M P a X U s e r G u i d e

Contents

Technical data

Compax 25XXS unit characteristics

Compax 45XXS/85XXS unit characteristics

Compax 1000SL Unit characteristics

Contents

Process interfaces 179

173

Optimization functions 125

Interfaces 138

Appendix 207

226

238

Please check the software version of your unit

General dangers

Compax 0260M

Key to unit designation Hauser type plate

Safe working practices

Safety instructions

Special safety instructions

General dangers

Conditions of warranty

Conditions of warranty

COMPAX-M / -S LED

Switch-on status

Configuration when supplied

Commissioning

Configuring

Motor is powered Compax display shows RUN Flow chart

Commissioning

Previous software ≤

Equipment replacement

Previous software ≥

Transferring system parameters

Compax 25XXS

Equipment replacement

NMD10 / Compax 45XXS / Compax 85XXS

Compax 35XXM

Start-up manual

Overview

Components required

Compax P1XXM COMPAX-M

Common function characteristics

Overview

Overview of unit technology

KVA

Dimensions DxHxW 146*180*85 mm Design

Design Power KVA

Dimensions DxHxW 275*350*125 mm Design Power KVA

Connector and terminal assignment

COMPAX-M unit features

COMPAX-M unit features

Connector and terminal assignment

COMPAX-M system network, NMD10 / NMD20 mains module

Short circuit connectors

Screened Connection Upper unit side

Wiring up mains

Power / control

Voltage Power supply Control voltage

COMPAX-M dimensions/installation

Compax P1XXM, Compax 05XXM, Compax 15XXM

Compax 02XXM, NMD10, NMD20

Connector assignment COMPAX-M

Connector assignment COMPAX-M

Dimensions / installation

Mains module NMD10/NMD20

Overview NMD

CE conformity

NMD connector assignment

Technical data / power features NMD

Mains module NMD10/NMD20

NMD20

NMD10

Ready contact and green LED are coupled

If a phase malfunctions, no displays appear

Technical data / power features NMD

LED red LED green Possible errors Error Ready

Plug and connection assignment Compax 35XXM

Compax 35XXS unit features

Regeneration mode

Compax 35XXS unit features

Installation and dimensions of Compax 35XXM

Specific technical data

PE connection must be a version of at least 10mm2

Wiring Compax 35XXM

Assignment of X12 does not apply for the S3 option

Compax 35XXM connector assignment

Meaning of the LEDs on the front plate

Compax 25XXS unit characteristics

Compax 25XXS connector and connection assignment

LED / color Meaning, when switched on

On unit side

Compax 25XXS unit characteristics

Wiring up motor

Compax 25XXS connector and connection assignment

Compax 25XXS ≤ 1.0 kW Unlimited With R ext ≥ 56 Ω ≤ 2.5 kW

Compax 25XXS-specific technical data

Connecting ballast resistance to COMPAX-S

Compax 25XXS 1000 ∝ F / 27 Ws

Flat design

Compax 25XXS dimensions / installation

Compax 25XXS dimensions / installation

Design in series

O1...O8

Connector assignment Compax 25XXS

Plug and connection assignment Compax 45XXS/85XXS

Compax 45XXS/85XXS unit characteristics

Compax 45XXS/85XXS unit characteristics

Plug and connection assignment Compax 45XXS/85XXS

Meaning of the LEDs on the front plate

Compax 45XXS/85XXS installation / dimensions

Compax 45XXS/85XXS-specific wiring

Wiring up motor Control voltage Enable

Compax 45XXS/85XXS-specific wiring

Enable bridges

Enable internal ballast resistance X2/5 X2/6

