|

|

|

|

|

|

|

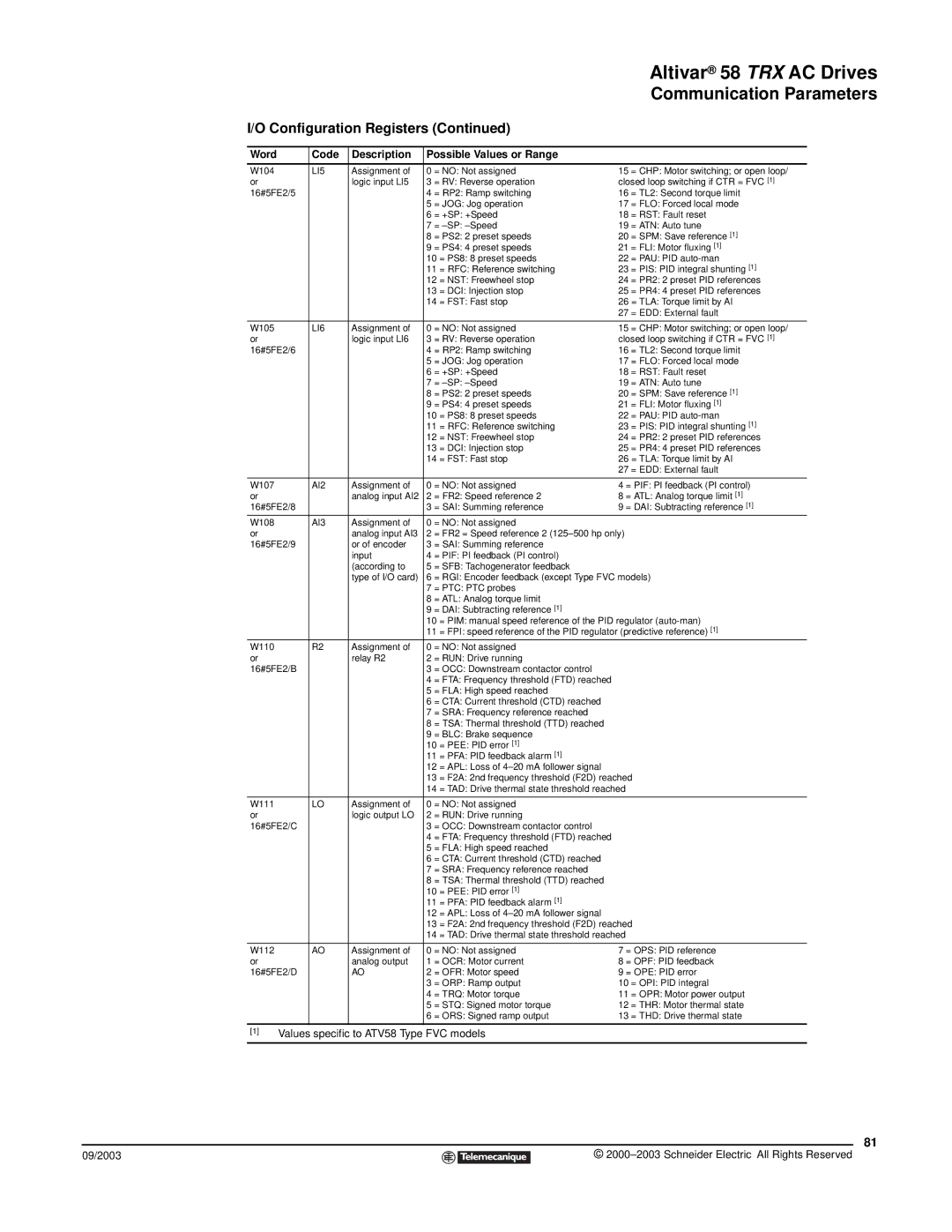

| Altivar® 58 TRX AC Drives | |

|

|

|

|

|

|

|

| Communication Parameters | |

I/O Configuration Registers (Continued) |

|

|

| ||||||

|

|

|

|

|

|

|

| ||

Word |

| Code | Description | Possible Values or Range |

|

|

| ||

|

|

|

|

|

|

|

| ||

W104 |

| LI5 | Assignment of | 0 = NO: Not assigned | 15 | = CHP: Motor switching; or open loop/ | |||

or |

|

| logic input LI5 | 3 = RV: Reverse operation | closed loop switching if CTR = FVC [1] | ||||

