New High-performance inverter

Limits in purpose

Safety precautions

General Operation

Transportation & installation

Reference

Wiring

Operations

When retry function is selected

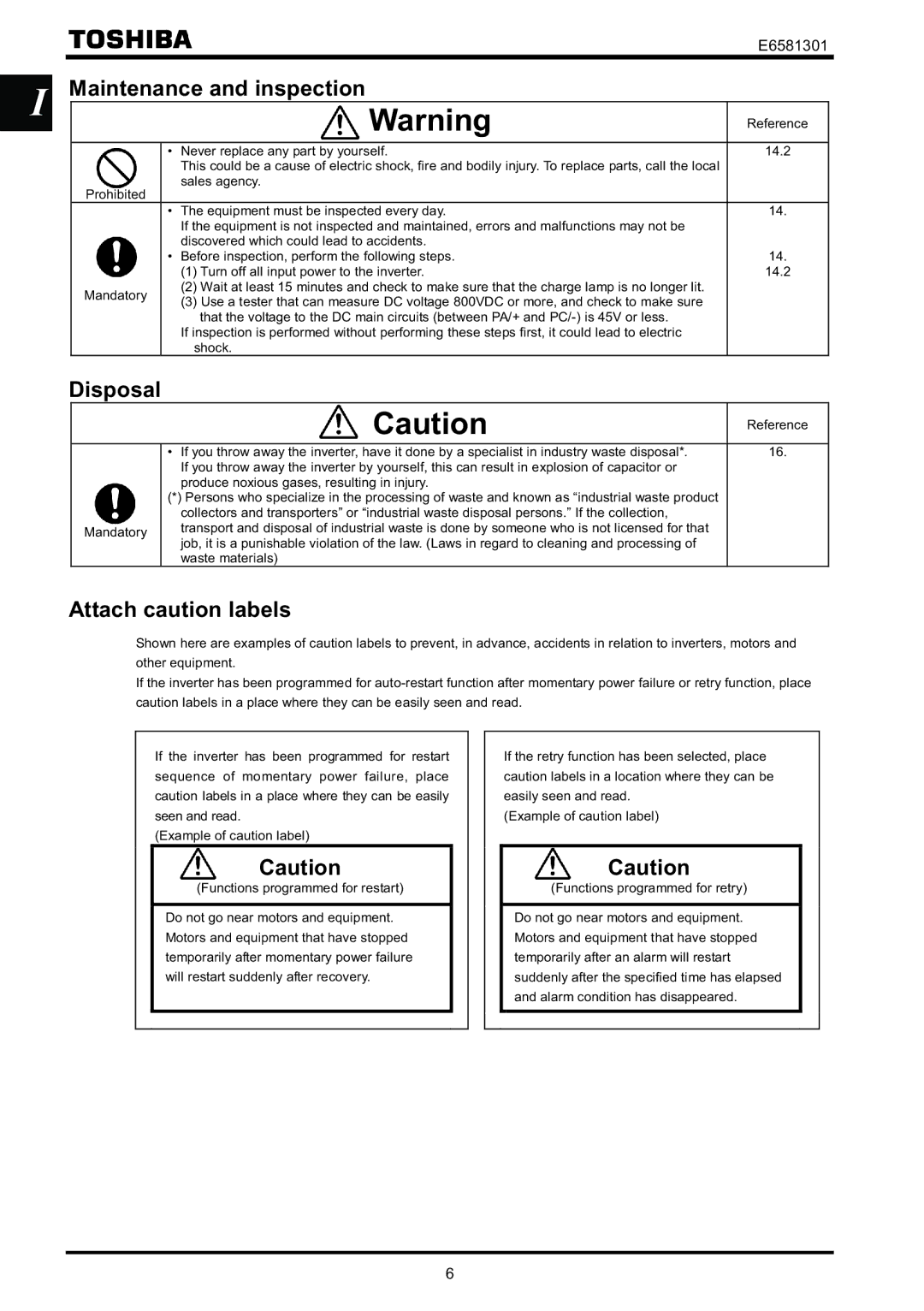

Maintenance and inspection

II. Introduction

Contents

14.4

13.1

13.2

14.3

25.1

24.1

24.2

24.3

36.5

36.2

36.3

36.4

12.1

10.6

10.6.1

10.6.2

Type Form

Contents of the product code

Check the product

Explanation of the type and form written on the label

Names and functions 1 Outside view

Structure of the main body

PRG lamp

Mode key MON lamp

RS485 connector/cover

RUN lamp

Main circuit terminal

Switch Grounding terminal M5 screw Screw hole for EMC plate

M5 screw

E6581301

VFAS1-4300PL, 4370PL

VFAS1-4132KPC

VFAS1-4110KPC

VFAS1-4160KPC

VFAS1-4500KPC

For details on all terminal functions, refer to Section

Control circuit terminal block

Detaching the cover

Control circuit terminal block is common to all equipment

E6581301

E6581301

Grounding capacitor switching method

200V! 18.5#22kW 400V! 22kW 200V/400V Class

Small

E6581301

Installing the DC reactor

Operation in the low-speed area

Comparisons with commercial power operation

Adjusting the overload protection level

Motors

Low loads and low inertia loads

Braking a motor when power supply is lost

High-speed operation at and above 50Hz/60Hz rated frequency

Method of lubricating load mechanisms

Inverters

Effects of leakage current across ground

If power supply distortion is not negligible

Disposal

Measure to take against leakage Current

Affects of leakage current by cable length

Affects of leakage current across supply lines

Remedies

Installation Installation environment

Resistors Place far away from VF-AS1 Inverter

How to install

6001Without top cover

Standard installation Side-by-side installation

4001Without top cover

5001Without top cover

Output

Ambient temperature Continuous

Ambient temperature 4001Without top cover

4001With top cover F631=0

With top cover

Carrier frequency Ambient temperature

4001With top cover

5001With top cover

6001Without top cover Current

E6581301

Installing more than one unit in a cabinet

Connection equipment

Wiring

Control and main power supply

Preventing radio noise

Between PO and PC

Standard connections

Standard connection diagram sink logic

Standard connection diagram sink logic

Standard connection diagram sink logic

Standard connection diagram source logic

Standard connection diagram source logic

Standard connection diagram source logic

Connection with peripheral equipment

Power supply and motor connections

Description of terminals

Main circuit terminals

RR/S4

RES

OUT2

PLC

VI/I

OUT1

FLC

+SU

FLA

FLB

Source logic

Sink logic

1Be sure to short across NO-CC

SOURCE! INT/PLC

3 RS485 communication connector

Operations

VF-AS1 has the following three setting/monitor modes

Setting/monitor modes

OFF

Simplified operation of the VF-AS1

Example of standard connection

Mccb

+ RR/S4 CCA

Frequency setting

+ VI/II

+ RX CCA

Setting the frequency using input voltage 0~10Vdc

Setting the frequency using input voltage 0~±10Vdc

+ VI/II CCA

