FR-F500

This section is specifically about safety matters

Safety Instructions

Additional instructions

Emergency stop

Treat as industrial waste

Contents

103

100

102

104

163

Watt-hour meter clear/actual operation hour meter clear

184

192

195

Chapter Outline

Chapter

Wiring

Precautions for operation

Installation

Pre-Operation Information

Japanese Harmonic Suppression Guideline

Basic Configuration

Basic configuration

Name Description

Front view

Structure

Appearance and structure

Without front cover

Removal and reinstallation of the front cover

FR-F520-0.75K to 11K, FR-F540-0.75K to 11K

FR-F520-30K to 55K, FR-F540-30K to 55K

Removal and reinstallation of the operation panel

Chapter

Clearances around the inverter

Installation

Instructions for installation

97inches1.97inches

Wiring cover and handling 22K or less

For installation in an enclosure

Vertical mounting

NFB

Description of main circuit terminals

Symbol Terminal Name Description

Type Symbol Terminal Name Description

Description of control circuit terminals

RUN

Type

Terminal Name Description

IPF

Overall wiring length 1.5K or more

Wiring of the main circuit

Wiring instructions

Inverter Capacity 75K 5K or more

Motor Capacity Ground Cable Gauge 200V class 400V class

FR-F520-5.5K, 7.5K FR-F520-55K

Terminal block layout

FR-F520-1.5K, 2.2K, 3.7K FR-F520-45K

FR-F520-11K

FR-F540-15K, 18.5K, 22K

400V class FR-F540-0.75K, 1.5K, 2.2K, 3.7K FR-F540-30K, 37K

FR-F540-5.5K, 7.5K, 11K FR-F540-45K, 55K

Terminal names in parentheses are those of the EC version

Connection of the power supply and motor

Cables, crimping terminals, etc

Connection procedure

Model FR-F520-0.75K to 3.7K, FR-F540-0.75K to 3.7K

Model FR-F520-5.5K to 55K, FR-F540-5.5K to 55K

Wiring of the control circuit

Terminal screw size M3.5 Tightening torque 1.2 N⋅ m

Changing the control logic

Current flow related to RUN signal

How to use terminals STOP, CS and PC

PU connector pin-outs

Connection to the PU connector

Recommended cable connector

System configuration example

RS-485 terminal Computer

Wiring method

Wiring of one RS-485 computer and one inverter

Max m

Connection of stand-alone option units

Connection of the FR-BU brake unit option

Connection of the FR-HC high power factor converter option

Connection of the conventional BU brake unit option

Connection of the FR-RC power regeneration converter option

Connection of the power factor improving DC reactor option

Interlock Power Supply MC2 Leakage current

Design information

MC1

Other wiring

Power harmonics

Harmonics RF Noise

Conversion Factors for FR-F500 Series

Received Power 5th 7th 11th 13th 17th 19th 23rd Over 23rd

Japanese harmonic suppression guidelines

Class Circuit Type

Harmonic Content Values at the fundamental current of 100%

Equivalent Capacity Limits

Harmonic suppression techniques

ACL, DCL

FR-HC

Inverter-generated noises and reduction techniques

Following measures must be taken

Data line filter

Noise Path Measures

Bundle them

Noise Terminal Voltage of Inverter and Example

Noise Induced to Signal Cables by Inverter Output

Data examples

Its Reduction by Noise Filters

# Example of counter measures against noise

Leakage currents and countermeasures

To-ground leakage currents

# Countermeasures

Rectifying the motor insulation

Inverter-driven 400V class motor

Line-to-line leakage currents

Suppressing the surge voltage on the inverter side

Peripheral devices

Selection of peripheral devices

400V class

Example

Branch circuit protection

