Page

Page

Page

Preface

Page

Table of Contents

Parameters

Troubleshooting

Operation and Start Up

Appendix a Specifications Appendix B Accessories

Fault Code Information and Maintenance

Recommended Position the Rubber Magnet of the Digital Keypad

Appendix C How to Select the Right AC Motor Drive

Introduction

Nameplate Information

Receiving and Inspection

Model Explanation

VFD110VL23A

15HP/5.5-11kWFrame C 20-30HP/15-22kWFrame D

Series Number Explanation

Drive Frames and Appearances

VFD750VL43A

Please refer to .3 for exact dimensions

40-100HP/30-75kWFrame E

Communication Port Internal structure Removable fan

Drive Features

Operation

Preparation for Installation and Wiring Ambient Conditions

Storage

Transportation

15HP/5.5-11kWframe C & 20-30HP/15-22kWframe D

Remove Front Cover

Step

Lifting

40-100HP/30-75kW frame E

Fixed plate Fixed pl ate

Flange Mounting

Fixed plate

15HP/5.5-11kW frame C

Cutout Dimensions

20-30HP/15-22kW frame D

Frame C

Dimensions

Unit mm inch

Frame

Frame D VFD150VL23A/43A, VFD185VL23A/43A, VFD220VL23A/43A

Frame D

255.0 226.0 403.8 384.0 360.0 21.9 168.0 10.04 15.90 15.12

Frame E

This page intentionally left blank

Wiring

Installation and Wiring

Installation and Wiring

Sink NPN mode Source PNP mode

Used with internal power +24Vdc

Used with external power

Run

DC voltage Low voltage level Battery voltage

Valve

EPS detection MI-COM=43 Electromagnetic Valve Drive ready

Grouning terminals

Loops

External Wiring

Brak e res istor

Main Circuit Main Circuit Connection

Pti onal Non-fuse break er

Motor

Output terminals for main circuit U, V, W

Mains power terminals R/L1, S/L2, T/L3

Models

Models Wire Torque Wire Type

Main Circuit Terminals

Position of External Terminals

Torque Wire Type

Control Terminals

REV

OFF

MI1

MI2

Analog input terminals ACI, AUI1, AUI2, ACM

Digital outputs MO1, MO2, MCM

Frame Torque Wire

AWG 0.3-2.1mm2

Terminal 0V/24V Kgf-com1.4 in-lbf AWG 0.051-1.3mm2

Installation and Wiring

Operation Method

Operation and Start Up

RUN

STOP/RESET

KPVL-CC01

Trial Run

Basic parameter settings Motor tuning

Auto-tuning Operations Flow Chart

Explanations for the Auto-tuning Steps

Operation and Start Up

IM motor

Step

PM motor

Step

EMVL-PGABO/ABL

SIN/COS

EMVL-PGABL

EMVL-PGH01/02

Step

Operation and Start Up

Trial run

Operation and Start Up

Operation and Start Up

Operation and Start Up

Parameters