Maximum braking power of the internal ballast resistance

Assignment/ cable

Compax 45XXS/85XXS connector and pin assignment

LED display

Compax 1000SL Unit characteristics

Connector and terminal assignment for Compax 1000SL

PE terminal

Compax 10XXSL 660 ∝ F / 17 Ws

Compax 1000SL Unit characteristics

Unit wiring

Connector and terminal assignment for Compax 1000SL

Connector assignment Compax 1000SL overview

Mating connectors X1, X2, X3

Bridges for test operation

Mounting and dimensions Compax 1000SL

Mounting and dimensions Compax 1000SL

Safety chain / emergency stop functions

Readiness, safety chain Emergency stop

Emergency stop and ready on connector

60V, 30W

Emergency stop input direct to COMPAX-M

Emergency stop input on COMPAX-M

Ready contact max .5A

Resolver / SinCos

Connections to the motor

Resolver / SinCos

Cable assignment in the terminal boxes

Code

Connections to the motor

Length codes for preformed cables

Length m

Material

Procedure

MOK42 max ,8A

Packaging of device

MOK21

MOK21 max ,9A

Version in high-flex GBK17 same layout

SinCos cable for HJ and HDY motors

External contact connection

Connections to the motor Additional brake control

Assignment of X10 Input/Output

Interfaces

Digital inputs and outputs excluding Compax 1000SL

Assignment of X8 Input/Output

24VDC

Interfaces Digital inputs and outputs for Compax 1000SL

GND

Start

Compax 1000SL

Technical data / Connections of inputs and outputs

Connection plan for the initiators with initiator connector

Interfaces Initiators and D/A monitor

Connection assignment on

Wiring of override with screened cables only

Service D/A monitor / override

Service D/A monitor

Service D/A monitor / override

Measuring

Interfaces

Monitor

Standard

Meaning and range of values of P71 P74

7 D/A monitor option D1

Cable plan GBK1/.. Compax absolute value sensor

Wiring diagram SSK1/...COMPAX PC/terminal

8 RS232 interface

Absolute value sensor option A1 Interfaces

Assignment on

Encoder interfaces / analogue rpm specification for Compax

10 X13 Encoder interfaces

Area of application of process interfaces

Encoder interface Step direction input for Compax 1000SL

Process interfaces Configuration options

Applications with Compax 1000SL and encoder

Configuring

Process

Interfaces

SSK14

Interfaces Heda interface option A1/A4

Bus connection

Cable plan

Power characteristics

Technical data

Bus connection optional

Standard delivery

Housing

Permissible 3-phase mains

Operation

Operating Instructions

Program memory / parameter memory

Operating Instructions

PLC data interface

RS232 / RS485 Bus-Systems

System controller

Setting Parameters

Explanations for the block structure

Functions

Deactivate

Password protection

Interfaces for signals

Password Protection Activate password

Front plate operation not available with Compax 1000SL

Configuration

Configuration

Meaning of the bus parameters Acknowledging error messages

Switching off the drive Modifying parameters

Configuration when supplied

Configuration process

Power on with motor switched off

Safety instructions for initial start-up

Power on for drive

Risks from incorrect wiring

Unit for travel data

Configuration parameters

Operating mode

Normal mode Continuous mode Speed controller

Motor type

Ramps

Linear

