Multiranger

This document is available in bound version

Technical data subject to change

Manual for agreement with

Instrumentation described, variations

Table of Contents

Dolphin Plus Toolbar Buttons

Set Relays to First in First OUT Fifo Assist MR

Iii

Starting Pumps by Rate of Level Change MR

Open Channel Monitoring OCM

100

Communication Appendix a Single Parameter Access SPA

Vii

Viii

Connecting a transducer with RG62 coaxial extension cable

Set the MultiRanger to Ignore the Bad Echo

Coaxial Transducer Extention

Manual

MultiRanger 100

MultiRanger

MultiRanger 100/200

Configuration Examples

Manual Symbols

Power

Specifications

Specifications

Mounting

Temperature Compensation

Resolution

Temperature Error

Accuracy

Outputs

Inputs

Weight

Enclosure

Approvals

Maximum

Cable

Mounting

Installation

Mounting Locations

Recommended

Mounting Instructions

Enclosure Dimensions

Wall Mount

Mounting the Enclosure

Cable exposed and entering through the cable glands

Cable routed through a conduit

Unscrew the glands and attach them loosely to the enclosure

Tighten the glands to form a good seal

Panel Mount

Cutout Dimensions

Cutout Instructions

Mounting the Enclosure

Panel Mount Dimensions

Helpful hint

MultiRanger Board

Installing the Battery

Open the enclosure lid

Close and secure enclosure lid

Installing SmartLinx Card

Wiring

Wiring

MultiRanger

Cables

Terminal Board

Please do not overtighten the screws

Connection Cable Type

Transducers

Power Failure

Relays

Relay Ratings

MA Input MR 200 only

Temperature Sensor

MA Output

Sensor only. Leave

Level System Synchronization

Power

RS-232 Serial Connection

Digital Communications

RS-485 Serial Connection

Discrete Inputs

RUN Mode

RUN Mode

Operating the MultiRanger

Operation

Icons indicating index type Item 1 edited in Program mode

Readings in RUN Mode

Icon Index Type

Operation Key

Values

Status Parameters

Controlling the Display

Adjusting the primary reading for four-digit LCD readout

Auxiliary Reading

Action

Multiple Readings MR 200 only

Setting the Default Auxiliary Reading

Parameter Index Value Description

Changing Number Scrolling Speed

Starting Program Mode

Program Mode

Hand Programmer

To activate Program from RUN mode, press Program and then

Programmer Keys

Operation Keys Programming Mode

Digit Totalizer toggle MR 200 only

Compatible with product software versions 1.06 and earlier1

Dolphin Plus

Button Action

Dolphin Plus Toolbar Buttons

Device Description

Simatic Process Device Manager PDM

Compatible with product software versions 1.07 and later1

See P900 for Software Revision Number 7ML19981FB06

Changing Parameters

Activating the MultiRanger

Helpful Hints

Security

Using Units or Percent %

Parameters Types

Maximum

Default Values

Parameter Reset

Master Reset P999

Display Readout

Changing ParametersDolphin Plus

Parameter Indexing

Accessing a Parameter Index

MultiRanger Display

Index Number

Example Setting P1113 =

Accessing a Secondary Index

Primary and Secondary Indexes

Primary Index

Single Point Models

Starting Measurement

Example MR 200 only

Parameter

Average or Differential MR 200 only

Dual Point Models

Operation Index Description

Index Value Description

Measurement Conditions

Dimensions MR 200 only

Response Rate

Failsafe

Relays

Alarm

General Introduction

