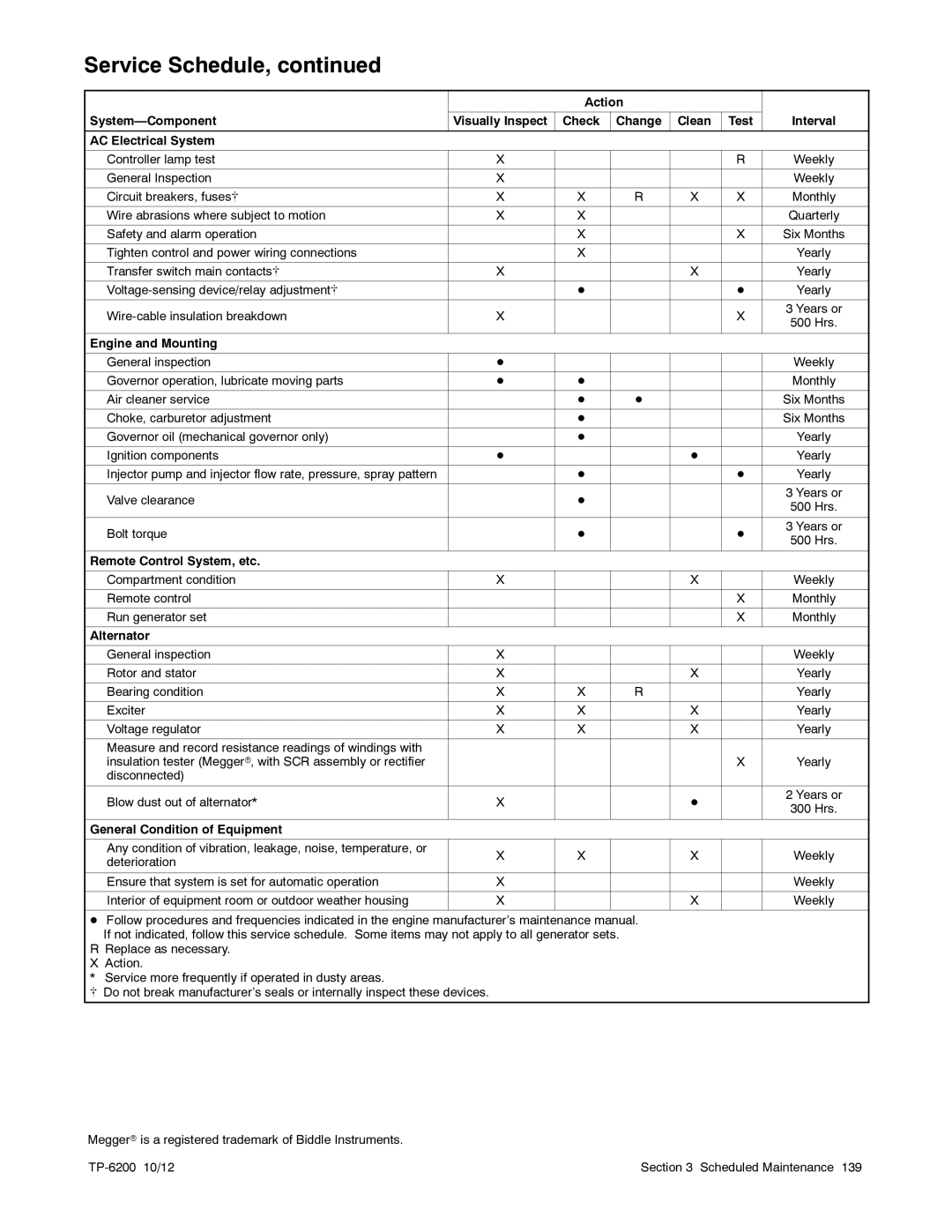

Service Schedule, continued

|

| Action |

|

|

| |

|

|

|

|

|

|

|

Visually Inspect | Check | Change | Clean | Test | Interval | |

|

|

|

|

|

|

|

AC Electrical System |

|

|

|

|

|

|

|

|

|

|

|

|

|

Controller lamp test | X |

|

|

| R | Weekly |

|

|

|

|

|

|

|

General Inspection | X |

|

|

|

| Weekly |

|

|

|

|

|

|

|

Circuit breakers, fuses[ | X | X | R | X | X | Monthly |

|

|

|

|

|

|

|

Wire abrasions where subject to motion | X | X |

|

|

| Quarterly |

|

|

|

|

|

|

|

Safety and alarm operation |

| X |

|

| X | Six Months |

|

|

|

|

|

|

|

Tighten control and power wiring connections |

| X |

|

|

| Yearly |

|

|

|

|

|

|

|

Transfer switch main contacts[ | X |

|

| X |

| Yearly |

|

|

|

|

|

|

|

| D |

|

| D | Yearly | |

|

|

|

|

|

|

|

X |

|

|

| X | 3 Years or | |

|

|

| 500 Hrs. | |||

|

|

|

|

|

| |

|

|

|

|

|

|

|

Engine and Mounting |

|

|

|

|

|

|

|

|

|

|

|

|

|

General inspection | D |

|

|

|

| Weekly |

|

|

|

|

|

|

|

Governor operation, lubricate moving parts | D | D |

|

|

| Monthly |

|

|

|

|

|

|

|

Air cleaner service |

| D | D |

|

| Six Months |

|

|

|

|

|

|

|

Choke, carburetor adjustment |

| D |

|

|

| Six Months |

|

|

|

|

|

|

|

Governor oil (mechanical governor only) |

| D |

|

|

| Yearly |

|

|

|

|

|

|

|

Ignition components | D |

|

| D |

| Yearly |

|

|

|

|

|

|

|

Injector pump and injector flow rate, pressure, spray pattern |

| D |

|

| D | Yearly |

|

|

|

|

|

|

|

Valve clearance |

| D |

|

|

| 3 Years or |

|

|

|

| 500 Hrs. | ||

|

|

|

|

|

| |

|

|

|

|

|

|

|

Bolt torque |

| D |

|

| D | 3 Years or |

|

|

| 500 Hrs. | |||

|

|

|

|

|

| |

|

|

|

|

|

|

|

Remote Control System, etc. |