Press the Enter key to display the first extended parameter

Default setting

Press Key to change to

Stop the motor

Panel operation

Set frequency

Motor starts

Press the Stop key again

Selecting a stop mode with the operation panel

Example of operation panel control

Deceleration stop 1 Press the Stop key

Quick mode Easy

Searching and setting parameters

Setting parameters in the selected quick mode

How to set parameters

Setting parameters in the standard setting mode

Changed parameter search function

Function

Setting methods

History function

History function

Automatic acceleration/deceleration

Setting acceleration/deceleration time

When load is small

When load is large

Automatic torque boost

Manually setting acceleration/deceleration time

Constant torque characteristics default setting

Increasing starting torque

If vector control cannot be programmed

Automatic torque boost and V/f control mode selection

Increasing torque manually V/f constant control

Automatically programmed functions and parameter set values

Setting parameters by operating method

Automatic function setting

Frequency Voltage/current Setting on Default

Command mode selection Frequency setting mode selection

Selection of operation mode

Command mode selection

Operation panel input

VI/II input

RR/S4 input

RX input

Set this parameter at terminal board Any setting is valid

Preset speed operation

Run/stop Press the RUN and Stop keys On the operation panel

Standby connection of terminals ST and CC

Run/stop ON/OFF of terminals F-CC/R-CC

Or 40~20mAdc

Constant torque characteristics Normal way of use

Selecting control mode

Control mode selection

Output frequency Hz Base frequency

Torque boost rate is adjusted automatically

Decreasing output voltage

Motor constant must be set

Setting of V/f control mode selection = V/f 5-point setting

Setting of V/f characteristic arbitrarily

VF5 VF4 VF3 VF1 VF2

Setting of V/f control mode selection = PM control

Base frequency voltage 5-point setting Output voltage

Operating a permanent magnet motor

Precautions on automatic torque boost mode or vector control

Base frequency Base frequency voltage

Manual torque boost-increasing torque boost at low speeds

Base frequency

Manual torque boost

Upper limit frequency Lower limit frequency

Maximum frequency

Upper limit and lower limit frequencies

Maximum frequency

Preset speed operation speeds in 15 steps

Setting frequency command characteristics

RR/S4 RR/S4-CC

ST-CC OFF

Forward/reverse run selection

Selecting forward and reverse runs operation panel only

Explanation of terms

Setting the electronic thermal

= motor rated current/inverter output rated current x

Using a VF motor motor for use with inverter

First basic parameter History function is displayed

Press either the key or the key to change the parameter to

01Hz *1 No less than Motor overload

Setting the motor overload starting level

Motor 150%-overload time limit

Operation frequency Frequency

Inverter overload characteristics

Current/voltage unit selection

Changing the display unit % to a ampere/V volt

VF-AS1

Meter setting and adjustment

Regenerative braking resistance overload factor OLr data

