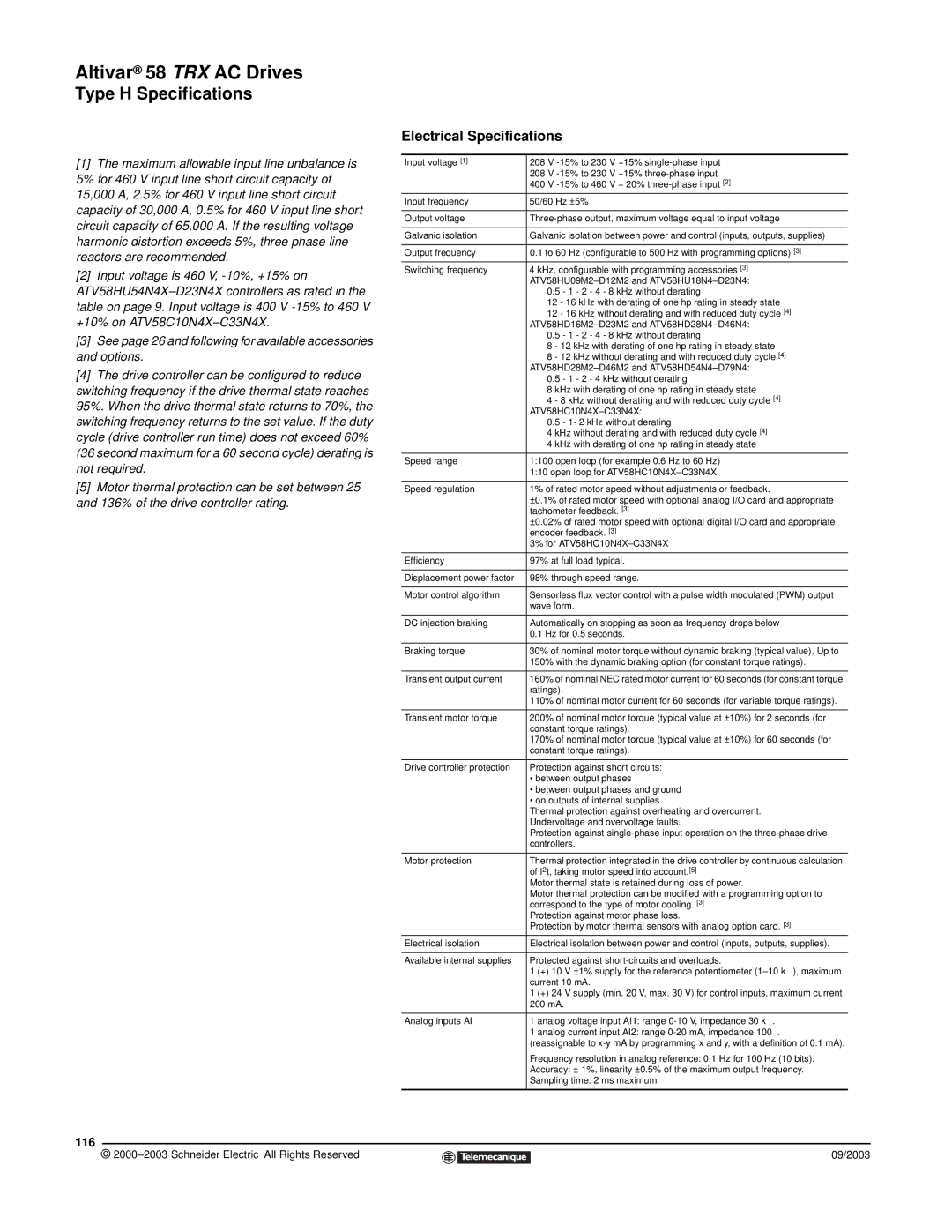

Altivar® 58 TRX AC Drives

Type H Specifications

[1]The maximum allowable input line unbalance is

5% for 460 V input line short circuit capacity of

15,000 A, 2.5% for 460 V input line short circuit capacity of 30,000 A, 0.5% for 460 V input line short circuit capacity of 65,000 A. If the resulting voltage harmonic distortion exceeds 5%, three phase line reactors are recommended.

[2]Input voltage is 460 V,

[3]See page 26 and following for available accessories and options.