Transfer of P94

Drive type

Spindle drive

Smooth Quadratic

General drive

Specifying software end limits

Reference system

P215 direction of rotation

P213=0 P213=1

Absolute value function with standard resolver

Absolute value function with standard resolver

Activated with

P206=2

Machine zero mode

Machine zero

Real zero

P212 =1 Find machine zero Application

P213 Standard machine Zero mode for linear Movements

Machine zero equals external initiator & resolver zero

Additional machine zero modes

Position of the rotor position

Machine zero initiator MZ-INI is

Low active

Resolver zero pulse is a fixed

Conditions for this operating mode

Machine zero equals external zero pulse

P213=0 P29=0 P29=90 General rotatory

Find machine zero Application

P212=4 only permitted for Compax XX00 and Compax

Machine zero equals resolver zero

P212 =5 Find machine zero Application

P212 =7 Find machine zero Application

P212 =8 Find machine zero Application

Wiring up

Function

Condition

Operating Instructions

Limit switch operation

COMPAX-M / -S

Configuring Compax

Configuration via PC using ServoManager

Configuration via PC using ServoManager

Installing ServoManager

Min-1

Other parameters are derived from the type plate data

Nominal motor speed for the Hbmr motors

EMC

Parameter for saturation characteristic curve

Holding brake For motors with holding brake

Drive type

Individual configuration of synchronous motors

Safety instructions for the first start-up

Positioning and control functions

Positioning and control functions

Start program

Posa value

Absolute positioning Posa

Relative positioning Posr

Absolute positioning Posa

Acceleration and braking time Accel

Process velocity Speed

O12=1010

Setting/resetting an output Output

Setting multiple digital outputs Output O12=1010

Switch off drive unit. Output O0

External speed set via option E7

Password Goto

External velocity specification. Speed Sync

Password Goto

Mark-related positioning Posr

Syntax Example

Preparatory instructions

Changes in speed within a positioning process Posr Speed

Preparatory instructions

Changes in speed within a positioning process Posr Speed

Compatibility

Posr x Speed y Accel z

Speed step profile extended by ramp time

Comparators during positioning Posr Output

Diagram of specified example for Posr Output

Diagram of example using Posa -1000 as positioning

Comparators during positioning Posr Output

Outputs of the cam controller

Cam controller with compensation for switching delays

Cam controller with compensation for switching delays

Function of the cam controller

Problem point

Explanation regarding cam controller

105

Explanation

Example 2 Positioning with subsequent cam operation Compax

Instruction to end a sub-program. Return

Rogrammable waiting time Wait

Program jump Goto

Sub-program jump Gosub

Binary if query of inputs if I12=101-1

Start a program loop Repeat

Branching if I7=1

If I7=1

Comparative operations

Specific processing of data record groups. Wait Start

Jump with data record selection Goto EXT

Sub-program jump with data record selection Gosub EXT

Error handling if Error Gosub

Function Priority Error program

If Error Gosub

Stop / Break handling if Stop Gosub

Error program with

Stop / Break handling if Stop Gosub

Wait Start

N243 Return

Stop program