Group 0 System Parameters

Summary of Parameter Settings

Parameter can be set during operation

Focpg Tqcpg Focpm

Vfpg SVC Focpg Tqcpg Focpm

Group 1 Basic Parameters

Vfpg SVC Focpg Tqcpg

Group 2 Digital Input/Output Parameters

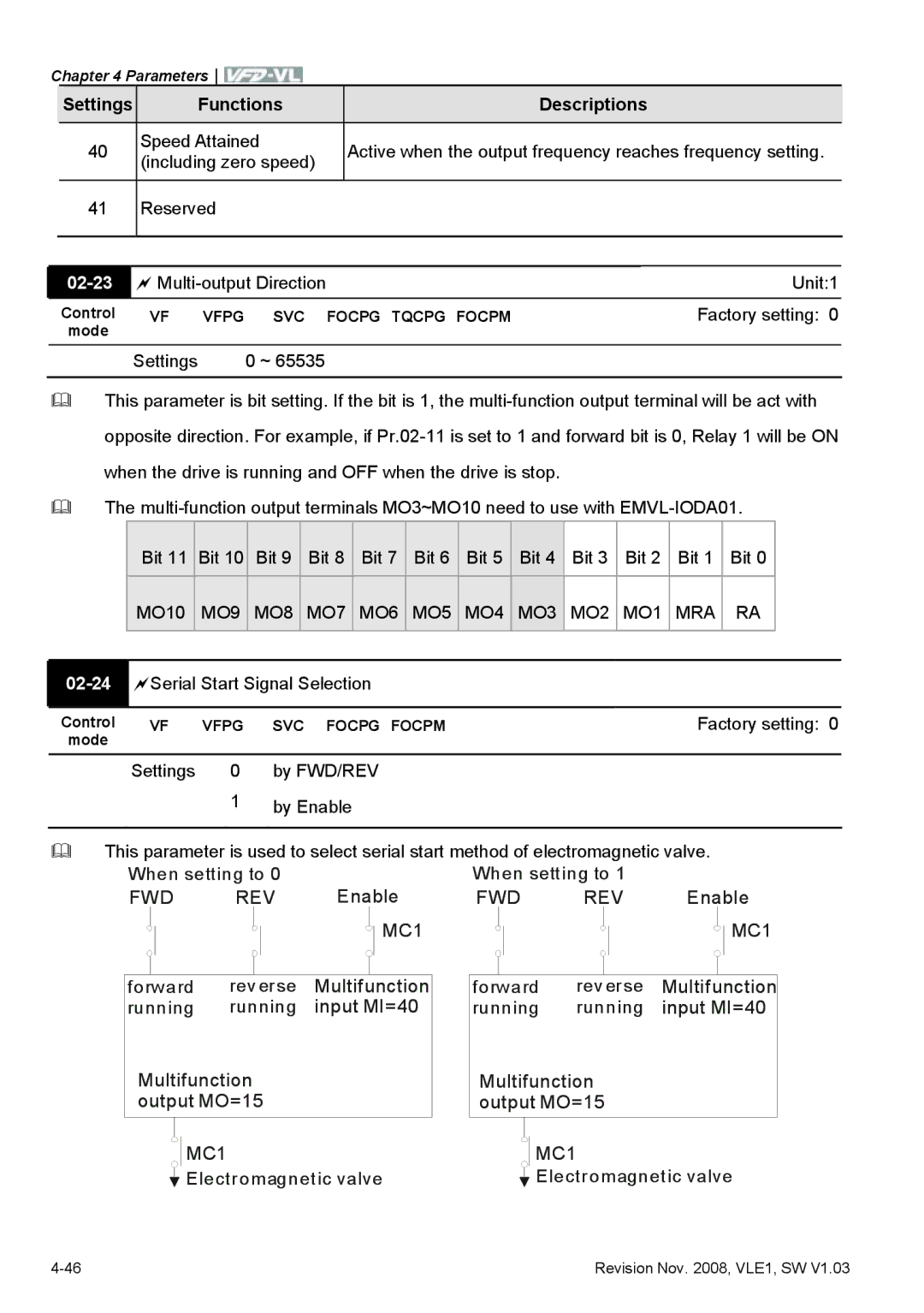

By FWD/REV By Enable 02-25

Group 3 Analog Input/Output Parameters

Explanation Settings

03-19

Group 4 Multi-Step Speed Parameters

Group 5 IM Motor Parameters

Group 6 Protection Parameters

~100.0%

Group 7 Special Parameters

Group 8 PM Motor Parameters

Group 9 Communication Parameters

SIN/COS

Group 10 Speed Feedback Control Parameters

Group 11 Advanced Parameters

Group 12 User-defined Parameters

Group 13 View User-defined Parameters

00-01

Description of Parameter Settings

00-00

Content of Multi-Function Display

Factory setting

Factory setting

00-02

SEEEEEEE0 0 HzEE

DOEON/ OFFESt a t

DI EON/ OFFESt a t

FFF

MI8 MI7 MI6 MI5 MI4 MI3 MI2 MI1 REV FWD

Settings Read Only Display #.##

Factory setting Read Only

00-05

User Defined Coefficient K

Password Set Unit

Password Input Unit

Settings To 9998 and 10000 to Display

00-07

00-09Control Method

Decoding Flow Chart

Pass word Setting

00-11

00-10

00-12

230V/460V Series

Source of the Operation Command

Source of the Master Frequency Command

00-14

00-15

01-03

01-01

01-02

01-05

01-04

01-06

01-07

01-10

01-09

Output Frequency Upper Limit Unit

01-11

01-14

01-12

01-16

01-18

01-22

Switch Frequency between 1st/4th Accel/decel Unit

JOG Frequency Unit

01-23

1st/4th Acceleration/Deceleration Switching

01-31

01-29

01-28

Parameters

02-00 Control Circuits of the External Terminal

02-00

02-01

02-03

02-02

02-04

02-05

Settings Functions Descriptions

Eeprom

By Pr.07-28 setting

02-09

MI8 MI7 MI6 MI5 MI4 MI3 MI2 MI1 REV

02-10

02-11

02-12

Settings Control Mode

Settings Functions Descriptions

Active when the warning is detected

Input MI=40

Enable

Multifunction output MO=15

02-23

02-26

02-25

02-27

02-28

02-32

02-31

2 7=S

02-35

02-33

02-34

03-02

03-00

03-01

03-03

Settings 100.0~100.0%

Analog Input Bias 1 AUI1 Unit

03-04

03-06

03-05

03-07

03-08

03-13

03-12

03-14

03-15

03-21

03-18

Analog Output Gain Unit

04-01

04-00

04-02

04-03

05-00

Pr 06 Pr Equivalent circuit for VFD -VL ser ie s

Settings 40 to 120%

Factory setting #.##

05-02

05-03

05-13

05-12

05-15

05-14

05-16

05-17

Core Loss Compensation Unit

