Page

Page

Regulatory

Table of Contents Section Descriptionpage

Feature Description

Feature Access Codes

Section Glossary of Abbreviations

DSS/BLF

Feature

Section

140

MEL Issa SEP MON

100-2 Two Line

Dssiblf Console. The Transfers may be

Multiline Terminals 100-5

Ability Set Call

While they

Talking

Away from Their

Chapter

LED

External Zone Paging with Meet ME

Night Mode

External Tone Ringing four tones is

Hold Exclusive and NON-EXCLUSIVE

Holding

ETE-6- LED is red, while at other stations it will Remain

Handsfree Dialing and Monitoring

Internal Zone Paging with MEET-ME

Function of the Electra Mark11 System which

Station user dials the number indicated. Once

Electra MarkII’s trunks to meet almost any

Terminal With LCD equipped with a DTA-E Unit

Such

Provide Auto Answer

By an SLI-E ETU port, a Multiline

APRIL,1990

100

TRUNK/MFR Test and Busy OUT Attendant

Chapter

LCD Indications

150

Conference LK16 TR Cocall LK16 NE1L.A

Code

Error

Not Install

LCD Indications

Section Feature Access Codes Numbering Plan

SLT

Feature Condition Code

Section Equipment Identification

Equipment Description

General Information

RAA-E Unit

This power supply accepts a DC input voltage

PSE-DD-1 PSU

RSG-E Unit

TLI-E ETU

CBL-E Unit

COI-E ETU

COI-EB ETU

ECR-E ETU

SLI-EB ETU

MFR-EA ETU

CNF-E ETU

ND-29292

ADA-ER Unit

HFU-E Unit

DPA-E Unit

ADA-E Unit

Hardware Installation

Chapter Table of Contents

Programming Station

Section Specifications

PSE-AD-l, PSE-DD-1 PSUs

200-3

To determine

An ESE-32B-1 CCU is always required ESE-32E-1 CCU

VMI-E

MFR-EA

CNF-E

ECR-E

= Compatible with other

Power Requirements

NC = Not connectable

By an

Buffers

Electra Mark11 capacities are as follows System Ports

Intercom paths Multiline Terminals

110

220.10

Expansion

Basic

Expansion CCUs

ZOO-8

RAA-E

RSG-E

PCM

Battery Backup

Dialing Specifications

Smdr

CO/PBX

OFF

On DND

LED OFF

DSS KEY

Construction

Site Preparations and MDFlIDF

Station Equipment

Main Distribution Frame MD!? consists of two

Parallel

Practice generally results

@ee

KEY

Por4Relatior

TIP

Central Control Units CCUs

They can operate as

MDF Co3

J8 AC OUT

Floor Mounting the CCU

15 Floor Mounting 4 CCUs 200

#!9

Level ETU

Or Higher

Common Control

CPU-EB CPU-EC

CPU-EC ETU DIP Switch

18 TSW-E Switch Layout 200

CPU-E

TSW-EB ETU

MMC-E ETU

4db

Odb

On = 2db

ON=

MON

ESI-EA/EB ETU