N001 if Stop Gosub

N241 Wait Start

Example

Arithmetic

Parameter assignments

Curve memory

Status values Variables

Arithmetic and variables

Division y = x1 Example

Or absolute

115

Read status and assign variables Initializing variables

OM3

Position monitoring P93=1, 2

Functional description

OM2

OM3 O5 = 1 nominal value reached

OM2 O5 = 1 nominal value reached and lag error P14

Idle display

Idle display

Bit counting begins with 119

OM1 O5 toggles when speed is reached

Speed monitoring in speed control mode P93=4

Reached

Can be adjusted using P227 bit 429 =0 default setting

OM3 O5 =

Nominal value

PLC sequential step tracking

PLC sequential step tracking

Implementation

Range of values

Final stage blocked by Final stage is enabled via

Engaging and disengaging the motor brake

Via

Service D/A monitor channels

Output of variable voltage

Option D/A monitor channels

Optimizing with the ServoManager

User-defined settings

Optimization functions

Optimizing the movement cycle

Increase control dynamic

User-defined settings with variant P59=

Output of variable voltage Optimization process

Sensor

Variants

P59 Structure switch measuring P23 stiffness of drive

Optimization parameters

Structure

P24 damping of drive

P56 D section rpm controller

Increase damping Reduce damping

Without advance control measures

Advance control of speed, acceleration and power

Optimization functions

Advance control measures

Advance speed control

P26 Advance acceleration control P70 Advance power control

P25 Advance

Speed control

Accel

Control processes for optimization

Speed determination standard

Function Settings Using the speed monitor

Speed monitor

Speed monitor

Optimization display

Optimization display

P233/P23430 Meaning

Use the effective value

Square of peak motor current

You will find a complete status list on Page207

Reference value 80 000A2

P233/P234 Meaning

Access to additional parameters via S13 and S14

External position localization with position adjustment

Configuring the external position adjustment

Only available in Compax

Drive type Measuring unit Determining

Slip filter for external position localization

Limit values

P214

Input Assignment

Digital inputs and outputs

Assignment of standard unit

Digital inputs and outputs

Digital inputs and outputs Output Assignment

P157 bit

Allocation of logic inputs for input pins

Digital inputs and outputs for Compax 1000SL

P156 bit

Digital inputs and outputs Example

Following assignment must be configured Input X19 pin

Operating Instructions

Free assignment of outputs

Free assignment of inputs and outputs

Free assignment

Inputs

Output Function Valency

Heda

Compax virtual inputs

Interrogation of inputs in the Compax program if

Remarks regarding the structural diagram

1.4 I/O assignment of variants

Function of inputs

Hand+/Hand

Exception Start

Find MZ

Approach RZ

Input Shift

Quit Start Stop

Activate position adjustment

Break

P211 blocking and modifying teach in functions

Synchronous Stop

Synchronous Stop using

Diagram

Fast start

Additional assignment of P219

No fault

Function of outputs

No warning

Diagrams

Data record memory mode

Caption

Before the 1st machine zero travel, O3=0

Direct command

Specification

Finding machine zero in normal mode Approaching real zero