Settings To 250%

05-20

06-02

06-00

06-01

06-04

06-03

06-06

06-05

06-07

06-08

Pr.06-09

Pr.06-06

Pr.06-07

06-10

Load

Operation time min

Fac tor %

60Hz

06-16 06-17 06-18 06-19 06-20 06-21

Readings No fault

Parameters

06-30

Setting Method of Fault Output

Bit Fault code

Bit Fault code

06-22

Fault code Bit0 Bit1 Bit2 Bit3 Bit4 Bit5 Bit6 Current Volt

06-23

06-24

Bit1 Bit2 Bit3 Bit4 Bit5 Bit6 Fault code Volt

Bit0 Bit1 Bit2 Bit3 Bit4 Bit5

Fault code Current Volt. OL

06-27

06-26

06-28

06-29

07-01

07-00

07-02

07-03

07-0

07-05

07-06

07-07

07-13

07-11

07-12

07-15

07-14

07-17

07-18

07-20

07-19

07-21

07-22

07-24

07-23

07-25

07-26

300% x 07-29=t

100%

00-01

07-28

Settings No function

08-00Motor Auto Tuning

08-02

Rated Power of Motor Unit

08-04

08-03

08-05

08-06

Parameters

09-00

RS-485 5 NC 6 NC

09-01

09-02

Code Description

Ascii mode

RTU mode

Data

STX

END

Start

5CH

FEH

A0H

F7H

Count by word 02H CRC CHK Low

6FH

AC drive Parameters Command Write only

Content

Address Function

GG means parameter group, nn means parameter number

Content Address Function

Exception

Ascii mode RTU mode

A1H

09-05

SIN/COS+

ABZ

Motor will run Motor won’t run 10-00=5

Settings Disable

Motor will run 10-00=6

10-01

10-04

10-03

10-05

10-06

10-11

10-08

10-09

10-12

10-19

10-18

10-20

10-21

10-24

10-22

10-23

Adjust by requirement

Setting auto gain adjustment Pr.11-00=1

11-00

System Control

11-02

11-01

11-03

11-04

11-06

11-05

11-07

11-08

11-12

11-10

11-11

11-15

11-13

11-14

SEEEEEE6 0 1 2 0 0 Prog

FREQ. Esetpoi NTn t

Umap ADD0 Eeeetee SEEEEE0 8 0 3 0 8 0 3 0

PMSMOTORUB- Emf ET SEEEEEE6 0 1 3 0 0 Prog

SEEEEEE6 0 1 2- 0 0 Prog

FREQ. Esetpoi NTn t SEEEEEE6 0 Hz EEE

EEE- EEn d . E- EEE Eeeeeeeeeeeeeeee

DI SPL AYEUSER- SET SEEEEEE6 0 1 3 0

Systemsparameter press SEEEEEE6 0 0 0 EE twice

FREQ. Esetpoi NTn t SEEEEEE6 0 Hz EEE Prog

Ma x Eo f s Fc md i n t ET SEEEEEE6 0 1 3 0

2127

13-00

Settings Refer to group 12 for details

View User-defined Parameters

13-31

Over Current OC

Troubleshooting

Over Voltage OV

Ground Fault

Ground fault

Low Voltage Lv

Suitable power

Overload

Over Heat OH

Yes

Phase Loss PHL

Display of KPVL-CC01 is Abnormal

Motor cannot Run

Motor Speed cannot be Changed

Motor does not Run as Expected

Motor Stalls during Acceleration

Environmental Condition

Electromagnetic/Induction Noise