SLI-EA/EIB ETU

MFR-EA ETU

SW1

24 SMDR-E ETU Switch Layout

PIN # Function

200-26

LCR-EETU

200-29

ITC

OGC

ICC

OTC

Figure ZOO-29 Smdr

30 LCR-E ETU DIP1 Switch

Section Power Supply Installation

Green

’7 Interconnection of PSE-DD-1 PSU

Section Ancillary Device Connection

I260.2. Handsfree Unit HFU-E

= Compatible

Ancillary Device

Ancillary Devices HFU-E ETU DPA-E ETU ADA-E ETU DTA-E ETU

Ancillary Device Adaptor UNIT. ADA-E

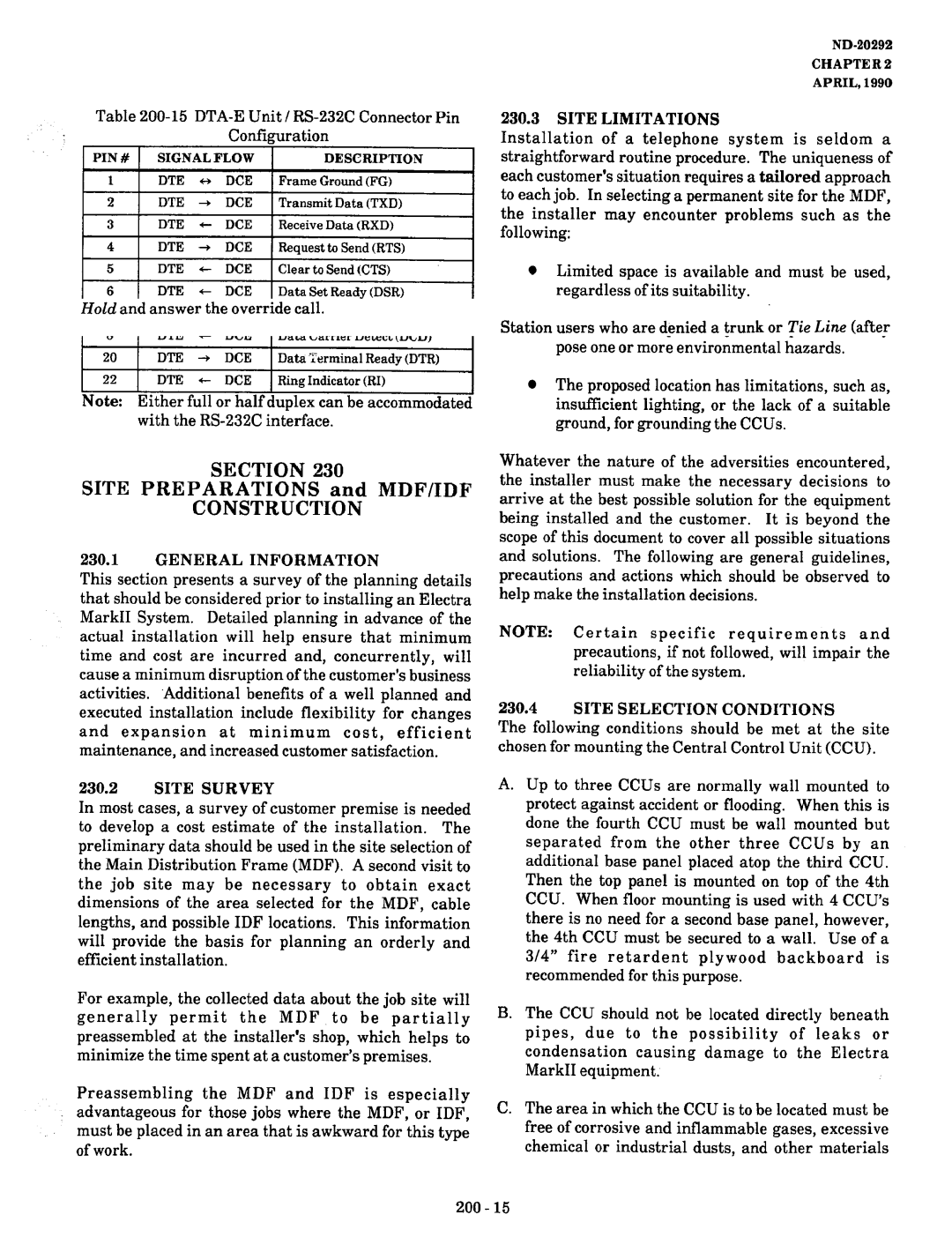

Data Terminal Adaptor Unit DTA-E

45 DTA-E Unit 200

Wall Mount Unit Installation

Reinstall the two screws and designation strip 200

DTA-E Installation

CTS

Switch Assignment

SW3

Music on Hold

Figure ZOO-47

External Tone Ringing / Night Chime

Background Music / Delay Announcement

External Paging

Offoff Offon Onoff Onon

Modem Termination

Installation

Electra MARK11

Shown in Figure

To pins

Feet Max

On both Ends

RS-232C Male Connector

Chapter

Page

Programming

Table of Contents

RAA SLT

III

360 Code/Call Restriction

Charts

350 Function

+ dialing areas Direct Dialing areas

HOW to USE TR’I~~BA~-X~.~+M

Reader directions and recommendations for using Chapter

’ 310 General

300-2

Memory Memory Feature Feature Section Item

DEtlGNAGNNl-5 A--E l-10 Feature KEY Fl-F5

=CO/PBX

Resident SY I’EM Default Values Memory Function

1ECTION330

Values Block

Default Values

Function Default Values

Function Default Values

TIE Line

None

TLI-II

Block

Memory Function Default

This page Left Blank Intenionally

INE Assign

Program Mode

OFF-LINE

Terminal

System. Each Other than PE i

Guide to Feature Programming

General Information Line KEY Assignment

3B9,3B10,4B4

TEL105

Line Program Mode Terminal DAY

Memory Block 1B Ringing Assignment

Ring DAY

1D3,2D2

Guide to Feature Programming

General Information Ringing Assignment

Dssi Vacant DSS ATT

Line Program

Terminal DSS/BLF ATT

7DSS ATT

DSS/BLF to Attendant

Information

Assignment

General

Go off line Depress Fl, then F8 Depress F12

F Line Program Mode TERMINALDSS/BLF BLF T E L Assign

KFY FI JNC Tion OFF Linf

General Information BLF Terminal Assignment

LE2

DSS OWI TEL

Feature OW6 Vacant Dssi ZONE?? DSS ROW1

PROGRAMMODE1 TERMINALDSS/BLF Dssdss KEY Devi CE? Dssi

2ClO

Feature Station Appearance

General Information

DSS/BLF Button

FLX Feature FLX2

F Line Program Mode Terminal

Dssi FLX Feature

ZONE?? DSS X . Feature MSG Wait