Relay Function

Miscellaneous

Pump

Relay Related Parameters

Relay States

Relay Status Non Run Modes

Relay Types

Relay Activation

Relay Wiring Test

Relay Logic is Modified

Relay Failsafe

HOLd Keeps the relay in the current state

Energizes the relay

Value Parameters Affected

Preset Applications

Backup Level Override Parameters

Backup Level Override

Backup Level Override

Discrete Inputs

Wiring the Discrete Inputs

Programming the Discrete Input Logic

MA Input MR

MA I/O

Level Reading Parameters

MA I/O

Calibrating 4 mA Output

MA LI/O

Calibrating 20 mA Output

Verifying the mA Range

Tank Shape and Dimensions

Volume MR

Volume

Readings

Example Chart

Characterization Chart MR

P051

Level P054

Determines the volumes which

Which the volumes are known

MultiRanger 200 only

All level readings

Alarms

Alarms

Level

Set the Common Parameters

Alarm Designation

Setting Simple Level Alarms

Setting a Filling Rate Alarm

Rate MR

Temperature MR

Cable Fault

Bounds/ Out of Bounds Range MR

Parameter Index Value

Loss of Echo LOE

This shows a high alarm

Setting a group of three pumps to pump down a wet well

Setting a Pump Down Group

Pump Control

Example Sewage Wet Well

Set Relays to Alternate Duty Assist

Setting a Pump Up Reservoir Group

Set the on Setpoints

Set the Relay OFF Setpoints

3m By using index 0 all six relays are set at

Sample values

4m Sets the three setpoints for the pump relays

Set Relays to Fixed Duty Assist

Other Pump Control Algorithms

Set the Relay on Setpoints MR

Set the Relay OFF Setpoints MR

Set Relays to Alternate Duty Service MR

Set Relays to Fixed Duty Backup MR

Fixed Duty BACKUP. Only one pump will

Ever run at one time

Starting Pumps by Rate of Level Change MR

Optional Pump Controls

Pump Control Parameter

P112 P113 P121 P132

Single and Dual Point MR

Rotating Pumps by Service Ratio MR

Time

Setting Independent Failsafe Controls

Totalizing Pumped Volume MR

Set in RUN Mode

Setting the Pump Start Delays MR

Setting a Pump to Run On MR

Reducing Wall Cling MR

Grouping Pumps MR

Setting a Flush Valve MR

Groups Pumps One and Two

Groups Pumps Three and Four

Tracking Pump Usage

Information Available Parameter Access

Relay Controlled by Communications

Rake Screen Control MR

Setting a Rake Control

Point Three Level Distance = h1 -h2

Set Relays 2 to 4 Level Alarms

Setting the Common Parameters

Set Relay 1 Operate Rake

Screen Control

Relay Contacts

External Totalizers and Flow Samplers MR

Totalizer

Counter Formula

Flow Sampler

Based on Volume and Time

Source of units depends on the operation

Operation Units Source Parameter

Open Channel Monitoring OCM MR

Dimensional P600 = 2,3,6,7

Common Parameters

Exponential P600 =

Channel Monitoring

Setting Zero Head

Examples on the following pages show both methods

P603 P006 P007 P605

Applications Supported by MultiRanger

Setting Totalized Volume

BS-3680 / ISO 1438/1 Thin plate V notch weir

Plan View 4 to 5 x hmax hmax = P007

BS-3680 / ISO 4359 Rectangular Flume

P600 P602

P605 P608

Application Information

Palmer Bowlus Flume

Flume Size Diameter in feet Point of Measurement Cminches

Flume

Flume

Flume height D

Standard Weirs

Applicable Weir Profiles

P600 Exponential Function P601

Weir Profile

Parshall Flume

Non-Applicable Weir Profiles

Sized by throat width Set on solid foundation