[4]The drive controller can be configured to reduce switching frequency if the drive thermal state reaches 95%. When the drive thermal state returns to 70%, the switching frequency returns to the set value. If the duty cycle (drive controller run time) does not exceed 60% (36 second maximum for a 60 second cycle) derating is not required.

[5]Motor thermal protection can be set between 25 and 136% of the drive controller rating.

Electrical Specifications

Input voltage [1] | 208 V |

| 208 V |

| 400 V |

Input frequency | 50/60 Hz ±5% |

|

|

Output voltage | |

|

|

Galvanic isolation | Galvanic isolation between power and control (inputs, outputs, supplies) |

|

|

Output frequency | 0.1 to 60 Hz (configurable to 500 Hz with programming options) [3] |

Switching frequency | 4 kHz, configurable with programming accessories [3] |

| |

| 0.5 - 1 - 2 - 4 - 8 kHz without derating |

| 12 - 16 kHz with derating of one hp rating in steady state |

| 12 - 16 kHz without derating and with reduced duty cycle [4] |

| |

| 0.5 - 1 - 2 - 4 - 8 kHz without derating |

| 8 - 12 kHz with derating of one hp rating in steady state |

| 8 - 12 kHz without derating and with reduced duty cycle [4] |

| |

| 0.5 - 1 - 2 - 4 kHz without derating |

| 8 kHz with derating of one hp rating in steady state |

| 4 - 8 kHz without derating and with reduced duty cycle [4] |

| |

| 0.5 - 1- 2 kHz without derating |

| 4 kHz without derating and with reduced duty cycle [4] |

| 4 kHz with derating of one hp rating in steady state |

|

|

Speed range | 1:100 open loop (for example 0.6 Hz to 60 Hz) |

| 1:10 open loop for |

|

|

Speed regulation | 1% of rated motor speed without adjustments or feedback. |

| ±0.1% of rated motor speed with optional analog I/O card and appropriate |

| tachometer feedback. [3] |

| ±0.02% of rated motor speed with optional digital I/O card and appropriate |

| encoder feedback. [3] |

| 3% for |

|

|

Efficiency | 97% at full load typical. |

|

|

Displacement power factor | 98% through speed range. |

|

|

Motor control algorithm | Sensorless flux vector control with a pulse width modulated (PWM) output |

| wave form. |

|

|

DC injection braking | Automatically on stopping as soon as frequency drops below |

| 0.1 Hz for 0.5 seconds. |

|

|

Braking torque | 30% of nominal motor torque without dynamic braking (typical value). Up to |

| 150% with the dynamic braking option (for constant torque ratings). |

|

|

Transient output current | 160% of nominal NEC rated motor current for 60 seconds (for constant torque |

| ratings). |

| 110% of nominal motor current for 60 seconds (for variable torque ratings). |

|

|

Transient motor torque | 200% of nominal motor torque (typical value at ±10%) for 2 seconds (for |

| constant torque ratings). |

| 170% of nominal motor torque (typical value at ±10%) for 60 seconds (for |

| constant torque ratings). |

|

|

Drive controller protection | Protection against short circuits: |

| • between output phases |

| • between output phases and ground |

| • on outputs of internal supplies |

| Thermal protection against overheating and overcurrent. |

| Undervoltage and overvoltage faults. |

| Protection against |

| controllers. |

|

|

Motor protection | Thermal protection integrated in the drive controller by continuous calculation |

| of I2t, taking motor speed into account.[5] |

| Motor thermal state is retained during loss of power. |

| Motor thermal protection can be modified with a programming option to |

| correspond to the type of motor cooling. [3] |

| Protection against motor phase loss. |

| Protection by motor thermal sensors with analog option card. [3] |

Electrical isolation | Electrical isolation between power and control (inputs, outputs, supplies). |

|

|

Available internal supplies | Protected against |

| 1 (+) 10 V ±1% supply for the reference potentiometer |

| current 10 mA. |

| 1 (+) 24 V supply (min. 20 V, max. 30 V) for control inputs, maximum current |

| 200 mA. |

|

|

Analog inputs AI | 1 analog voltage input AI1: range |

| 1 analog current input AI2: range |

| (reassignable to |

| Frequency resolution in analog reference: 0.1 Hz for 100 Hz (10 bits). |

| Accuracy: ± 1%, linearity ±0.5% of the maximum output frequency. |

| Sampling time: 2 ms maximum. |

|

|

116

© |

| 09/2003 |

| ||

|

|

|