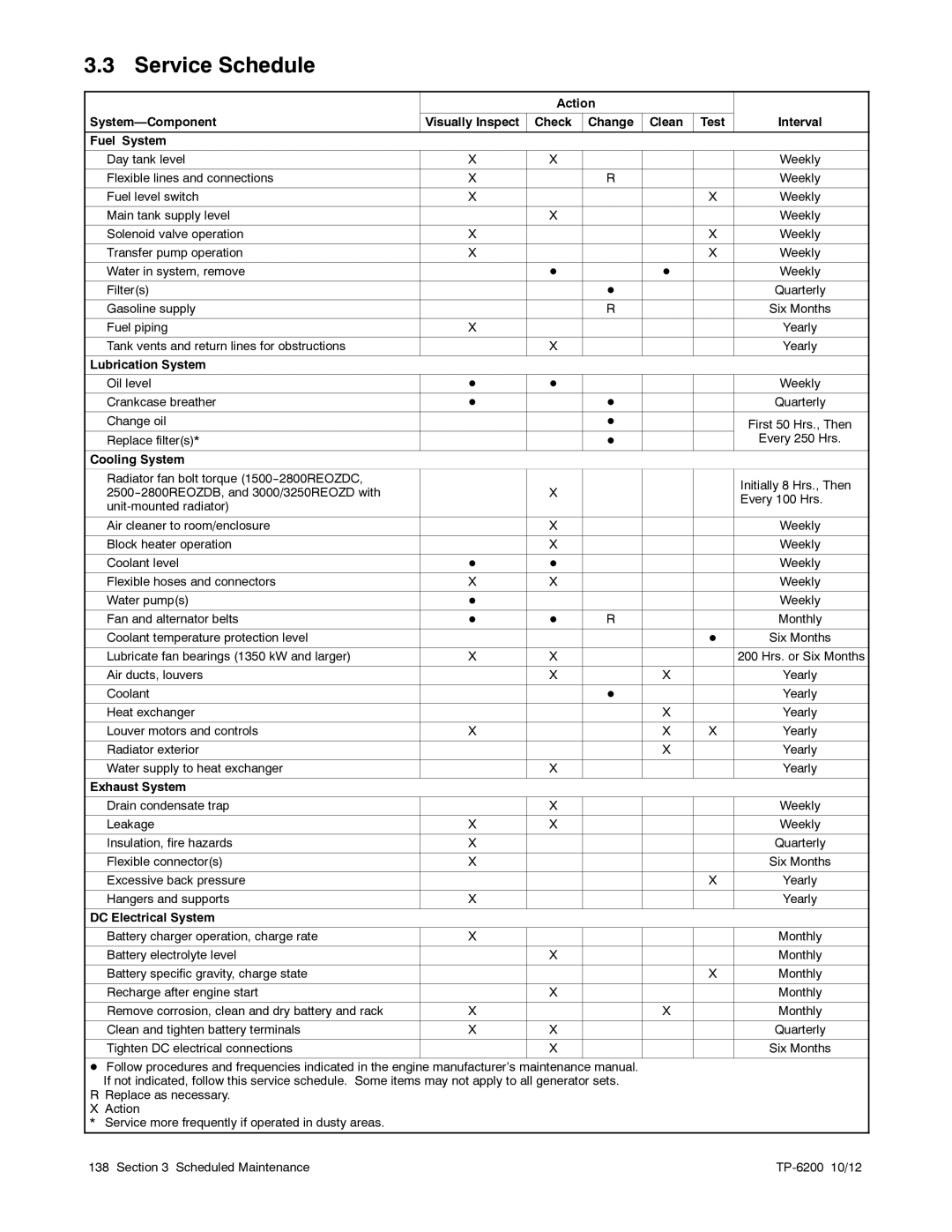

3.3 Service Schedule

|

| Action |

|

| ||

|

|

|

|

|

|

|

Visually Inspect | Check | Change | Clean | Test | Interval | |

|

|

|

|

|

|

|

Fuel System |

|

|

|

|

|

|

|

|

|

|

|

|

|

Day tank level | X | X |

|

|

| Weekly |

|

|

|

|

|

|

|

Flexible lines and connections | X |

| R |

|

| Weekly |

|

|

|

|

|

|

|

Fuel level switch | X |

|

|

| X | Weekly |

|

|

|

|

|

|

|

Main tank supply level |

| X |

|

|

| Weekly |

|

|

|

|

|

|

|

Solenoid valve operation | X |

|

|

| X | Weekly |

|

|

|

|

|

|

|

Transfer pump operation | X |

|

|

| X | Weekly |

|

|

|

|

|

|

|

Water in system, remove |

| D |

| D |

| Weekly |

|

|

|

|

|

|

|

Filter(s) |

|

| D |

|

| Quarterly |

|

|

|

|

|

|

|

Gasoline supply |

|

| R |

|

| Six Months |

|

|

|

|

|

|

|

Fuel piping | X |

|

|

|

| Yearly |

|

|

|

|

|

|

|

Tank vents and return lines for obstructions |

| X |

|

|

| Yearly |

|

|

|

|

|

|

|

Lubrication System |

|

|

|

|

|

|

|

|

|

|

|

|

|

Oil level | D | D |

|

|

| Weekly |

|

|

|

|

|

|

|

Crankcase breather | D |

| D |

|

| Quarterly |

|

|

|

|

|

|

|

Change oil |

|

| D |

|

| First 50 Hrs., Then |

|

|

|

|

|

| |

Replace filter(s)* |

|

| D |

|

| Every 250 Hrs. |

|

|

|

|

|

|

|

Cooling System |

|

|

|

|

|

|

|

|

|

|

|

|

|

Radiator fan bolt torque |

|

|

|

|

| Initially 8 Hrs., Then |

| X |

|

|

| ||

|

|

|

| Every 100 Hrs. | ||

|

|

|

|

| ||

|

|

|

|

|

| |

|

|

|

|

|

|

|

Air cleaner to room/enclosure |

| X |

|

|

| Weekly |

|

|

|

|

|

|

|

Block heater operation |

| X |

|

|

| Weekly |

|

|

|

|

|

|

|

Coolant level | D | D |

|

|

| Weekly |

|

|

|

|

|

|

|

Flexible hoses and connectors | X | X |

|

|

| Weekly |

|

|

|

|

|

|

|

Water pump(s) | D |

|

|

|

| Weekly |

|

|

|

|

|

|

|

Fan and alternator belts | D | D | R |

|

| Monthly |

|

|

|

|

|

|

|