|

|

|

|

|

|

|

|

|

|

|

|

|

Compartment condition | X |

|

| X |

| Weekly |

|

|

|

|

|

|

|

Remote control |

|

|

|

| X | Monthly |

|

|

|

|

|

|

|

Run generator set |

|

|

|

| X | Monthly |

|

|

|

|

|

|

|

Alternator |

|

|

|

|

|

|

|

|

|

|

|

|

|

General inspection | X |

|

|

|

| Weekly |

|

|

|

|

|

|

|

Rotor and stator | X |

|

| X |

| Yearly |

|

|

|

|

|

|

|

Bearing condition | X | X | R |

|

| Yearly |

|

|

|

|

|

|

|

Exciter | X | X |

| X |

| Yearly |

|

|

|

|

|

|

|

Voltage regulator | X | X |

| X |

| Yearly |

|

|

|

|

|

|

|

Measure and record resistance readings of windings with |

|

|

|

|

|

|

insulation tester (Meggerr, with SCR assembly or rectifier |

|

|

|

| X | Yearly |

disconnected) |

|

|

|

|

|

|

|

|

|

|

|

|

|

Blow dust out of alternator* | X |

|

| D |

| 2 Years or |

|

|

| 300 Hrs. | |||

|

|

|

|

|

| |

|

|

|

|

|

|

|

General Condition of Equipment |

|

|

|

|

|

|

|

|

|

|

|

|

|

Any condition of vibration, leakage, noise, temperature, or | X | X |

| X |

| Weekly |

deterioration |

|

| ||||

|

|

|

|

|

| |

|

|

|

|

|

|

|

Ensure that system is set for automatic operation | X |

|

|

|

| Weekly |

|

|

|

|

|

|

|

Interior of equipment room or outdoor weather housing | X |

|

| X |

| Weekly |

|

|

|

|

|

|

|

D Follow procedures and frequencies indicated in the engine manufacturer’s maintenance manual. If not indicated, follow this service schedule. Some items may not apply to all generator sets.

R Replace as necessary. X Action.

* Service more frequently if operated in dusty areas.

[ Do not break manufacturer’s seals or internally inspect these devices.

Meggerr is a registered trademark of Biddle Instruments.

| Section 3 Scheduled Maintenance 139 |