For

Page

Foreword

Foreword

Exclusions from Guarantee

Period of Guarantee

Details of Guarantee

Limitations on Guarantee

After-sales Service

Installation

Available Training Programs

Safety Summary

Maintenance of Warning Labels

Safety SUMMARYcont’d

Electrical Hazard

High Temperature Hazard

Laser light Hazard

Fig S-1 Warning labels on the Main unit standard version

Fig S-2 Warning labels on the Display unit standard version

Pinch

Fig S-3 Warning labels on the Main unit Ansi style labels

Fig S-3 Warning labels on the Display unit Ansi style labels

Beware

Beware of high Rotary Pump Temperature

Electric shock

Electron Gun / Ion pump Baking

Laser Light

Water Leakage Detection

Backup of Important Data

Third Party’s Industrial or Proprietary Rights

Cooling Water

Protection against Computer Viruses

Do Not Change Computer Settings

Third Party’s Application Programs

Personal Computer PC

Power Failure

Fig S- 5 Location of Emergency Off button

Emergency Off Button

Power Supply and Grounding Connection

Main Power Disconnect

Unit power supply

Baking power supply

Electron Gun

Ion Pump

Fig S- 6 Location of safety interlock

Safety

Safety

Fig S- 9 Gravity location of Main unit Type1

Fig S- 10 Gravity location of Main unit Type2

Fig S- 11 Gravity location of Display unit

Fig S- 12 An example of the water-leakage detector

Precautions on Handling

Precaution

General Precautions

Others

Flashing

Status Transition of Adsorbed Gas Molecules on Cathode Tip

Precaution

Electron Optics

Magnification

Display Unit

Specimen Stage

Protection Devices

Evacuation System

Installation Environment

Power Requirements

Physical Dimensions

Oscillation Allowable Amplitude Z

Oscillation Allowable Amplitude X, Y

∝m Peak to Peak

Water Supply and Drain

Model S-4800 Field Emission Scanning Electron Microscope

Table of Contents Cont’d

Functions

Table of Contents Cont’d

Maintenance

Replacement Parts

Room Temperature and Humidity

Installation Requirements General

Grounding

Line Power Requirement

Stray Magnetic Field

Allowable Vibration

Floor Vibration

Vibration Allowable Amplitude X, Y

Vibration Allowable Amplitude Z

Vibration Transmittance Frequency Characteristics

External Noise Sources

Power Line Noise and Electric Field Noise

Site Requirements

Disturbance by Sound Waves

Installation Layout example

Materials or Instruments to be prepared by User

Wiring

Connection of the step down transformer

Power and Ground Wirings

100/200V Safety circuit

Functions

S-4800 Main Unit type

Control Knobs and Switches on Main Unit Main unit Column

Sectional View of S-4800 Column

Specimen Stage type

Large Specimen Stage type

Specimen exchange device

Evacuating System

8a Evacuation Control Panel

8a Display / Operation area

IP1

Page

Page

Shows the display unit

Control Knobs and Switches on Display Unit

10 PC Panel

PC power switch

12 Mouse

4800 Power user level, no password

Initially following users are set when sipped

Administrator Administrator level, no password

15 S-4800 Loin dialog window

16 S-4800 Main window

2 S-4800 SEM Main Window

Page

Page

Open SEM Data Manager Opens the SEM Data Manager window

Menu

Direct Save

Direct Photo

Column

Mag Mode

Condition Load

Condition Save

Run Freeze

Split DM Mode

Capture

Capture Reso

Optional Setup Stage

Optional Setup

Optional Setup General

Login Setting

ECO mode setting

Maintenance

Functional blocks on the Control Panel

Control Panel

18 Control panel HV control block

Vacc select

Execute button

Intensity

Auto control

Scan control block

Magnification control

Monitoring function Align

Capture button

Image recording

