Chapter 10 HXYX

1-1-3 Tightening torque

• The accurate tightening torque will differ according to the seating face fric- tional coefficient and the female screw material, etc. The following tightening torque is recommended as a guide.

Recommended torque | 22.5N.m to 36.3N.m (230kgf.cm to 370kgf.cm) |

1-1-4 Installation methods

![]() WARNING

WARNING

Always use the designated bolt, and securely tighten it with the correct torque. Failure to observe this could cause the robot position to deviate, and could also lead to serious accidents.

1)Tap M8 coares screw thread holes into the installation base where the robot is to be installed.

Refer to the

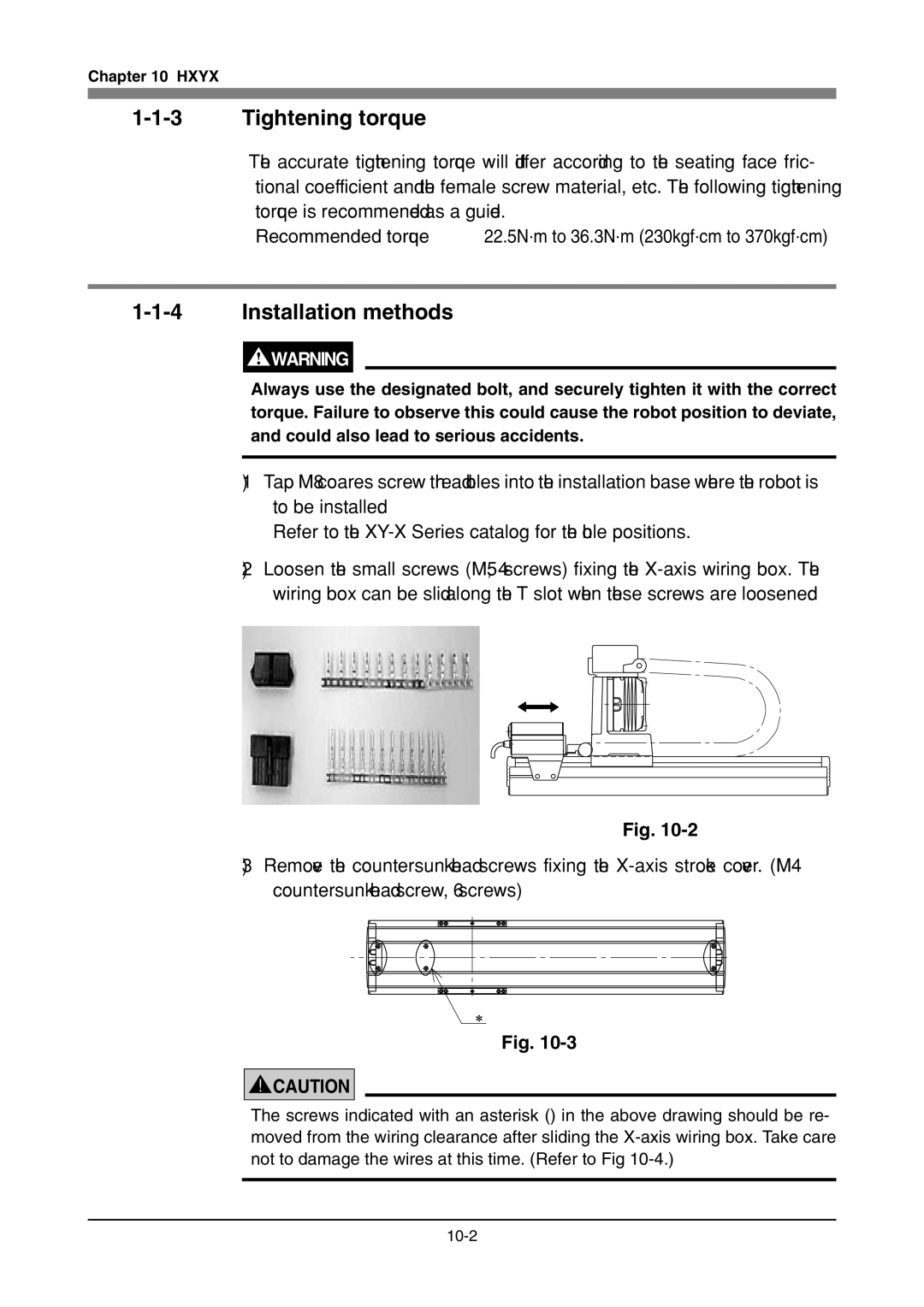

2)Loosen the small screws (M5, 4 screws) fixing the

Fig.

3)Remove the countersunk head screws fixing the

Fig.

!CAUTION

The screws indicated with an asterisk (*) in the above drawing should be re- moved from the wiring clearance after sliding the