After reconnecting the battery cables, coat the terminals with petroleum jelly, silicon grease, or other nonconductive grease.

1 | 2 | 1 | 2 |

| |||

|

|

1 2

1.To positive (+) terminal on starter solenoid.

2.To ground

Figure 3-16 12-Volt Engine Electrical System Single Starter Motor Typical Battery Connection

12

21

1 | 2 |

2 | 1 | 1 | 2 | |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1.To positive (+) terminal on starter solenoid.

2.To ground

Figure 3-17 24-Volt Engine Electrical System Single Starter Motor Typical Battery Connection

1 2 3 4

1 | 2 |

| 3 | 4 | |||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1.To positive (+) terminal on starter solenoid.

2.To ground

3.To positive (+) terminal on second starter solenoid.

4.To ground

Figure 3-18 24-Volt Engine Electrical System Dual

Starter Motors Typical Battery

Connections

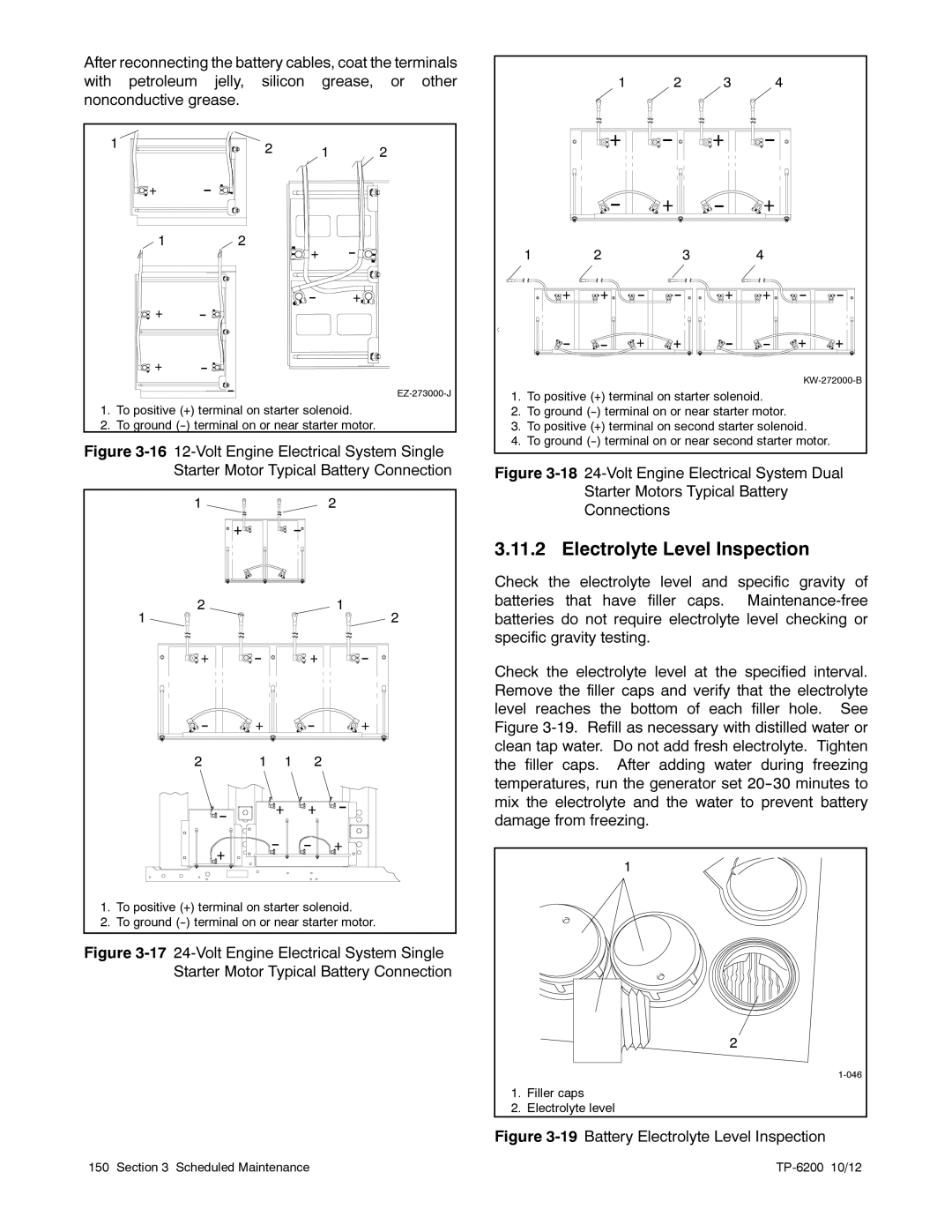

3.11.2 Electrolyte Level Inspection

Check the electrolyte level and specific gravity of batteries that have filler caps.

Check the electrolyte level at the specified interval. Remove the filler caps and verify that the electrolyte level reaches the bottom of each filler hole. See Figure

1

2

1.Filler caps

2.Electrolyte level

Figure 3-19 Battery Electrolyte Level Inspection

150 Section 3 Scheduled Maintenance |

|