Transducer P006

Leopold Lagco Flume

Maximum Head preset P007

Leopold Lagco Flume

Cut Throat Flume

Cut Throat Flume

Typical Flow Characterization

Universal Calculation Support

P611 Linear Flow Curved Head P610

Zero Flow

Example Weirs

Example Flumes

Trapezoidal Dual Range nested Parshall

These weirs could require universal calculation

Testing the Configuration

Testing the Configuration

Simulation

Simulating a Single Measurement

Checking OCM Flow Characterization MR

Checking Volume Characterization MR

Press

No effect

Application Test

Checkout

Testing the Configuration

MultiRanger Communication Systems

MultiRanger Communications

Optional SmartLinxCards

Communications

Communication Ports

Communication Systems

Modbus

Port Connection Location Interface

P770 Modbus RTU slave P771

SmartLinx

P770 Dolphin P772

Data rate of 115.2 Kilo baud

Wiring Guidelines

Communications Installation

Comms Installation

Ports 1

Port 1 RS-232 RJ-11 Jack

To connect the unit to a modem using an RS-232 jack

Port 2 RS-485

Computer DB-9 male RJ-11 to DB 9 converter

To connect the unit to a modem using an RS-485 port

Configuring Communication Ports Parameters

P770 Port Protocol

P771 Network Address

P773 Parity

P772 Baud Rate

P774 Data Bits

P775 Stop Bits

P778 Modem Available

P779 Modem Inactivity Timeout

P782 Parameter Index Location

Hanging Up

Register Map for Most Common Data

Modbus Register Map

Type Description Start Data Type Read

Modbus Register Types

Map ID R40,063

Word Order R40,062

Modbus Register Types Description Start

Point Data R41,010 R41,031

Product ID R40,064

Totalizer R41,040 R41,043

Input/Output R41,070 R41,143

Relay Outputs R41,080

Discrete Inputs R41,070

MA Input R41,090 MR

MA Output R41,110-41,111

Pump OFF Setpoint R41,430 R41,435

Pumped Volume R41,440 R41,443 MR

Pump Hours R41,450 R41,461

Pump Starts R41,470 R41,475

Indexing the Parameter Access Area

Parameter Access R43,998 R46,999

Format Register # Parameter #

Usually, the parameters are all read / write

Global Index Method P782 =

Reading Parameters

Parameter Specific Index Method P782 =

Examples are

Writing Parameters

Global Index Method P782 =

Format Words R46,000 to R46,999

Parameter-Specific Index Method P782 =

Format Registers

Format

Decimal Offset Example

Decimal

Numeric Values

Data Types

Bit Values

Unsigned Double Precision Integer UINT32

Split Values

Yy = value % 256 128 where % is the modulus operator

One example is P807, Transducer Noise, where

Two registers are read as a 32-bit integer

Number Text Message as displayed on LCD

Text Messages

MultiRanger

Relay Function Codes P111 Only

Control Relay Function Code Number P111

Error Handling

Error Handling

Error Handling

Modbus Responses

Error Handling

Generally

Communication Troubleshooting

Specifically

Reading Parameters

Mapping

Communication Appendix a

Address Description

Format Register

Writing Parameters

Bits Values Description

Currently the MultiRanger has two error codes available

Error Codes

MultiRanger 100 and MultiRanger

Parameter Reference

Helpful Hints

Parameters

# of indexes

Index types

Transducer2

Up to 7 2

P000 Lock

Quick Start P001 to P007

P001 Operation

Single Point Model Dual Point Model

For DPD and DPA Programming MR

P002 Material

Single Point Model Use

Dual Point Model Use