Display returns to its original indications

Adjustment is complete. and the frequency are displayed

Press either Key to select

Press the Enter key to display the operation frequency

Display mode. When standard monitor display selection =

Select the AM terminal meter adjustment by pressing the key

Press the Enter key to switch to the data display mode

Return the parameter setting to output current display

PWM carrier frequency

Gradient bias adjustment of analog monitor output

Refer to .4.4, Current reduction curve Below 130%

Trip-less intensification

Operation and application of the auto-restart function

Synchronized acceleration/deceleration signal

An example of setting when =

Dynamic regenerative braking For abrupt motor stop

External braking resistor with a thermal fuse optional

Connecting an external braking resistor optional

When a using braking resistor without thermal fuse

Capacities of 400V-200kW or more

VFAS1-4280KPC

Selection of braking resistor option and braking unit

Minimum resistance of connectable braking resistors

60Hz default setting =

Standard default setting

Factory default setting

50Hz default setting =

Acceleration/deceleration time setting 0.1 to 6000 sec. =

Default setting =

Reset of user-defined parameters =

Acceleration/deceleration time setting 0.01 to 600.0 sec. =

Key to search for parameters in reverse direction

Automatic edit function

Press Key to select

Key to change the parameter displayed. Press

Easy key function

Quick mode/standard setting mode switching function =

Quick mode

Standard setting mode

Operation panel/remote key function =

Shortcut key function =

Peak hold function =

Output terminal setting

Low-speed signal Low-speed signal output frequency

Low-speed signal output Inverted

Connection diagram SW1 set to sink logic P24 OUT1 or OUT2

Parameter setting of output terminal selection

Parameter setting of frequency and detection band

Reverse run signal

Input signal selection

Parameter setting

Forward run signal

Command from the terminal board

Valid command

ST-CC

Output frequency Hz Set frequency Panel key Forward run

CC Jog run

Terminal function selection

Setting of contact input terminal function

Modifying input terminal functions

Connection method 1 a-contact input

PLC

Servo lock status

Basic parameters

Using the V/f adjustment function Adjustment rate

Manual torque boost Base frequency Thermal protection level

Parameters selected

S1-CC S2-CC

5-point setting VF3 frequency 5-point setting VF3 voltage

V/f 5-point setting

Switching with input terminal board =

Priority is given to Command set With

Automatic switching by means of switching frequencies =

Operation frequency

DC braking DC braking start frequency DC braking current

DC braking

DC braking time Forward/reverse DC braking priority control

~ ~

Motor shaft fixing control

~ ~

E6581301

Time limit for lower-limit frequency operation

Operation signal F-CC SW1 set to sink logic Time s

ST-CC S3-CC

Jog run mode

Status monitor mode

Adjustment with pulse signals Parameter-setting example

«Sample sequence diagram 2 Adjustment with pulse signals»

