Dc drives

Converter software version

Contents

Faults and Alarms

Start-up

Abbreviated Parameter List

Simplified Block Diagrams

Definitions

Qualified Personnel

Operating Instructions

Siemens Energy & Automation

Electro-statically sensitive devices

Siemens Energy & Automation

General Information

Base Drive Panel Description

Rated DC Current

Card Rack Assembly

Horsepower Amps DC Catalog No 240V DC 500V DC

Base Drive Panel Catalog Numbers

US Rating Quad Type

Spare Parts

Service

Technical Assistance

800-333-PIC1

Option Part Numbers

Options Order No

EB1, EB2, SBP and SLB boards

Spare Parts

Description Where Used Part Recom

Printed Circuit Boards

Cables

Fans/Blowers

Description Where Used Part Number Recom

Armature Converter Thyristor Modules, for 4-Quad Drives

Field Converter Thyristor Modules

Field Converter Diode Modules

Armature Converter DC Fuses, 4-Quad Only, 4PFU

Power Fuses Armature Converter AC Line Fuses, 1PFU 3 PFU

Control Transformer Primary Fuses 1CFU, 2CFU

Field Converter AC Line Fuses 1 & 2FSFU

Control Transformer Secondary Fuse 3CFU

Description

Main Contactor M

Control Transformer 1CTR, 2CTR, 3CTR

Contactor Coil Suppressor 1SP, Ensp

Auxiliary Relay, EN, and Rectifier Bridge, Mrec

Siemens Energy & Automation, Inc. Seller

Standard Terms and Conditions of Sale

Operating Instructions

Siemens Energy & Automation

Receiving, unpacking

Procedure for Shipping Damage

Siemens Energy & Automation

100

15ADC to 100ADC Base Drive Panels, 3AC 460V, 1 & 4Q

140 210 255 430 510 850

140ADC to 850ADC Base Drive Panels, 3AC 460V, 1 & 4Q

1180 1660 1680

Ambient temperature Reduction in base drive dc ampere rating

Applicable standards

Siemens Energy & Automation

Installation Information

Installation and Dimensions

Dimensions are mm inches

Base Drive Panel Outlines

15 30 AMP Base Drive PANELS, 1 & 4Q

AMP Base Drive PANEL, 1 & 4Q

Terminals 80 Power Terminals

L1 L2 L3 A1 A2

1120 44.1 1100 43.3

AMP Base Drive PANEL, 1 & 4Q

AMP Base Drive PANEL, 1 & 4Q

280 11.0 1200 47.2

740 29.1

965 38.0

AMP Base Drive PANEL, 1 & 4Q

965 38.0

Siemens Energy & Automation

Base Drive Panel Connections

Base Drive PANEL, 15 AMPS, 1 & 4 Quad

Base Drive Panel Schematics

Base Drive PANEL, 30 AMPS, 1 & 4 Quad

Base Drive PANEL, 60 AMPS, 1 & 4 Quad

Base Drive PANEL, 100 AMPS, 1 & 4 Quad

INCH- LBS

Base Drive PANEL, 140 AMPS, 1 & 4 Quad

Base Drive PANEL, 210 AMPS, 1 & 4 Quad

Base Drive PANEL, 255 AMPS, 1 & 4 Quad

1CTR

Base Drive PANEL, 430 AMPS, 1 & 4 Quad

Base Drive PANEL, 510 AMPS, 1 & 4 Quad

Base Drive PANEL, 850 AMPS, 1 & 4 Quad

3CTR

Base Drive PANEL, 1180 AMPS, 1 & 4 Quad

2CTR 3CTR

Base Drive PANEL, 1660 AMPS, 1 & 4 Quad

Catalog no RA7096-4GV62-0Z+X01, 4-QUAD

Base Drive PANEL, 1680 AMPS, 1 & 4 Quad

Operating Instructions

CUD

Control Connections CUD1

Terminal Locations CUD1

Optional CUD2 Control Connections

Control Connections CUD2

Terminal Locations CUD2

Base Drive Panel Power Connections 15 to 100 Amp

Description of Power/Control Terminals

Base Drive Panel Power Connections 430 to 1680 Amp

Function Terminal Connection values/Remarks Possible

Motor Armature circuit