16#5FE2/5 |

|

| 4 = RP2: Ramp switching | 16 | = TL2: Second torque limit | ||||

|

|

|

| 5 | = JOG: Jog operation | 17 | = FLO: Forced local mode | ||

|

|

|

| 6 | = +SP: +Speed | 18 | = RST: Fault reset | ||

|

|

|

| 7 | = | 19 | = ATN: Auto tune | ||

|

|

|

| 8 | = PS2: 2 preset speeds | 20 | = SPM: Save reference [1] | ||

|

|

|

| 9 | = PS4: 4 preset speeds | 21 | = FLI: Motor fluxing [1] | ||

|

|

|

| 10 | = PS8: 8 preset speeds | 22 | = PAU: PID | ||

|

|

|

| 11 | = RFC: Reference switching | 23 | = PIS: PID integral shunting [1] | ||

|

|

|

| 12 | = NST: Freewheel stop | 24 | = PR2: 2 preset PID references | ||

|

|

|

| 13 | = DCI: Injection stop | 25 | = PR4: 4 preset PID references | ||

|

|

|

| 14 | = FST: Fast stop | 26 | = TLA: Torque limit by AI | ||

|

|

|

|

|

|

| 27 | = EDD: External fault | |

|

|

|

|

|

|

|

| ||

W105 |

| LI6 | Assignment of | 0 = NO: Not assigned | 15 | = CHP: Motor switching; or open loop/ | |||

or |

|

| logic input LI6 | 3 = RV: Reverse operation | closed loop switching if CTR = FVC [1] | ||||

16#5FE2/6 |

|

| 4 = RP2: Ramp switching | 16 | = TL2: Second torque limit | ||||

|

|

|

| 5 | = JOG: Jog operation | 17 | = FLO: Forced local mode | ||

|

|

|

| 6 | = +SP: +Speed | 18 | = RST: Fault reset | ||

|

|

|

| 7 | = | 19 | = ATN: Auto tune | ||

|

|

|

| 8 | = PS2: 2 preset speeds | 20 | = SPM: Save reference [1] | ||

|

|

|

| 9 | = PS4: 4 preset speeds | 21 | = FLI: Motor fluxing [1] | ||

|

|

|

| 10 | = PS8: 8 preset speeds | 22 | = PAU: PID | ||

|

|

|

| 11 | = RFC: Reference switching | 23 | = PIS: PID integral shunting [1] | ||

|

|

|

| 12 | = NST: Freewheel stop | 24 | = PR2: 2 preset PID references | ||

|

|

|

| 13 | = DCI: Injection stop | 25 | = PR4: 4 preset PID references | ||

|

|

|

| 14 | = FST: Fast stop | 26 | = TLA: Torque limit by AI | ||

|

|

|

|

|

|

| 27 | = EDD: External fault | |

|

|

|

|

|

|

| |||

W107 |

| AI2 | Assignment of | 0 = NO: Not assigned | 4 = PIF: PI feedback (PI control) | ||||

or |

|

| analog input AI2 | 2 = FR2: Speed reference 2 | 8 = ATL: Analog torque limit [1] | ||||