Standard to comply UL 508C 1 Installation

Wiring of the power supply and motor

Short circuit ratings

EMC Directive

Instructions for compliance with the European standards

Motor overload protection

Our view of transistorized inverters for the EMC Directive

90% RH or less

Low Voltage Directive

During operation Storage During transportation

Maximum Altitude 000 m 10,000 m

Earthing methods

Earthing EC version

Earthing and Earth Leakage Current

Unit mm2

OPERATION/CONTROL

External/PU combined operation mode

External operation mode factory setting

PU operation mode

Devices and parts to be prepared for operation

Communication operation mode

Power on

Before switching power on, check the following

Key indications

Operation Panel

Names and functions of the operation panel FR-DU04

Unit indications, operating status indications

Frequency setting

Used to set the running frequency in the PU operation mode

Monitoring

Parameter setting method

Operation mode

Help mode

Alarm history

All clear

Alarm history clear

Parameter clear

User clear

Copy mode

#Parameter setting mode

Parameter checking

Parameter Checking and Setting

Simple mode parameter list

Pr user group read selection

Name Application

Setting of minimum frequency Pr minimum frequency

Main parameter settings

Setting of maximum frequency Pr maximum frequency

Parameter Factory Setting

Gain

Application Setting

Selection of load pattern Pr load pattern selection

0Hz at 4mADC, 60Hz at

Operation

Pre-operation checks

Operation at 60Hz

External jog operation

Description Image

Stop Press

PU jog operation

Start Press

Motor is decelerated to a stop

Start

Decelerates when Pr = 9999 to a stop

Step Description

Hold down the key to change the frequency

Parameters

Parameter List

Parameter list

Setting Tion

F4 fourth frequency voltage

Minimum Factory Refer Cust Func Parameter Setting

Can be accessed when Pr =

PID

List of Parameters Classified by Purposes of Use

Function rewrite prevention

Parameter Function Details

Setting

Parameter Factory Setting Range Remarks

Torque boost Pr , Pr

Pr maximum frequency Pr minimum frequency

Use Pr to set the lower limit of the output frequency

120Hz To 120Hz

Base frequency, base frequency voltage Pr , Pr , Pr

8888

9999 To 120Hz Function invalid

Parameter Factory Setting Setting Range Remarks

Multi-speed operation Pr to Pr , Pr to Pr.27

60Hz To 120Hz 30Hz 10Hz 24 to 9999

Factory Setting Range Remarks

To 3600 s minimum setting increments 0.1 s

To 360 s minimum setting increments 0.01 s

Acceleration/deceleration time Pr , Pr , Pr , Pr , Pr , Pr

Acceleration

Electronic overcurrent protection Pr

Pr electronic thermal O/L relay

Decelerationtime s

Value Operated

DC injection brake Pr to Pr

Operated at

To 10 s

Starting frequency Pr

Pr starting frequency

5Hz To 60Hz

Load pattern selection Pr

Parameter Factory Setting Range

Output Characteristics

Pr load pattern selection

Pr jog frequency

Pr jog acceleration/deceleration timereference frequency

Jog operation Pr , Pr

Related parameters

MRS input selection Pr

Wiring example

Pr Setting Specifications of MRS Signal

Pr MRS input selection

To 120Hz 148

Parameter Number Factory Setting Setting Range Remarks

Stall prevention Pr , Pr , Pr , Pr , Pr , Pr

149

Not compensated

Multi-speed input compensation Pr

Pr multi-speed input compensation

Compensated

Acceleration/deceleration pattern Pr , Pr.140 to Pr.143

Function Description

Regenerative brake duty Pr.30

Setting When using the brake unit, power return converter