BCD coded

Input/output Meaning

Syntax of individual commands

Acceleration time

157

Operating Instructions

Function codes

Commands

Procedure for transmitting a sign

Signal procedure using the example of a status query

Interface description

3 RS232 interface

$=com19600,N,8,1

RS232 interface Function Activation using P20 Valid From

Influencing the active positioning process

Interface functions Direct command entry

Commands permitted for the various modes of operation

Positioning commands

Read and write program sets and parameters

Read the status values

Quit

Negative command acknowledge- ment

Transmitting control instructions

P211 blocking and modifying the teach in functions

Output O0

Commands available

All operating modes

Statuses

Binary data transfer using RS232

P20 switching on binary data transfer

Meanings of the binary command codes

360 450,5

RS232 interface Valency *1

Examples of the number format of xx xx xx xx xx Number

MSB LSB

Process coupling using Heda Option A1 / A4

Fast start

Transmittable parameters Master output quantity

Slave input quantities

Permissible combinations and required parameter settings

P98 is identical in all units

Application examples 1st unit Master Slave

Process values

Error handling

Error messages

Synchronizing

172

System concept

System concept

174

Accessories and options

Options

Power module NMD

Current Aeff Aeff 5s With mains supply 230V AC

Unit Nominal Peak current Power kVA

Motors

EMD motors Linear motor

177

Hauser linear actuators

Hauser linear actuators

Initiator set

Data interfaces

1 RS232

Bus systems

Meaning Unit

Process interfaces

Process interfaces

Encoder interface

Encoder module and accessories

Individual connections

Applications with encoder

BUS 1/01

Compax Compax

Compax not

Requirements per Compax EAM 4/01

Encoder bus mixed

Following are required

Encoder module

Process interfaces Absolute value sensor A1

High resolution SinCos sensor system S1/S2

Technical data

Enable absolute value sensor input

See 184

Option S3 for linear motors

S2 option

SinCos multi-turn with programmable transmission factor

6 D/A monitor D1 option not available with Compax 1000SL

Process interfaces Heda interface

I16 = 1 external nominal value is valid

Configuration Accuracy Connection assignment

Connector Pin X13 or

Signal Circuit proposal EAM4/01 Input

External control panel not available for Compax 1000SL

Accessories

BDF1/02 for front plate installation

BDF1/03 with housing

SSK6

Wiring plan

Terminal module for Compax 1000SL EAM

Terminal assignment

Design of EAM5/01

3 EAM5/01 DC feed for COMPAX-M

EAM5/01 DC feed for COMPAX-M

Input voltage range 100V DC 650V DC

Delivery scope

Power filter

EMC measures

NMD10 / Compax 45XXS / 85XXS

Length of connection between power filter

Motor output throttle

Compax 25XXS Compax 10XXSL

Compax 25XXS with external ballast resistance of 56Ω

Dimension diagram BRM4, BRM6 and BRM7

BRM5/01 is fitted with a 0.3m connecting cable

External ballast resistors

Is 2m

Diagrams Brake pulse power cooling period

Authorised braking impulse power with NMD20

Maximum permitted length

195

Authorised braking impulse power for NMD20 with BRM4/02

196

Authorised braking impulse power for NMD20 with BRM4/01

Authorised braking impulse power for Compax 4500S