P004 Transducer

P003 Maximum Process Speed

Determines level change reaction

P005 Units

Specifies measurement units used for dimensional values

P006 Empty

P007 Span

Volume P050 to P055 MR

Sets the range levels to be measured

Preset Flat Level Bottom

Volume calculation not required

P050 Tank Shape MR

Parabola Bottom

Examples

P051 Maximum Volume MR

P053 Tank Dimension L MR

P052 Tank Dimension a MR

P054 Level Breakpoints Universal Volume Calculation MR

Entering a Level Breakpoint

Entering a Volume Breakpoint

Typical volume calculations

Display and Reading P060 to P062

P060 Decimal Position

P062 Offset Reading

P061 Convert Reading MR

P607 Flowrate Decimal

Range -999 to

P064 Reading Override Enable

Backup Level Override

P065 Reading Override Value

P069 Password

P066 Override Time Delay

Material level reported when a Failsafe State is initiated

P070 Failsafe Timer

Failsafe P070 to P072

P071 Failsafe Material Level

P072 Failsafe Level Advance

Relays P100 to P119

Six preset applications to configure or bench test the unit

P100 Preset Applications MR

Control Functions P111

Setpoints P112, P113

Dual Point Mode optional

Single Point Mode standard

P110 Level Source

P111 Relay Control Function

Values For P111 Control Type Relay Control

P112 Relay on Setpoint

P113 Relay OFF Setpoint

Distance above and below the bound alarm setpoints

P115 Relay Interval Setpoint MR

P116 Dead Band MR

Power Failure

Value Logic Alarm

P118 Relay Output Logic

Relay States

P119 Relay Logic Test

P118 is preset to 2 which is positive logic

P121 Pump by Rate MR

Positive Logic

Independent Relay Failsafe P129

P122 Pump Service Ratio MR

P129 Relay Failsafe

This parameter only relates to relays with P111 = 54 or

Advanced Pump Control Modifiers P130 to P137 MR

Relay Function P111 Preset P129

P130 Pump Run-On Interval MR

To select an independent Relay Failsafe value

P133 Pump Power Resumption Delay MR

P132 Pump Start Delay MR

Sets the minimum delay in seconds between pump starts

P131 Pump Run-On Duration MR

P137 Pump Group MR

P136 Wall Cling Reduction MR

Dual Point Mode

Single Point Mode

Flush Systems P170 to P173 MR

P170 Flush Pump MR

P172 Flush Interval MR

P171 Flush Cycles MR

P173 Flush Duration MR

Sets the number of pump cycles requiring flush control

P200 mA Output Range

MA Output P200 to P219

P201 mA Output Function

Determines the mA output range

P202 mA Output Allocation

Displays current mA output value for the Point Number

P203 mA Output Value / Transducer

Independent mA Setpoints P210 and P211

P201-mA Function Action Settings

MA Output Limits P212 and P213

P210 0/4 mA Output Setpoint

P212 mA Output Min Limit

MA Output Trim P214 to P215

P213 mA Output Max Limit

P214 4 mA Output Trim

MA Input P250 to P260 MR

MA Output Failsafe P219 MR

P215 20 mA Output Trim

P219 mA Output Failsafe MR

P251 0 or 4 mA Input Level MR

P250 mA Input Range MR

P252 20 mA Input Level MR

Shows the mA input range of the connected mA device

P253 Input Filter Time Constant MR

Discrete Input Functions P270 to P275

P254 Scaled mA Input Value MR

P260 mA Raw Input MR

Standard Data Logging P300 to P321

Record Temperatures P300 to P303

P270 Discrete Input Function

P275 Scaled Discrete Input Value

P301 Temperature, Transducer Minimum

P300 Temperature, Transducer Maximum

P302 Temperature, Sensor Maximum

