Chapter 9 MXYX

1-5 Installation methods (Gantry type support axis)

The MXYX and HXYX gantry types have a guide rail for support on the Y-axis end so that heavy loads can be handled. When installing, take care to the parallel- ism of the X-axis and guide rail and to the difference in height from the installa- tion surface.

If the distance between the X-axis and guide rail is within ±5mm, it can be changed or adjusted. The procedures are given below.

!CAUTION

Move the X-axis as much as possible, and tighten the bolts where the move- ment is the lightest.

Set the X-axis and guide rail parallelism during installation. Make sure that there is no difference in the height direction of the X-axis and guide rail installa- tion surface.

1)Fix the robot onto the specified position of the installation base with bolts. Do not tighten the guide rail bolt at this time. Securely fix the X-axis section onto the installation base.

2)When the ZR-axis is provided, or if tools are already attached, move as close to the X-axis side as possible so that a load is not applied on the guide rail.

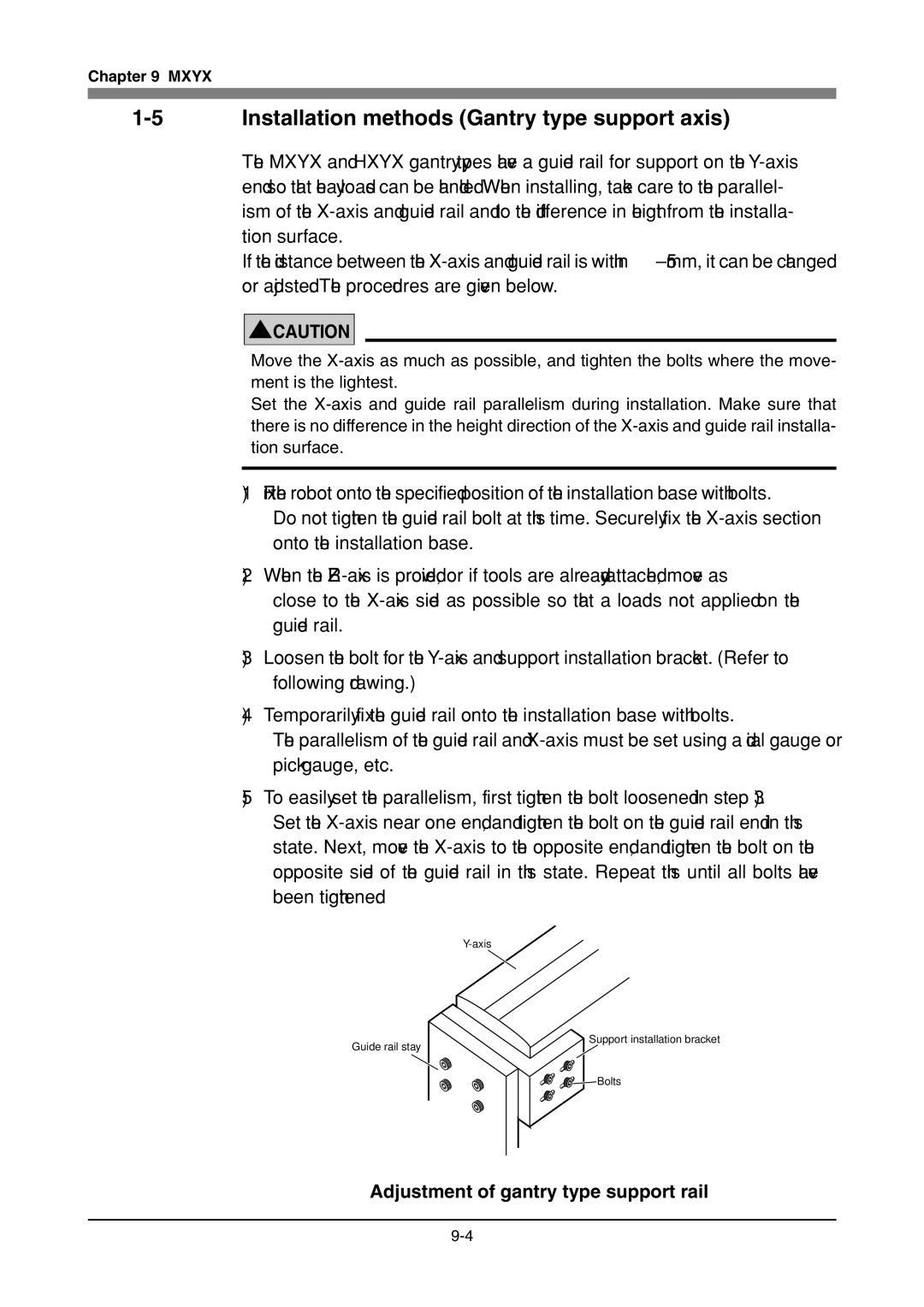

3)Loosen the bolt for the Y-axis and support installation bracket. (Refer to following drawing.)

4)Temporarily fix the guide rail onto the installation base with bolts.

The parallelism of the guide rail and X-axis must be set using a dial gauge or pick gauge, etc.

5)To easily set the parallelism, first tighten the bolt loosened in step 3). Set the X-axis near one end, and tighten the bolt on the guide rail end in this state. Next, move the X-axis to the opposite end, and tighten the bolt on the opposite side of the guide rail in this state. Repeat this until all bolts have been tightened.

Y-axis