Jump frequency

Jump frequency jumping resonant frequencies

Jumping width

Preset speed operation frequency 8 to

Preset speed operation frequencies

Preset speed operation frequencies 8 to

Trip-less intensification

Output Frequency Overvoltage stall protection Voltage

Supply voltage correction

Output voltage adjustment

Reverse run prohibition Reverse run prohibition selection

Drooping control

Output voltage waveform selection

Gain1

Braking function

Light-load high-speed operation function

Creeping time Hoisting torque bias input

Creepinjg frequency

Reverse run Forward run

Acceleration/deceleration suspend function

Stall control

Commercial power/inverter switching

Timing chart example

Differential D gain

PID control switching Process lower limit

PID control feedback control signal selection

PID control

CCA VI/II

External connection

Types of PID control interface

Process value DC0~10V RR/S4

Low proportional gain

Setting the PID control

Adjust PID control gain

Fast response

Adjusting the analog command voltage and current

Stop position control function

Setting motor constants

Not set correctly. Check their

Settings

YES

Base frequency Voltage Rated capacity

Setting auto-tuning

Examples of setting the motor constants

Exciting strengthening coefficient Stall prevention factor

Reference selection

Torque control

Speed limit torque=0 band

E6581301

Torque limit

Power Regenerative Running

10V +10V

RX-CCA RR/S4 -CCA, VI/II-CCA

VI/II-CCA

Torque limit level

Torque is h eld at a limit level even

After the mechanical brake is released

Stall prevention function

Power running stall continuous trip detection time

Regenerative braking stall prevention mode selection

Stall prevention control switching

Max output voltage modulation rate

Current and speed control adjustment

Operating a synchronous motor

Fine adjustment of frequency setting signal

Deceleration time Acceleration time

Acceleration S-pattern lower limit adjustment

Deceleration S-pattern lower limit adjustment

Acceleration/deceleration

Acceleration/deceleration switching signal

Set frequency

Pattern operation

E6581301

Function selection

Preset speed mode

~ Preset speed operation modes

Pattern operation finished OFF signal

Protection functions

Setting of stall prevention level Stall prevention level

Emergency stop Emergency DC braking control time

Output phase failure detection mode selection

Output phase failure detection

Function

OFF ON! OFF

Cooling fan control selection

Cumulative operation time alarm setting

Braking answer waiting time

Rush current suppression relay activation time

33.18 VI/II analog input wire breakage detection level

Refer to 5.19 for details

DC voltage Rush current suppression relay

Ground fault detection selection

Disconnection detection of remote keypad

Override

Ex.2 = VI/II input, = disabled

Ex.1 = VI/II input, = disabled

Adjustment parameters

SW2 0-10V/0-20mA side

FM terminals setting example

Large gain

Operation panel parameter

Resetting method

Monitor-displayed or parameter-set frequency

Value displayed

When is not , and is not

When is not , and is disabled

An example of setting When is , and is

Example of setting

Trace selection Trace cycle Trace data

Tracing functions

To acquire trace data at the time of triggering =

Acquisition of trace data

Trace data communication number

Integrating wattmeter

Relationship between pointer and data

Communication function

Send waiting time 2-wire RS485

TOSHIBA, Modbus

Wire RS485

No action Common to 2-wire RS485 and 4-wire Alarm

Alarm No action

E6581301

Response data INV → host

~ ~

Data Host →!INV

Wiring Data Master → Slave

Toshiba Modbus

Alarm No action Trip

E6581301

Traverse function

My function

Input function target 11~ My function selection

DEV002Z

ETB003Z

ETB004Z

VEC007Z

External operation

Case of control panel operation command input

Case of control panel operation the frequency

Functions of input terminals in case of sink logic

Input terminal function selection RR/S4 Preset speed

LI1~LI8

COM

Inverter Input terminal Programmable controller

Acceleration/deceleration3, V/f 3, torque limit

Acceleration/deceleration2, V/f 2, torque limit

OUT1 OUT2

Output terminal function Selection Low-speed signal

Functions of output terminals incase of sink logic

FLA FLB FLC

E6581301

PROFIBUS/DeviceNet/CC

Stop

Response time setting

Setup of input terminal operation time

Analog input filter

Setup of external speed command analog signal

Frequency meter

Setup by analog input signals RR/S4 terminal

Running frequency characteristic

Connection and calibration

~10Vdc

Setup by analog input signals VI/II terminal

Run/stop setup

Setup by analog input signals RX terminal

Monitoring the operation status

Screen composition in the status monitor mode

LED

Setting procedure EX. operation at 60 Hz

Monitoring the status

Status monitor under normal conditions

OFF

No. FE07