Internally connected to incoming 460 VAC, 3 Phase

Siemens Energy & Automation

Start-Up

General safety information for start-up

Simple operator control panel PMU Parameterization Unit

Operator control panels

LED displays

User-friendly operator control panel OP1S

Parameterization procedure

Parameter types

Parameterization on simple operator control panel

Operating Instructions

Typical Connection Diagrams

PMU

A1+ A2- 80+

Speed

Execution of the default function

Reset to factory default values and adjust offsets

Panels

Start-up procedure

Adjustment of converter rated currents

Access authorization

Adjustment to actual converter supply voltage

Input of motor data

Operation with pulse encoder

Freely wired actual value

Pulse encoder type Normal selection

Operation without tachometer EMF control

Selection of basic technological functions

Field data

Execution of optimization runs

Siemens Energy & Automation

Operating Instructions

Setting Application Functions

Checking and possible fine adjustment of maximum speed

Source of Start Command P654 =

Starting the Drive

Source of Speed Setpoint P433 =

Speed Setpoint Selection

Jog Inching Configuration

Source of Jog Command P435 = Value

Source of Jog Setpoint P436 = Value

Documentation of setting values

Siemens Energy & Automation

Fault messages

General information about faults

On the OP1S

Further information about the causes of fault messages

List of fault messages

2.1 Supply faults

F001 Failure of electronics power supply

P078.001 ∗ 100%P353

Fault Description

F007 Overvoltage

F006 Undervoltage

Parameter P363

Interface error

F011 Telegram failure at GSST1

USS telegram failure at G-SST1

USS telegram failure at G-SST2

F012 Telegram failure at GSST2

Peer-to-peer telegram failure at G-SST2

F013 Telegram failure at GSST3

F016 Hardware fault on expansion board EB1

External faults

F017 Hardware fault on expansion board EB2

F015 Telegram failure on one Simolink board

F021 External fault

Fault messages from motor sensors

F022 External fault

F023 Fault message from free function block FB2

F029 Motor overtemperature active in all operating states

Drive faults

P493=2 or 3 temperature sensor at terminals 22 / 23 or

P494=2 or 3 temperature sensor at terminals 204

F034 Fault message from free function block FB5

F035 Drive is blocked

F038 Overspeed

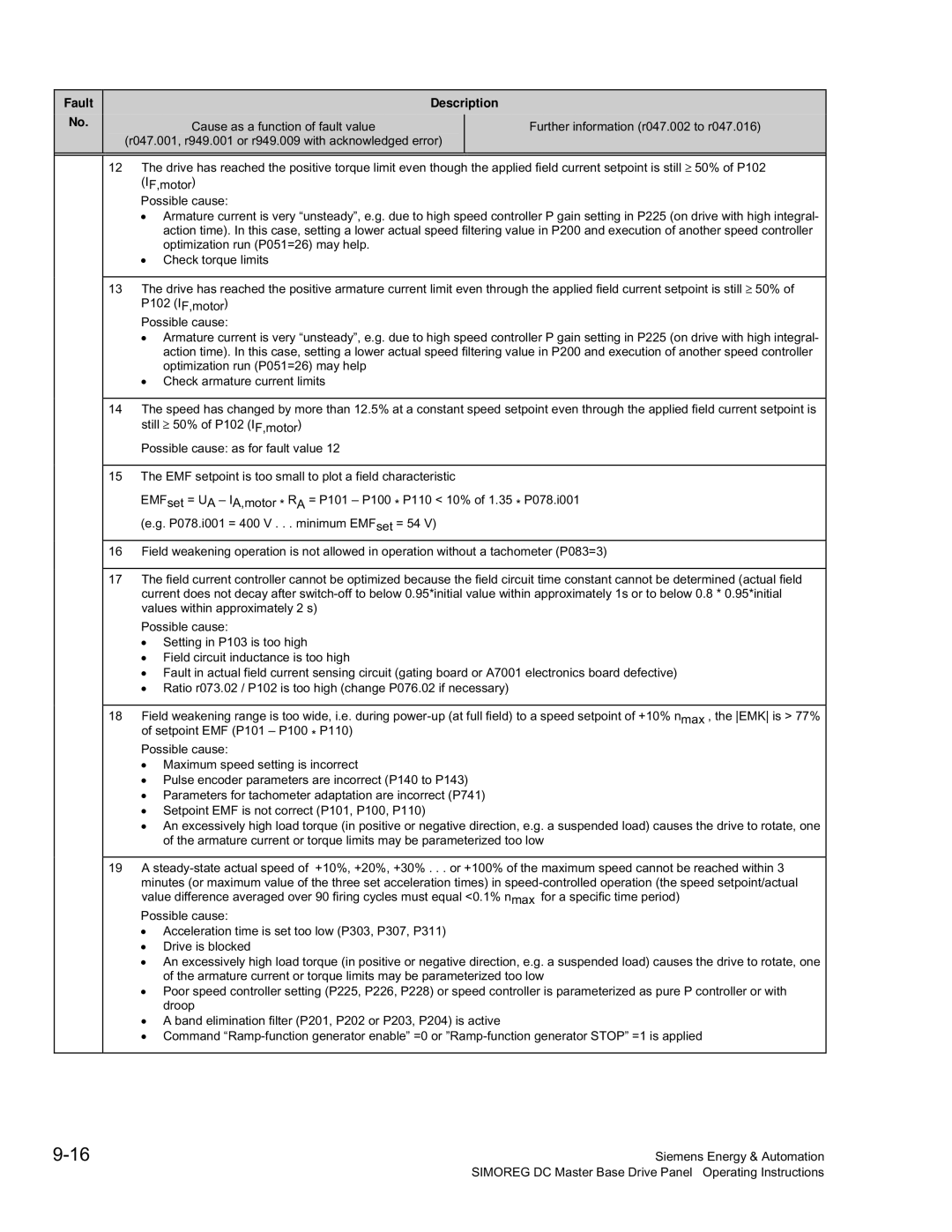

Cause as a function of fault value

F042 Tachometer fault

Fault Description

F050

Start-up faults

Fault Description

Fault Description

Fault Description

Fault Description

V2.1 and later

F051 No optimization run when permanent memory is disabled

F056 Important parameter is not set

F058 Parameter settings are not consistent

Operating Instructions

Hardware faults

Internal faults

Number of faulty parameter

R047 Index 002 to

F064 Watchdog timer has initiated a reset

Fault

F067 Converter cooling faulty

F063

F069 Mlfb data are faulty active in all operating states

Communication errors with supplementary boards

F081 CB/TB heartbeat error

F080 Error in initialization of a CB/TB board

F082 CB/TB message timeout or error in data exchange

F078

F101 to F147