Page

19 Control Panel Dual screen mode Run / Freeze buttons

Extension for Dual screen mode

20 Operation panel

Operation Panel

Signal Select block

OPE Condition block

6.3 R.ROTATION block

Scan Mode block

Data Entry block

Scan Size block

Smooth

Signal Processing block

Sharpen

Edge Enhance

Color Mixing block

Tilt Compensation block

Other optional function block

Scroll bar and area marker block

Arrangement of control blocks

Mouse operation on the scanning image

21 Mouse Focus/stigma/contrast/brightness adjustment

Exchanging mouse control functions

22 Mouse control Focus/stigma/contrast/brightness

Page

23 Mouse control stage

Setup dialog window

Stage and image shift tools

Column tab

Page

Image tab

1Auto Data Display

Record tab

5Embed into Image checkbox

1Memory Photo

1Film Speed

24 Condition Load/Save

8.4 OP. Cond tab

Captured Image Window

Reset All button

Reset button

SEM Data Manager Window

Alignment Dialog Window

Comm Port Selects one of communication ports Speed

Oblique Dialog Window

Password Setting Dialog Window

Split/Dual Mag Controller

Opt Signal Processing Dialog Window

Save Image Dialog Window

Using Short-Cut Keys

Operation

Display Power

Preliminary Operation Check of Column Vacuum

Flow the cooling water

Starting the Display

Use of Anti-Contamination Trap

Specimen Preparation for Materials

Specimen Setting and Specimen Exchange

Specimen Exchange Position

Adjustment of Specimen Height

Extracting specimen from stage

How to Set Specimen

Page

Turn the knob clockwise so as the Unlock mark comes upwards

Setting a specimen

Opening the specimen exchange chamber door

Flashing About flashing

Flashing Procedure

Accelerating VoltageEmission Current

Setting of Accelerating Voltage and Emission Current

Application of High Voltage

Selecting Electron Optical Column Condition

Optimizing the Electron Beam Selecting a Magnification Mode

High Mag mode

Objective lens Specimen

Low Mag mode area

Page

Low Mag Mode

Column Alignment Operation

Circular image Adjust

Page

WD mm Lowest magnification High Mag Mode

SE detector

Operation for Image Observation

BSE-H

Signal Control

General Characteristic of signals utilized in S-4800

Page

Selecting Magnification

Selecting Scanning Speed

Slow 4 38 sec/frameFull screen

Image Brightness and Contrast Adjustment

Page

Page

Focus and Astigmatism Correction

Page

Defocusedfocused

Movable range limitation of X, Y and R axes

Operation of the Specimen Stage Type I Manual Stage

Movable range and specimen exchange position

Tilt and Z axes limitation

6.4 3 axes motorized stage Type1 stage option

Stage Locking

Movable range of X and Y directions 3 axes motorized stage

Coordinate notation

Movable range and specimen exchange position

Specimen block

Setting specimen size and detectors in use

Valious operation for specimen stage

Stage tab

Upper button Ball Lower button

7.6 X, Y, R axes operation

Tilt axes operation

Page

Stage mouse operation on the scanning image

Page

Page

Page

Page

Adjust tool

Position memory function

Stage History function

Image Navigation

Page

Rotation Assist function

35、-55 75,-55 62.5,0 35,0 50,10 -34,10 35,55 75,55

Rotation / tilt eucentric function and calibration

Calibration Following calibration commands are provided

Page

Page

Page

Stage lock

Stopping stage and Returning to previous stage position

Moveable range and limitation by optional detectors

Φ75 specimen

XY movable range for various specimen size

Allowable minus Tilting angle

Allowable plus Tilting angle for various specimen size

Saving and Recording Images

Preparing Images for Recording

Setting Conditions for Image Capturing

