Altivar® 58 TRX AC Drives

Type FVC Analog Inputs

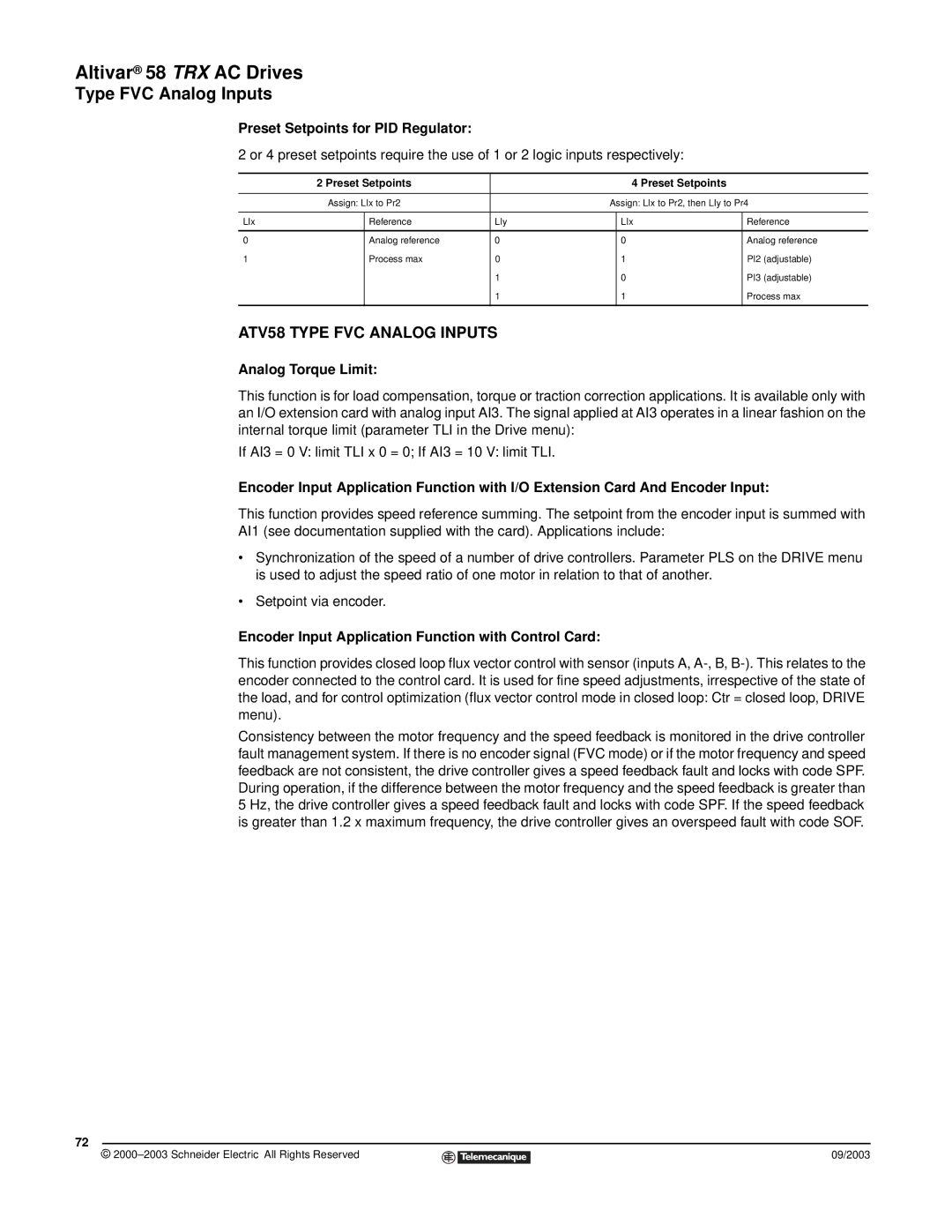

Preset Setpoints for PID Regulator:

2 or 4 preset setpoints require the use of 1 or 2 logic inputs respectively:

| 2 Preset Setpoints |

|

| 4 Preset Setpoints |

| |

|

|

|

| |||

| Assign: LIx to Pr2 |

| Assign: LIx to Pr2, then LIy to Pr4 | |||

|

|

|

|

|

|

|

LIx |

| Reference | LIy |

| LIx | Reference |

|

|

|

|

|

|

|

0 |

| Analog reference | 0 |

| 0 | Analog reference |

1 |

| Process max | 0 |

| 1 | PI2 (adjustable) |

|

|

| 1 |

| 0 | PI3 (adjustable) |

|

|

| 1 |

| 1 | Process max |

|

|

|

|

|

|

|

ATV58 TYPE FVC ANALOG INPUTS

Analog Torque Limit:

This function is for load compensation, torque or traction correction applications. It is available only with an I/O extension card with analog input AI3. The signal applied at AI3 operates in a linear fashion on the internal torque limit (parameter TLI in the Drive menu):

If AI3 = 0 V: limit TLI x 0 = 0; If AI3 = 10 V: limit TLI.

Encoder Input Application Function with I/O Extension Card And Encoder Input:

This function provides speed reference summing. The setpoint from the encoder input is summed with AI1 (see documentation supplied with the card). Applications include:

•Synchronization of the speed of a number of drive controllers. Parameter PLS on the DRIVE menu is used to adjust the speed ratio of one motor in relation to that of another.

•Setpoint via encoder.

Encoder Input Application Function with Control Card:

This function provides closed loop flux vector control with sensor (inputs A,

Consistency between the motor frequency and the speed feedback is monitored in the drive controller fault management system. If there is no encoder signal (FVC mode) or if the motor frequency and speed feedback are not consistent, the drive controller gives a speed feedback fault and locks with code SPF. During operation, if the difference between the motor frequency and the speed feedback is greater than 5 Hz, the drive controller gives a speed feedback fault and locks with code SPF. If the speed feedback is greater than 1.2 x maximum frequency, the drive controller gives an overspeed fault with code SOF.

72

© |

| 09/2003 |

| ||

|

|

|