Fault messages from supplementary boards

Alarm messages

A028 Motor overtemperature active in all operating states

Alarm Description A025 Brush length too short

A029 Motor overtemperature active in all operating states

A026 Poor bearing condition active in all operating states

A039 I2t value of power section too high

A034 Alarm message from free function block FB9

A047 Analog select input 1 terminals 6 and 7 faulty

A035 Drive blocked

A053 Alarm message from free function block FB258

Alarm Description A049 SCB1 No SCI slave connected

A054 Alarm message from free function block FB259

A067 Converter cooling faulty

Siemens Energy & Automation

Overview

10-1

Simoreg DC Master Base Drive Panel Operating Instructions

Range of parameter numbers Function

10-2

P899 Parameters for DriveMonitor and OP1S

R999

Overview of abbreviations

10-3

S00

10-4

10-5

Operating status display

10-6

10-7

General visualization parameters

10-8

10-9

10-10

10-11

Access authorization levels

10-12

10-13

Definition of Simoreg DC Master converter

R065 Software identifiers

10-14

P067 Load class

R068 Options according to rating plate

10-15

P077 Total thermal reduction factor

10-16

Temp = k1

P078 Reduction of converter rated supply voltage

10-17

Setting values for converter control

P080 Control word for brake control

P081 EMF-dependent field weakening

External field power module 40.00A field

Internal field power module

10-18

No field

10-19

P085 Wait period after cancellation of inching command

P086 Voltage failure period for automatic restart

P087 Brake release time

10-20

P090 Stabilization time for line voltage

P091 Setpoint threshold

P094 Switch-off delay for auxiliaries

P093 Pick-up delay for line contactor

10-21

P095 Pick-up time for a contactor in the DC circuit

10-22

Definition of motor

10-23

10-24

Magnetization characteristic field characteristic

10-25

10-26

Example of a field characteristic

10-27

10-28

P142 Matching to pulse encoder signal voltage

Single/multiple evaluation of encoder pulses

P140 Selection of pulse encoder type

P144 Multiple evaluation of encoder signals

10-29

Rev/min FS=500.0 P051 G145 1rev/min Type O4 Online 100%

10-30

10-31

10-32

Current limitation, torque limitation

10-33

Auto-reversing stage, armature gating unit

Speed controller

10-34

10-35

10-36

Closed-loop field current control, field gating unit

10-37

10-38

Closed-loop EMF control

Ramp-function generator

P295 Mode for rounding the ramp-function generator

10-39

P296 Ramp-down time of ramp generator with quick stop OFF3

10-40

10-41

Setpoint processing

10-42

Setting values for monitoring functions and limits

10-43

Setting values for limit-value monitors

10-44

10-45

Settable fixed values

10-46

Fixed control bits

10-47

10-48

Position sensing with pulse encoder

Connector selector switches

Motorized potentiometer

10-49

10-50

Oscillation

Definition of Motor interface

10-51

P496 Bearing condition Tripping of alarm or fault message

Tripping of alarm or fault message

P497 Air flow Tripping of alarm or fault message

P498 Temperature switch Tripping of alarm or fault message

Configuring of torque shell input