KFY Function OFF 1 INF

General Information Dswblf Flexible Function KEY Assignment

1Cl

2A7

Admodule

Memory Block 1CS DSS to CO ADD-ON Module Assignment

F Line

Terminal DSS/BLF

General Information Dssto CO ADD-ON Module Assignment

Assign Admod ROW1

Memory Block lC6 CO ADD-ON Module Line KEY Assignment

DsshL~

ADMOD? Assign Admod OWI

KFY FUNfTION fOFF Linfi PKR ON/OFF Line

LC6

General Information CO ADD-ON Module Line KEY Assignment

LC5 1Cl. lC7 C8.1 E2

DAY RI NG

F Line Program Mode

Memory Block lC7 CO ADD-ON Module DAY Ring Assignment

S / B L-F

Enter Enter each assignment Backward Decrements row number

General Information CO ADD-ON Module DAY

Ring Assignment

LC5.1C6 LC8,lEZ 2D2,3A2

Admod

Night RNG

Rowz

2D&2

LC8

General Information CO ADD-ON Module Night

LCS.lC6 1C . E2

Prime

F Line Program

PRM RNG Pref

PRM RNG.L.PREF

All CPU levels. See Step

Digit Code Feature

KFY Function OFF I INF

Depress

Data Service Assignment

Line Program Mode Terminal Feature Data Service

Data Term

4B4 287

Service Assignment

Data

General Information

User

Memory

User Program Assignment

User Program

Ringing Note Riig

= Default

General Information User Program Assignment

KFY FI JNfTION OFF LINF! Qpkr ON/OFF Line

Operation q Go off line Depress Fl, then F9 Depress F14

Memory Block lD4 Trunk Group Incoming Restriction

TRK.GINCOM.REST TEL??? TRK.GINCOM.REST TEL104

TRK.G INCOM.REST

2Cl2c2

General Information Trunk Group Incoming Restriction f

~.3

Line Program Mode Terminal Feature RK. G OUTGO.REST

Memory Block lD5 Trunk

Group Outgoing

2Cl 2C2,2C3

General Information Trunk Group Outgoing Restriction

Code REST.#104

Terminal Feature

Restriction

Code Restriction

3E10,2Cl-2C3

General Information Code Restriction Table Access

107 3El.3E2.3E3

3E4,3E7,3E8

Svc #lO

Memory Block lD7 Class of Service Assignment

Classof Service TEL??? CLS.OF

Svc

LZDl,ZD2,203 12E1,3B3

General Information Class of Service Assignment

LD7

481 or 4B6

Term ATT

Mode Terminal Feature ATT

Memory Block lD8 Terminal to Attendant Assignment

XsXX

Spkr ON/OFF Line

WY FUNrTlON cFF I INFj

3A2,3A3,3A4

ZONE2 TERM-ZONE Paging

Mode Terminal Feature TERM-ZONE Pagi

Paging

Zonex Term

KFY FUNt Uoff

Guide to Feature Programming

General Information Terminalto Paging Zone Assignment

2El

L 1 OL4 PIC.Gl

Memory Block lDl0 Call PICK-UP Group Assignment

CALLPICKUP.G TEL??? TEL104-PIC.G?