Affecting Other Machines

Fault Code Information

Fault Code Information and Maintenance

EEE Fault Co d e 0 E

Common Problems and Solutions

Ea t EAc c e l Eeeee

EEE F a u l t code 0 E3

Motor drive protection, not for protection of the user

EEE Fault Co d e 0 9 E

Display Description Ground fault Corrective Actions

Ea t ES t o p Eeeeee

EEE Fault code 1 E

Eeef a u l t code 2 2 E

EEE Fault code 2 E0

EEE Fault code 3 2 E

EEE Fault code 3 0 E

EEE Fault code 3 E

EEE Fault code 2 E7

EEE Fault Co d e 4 E

FEEEFault code 3 E9

EEE Fault code 4 E

EHWEEr r o r Eeeee

PC EE r r ECo mma n d EE

EEE Fault Co d e 5 E

EEE Fa u l t code 5 E

EEEFa u l t code 5 E6

Eeef a u l t code 6 3 E

Reset

EEE Fault code 5 E

Fault Code Information and Maintenance

Voltage Maintenance Check Items Methods and Criterion

Maintenance and Inspections

Keypad Maintenance Check Items Methods and Criterion

One

Change of copper plate

Main circuit Maintenance Check Items Methods and Criterion

Visual, aural inspection and smell Or peculiar smell

Year

Change fan Overheat

Daily

Daily

This page intentionally left blank

Appendix a Specifications

Per torque 100% Accel up 140% Cruise 80% Decel up Post

General Specifications

This page intentionally left blank

Appendix B Accessories

Decrease accordingly. Recommended cycle time is one minute

All Brake Resistors & Brake Units Used in AC Motor Drives

Appendix B Accessories

Dimensions are in millimeter

Dimensions and Weights for Brake Resistors

Order P/N BR500W030, BR500W100, BR1K0W020, BR1K0W075

Specifications for Brake Unit

189.5 200.0

Dimensions for Brake Unit

121.0 80.0 130.0

VFDB4132

Fuse Specification Chart

Non-fuse Circuit Breaker Chart

Phase Model

Model Recommended Input Current a

142 145 250

110 120 225

130 110 250

160 150 300

AC Output Reactor Recommended Value

AC Reactor AC Input Reactor Recommended Value

Impedance

37.5 52.5 18.5 67.5 82.5 120 100 150 130 195

37.5 52.5 18.5 67.5 120 100 150 130 195 160 240

Applications for AC Reactor

M1 reactor

Correct wiring

AC motor drive

AC motor drive Motor

Silicon rectifier Powerreactor AC motor drive Reactor Motor

Diagram a

Zero Phase Reactor RF220X00A

Diagram B

Nominal Method

460Vac 18.5 Built-in 50/60Hz Phase 110 125 200 100 240

230Vac Built-in 50/60Hz 18.5 110 Phase 125 460V DC Choke

DC Choke Recommended Values

230V DC Choke

Description of the Digital Keypad KPVL-CC01