When using the high power factor converter FR-HC

Pr regenerative function selection

Frequency jump Pr to Pr

Pr.3335Hz Pr.3430Hz

Speed display Pr , Pr

Pr speed display Pr speed setting switch-over

Running Speed Parameter Setting Unit Pr Setting

144 4, 6, 8, 10 104, 106, 108

Up-to-frequency sensitivity Pr

Factory Setting Setting Range Setting Capacity

Automatic torque boost Pr , Pr

Pr up-to-frequency sensitivity

Output Signal

Output Signal

6Hz To 120Hz 9999 Same as Pr Setting

Output frequency detection Pr , Pr , Pr

120%

Pr Setting Operation

Second stall prevention Pr , Pr

Second stall prevention function is not activated

Parameter Number Factory Setting Setting Range

Set Pr to Pr and Pr in accordance with the following table

Set value 17, 24 monitor

Output frequency monitor

Output current monitor

100

Maximum output voltage of terminal AM is 10VDC

Setting Parameter

Monitoring reference Pr , Pr

To 120Hz Rated output

Frequency 162 Search No frequency 163

Parameter Factory Setting Remarks

9999 1 to No restart

164

Parameter Setting Description

To the load inertia moment, torque 165

Remote setting function selection Pr

Pr remote setting function selection

FrequencyOutput

Operation Mode Description Automatically Set

Intelligent mode selection Pr

Pr intelligent mode selection

Ordinary operation

Pr Ref. I for intelligent mode decel %

Setting Pr Reference I for intelligent mode

Pr Ref. I for intelligent mode accel

Setting Reference Current

Retry function Pr , Pr to Pr

Use Pr to select alarms to be reset for retry

Errors Reset for Retry Setting

P24

Use Pr to set the number of retries at alarm occurrence

Retry is not made

To 10 times Not output 101 to Output

Applied motor Pr

Pr applied motor

Motor

PWM carrier frequency Pr , Pr

Pr PWM frequency selection Pr Soft-PWM setting

Parameter Factory Setting Description

Refer to the following list and set the parameters

Related parameters

Voltage input Pr

Pr 0-5V/0-10V selection

To 5, 10 to

Reset Selection PU Disconnection Detection

Input filter time constant Pr

Pr filter time constant

Key from the PU during

Alarm code output

Alarm code output selection Pr

Pr alarm code output selection

Pr Setting Output Terminals

Pr parameter write disable selection

Parameter write inhibit selection Pr

Parameter Name

Reverse rotation prevention selection Pr

Pr reverse rotation prevention selection

External signal input terminal STF, STR

Operation mode selection Pr

Pr operation mode selection

To 4, 6 to

Switch-over mode

PU operation interlock

X12 MRS Function/Operation

Operating Condition

Operation mode external signal switching function

X16 Signal Operation Mode

X12 MRS

Confirm the settings of Pr , Pr and Pr

38 V/F control frequency voltage Pr to Pr

Parameter Number

Computer link operation Pr to Pr

117 118 192 119 Data length 120 121 To 10 122 9999

Parameter Factory Setting Range Number

Parameter Description Setting

123 9999 To 150ms 124

Required after no data error ACK. Refer to

Computer programming Communication protocol

Data format

Send data from computer to inverter during data read

Data definitions

Reply data from inverter to computer during data read

Control codes

Number of Bits

Response time

= Data sending time s

Stop bit length Bit Bits Data length Parity check

Instruction Data

H7F

HFF

Instructions for the program

Return

Setting items and set data

Instruction

H6E

HFA

H7A

H6D

H6C

Error Code List

Error Definition Inverter Operation

HEC

Communication error