Input terminal information

Data bit of communication

No. FE06

Unit times

Display of detailed information on a past trip

Press this key to return to past trip

Changing status monitor function

MON2

MON1

FD86

Default Item displayed Marking Unit Panel

FE56 01% FD85

COUNT1

Trip code display

Display of trip information

Error code Description Communication/Error code

Displayed.Forward run, Reverse run

Direction of rotation when the trip occurred is

Monitor display at tripping

FE01 Direction of rotation

Mode

Display of alarm, pre-alarm, etc

EMC directive

How to cope with the CE standard

Models with a built-in EMC filter

Measures to satisfy the EMC directive

Ex. Countermeasure inverter wiring

E6581301

VFAS1-4355KPC~ 100 EMF3-4600J ×

VFAS1-4160KPC~ 100 EMF3-4600J

Operation with external signals

Power supply wiring Shielded cabless

OUT2, CC

Low-voltage directive

Accessories for countermeasure

Measures to be taken to satisfy the low-voltage directive

Measures to be taken to satisfy the UL/CSA standards

Applicable Inverter model

AIC, Fuse and Wire sizes

VFAS1-4400KPC

10.1 ! Selection of wiring materials and devices

AWG

VFAS1-4355KPC

MCC

Magnetic contactor Input currentA

Selection of wiring equipment

Voltage Applicable Without Inverter model Reactor

Magnetic contactor in the secondary circuit

Installation of a magnetic contactor

Installation of an overload relay

Magnetic contactor in the primary circuit

ACL

Application and functions of options

E6581301

DCL

GTR7 Supply backup

CPS002Z

Suppression Supply Filter *4 Backup

Functions of Add-on type options

Table of optional devices

PG feedback option 6 7 Model VEC004Z, VEC005Z, VEC006Z

Functions of Plug-in type options

How to install

MCR-2550×5 parallel Required No required

Connection of a DC power supply and other electric units

Connection of a single-phase 200V power supply

When using the inverter along with a DC power supply

Connecting fans for a separate power supply

Power consumed by the fans

VFAS1

VFAS1-4200KPC4280KPC VFAS1-4355KPC, 4400KPC, 4500KPC

Speed Torque Control Reference

Vector control Title Cation Function Adjustment range

Speed Torque Reference

Basic parameter 2/4 Communi

E6581301

0304 Dynamic braking

Setting Braking ST-off Overload detect Function

Disabled Selection

Basic parameter 4/4 Communi

Setting unit Default Write during

~155 *1 Disabled 0112

0110 Always on function selection ~155 *1 Disabled 0111

Terminal function selection Communi

Speed Torque Reference

Vector control Title Function Adjustment range

F 5-point setting Communi

Default Speed Torque Reference Cation

E6581301

DC braking Communi

Default Speed

01~600.0kW 01/0.01 Disabled 0310

Tripless intensification setup 2/2 Communi

0307 Selection Disabled Correction of supply voltage

0308 Dynamic braking resistance ~1000 0.1 Disabled 0309

4enabled Enabled

Functions for lift 2/2 Communi

Process increasing rate speed type

Speed Torque

Motor constant Communi

E6581301

Torque limit 2/2 Communi

E6581301

Acceleration/deceleration 2 2/2 Communi

E6581301

Dhcp

Bootp

E6581301

Protection functions 2/2 Communi

55~100% Disabled

Cation Function Adjustment range

Meter output 2/2 Communi

E6581301

Operation panel parameters 2/3 Communi

0756 Quick registration parameter ~999 *1 600 Enabled

Control 0751 Quick registration parameter ~999 *1 Enabled

0752 Quick registration parameter ~999 *1 Enabled 0753 0754

0755 Quick registration parameter ~999 *1 Enabled

1MODBUS

Enabled RS485

Communication function 1/4

0TOSHIBA

0812 Point 1 frequency ~ Hz 0.01

0813 Point 2 setting ~100%

0814 Point 2 frequency ~ Hz 0.01

0000~ Enabled 0843

Vector control Title Communi Function Adjustment range

Enabled Wire RS485

0000~ Enabled 0842

E6581301

My function 1/5 Communi

22CLRN

2STN

4ANDN

6ORN

My function 3/5 Communi

1VI/II

My function 5/5 Communi

Control 0Disabled

Communi

Control Ion

01Hz FD17 FE17

Function Communicat Trip retention

01% FE56 FD85

E6581301

E6581301

LOW

126 127

120 121

122 123

124 125

248 249

242 243

244 245

246 247

Torque Base Acc/dec Dynamic

Standard specifications small/medium capacity types

Models and their standard specifications

However, this is unnecessary for DC input specifications

Standard specifications large capacity types

Voltage/frequency

Common specification

LED

Outside dimensions and weight

Fig. a

Outline drawing

Fig. G

Fig. K

Fig. O

Trip causes/warnings and remedies

Before making a service call Trip information and remedies

Input voltage fluctuates abnormally

E6581301

CPU2

E6581301

E6581301

Method of resetting causes of trip

If the motor does not run while no trip message is displayed

More

How to check other troubles

Check points

Regular inspection

Check items

Periodical inspection

Standard replacement cycles of principal parts

Replacement of expendable parts

Keeping the inverter in storage

Making a call for servicing

Warranty

Disposal of the inverter