Digital Keypad KPVL-CC01

=Sto p

=Ru n

Paramecopyeeeeee SEEESAVEE1 Ev 1

Paramecopyeeeeee SEEEREADE1 Eeeeee

Syst Emeparameter S0 EEEEEEEE0 0 EE

EEE- EEr r . E- EEE

To set parameters

How to Operate the Digital Keypad KPVL-CC01

Enter parameter settings

When Read 1 starts blinking, it starts to save to KPVL-CC01

From drive to KPVL-CC01

Press and hold on for about 5 seconds

Recommended Position the Rubber Magnet of the Digital Keypad

Dimension of the Digital Keypad

Specifications

Terminal Symbols

PG Card for Encoder

V, V, W, W

Line driver

Encoder

Division Factor

10 11

A/O B/O

A/O

B/O

Power source of encoder

Terminal Symbols Descriptions

Power source common for

TB1

Open collector

A/O, B/O, B/O Z/O

Leads B Leads a A/O B/O

Sinusoidal Encoder Function

EMVL-PGH01 only for Heidenhain ERN1387

SIN COS COS 900mech

+5V Vdc

900el

+ Z

Terminal Symbols Descriptions Specifications

SIN, SIN’

COS, COS’

Leads B Leads a

Division factor

+COS

EMVL-PGS01

Refcos

+SIN

+ +CO S

Encoder

+ +S

Data+

OA-GND

OA-GND OB-GND

Appendix B Accessories

AC Drives Model Number FootPrint

AMD-EMI Filter Cross Reference

50TDS4W4C VFD185VL43A

„ EN61000-6-4 „ EN61800-3 „ EN55011 1991 Class a Group

Length of motor cable

Saddle on both ends Saddle on one end

230VAC input voltage

Dimensions are in millimeter and inch

Order P/N RF110B43CA

Order P/N 50TDS4W4C Order P/N 100TDS84C

Order P/N 200TDDS84C

Order P/N 150TDS84C Order P/N 180TDS84C

AVO1-AGND AVO2-AGND

Max +24V/5mA MO3~MO10 Internal circuit MCM

AVO1 Agnd MO10 MO9 MO8

MCM MO7 MO6 MO5 MO 4 MO3

Relay contact Connect to J P19 On the c ontrol board

Safety Relay EMVL-SAF01 Functions of the Terminals

Wiring of the Safety Relay

Descriptions

This page intentionally left blank

Speed Time Overload Starting Torque Ratings

Related Specification

When one AC motor drive operates more than one motor

When one AC motor drive operates one motor

Capacity Formulas

„ Acceleration time ≧60 seconds Starting capacity=

⋅ IM ≤ the rated current of AC motor drive a

Selection Note

General Precaution

Parameter Settings Note

Standard motor

How to Choose a Suitable Motor

Torque% 25% 40% 60% 100 Continuous Frequency Hz

Pole-changing Dahlander motor

Special motors

Motor torque

Power Transmission Mechanism

This page intentionally left blank

![]() Electromagnetic valve

Electromagnetic valve![]() Electromagnetic valve

Electromagnetic valve