Image Capturing

Manager

Saving a Scanning Image Direct Save

Taking Photographs Option

Saving Captured Images

Page

Photographing saved images

Using SEM Data Manager

Taking Out a Specimen

Setting the Stage at the Specimen Exchange Position

Turning High Voltage Off

Page

Closing Windows and Shutting the Display Power

Screen Mode

Using Other Functions

Page

Split Screen and Dual Mag Mode

Signal Selection and Color Mixing

Page

Ray Analysis Mode

Drag the cursor with the mouse

Signal Processing

Page

Operating Condition Memory

Page

Data Entry Function

Pseudo Color Display

Page

Show

Raster Rotation, Dynamic Focus and Tilt Compensation

Page

Printing images using Report generation function

100

Copy Image information text

Oblique Image

Optional setting

104

Setting Login Name

106

Accelerating Voltage and Image Quality

Image Quality

Objective Lens Aperture Size and Image Quality

Condenser Lens Setting and Image Quality

Preparative Operation for Alignment

Mechanical Column Alignment

Alignment of the Beam Monitor Aperture

Mechanical Alignment of the Electron Gun

Mechanical Alignment of the Second Condenser Lens

Alignment of the Objective Lens Aperture

Mechanical Alignment of the First Condenser Lens

Aperture Alignment electro-magnetic alignment

Stigma Alignment electro-magnetic alignment

113

Precaution About SEM Data Manager

Functions 3.12.2.1 Image Database

Menu and tool buttons

117

118

Operation Registering Images on SEM Data Manager Database

Selecting User name and opening data tree

121

Data Entry

Image information

Viewer display

123

124

Contrast Conversion

→ →

127

Image Processing

Color Mixing

130

Image file operation

Printing images

132

133

Slide show

Optimizing and repairing database file

Replacement and Cleaning of Objective Lens Aperture

Maintenance

Objective Lens Aperture unit

Cleaning of Aperture Plates

Baking of Aperture Plate

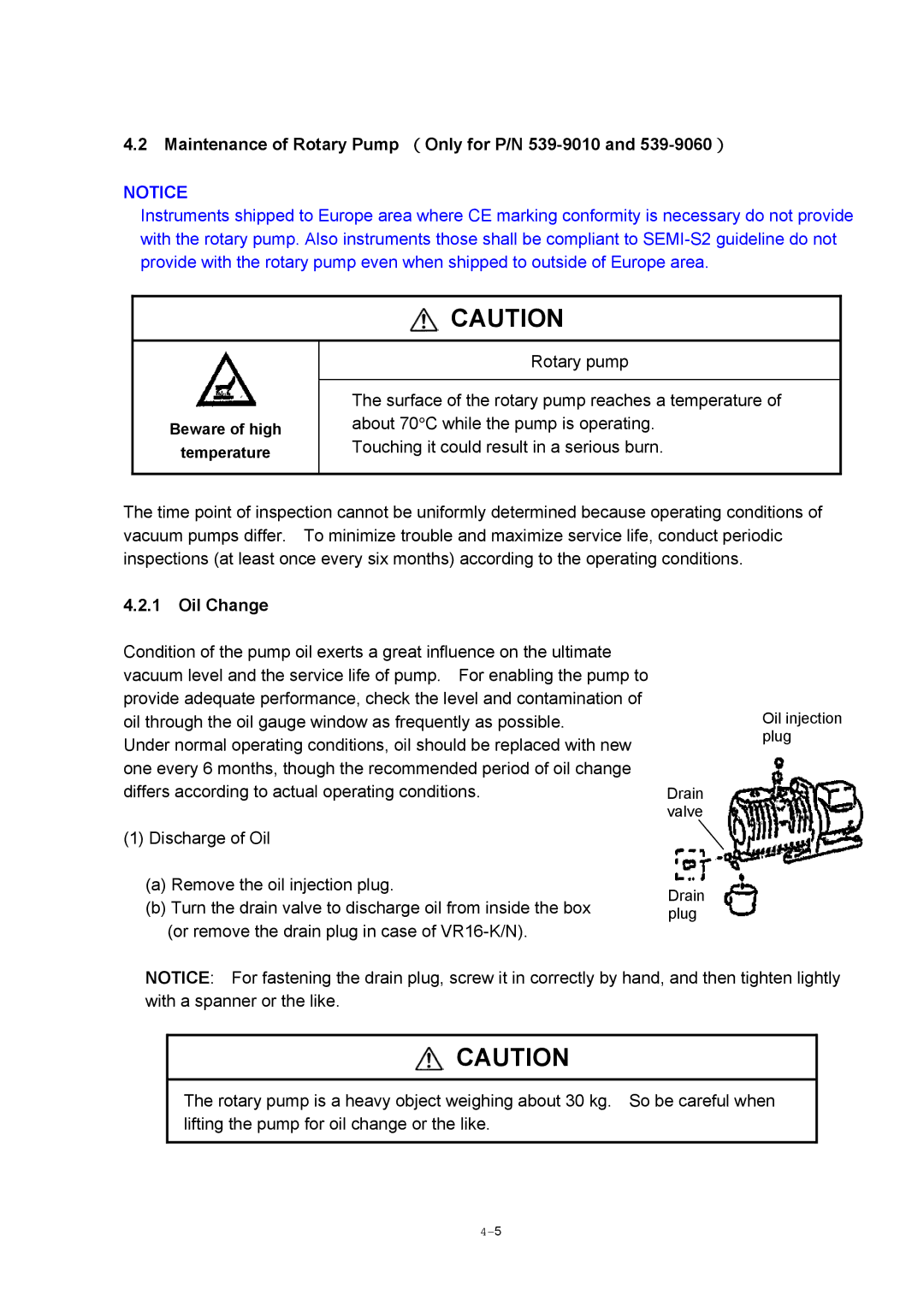

Oil Change

Replacement of Oil Mist Trap

Symptom Cause Countermeasure

Troubleshooting

Checkup and Maintenance

Page

Symptom Probable Cause Remedy

Troubleshooting of Air Compressor

Location and Functions of Major Components

When Specimen Exchange Chamber Vacuum is not Good

Troubleshooting When Column Evacuation does not Work

When Ion Pump Vacuum Degraded

When Specimen Chamber Vacuum is not Good

When Image is not Shown on Screen

When Emission Current is not Set at Normal Value

When Image is Very Noisy

When Auto Focus or Auto Stigma does not Work Satisfactorily

When You cannot Correct Astigmatism

When PC has Hanged up

When S-4800 control program does not start up

Operation when power was shut down by power line failure

When Error Messages are shown

Operation for shutting down all power supply of S-4800

Operation for Starting S-4800

Operation when Water supply stopped by failure

Operation when power line failure recovered

Gun Baking operation

Beware of high Temperature

Page

Beware of high Temperature

Page

Consumables

Consumables and Spare Parts

Part Name Use Expiration

Replacement Parts

Part Name Location ’ty Used

Spare Parts

Model S-5080 Auto-Camera option

Configuration

Configurations of Various Film Holder Units Option

Remarks

Specifications

Model S-5080 Auto-Camera option

4″ × 5″ Film Magnification

Assembling the Camera

Aperture for Each Kind of Film

Operation

Installation Manual for the SEC Guide Rail for Installer

Index

PRECAUTION-7, PRECAUTION-9, PRECAUTION-11

Edit menu Copy Attribute command 21, 3-101

PRECAUTION-8, PRECAUTION-11

PCI

PRECAUTION-10

Transfer 2-21, 2-31, 2-48, 3-72

![]() CAUTION

CAUTION![]() CAUTION

CAUTION