Call Pick

General Information Call Pickup Group Assignment

Depress Enter key F-W

Line Program Mode Terminal Assign

Memory Block 1El Terminal Exchange

TEL104 ? ?

Chapter

General Information Terminal Exchange

LC2,2Al, 3A2

SLOT?

Program Terminal TERM.ADD MOD?

TE RM.ADD MOD1 TERM.ADD MOD? Line

Slot

Type

LE2

General Information Terminal ADD Port Equipment

IN/OUT

F Line Program Mode Terminal Assign

MOD? Slot

MOD1 SLOT8

TEL

LE3

General Information Terminal Busy Assigni

4E9

TEL Informat DSS?

Terminal Assign

Nformat

MOD1

Clear Enter

General Information TERMINAL/TELEPHONE Information

MOD? Slot Port

Line Program Mode Terminal Assign Port

Memory Block lE5 Port Information

ION

All CPU levels. See Note

General Information Port Information

4Cl

KFY Functitn QEF Line

TEL??

Memory Block lE6 Telephone Number Exchange

OFF Line Program

TEL NBR Exchange

Enter Enter each number exchange Backward

LE6

General Information Telephone Number Exchange

LC3

TEL NBR Change

Program Mode Terminal Assign TEL NBR Change

Memory Block 1E7 Telephone

Number Change

Ction OFF NF

Change

Telephone Number

ZEl,lC3,2ClO

Digit

Digit Rest

DIGIT??

DIG

DI GIT Rest

II General Information CO Line Digit Restriction

Assignment

ZCl-2C3

Programmi TEL Number

FEATURE1

Block 2Al

System

TEL#

2Al

General fNFORMATlON Programming Terminal

LE2.4Cl

Code

Line Program Mode

SYS FEATURE1

Memory Block 2A2 Speed Dial Tenant Assignment

3A4,1D8

2A2

General Information Speed Dial Tenant Assignment

OFF Linf

Override TENANT?

Line Program Mode SYS

Memory Block 2A3

Dial Override Assignment

KFY FI JNfTlOhUOFF I Infi $PKR ON/OFF Line

General Information Speed Dial Override Assignment

PR1ME.L

Memory Block 2A4 Incoming Prime Line Pickup

Incom

Operation 1AND -WDISPLAY

KFY Functuoff

General Information Incoming Prime Line Pickup

To be dialed as a first digit on a CO appearance

Memory Block 2A5 CO * and # AS First Digit Assignment

Operation 1-AND -wDISPLAY Go off line

All CPU levels

Guide TO.FEATURE Programming

Eneral Information CO * and # AS First Digit Assignment

ClLEAR Enter Enter option

F2, then F6

Memory Block 2A6 Smdr Incoming

Smdr

Print Operation Display

YFY FUNCTlQbl OFF L@JF

2A6

General Information Smdr Incoming Print

201

Go off line Depress F2, then F6 Depress F17

Line Program Mode SYS FEATURE1 ALL Call

Internal all call feature. See Note 300

Memory BLOCK2A7 Internal ALL Call

TEL# Clear

2A7

General Information Internal ALL Call

Function OFF I INF

DIGIT-09

SYS FEATURE1 Account

Memory Block 2A8 Account Code Digit

DIGIT-XX Account

LD7,2Dl 2E1 3B3

Code Digit

General Information Account

PBX Outgoi

FEATURE1 PBX Outgoing

Memory Block ZAS PBX Outgoing Code

Outgoing

KFY Fumtion OFF I INF! Qpkr ON/OFF Line

2A9

General Information PBX Outgoing Code

4Bl or4B6

DIGIT12

Digi

Digitxx

KEY Function ..UFF 1INF

Using Tie Line

General Information TIE Line Digit Restriction Assignment

Modem Pooling Terminal Keyboard Dialing Assignment

Program Mode SYS FEATURE2 PC D I AL Assign

Memory Block 2Bl

Dialing Assignment

2Bl

2Dl

General Information Modem Pooling /TERMINAL Keyboard

AL LOW FWD 0 V E R

‘-A

Memory Block 2B2 Allow Forward OVERRIDE4

AL LOW FWD Over

Enter Enter assignment B/W

2B2

General Information Allow Forward Override

QPKR- ON/OFF Line TEL#

TRUNK?? TRK ANT TRUNK02 Tenantx TRUNK03 Antx

Line Program Mode FEATURE2

Memory BLOCK2B3 DIT Trunk to Tenant Assignment

‘1 ,’