Record Readings P304 and P305

P303 Temperature, Sensor Minimum

Pump Records P309 to P312

P304 Reading Max

P310 Pump Hours

P309 Pump RUN Time

P311 Pump Starts

P312 Pump Run Ons MR

LCD Totalizer P322 and P323 MR

Flow Records P320 and P321 MR

P320 Flow Max MR

P321 Flow Min MR

P322 LCD Total Low MR

Profile Records P330 to P337

P323 LCD Total High MR

Code Description

P330 Profile Record

Use to enable/disable the Auto Profile Record function

P331 Auto Record Enable

P332 Auto Record Transducer

P333 Auto Record Interval

P334 Auto Record on Setpoint

Auto Record on and OFF Setpoints P334 to P337

P335 Auto Record OFF Setpoint

P337 Auto Record LOE Time

P336 Auto Record Filling / Emptying

P340 Date of Manufacture

Installation Records P340 to P342

P341 RUN Time

P342 Start Ups

P600 Primary Measuring Device MR

Open Channel Monitoring P600 to P621 MR

Single Point Model Dual

Type of primary measuring device PMD used

Word on Exponents

P601 Flow Exponent MR

Exponent for the flow calculation formula

Example Exponents

Dimensions of the Primary Measuring Device PMD

PMD Type Exponent sample only

P604 Maximum Flow MR

P603 Maximum Head MR

Level value associated with Maximum Flow, in Units P005

Maximum flowrate associated with Maximum Head P603

Conditions Enter

P605 Zero Head MR

P607 Flowrate Decimal MR

P606 Time Units MR

Maximum number of decimal places to be displayed

P608 Flowrate Units MR

Volume units used to display total flow

Cubic metres / hour Cubic metres / day Cubic feet / second

Million gallons / day Imperial

P611 Breakpoint Flowrates MR

P610 Head Breakpoints MR

Head vs. Flowrate P610 and P611

Flowrate corresponding to each Head Breakpoint entered

P620 Low Flow Cutoff MR

Procedure, with head steady

P621 Auto Zero Head MR

Calibrates Zero Head P605 based on actual head measurements

P622 Inflow / Discharge Adjust MR

Pumped Volume Totalizer P622 MR

Or discharge

Totalizer P630 to P645 MR

Totalizer features apply to MultiRanger 200 only

P630 LCD Totalized Multiplier MR

P640 Remote Totalized Multiplier MR

P633 LCD Totalized Decimal Position MR

Enter the maximum number of decimal places to be displayed

100 1000

P642 Flow Sampler Exponent MR

P641 Flow Sampler Mantissa MR

Enter the mantissa Y for the exponent Z in the formula

Range Calibration P650 to P654

Offset Adjusts the measurements by a fixed amount

P645 Relay Duration MR

Enter the exponent Z for the mantissa Y in the formula

P650 Offset Calibration

Condition for use of this feature

P651 Sound Velocity Calibration

Offset Calibration

Value altered when an Offset Calibration is performed

Using Sound Velocity Calibration

P652 Offset Correction

P653 Velocity

P654 Velocity at 20C

Temperature Compensation P660 to P664

P660 Temp Source

Range -199 to 199 preset = 20 C

P663 Temperature Transducer Allocation

P661 Temp Fixed

P660 Temp Source

View the transducer temperature in C

P664 Temperature

Rate P700 to P708

P700 Max Fill Rate

Fill rate required to activate the LCD Filling indicator

P702 Filling Indicator

P701 Max Empty Rate

P003 Value Meters / Minute

Empty rate required to activate the LCD Emptying indicator

P703 Emptying Indicator

P704 Rate Filter

Damps Rate Value P707 fluctuations

P706 Rate Update Distance

P705 Rate Update Time

P707 Rate Value

P005 Units P007 Span