Communication specifications for RS-485 communication

Operation at alarm occurrence

Operation Mode Operation Location

Pr = 10

Setting Basic PID control configuration

PID control Pr to Pr

Pr = 20

PID action overview

Deviation

Sink logic

Pr =

Reverse action Forward action

Function Description Remarks

O signals

Signal

Entry Description

Gain K = 1/proportional band 9999

Parameter setting

Adjustment procedure

132

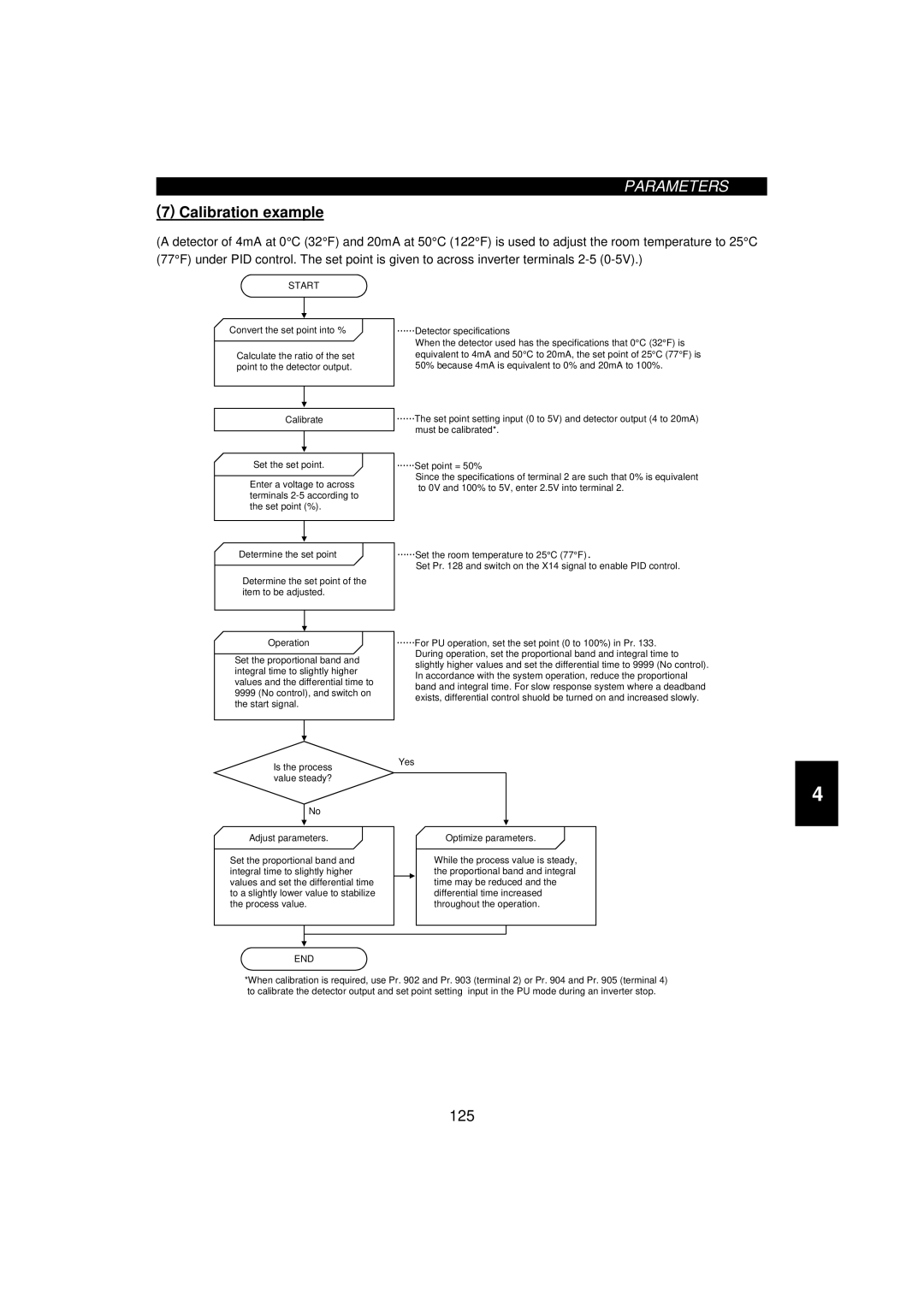

Calibration example

Start

Set point input calibration

Detector output calibration

135 136

137

138 139 9999 To 60.0Hz No automatic

Sink logic, Pr = 7, Pr = 6, Pr = 17, Pr = 18, Pr =

NFB MC1

Signal Terminal Used Description

Signals

Magnetic Place of Installation Role

Roles of the magnetic contactors MC1, MC2, MC3

Operation sequence

Parameter Name Setting Description

Commercial power To 60.0Hz 139

Sets the MC2 and MC3 operation interlock time

Signal on-off after parameter setting

Operation procedure

Operation procedure for running Operation pattern

OFF OFF →

Pr to Pr % Refer to Pr Pr , Pr % Refer to Pr

Zero current detection period

Zero current detection Pr , Pr

Zero current detection level

Related parameters Pr to Pr

Stall prevention function and current limit function Pr

RT signal activated condition selection Pr

Pr RT signal activated condition

Pr stall prevention operation selection

100 Driving

#...Operation not #...Not activated Acceleration

Deceleration

101 Driving

157 To 25 s No signal output

OL signal output timer Pr

Pr OL signal waiting time

Related parameters Pr RUN terminal function selection

160 9999 10, 11 173 174

User group selection Pr , Pr to Pr

Examples of use

Batch deletion

Input terminal function selection Pr to Pr

184 Current input selection AU For the NA and EC 185

Jog operation selection JOG

Setting Signal Functions Relevant Parameters

Output terminal function selection Pr to Pr

Refer to the following table and set the parameters

FAN

Commercial power supply Inverter switch-over MC1

Commercial power supply Inverter switch-over MC3 125

Sleep

Setting example

User initial value setting Pr

Pr users initial value setting

199

Cooling fan operation selection Pr

Output phase failure protection selection Pr

Pr output phase failure protection selection

Pr cooling fan operation selection

50%

Override bias/gain Pr , Pr

Pr override bias Pr override gain

150%

Advanced PID control Pr to Pr NA, EC versions only

Pr =0

Pr motor switch-over selection = 0 Basic Method

Pr motor switch-over selection = 1 Alternative Method

Pr =1

Pr motor switch-over selection = 2 Direct Method

System configuration

Pr motor switch-over selection = 0 Basic Method Example

DC24V

Parameter Number Name Additional Setting Description

Signal name Function

Parameter Number Name

Motor switch-over timing

Start Stop

Start

Name Setting Range

Output stop detection

Stopstart

Status transition chart

M1 operation

Sleep

Commercial power

EC version 50Hz

Supply operation

Calibration of terminal FM

Meter frequency meter calibration Pr , Pr

Pr FM terminal calibration Pr AM terminal calibration

Calibration of terminal AM

Operation procedure

When operation panel FR-DU04 is used

904 4mA 0Hz To 20mA To 60Hz 905

Frequency setting voltage current bias and gain Pr to Pr

902 0Hz To 60Hz 903

To 20mA To 120Hz

Power-on monitoring mode

Mode

Mode

#Parameter setting mode

#Setting change

Least significant

# Analog voltage A/D value % Across terminals

To 90 to Current setting of gain frequency