2B4 2C1,2C2,3A4

2B3

To Tenant Assignment

General Information Dittrunk

Memory Block 2B4 DIT / ANA Assignment

Program Mode SYS

DAY Mode

1D8,2B3,3A4

2B4

General Information DIT/ANA Assignment

LCR

OFF Line Program Mode

Memory Block 2B5 LCR 1+ Dialing Assignment

+DIAL

KFY Function

General Information LCR I+ Dialing Assignment

LCR Call OVE

SYS FEATURE2

Memory BLOCK2B6 LCR Local Call Override

LCR L oc Callove

2B5,2B9

2B6

Ii Generalinformation LCR Local Call Override Assignment

SLT150 RMl

S . FEATURE2

Memory Block 2B7 Modem Pool Assignments Operation

Modem Assign

L2D1, 4B4

2B7

General Information Modem Pool Assignment

LD2,2Bl

Operation 1AND T-WDISPLAY

Memory Block 2B8 VMI Assignment

VMI

LKI-4

Dtmf

General Information VMI Assignment

KFY Funcw

LCR LED OFF

Restricted Default Depress Enter Key See Note

Memory Block 2B9 LCR Bypass Assignment

LCR Bypass Line KEY

KFY F-OFF

2B9

General Information LCR Bypass Assignment

LD7 2B5,286

Tone or extension dial tone. See Note 300

Line Program Mode SYS FEATURE2 Recall

Memory BLOCK2BlO

Recall KEY Operation For TIE Lines

Function !OFF 1INF

General Information Recall KEY Operation for TIE Lines

Trunk TRUNK.G U N K

Display Line Program Mode SYS Group Trunk TRUNK.G TRUNK??