Compax 8500S

197

198

199

200

ServoManager

Hand-held terminal

ServoManager

Special functions

Special Compax XX70 commands

Hand-held terminal Functions

Keys Function

Status Level

Hand-held terminal Menu

Hand-held terminal

View Edit, delete program

Exits the menu without VC

View, edit and reset parameter

View, set configuration

VC is generated when you exit the menu

205

Set configuration

206

Appendix Compax components

Diagnosis values

Status values of the standard unit Compax

Status values of the standard unit Compax XX00

Actual values

Meaning of status bits

Appendix

Unit designations

Special Compax XX00 status values

Explanation of error history S18

Output of status bits via the front plate

S16, S17

Scaled longitudinal voltage For amplification 1 use 10V =

Selection of status value using P182 Measuring parameter

Additional Compax measuring quantites

Status monitor S15

211

Additional Compax measuring quantites

Compax parameter

VP parameter46can be modified On Line

Compax standard parameters

List of parameters, sorted by number

Only permitted with P18 when bit 1=1

Compax parameter

Remark

Compax standard parameters

P20 setting

Drive Type Spindle drive P80=2

Rack

General drive drive type P80=16

EMC

P115 Angular speed 100 200

P112 Slip frequency MHz 100 P113 Maximum speed Min-1 9000

Bit 0 Input

P144 Settting encoder channel

X19

Source for

Settings 3 and 4 with Compax XX00

Default value P184=0

Enable final stage with Output O0=0 without

P212 Machine zero mode

Output Word

O8 to the Heda

P243 Heda operation

Mode

P245 Assign outputs O1

Static monitoring

Monitoring and limitation characteristics

Structural diagram

Dynamic monitoring

Error handling and error messages

Error handling and error messages

With Compax 70 Curve number not present 223

Too hard E40

224

Speed control mode, control is referenced to speed

Response to lag error error E10 Position controller

Response to E15

Quit is not required

Application examples

Assignments

Wiring up the digital inputs and outputs

External data record selection

Application

List of programs

Configuration

Programming

Names of inputs and outputs

Mark-referenced positioning

Mark-referenced positioning

Message = mark found

Sets the acceleration and braking ramp

N003 Output O7=0 Shears = block

Mark reference = block

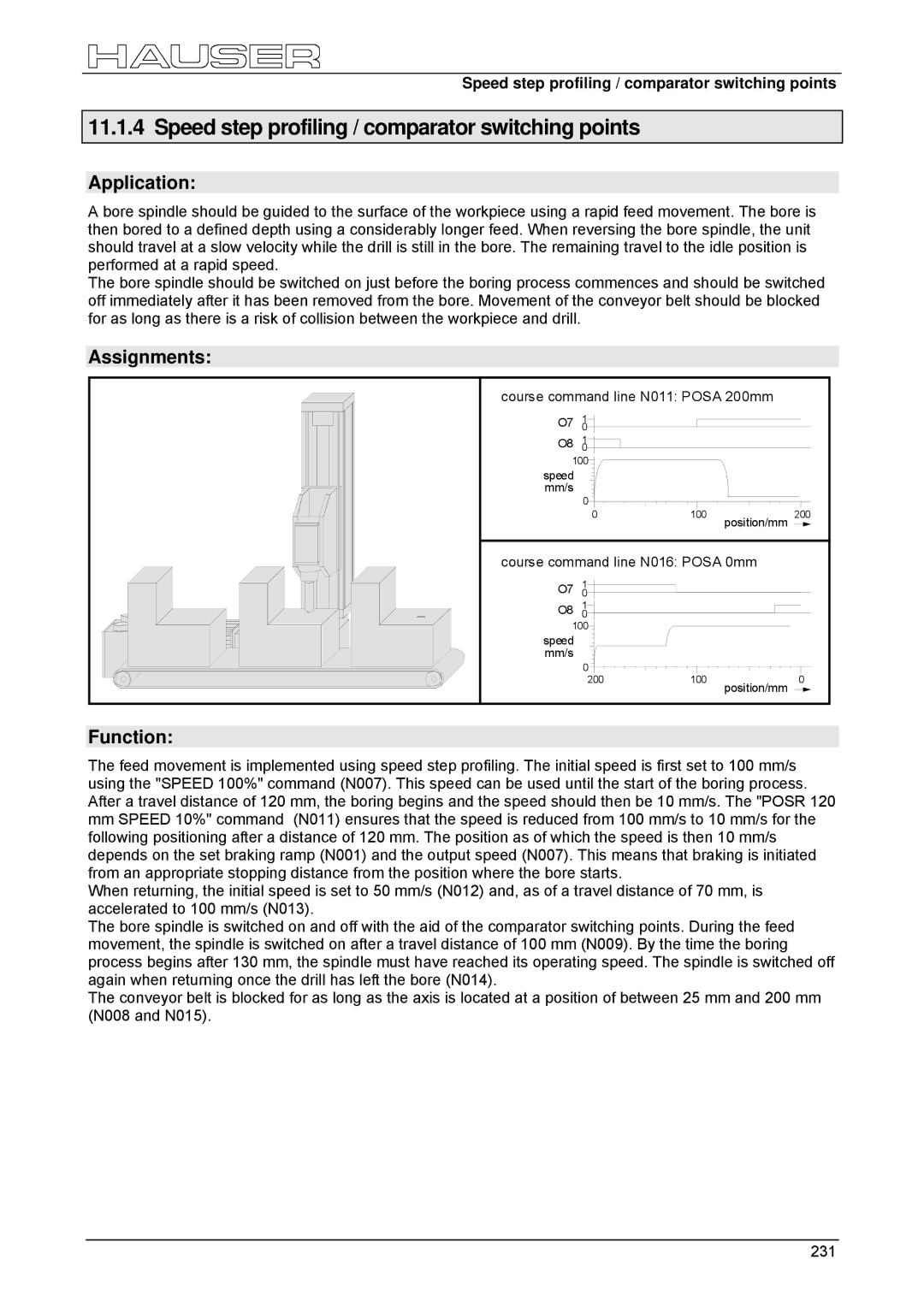

Speed step profiling / comparator switching points

Speed step profiling / comparator switching points

Names of the inputs and outputs

Speed Sync

Speed control mode

Design and wiring up of the digital inputs and outputs

Speed control mode

Sets the accelerating and braking ramps to 10s

N019 if I10=0 Goto removing Operating mode query

Light barrier

Interlock # closed # open

Fast start

Assignments Function

Fast start

Implementing a torque controller

Using speed control mode

Position controller mode

Changing error response

Index

COMPAX-25XXS

COMPAX-M / NMD

If Error Gosub

Limit switch monitoring Without locking

Installation / dimensions

Installation Dimensions

Installation arrangement COMPAX-M

Safety chain Emergency stop

Power on with motor

Power with linear motor

Process interfaces Configuration options

Compax 25XXS Compax 45/85S

Compax 25XXS Compax 45/85S COMPAX-M

![]()

![]()

![]()