16#5FE2/8 |

|

| 3 = SAI: Summing reference | 9 = DAI: Subtracting reference [1] | |||||

W108 |

| AI3 | Assignment of | 0 = NO: Not assigned |

|

|

| ||

or |

|

| analog input AI3 | 2 = FR2 = Speed reference 2 |

|

| |||

16#5FE2/9 |

| or of encoder | 3 = SAI: Summing reference |

|

|

| |||

|

|

| input | 4 = PIF: PI feedback (PI control) |

|

|

| ||

|

|

| (according to | 5 = SFB: Tachogenerator feedback |

|

|

| ||

|

|

| type of I/O card) | 6 = RGI: Encoder feedback (except Type FVC models) | |||||

|

|

|

| 7 | = PTC: PTC probes |

|

|

| |

|

|

|

| 8 | = ATL: Analog torque limit |

|

|

| |

|

|

|

| 9 | = DAI: Subtracting reference [1] |

|

|

| |

|

|

|

| 10 | = PIM: manual speed reference of the PID regulator | ||||

|

|

|

| 11 | = FPI: speed reference of the PID regulator (predictive reference) [1] | ||||

W110 |

| R2 | Assignment of | 0 = NO: Not assigned |

|

|

| ||

or |

|

| relay R2 | 2 = RUN: Drive running |

|

|

| ||

16#5FE2/B |

|

| 3 = OCC: Downstream contactor control |

|

|

| |||

|

|

|

| 4 | = FTA: Frequency threshold (FTD) reached |

|

|

| |

|

|

|

| 5 | = FLA: High speed reached |

|

|

| |

|

|

|

| 6 | = CTA: Current threshold (CTD) reached |

|

|

| |

|

|

|

| 7 | = SRA: Frequency reference reached |

|

|

| |

|

|

|

| 8 | = TSA: Thermal threshold (TTD) reached |

|

|

| |

|

|

|

| 9 | = BLC: Brake sequence |

|

|

| |

|

|

|

| 10 | = PEE: PID error [1] |

|

|

| |

|

|

|

| 11 | = PFA: PID feedback alarm [1] |

|

|

| |

|

|

|

| 12 | = APL: Loss of |

|

|

| |

|

|

|

| 13 | = F2A: 2nd frequency threshold (F2D) reached | ||||

|

|

|

| 14 | = TAD: Drive thermal state threshold reached |

|

| ||

|

|

|

|

|

|

|

| ||

W111 |

| LO | Assignment of | 0 = NO: Not assigned |

|

|

| ||

or |

|

| logic output LO | 2 = RUN: Drive running |

|

|

| ||

16#5FE2/C |

|

| 3 = OCC: Downstream contactor control |

|

|

| |||

|

|

|

| 4 | = FTA: Frequency threshold (FTD) reached |

|

|

| |

|

|

|

| 5 | = FLA: High speed reached |

|

|

| |

|

|

|

| 6 | = CTA: Current threshold (CTD) reached |

|

|

| |

|

|

|

| 7 | = SRA: Frequency reference reached |

|

|

| |

|

|

|

| 8 | = TSA: Thermal threshold (TTD) reached |

|

|

| |

|

|

|

| 10 | = PEE: PID error [1] |

|

|

| |

|

|

|

| 11 | = PFA: PID feedback alarm [1] |

|

|

| |

|

|

|

| 12 | = APL: Loss of |

|

|

| |

|

|

|

| 13 | = F2A: 2nd frequency threshold (F2D) reached | ||||

|

|

|

| 14 | = TAD: Drive thermal state threshold reached |

|

| ||

|

|

|

|

|

|

| |||

W112 |

| AO | Assignment of | 0 = NO: Not assigned | 7 = OPS: PID reference | ||||

or |

|

| analog output | 1 = OCR: Motor current | 8 = OPF: PID feedback | ||||

16#5FE2/D |

| AO | 2 = OFR: Motor speed | 9 = OPE: PID error | |||||

|

|

|

| 3 | = ORP: Ramp output | 10 | = OPI: PID integral | ||

|

|

|

| 4 | = TRQ: Motor torque | 11 | = OPR: Motor power output | ||

|

|

|

| 5 | = STQ: Signed motor torque | 12 | = THR: Motor thermal state | ||

|

|

|

| 6 | = ORS: Signed ramp output | 13 | = THD: Drive thermal state | ||

|

|

|

|

|

|

|

| ||

[1] | Values specific to ATV58 Type FVC models |

|

|

| |||||

|

|

|

|

|

|

|

|

|

|

81

09/2003 |

| © |

| ||

|

|

|