Coolant temperature protection level |

|

|

|

| D | Six Months |

|

|

|

|

|

|

|

Lubricate fan bearings (1350 kW and larger) | X | X |

|

|

| 200 Hrs. or Six Months |

|

|

|

|

|

|

|

Air ducts, louvers |

| X |

| X |

| Yearly |

|

|

|

|

|

|

|

Coolant |

|

| D |

|

| Yearly |

|

|

|

|

|

|

|

Heat exchanger |

|

|

| X |

| Yearly |

|

|

|

|

|

|

|

Louver motors and controls | X |

|

| X | X | Yearly |

|

|

|

|

|

|

|

Radiator exterior |

|

|

| X |

| Yearly |

|

|

|

|

|

|

|

Water supply to heat exchanger |

| X |

|

|

| Yearly |

|

|

|

|

|

|

|

Exhaust System |

|

|

|

|

|

|

|

|

|

|

|

|

|

Drain condensate trap |

| X |

|

|

| Weekly |

|

|

|

|

|

|

|

Leakage | X | X |

|

|

| Weekly |

|

|

|

|

|

|

|

Insulation, fire hazards | X |

|

|

|

| Quarterly |

|

|

|

|

|

|

|

Flexible connector(s) | X |

|

|

|

| Six Months |

|

|

|

|

|

|

|

Excessive back pressure |

|

|

|

| X | Yearly |

|

|

|

|

|

|

|

Hangers and supports | X |

|

|

|

| Yearly |

|

|

|

|

|

|

|

DC Electrical System |

|

|

|

|

|

|

|

|

|

|

|

|

|

Battery charger operation, charge rate | X |

|

|

|

| Monthly |

|

|

|

|

|

|

|

Battery electrolyte level |

| X |

|

|

| Monthly |

|

|

|

|

|

|

|

Battery specific gravity, charge state |

|

|

|

| X | Monthly |

|

|

|

|

|

|

|

Recharge after engine start |

| X |

|

|

| Monthly |

|

|

|

|

|

|

|

Remove corrosion, clean and dry battery and rack | X |

|

| X |

| Monthly |

|

|

|

|

|

|

|

Clean and tighten battery terminals | X | X |

|

|

| Quarterly |

|

|

|

|

|

|

|

Tighten DC electrical connections |

| X |

|

|

| Six Months |

|

|

|

|

|

|

|

D Follow procedures and frequencies indicated in the engine manufacturer’s maintenance manual. If not indicated, follow this service schedule. Some items may not apply to all generator sets.

R Replace as necessary. X Action

* Service more frequently if operated in dusty areas.

138 Section 3 Scheduled Maintenance |

|