Press to change the set frequency Press for 1.5 s

⋅ 9 times

Once to display the current For 0V 0mA, 100% for

Analog voltage calibration value 5V 10V, 20mA

#Press

Buzzer control Pr

Pr buzzer control

990 Without beep, 1 With beep

Protective Functions

Errors Alarms

Error alarm definitions

Major faults

Check for too slow acceleration

OC During Dec

OV During Acc

Decrease the acceleration time

Instantaneous power failure is within 15ms

Find the cause of instantaneous power failure occurrence

Remedy the instantaneous power failure

Output side ground fault overcurrent protection

Set the ambient temperature to within the specifications

Ground Fault

Check for a ground fault in the motor and connection cable

Check the communication cable for wire breakage

Option slot alarm 1 to

Check for a wrong option function setting and operation

Parameter storage device alarm

Fault

Find the cause of alarm occurrence

CPU Fault

CPU error

P24

Check for a short circuit in the PU connector cable

Output phase failure protection

Check for a short circuit in the PC terminal output

Minor fault

Key of the PU has been set in Pr PU

Reduce the load volume or the frequency of operation

PU stop Stop made by pressing

Stop selection

To know the operating status at the occurrence of an alarm

Correspondences between digital and actual characters

Actual Digital

Alarm code output

Resetting the inverter

Key to reset the inverter

Motor remains stopped

Troubleshooting

Speed greatly differs from the setting

Motor rotates in opposite direction

Motor current is large

Operation mode is not changed properly

Power lamp is not lit

Speed does not increase

Check items

Precautions for Maintenance and Inspection

Precautions for maintenance and inspection

Periodic inspection

Insulation resistance test using megger

Pressure test

Daily and Periodic Inspection

Inspection Description Periodic Method Crlterlon Instrument

Disconnect cables

Analog meter Converter Across terminals

Assumes the use of an analog meter

Checking method

Module device numbers and terminals to be checked

Tester Polarity Measured Value

Cooling fan

Replacement of parts

Part Name Standard Replacement Interval Description

Smoothing capacitor in main circuit

Inverter replacement

Smoothing capacitors

Relays

Measurement of main circuit voltages, currents and power

Measurement of voltages and currents

Typical Measuring Points and Instruments

5VDC

Measuring Points and Instruments

Measuring Point

10VDC

Specifications

Standard Specifications

Model specifications

Voltage, frequency Permissible AC

36.0

Common specifications

Setting To +10V, 11 bits/-5 to +5V

Collector output

Alarm

Outline drawings

Unit mm inches

# FR-F520-5.5K, 7.5K, 11K # FR-F540-5.5K, 7.5K, 11K

Unit mm inches

FR-F520-55K 480 410 460 700 675 250 154

Inverter Type FR-F520-37K 340 270 320 550 530 195 71.5

FR-F520-45K 450 380 430 550 525 250 154

W1 W2 H H1 FR-F540-30K,37K 340 270 320 550 195 71.5

Outline drawing Panel cutting dimension drawing

# Operation panel FR-DU04

Chapter Options

Option List

Stand-alone options

193

Inboard dedicated options

Name Type Function

Appendices

Data Codes

Appendix Data Code List

Multi-speed setting speed

Read

118 Communication speed

PID

Read Write

Func

Name Read

Auxiliary motor start delay frequency

Motor switch-over selection

Output stop cancel process value level

Auxiliary motor stop delay frequency

Manual number is given on the bottom left of the back cover

Print Data Manual Number Revision