Press Reading to toggle between percent and volume

P708 Volume Rate Display MR

Measurement Verification P710 to P713

P710 Fuzz Filter

Global Transducer Off

P711 Echo Lock

P713 Echo Lock Window P820 Algorithm

Adjusts the size of the Echo Lock Window

P711 value P712 preset value

P712 Echo Lock Sampling

P713 Echo Lock Window

Enables the System Sync on the terminal block

P727 Scan Delay

Transducer Scanning P726 to P729

P726 Level System Sync

Display P730 to P739

P728 Shot Delay

P729 Scan Time

P730 Auxiliary Reading

P733 Scroll Access

P732 Display Delay

Adjusts the Point Number display scroll speed

P731 Auxiliary Reading Key

P735 Backlight

P741 Communications Timeout

P737 Primary Reading MR

Controls the LCD backlighting

Communications P770 to P782

SmartLinx Reserved P750 to P769

P770 Port Protocol

P771 Network Address

P773 Parity

P772 Baud Rate

P774 Data Bits

P775 Stop Bits

P779 Modem Inactivity Timeout

P778 Modem Available

P790 Hardware Error

SmartLinx Hardware Testing P790 to P795

P782 Parameter Index Location

Global

P792 Hardware Error Count

P791 Hardware Error Code

P794 SmartLinx Module Type P795 SmartLinx Protocol

P799 Communications Control

Echo Processing P800 to P807

P800 Near Blanking

Space near the transducer face which cannot be measured

P802 Transducer with Submergence Shield

P801 Range Extension

P804 Confidence Threshold

P803 Shot / Pulse Mode

Determines what type of ultrasonic shots are fired

Determines which echoes are evaluated by software

P806 Echo Strength

P805 Echo Confidence

P807 Noise

Display Description

P815 Echo Time Filtered

Advanced Echo Processing P815 to P825

P816 Echo Time Raw

Time in ms from the transmit pulse to the processed echo

P820 Algorithm

P822 Narrow Echo Filter

P821 Spike Filter

Dampens spikes in the echo profile to reduce false readings

Filters out echoes of a specific width

P825 Echo Marker Trigger

P823 Reform Echo

Smoothes jagged peaks in the echo profile

P830 TVT Type

Advanced TVT Adjustment P830 to P835

P831 TVT Shaper

Selects the TVT Curve used

P833 TVT Start Min

P832 TVT Shaper Adjust

P835 TVT Slope Min

P834 TVT Start Duration

P833 TVT Start Min P835 TVT Slope Min

P837 Auto False-Echo Suppression

Display before Auto False Echo Suppression Or when P837 =

Values

P838 Auto False-Echo Suppression Distance

Set Up

P839 TVT Hover Level

Display after Auto False Echo Suppression

P840 Short Shot Number

Advanced Shot Adjustment P840 to P852

P841 Long Shot Number

P843 Long Shot Frequency

P842 Short Shot Frequency

P844 Short Shot Width

Range 30 to Preset P840 Short Shot Number

Adjust the width in ms of the long shot transmit pulse

P845 Long Shot Width

P850 Short Shot Bias

P852 Short Shot Range

Test P900 to P913

P900 Software Revision Number

P901 Memory

P903 Display

P902 Watchdog

P904 Keypad

P905 Transmit Pulse

P908 Scanner

P912 Transducer Temperature

P910 Toggle Relays

P911 mA Output Value

To Access in RUN Mode

P913 Sensor Temperature

Measurement P920 to P927

P914 mA Input MR

P922 Space Measurement

P921 Material Measurement

P923 Distance Measurement

P001 P050 = P050 ≠

P925 Flow Measurement MR

P924 Volume Measurement MR

P926 Head Measurement MR

Calculated flowrate in Max Flow P604 units or % of Max Flow

This feature resets all parameters to original values

Master Reset P999

P927 Distance Measurement