Group Assignment

2c1

General Information Trunk to Trunk

Trunk Groups to the tenant chosen. See Note

Line Program Mode SYS Group Trunk Tenant TENANT? TENANT1

Memory BLOCK2C2 Trunk Group to Tenant Assignment

Trunk Tenant TENANT2

3C2

2c2

Generalinformation Trunk Group To Tenant Assignment

2Cl

TRK.65

Memory Block 2C3 Trunk Group to Access Code Group

Liine RIA Mode SYS Group RIK TRK.G-A.C.G TRK.G4

TRK.64

M.B El

General Information Trunk Group to Access Code Group

Access Accessitem Itemdialcodes Code A.C.G

KFY Functionjoff I INF

Memory Block 2C4 Voice Mail Hunt Group Assignment

After , the display will show any previous assignment

Generalinformation Voice Mail Hunt Group Assignment

KEY Function OFF Line

Memory Block 2C5 Delay Announcement Assignment

Enter Enters each assignment Decrements trunk number

General Information Delay Announcement Assignment

2C5

3B5-3B8

A02

SYS Group TRK.A.C.G

Group Assignment

General Information Uniform Dial to Trunk Access Code

Trunk Access Code Groups to Various Uniform Dial Numbers

Night Chime

Memory Block 2C7 Night Chime Assignment

SYS Group

GHT Chime

Assign Trunk Groups to

2C7

Night Chime

2c1 2c9

EXT INTERVAL2

F -LINE Program Mode

Memory Block 2C8 External Ringing

EXT

Interval Numberringing Pattern

Generalinformation External Ringing Control Assignment

Ight Chime Asgn

Line Program Mode SYS Group Relay Assign

Memory Block 2C9 ECR Relay Assignment

Ight Chime

LK3

General Information ECR Relay Assignment

EXTENSION-200

Memory Block

Virtual Extension

ASS

Total number of Virtual 300

General Information Virtual Extension

LA, 2El

VE48 = EXT

Memory Block 2Dl- Time Base Assignment

CPU-EC4

Line KEY Timer

General Information Time Base Assignment

CPU-EC3

Talk Start

Line Program Mode SYS Base Isec Depress KEY

Memory Block 2D2 Time Base Assignment

OUT Base Isec

2D3, lA

2D2

1D7,4Bl

Auto Scon

Line Program Mode Base

Memory Block 2D3 Time Base Assignment

OMI Depress KEY

Information Time Base Assignment Ill

2D3

General

ITEM23 Internal PAG

Line Program Mode SYS Access

Code Assignment

ITEM23 Internal

KEY Function OFF Linf

General Information System Access Code Assignment

2El

Flexible

Codes Feature

Fixed Codes

Flexible Codes

CPU-EBB

Depress F3

Memory Block 3A2 Attendant 3rd and 4th Assignment

ATT3 Asgn Depress

Operation -AND -DISPLAY

General Information AlTENDANT 3rd & qfh Assignment

Attendant

Memory Block 3A3 Attendant Overflow Assignment

ATT Overflow ATT? ATT2-+ ATT? ATT2-+ ATT4 ATT3-+ ATT?

300-138

Overflow is for internal operator Dia .l 01 calls only

General Information Attendant Overflow Assignment

Display Shows any previous Assignment

To be set

ATT Tenant Asgn

Block 3A4 Attendant To Tenant Assignment

ATT1 TE Nanti ATT -T E Nant Asgn ATT2-- Tenantx

N a NLT

Generalinformation AlTENDANT to Tenant Assignment

300-142

Sysz FEATURE1

Memory Block 3Bl- First Ring Pattern Assignment

Pattern Depress Line

Spkr ON/OFF Line TEL# Forward

3Bl

General Information First Ring PAlTERN Assignment

3B2,4B6

Depress Line

Memory Block 3B2 Centrex Ringing Assignment

Centrex Ringing Trunk GROUP?

CTX

4B6 3Bl

382

General Information Centrex Ringing Assignment

Forced

Memory Block 3B3 Forced Account Code Digit Assignment

ACC Code

Digits

300-147

3B3

General Information Forced Account Code Digit Assignment

TERM???

OFF Line Program Mode Sysz FEATURE1

Memory Block 3B4 RAA SLT Assignment

ASS.1

RAA and an SLT Information See f 300-149

3B4

General Information RAA SLT Assignment

HNT.GZ

Memory Block 3B5 Station Hunting Pilot Number Assignment

OFF Line Program Mood E Sysz

HUNT.G-P~ILOT HUNT.G? HUNT.G-PILOT HNT

385

TAT

Memory Block 3B6 Station to Hunt Group Assignment

Station

EXTENSION100

3B5 3B7,3B8

3B6

General Information Station to Hunt Group Assignment

Huntsearch HUNT.GZLINEAR

Memory Block 3B7 Station Hunt Type Assignment

UN Tl. G 1 Linear

HUNT.GlCIRCULAR

Enter Enters each assignment Decrements Hunt Group number

General Information Station Hunt Type Assignment

3B5,3B6 3B8

ON/OFF Line

HUNT.GFWD Asgn HUNT.GZ-FWD???

HUNT.GFWD Asgn Hunt .G?

FWD

HUNT.G FWD

IS/W

3B8

General Information Station Hunt Group Forward Assignment

365,366 3B7

‘0 F F -LINE

Memory Block 3B9 Trunk Group to Line Pool Group Assignment

300-159

Ispkr ON/OFF Line

Memory Block 3BlO Line Pool Group Auto Extension Assignment

Clep

Appearance of Multiline Terminals. Primary

As PAEs 300-161

SYS

Name Assignment

Space ISI

General Information Telephone Name Assignment

Dial PAD Keys

Ispace

Trunkname TRUNK??

SYS Name

Trunk Name TRUNK??

