Chapter 11 FXYBX/SXYBX

7)If the value measured in step 4) is smaller than the value given in Table

8)Measure the belt tension again with the procedure given in step 4).

If the measured value is within the range shown in Table

9)Tighten the M4 bolt q with the specified tightening torque.

Specified torque | 4.5N.m (46kgf.cm) |

10) Return the cover to the original position.

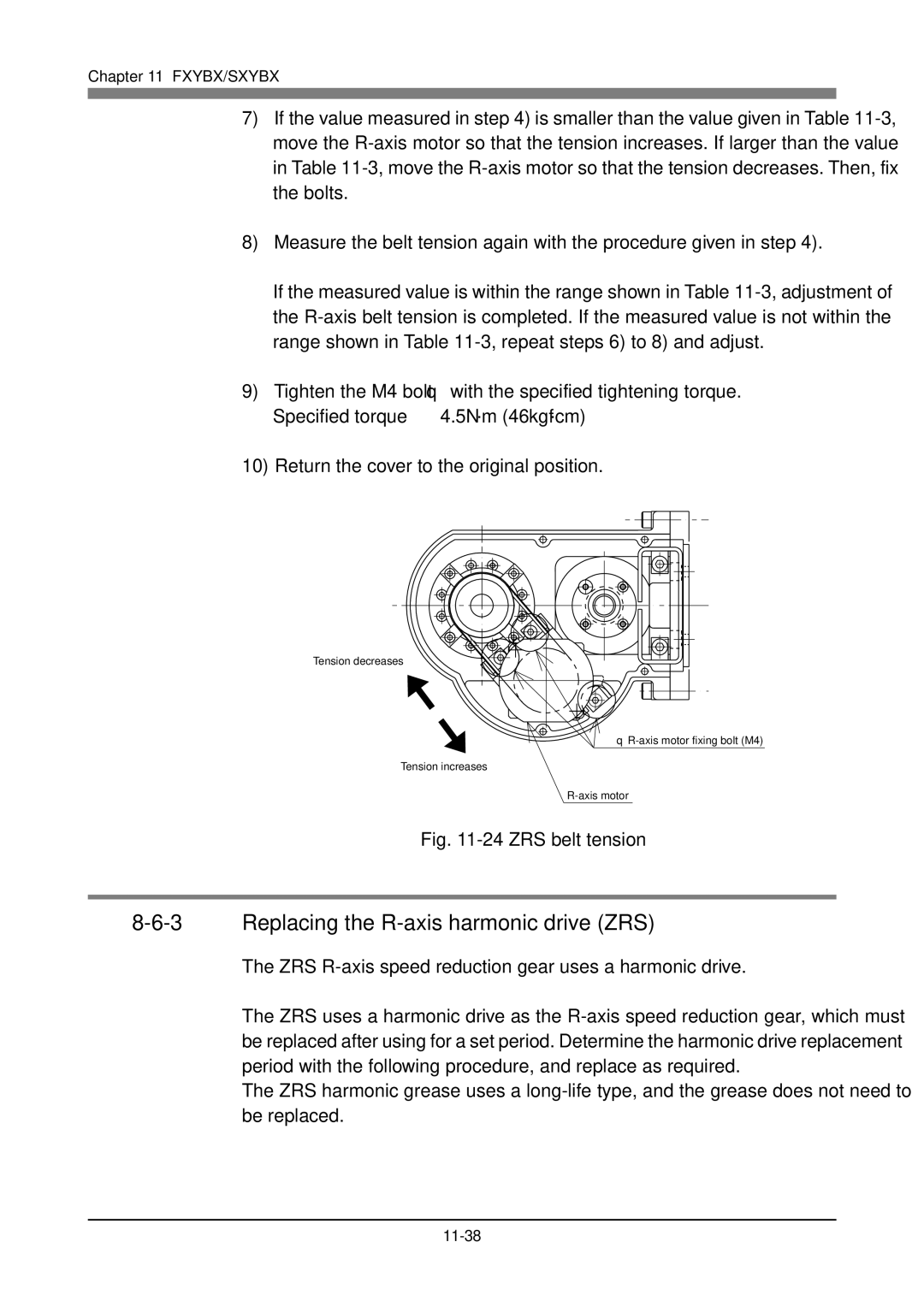

Tension decreases

Tension increases

Fig. 11-24 ZRS belt tension

8-6-3 Replacing the R-axis harmonic drive (ZRS)

The ZRS

The ZRS uses a harmonic drive as the

The ZRS harmonic grease uses a