Speed limiting controller

10-53

10-54

Friction compensation

10-55

Compensation of moment of inertia dv/dt injection

Speed controller adaptation

10-56

P550 Gain in the adaptation range

P551 Integration time in the adaptation range

10-57

Input quantities for signals

Field reversal

10-58

10-59

Configuring of closed-loop control

Speed limiting controller . Both values are added

10-60

P602 Source for armature current controller actual value

Actual value

P605 Source for variable positive torque limit

10-61

P606 Source for variable negative torque limit

P607 Source for torque setpoint for master drive

10-62

10-63

10-64

10-65

10-66

10-67

Control word, status word

10-68

10-69

10-70

Further configuring measures

P690 Source for control word 2, bit30

P691 Source for control word 2, Bit31

10-71

P713 Mode of signal injection at Analog selectable input

P707 Resolution of Main setpoint analog input

10-72

P711 Normalization of Analog selectable input

10-73

10-74

10-75

Analog outputs

10-76

10-77

Binary outputs

10-78

Configuration of serial interfaces on basic converter

R789 Diagnostic information for G-SST1

See Change Access / Status P786 USS bus address for G-SST1

10-79

P787 Telegram failure time for G-SST1

P792 Length of parameter jobs for G-SST2

10-80

P793 Baud rate for G-SST2

Ind None P052 = Baud FS=6 P051 = G171 Type O2 Offline G173

10-81

See Change Access / Status P795 Options for G-SST2

P796 USS bus address for G-SST2

P797 Telegram failure time for G-SST2

Violation of telegram residual transfer time USS prot. only

10-82

P801 Number of process data for G-SST3

P802 Length of parameter jobs for G-SST3

10-83

See Change Access / Status P803 Baud rate for G-SST3

P804 Source for transmit data for G-SST3

P805 Options for G-SST3

R809 Diagnostic information for G-SST3

10-84

P808

10-85

See Change Access / Status R810 Receive data on G-SST1

R811 Transmit data on G-SST1

R812 Receive data on G-SST2

R815 Transmit data on G-SST3

10-86

Deactivation of monitoring functions

Compensation values

10-87

Parameters for DriveMonitor and OP1S

Thyristor diagnosis

Profile parameters

10-88

R947 Fault memory

Fault memory

R949 Fault value

R951 Fault text P952 Number of faults

10-90

Visualization parameters Alarms

Device identification

Visualization parameters Control and status word

10-91

R981 List of existing parameter numbers, continuation

R980 List of existing parameter numbers, start

R982 List of existing parameter numbers, continuation

R983 List of existing parameter numbers, continuation

10-93

10-94

Basic functions

Simplified block diagrams

Siemens Energy

Sheet 1 Legend

Setpoint System

Sheet 2 Speed

Controller and Current Limit

Sheet 3 Speed

Control

Sheet 4 Armature Current

Sheet 5 EMF and Field Current Control

11-6

Sheet 6 USS

USS interface

Interface 1

Sheet 7 USS

Interface 2

X172

Peer-to-peer interface

Sheet 8 Peer to Peer Interface

Exchange CB / TB to Base PZD

Sheet 9 Data

Sheet

Word

Control word

Sheet 11 Control

11-12

Status word

Status Word

Meaning

11-14

Signals

Signals

Sheet

Sheet 15 Miscellaneous

11-16

Siemens Energy & Automation, Inc