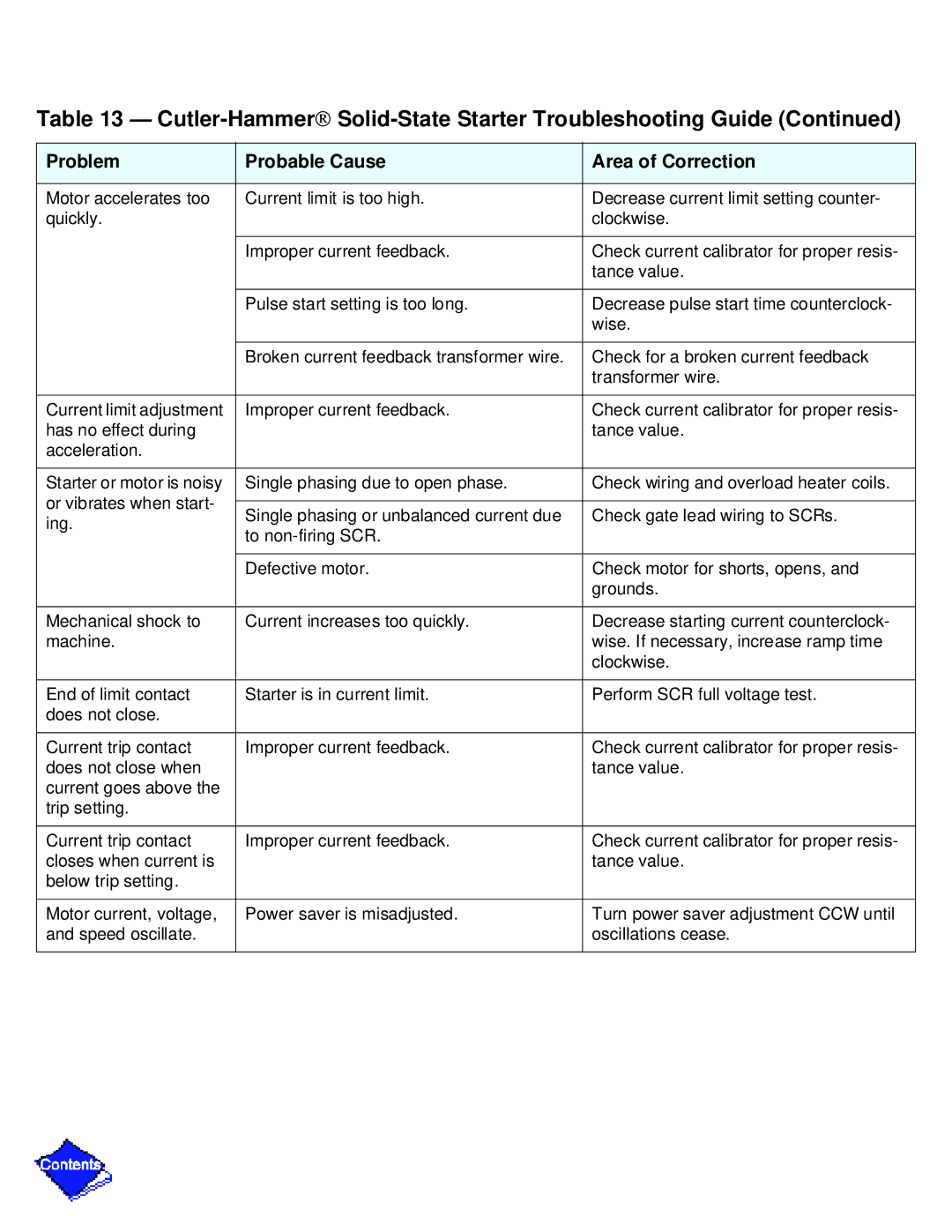

Table 13 — Cutler-Hammer ® Solid-State Starter Troubleshooting Guide (Continued)

Problem | Probable Cause | Area of Correction | |

|

|

| |

Motor accelerates too | Current limit is too high. | Decrease current limit setting counter- | |

quickly. |

| clockwise. | |

|

|

| |

| Improper current feedback. | Check current calibrator for proper resis- | |

|

| tance value. | |

|

|

| |

| Pulse start setting is too long. | Decrease pulse start time counterclock- | |

|

| wise. | |

|

|

| |

| Broken current feedback transformer wire. | Check for a broken current feedback | |

|

| transformer wire. | |

|

|

| |

Current limit adjustment | Improper current feedback. | Check current calibrator for proper resis- | |

has no effect during |

| tance value. | |

acceleration. |

|

| |

|

|

| |

Starter or motor is noisy | Single phasing due to open phase. | Check wiring and overload heater coils. | |

or vibrates when start- |

|

| |

Single phasing or unbalanced current due | Check gate lead wiring to SCRs. | ||

ing. | |||

to |

| ||

|

| ||

|

|

| |

| Defective motor. | Check motor for shorts, opens, and | |

|

| grounds. | |

|

|

| |

Mechanical shock to | Current increases too quickly. | Decrease starting current counterclock- | |

machine. |

| wise. If necessary, increase ramp time | |

|

| clockwise. | |

|

|

| |

End of limit contact | Starter is in current limit. | Perform SCR full voltage test. | |

does not close. |

|

| |

|

|

| |

Current trip contact | Improper current feedback. | Check current calibrator for proper resis- | |

does not close when |

| tance value. | |

current goes above the |

|

| |

trip setting. |

|

| |

|

|

| |

Current trip contact | Improper current feedback. | Check current calibrator for proper resis- | |

closes when current is |

| tance value. | |

below trip setting. |

|

| |

|

|

| |

Motor current, voltage, | Power saver is misadjusted. | Turn power saver adjustment CCW until | |

and speed oscillate. |

| oscillations cease. | |

|

|

|