Pressing the Clear keys 7ML19981FB06

Parameters

Global View only Breakpoint

Appendix a Index Types

Parameter depen Dent up to 7 2 Or 3

Echo Processing

Transmit Pulse

Dolphin Plus Display

Cursor

Auto False-Echo Suppression

TVT Time Varying Threshold curves

Sound Velocity

Distance Calculation

Scanning

Volume Calculation MR

MultiRanger 100/200

Universal, Linear P050 =

Universal, Curved MR

Flow Calculation

Set P050 =

See also Typical Flow Characterization on

Universal, Linear MR

Parameter Units

Maximum Process Speed

Values Dependent on Maximum Process

Fast

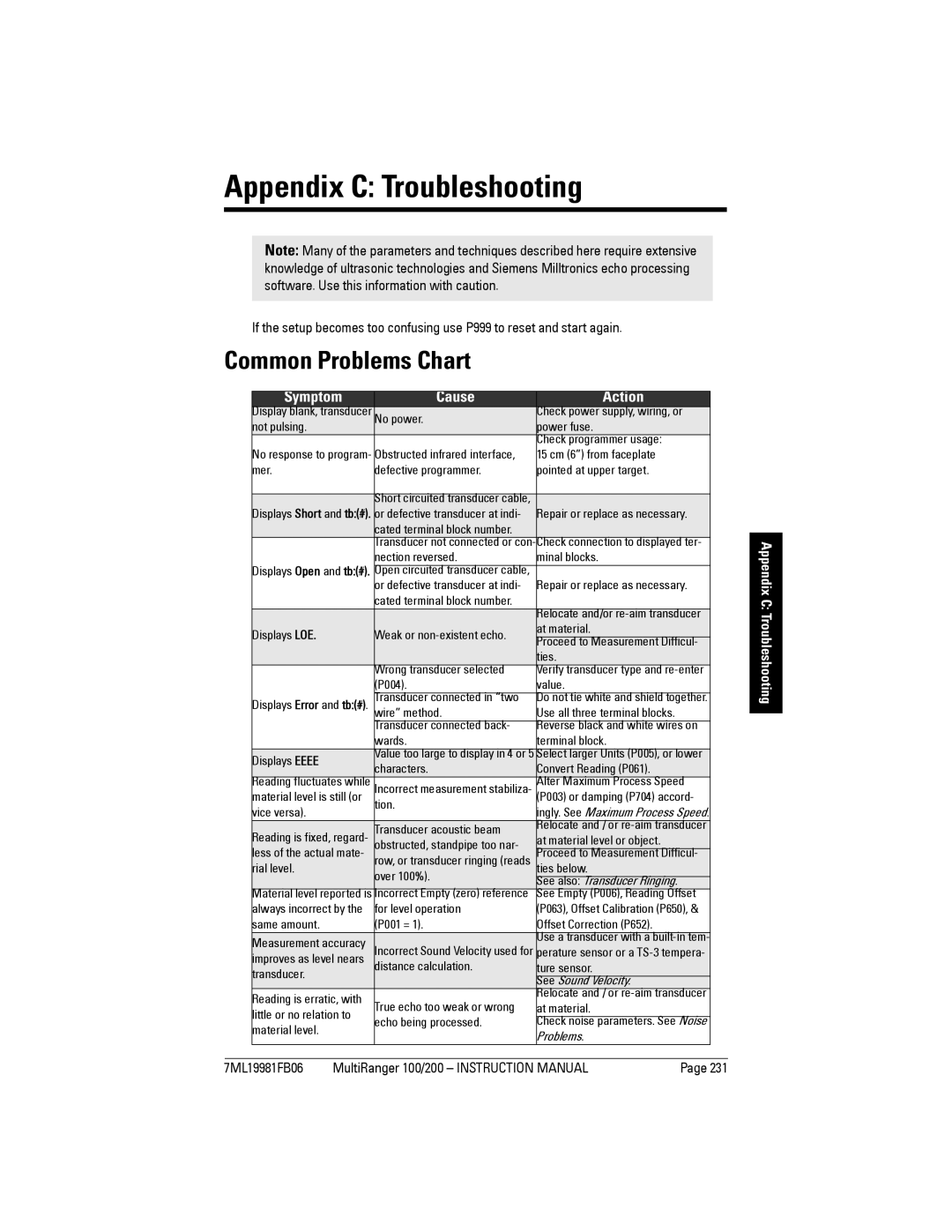

Common Problems Chart

Appendix C Troubleshooting

Symptom Cause Action

Determine the Noise Source

Noise Problems

Removed + removed Go to

Acoustical Noise

Non-Transducer Noise Sources

Common Wiring Problems

Reducing Electrical Noise

Reducing Acoustical Noise

Measurement Difficulties

Adjust Transducer Aiming

Flashing LOE Display

Obstructions in the Sound Beam

Fixed Reading

Nozzle Mountings

Wrong Reading

Adjust the Echo Algorithm

Set the MultiRanger to Ignore the Bad Echo

Types of Wrong Readings

Normal Ring Down

Transducer Ringing

Poor Ring Down

Ring Down TVT curve

Unit Repair and Excluded Liability

Pump Control Algorithms

Pump Control Options

Pump Groups

Pump by Rate MR

Fixed Duty Assist P111 =

Fixed Duty Backup P111 = 51 MR

Alternate Duty Assist P111 =

Alternate Duty Backup P111 = 53 MR

Index Relays

Cycle Relays

Relay Operation for P118 = 2 MR

Service Ratio Duty Assist P111 = 54 MR

Other Pump Controls MR

Service Ratio Duty Backup P111 = 55 MR

First In First Out Fifo P111 = 56 MR

Pump by Rate P121 MR

Flush Device P170 to P173

Updating Software

Appendix E Updating Software

Appendix F Upgrading

Connecting the Transducer

Mounting a MultiRanger 100/200

Coaxial Transducer Extention

Existing installation

Connecting a transducer with RG62 coaxial extension cable

MultiRanger Plus

Alarm

Relay Parameter Value

On setpoint

Appendix G

Appendix G Conduit Entry for Class 1, Div 2 Applications

7ML19981FBO6

23650314

Soft

MultiRanger

Changes

Soft Ware Date Changes Rev

Property no Reset

Systems testing

Simatic PDM related TVT display

Improvement to prevent it from going

Improved Preset Application values

Eliminated rogue watchdog resets when

Using Dolphin+

Changed P132 to global

From Modbus map reg

OCM Time Units improvement

Now being protected from other units’ Transmit pulse

DDs required 7ML19981FB06

Improved volume calculation for 3rd point

Property noReset

Volume

Reading some floats as decimal shifted

Parameter Charts

Programming Charts

P000 Lock G

P113 Relay OFF Setpoint P115

P121 Pump by Rate MR P122 Pump Service Ratio MR

P116 Deadband P118 Relay Output Logic P119 Relay Logic Test

P210 0/4 mA Output Setpoint P211 20 mA Output Setpoint

P304 Reading Max P305 Reading Min

P219 mA Output FailsafeMR

P320 Flow Max MR P321 Flow Min MR

P322 LCD Total Low MR P323 LCD Total High MR

Open Channel Monitoring

P340 Date of Manufacture P341 RUN Time P342 Start Ups

Temperature Compensation

SmartLinx Reserved Communications

P737 Primary Reading MR P741 Communications Timeout

Reserved

Parameter

Index

105

Parameter access

153

103

212

203

207

162

Testing

Service ratio

110

242

Weir

Characterization chart

167

233

Page

Page

7ml19981FB06