Name LIL

General Information Trunk Name Assignment

3C2

12oo

Memory Block 3Dl- First Initialization

SYS Initialize

ALI Depress

System software and hardware

Enter First initialization command

3Dl

General Information First Initialization

Depress Enter key. See Notes 1

Memory Block 3D2 Second Initialization

2ND

04 15 NOV 25 TUE

’ Ispkr ON/OFF Line

Enter Second initialization command

3D2

General Information Second Initialization

LNlTlALlZE

Memory Block 3D3 Slot Initialization

On Assigned OFF Not assigned

IIGENERAL Information Slot Initialization

Initialize Not Initialized

Memory Block 3D4 Terminal TEL, DSS Initialization

INlTlALiZE

TEL120

General Information Terminal TEL, DSS Initialization

Area Assign Direct

Line Program Mode SYS Rest Area Assign

Memory Block 3El- Regional

Xxxxxxxxxxxxxxx

Region Number Dialing Type

General Information Regional Dialing Assignment

107 LD6,4Blor4B6 2A9,2Cl-2C3 LE10,3E2-3ElO

F3, then FlO

3E2 1+ Dialing

SYS Rest

4Bl or4B6 a

3E2

General Information + Dialing Assignment

LD7 1D6,2A9 2Cl-2C3, 3E1

CODE2

Memory Block 3E3 Rejection

‘ASGN

CODE1

2Cl-2C3,3El 3E2,3E4-3ElO 4Blor4B6

3E3

General Information Rejection Code Assignment

LD7 LD6,1ElO,ZA9

Memory Block 3E4 System ALLOW/DENY Assignment

Line Program Mode SYS Rest AL LOW DE NY

3El-3E3 3E5-3ElO 4Blor4B6

3E4

General Information System ALLOW/DENY Assignment

LD7 LD6,1ElO 2A9,2Cl-2C3

TBL15

Memory Block 3E5 Table Allow /DENY

3E6,3E9 3El-3E4.3E7 3E8.3ElO.lElO 14Blor4B6

3E5

General Information Table ALLOW/DENY

LD6,1D7 2A9,2Cl-2C3

Go off line Depress F3, then FlO Depress F16

Memory Block 3E6 Trunk Group to Code Table Assignment

Trunk TABLE?? TRK

TRK TBL

Enter Enters each table assignment Decrements table number

3E6

General Information Trunk Group to Code Table Assignment

3E5,3E9 3El-3E4,3E7 3EB,3ElO,lElO 4Blor4B6

LAG

Line Program Mode SYS Rest

Memory Block 3E7 Table OCC Flag Assignment

LAG TABLE??

General Information Table OCC Flag Assignment

3E7

10233

Memory Block 3E8 Table OCC Code ‘ASSIGNMENT

Code TABLE??

Code TBL14 CODE1

Carriers.i

3E8

General Information Table OCC Code Assignment

LD6, lD7 2A9,2Cl-2C3 3E5-3E7,3E9 3El-3E4,3ElO 4Blor4B6,lElO

07 7

Memory Block 3E9 Restriction Table Code Assignment

A516

Code Asgn TBL14 CODE5

General Information Restriction Table Code Assignment j

3E9

144

Line Program Mode SYS Rest Special

Memory Block 3ElO Special Code Assignment

CODE1 Special

General Information Special Code Assignment

Go off line Depress F4 Depress F6 Depress Fll. See Note

Memory Block 4Al- System ALL Busy Restore Assignment

System Restore

Card System AL L

TEL# Clear

General Information System ALL Busy Restore Assignment

Depress F4, then F6

Memory Block 4A2 System ALL Busy OUT Assignment

System AL L

System Busy

Processing 300

4A2

General Information System ALL Busy OUT Assignment

4Al

COI ALI

COI-I

ALI

ZEI

General Information COI-I Initialized Values

MOD1 SLOT? ALI

Card Mode

4B2

COI-II Initialized Values

IDI

General Information COI-II Initialized Values

Line Buttons

14B1,4B6,4B7

Operation 4-AND

F Line Program Mode R D Mode NI TI ALI Ommo

Memory Block 4B3 SLI Common Values

Values

4B3 1’1

Lo!0

SLI Common

Module

MODULE?

Module

NI TI ALI MODULE2

With Data Adapter DTA-El Assigned To an

All CPU levels See Note

300-206

4B6

COI-III Initialized Values

TRUNKGROUP3

General Information COI-Ill Initialized Values

ZE4

Line Program Mode Card COI ALI

COI NI TI ALI

Go off line Depress F4, then F7 Depress F17

IiPARAMETERS

4B7

General Information COI-IV Initialized Values Programming

SLOT7 Initial

Mode Initial

Memory Block 4B8 VMI Initialize 1 Assignment

SLOT? VMI Initial

Ll L2 L3 L4 L5 L6 L7 L8 L9 LIO Lll L12

VMI

Initialize 1 Assignment

2B4,2B8,2C4 4B8,- 2D2,3C1,4B9 3B5-3B8.4Cl

INITIALIZE2 MOD1 CH? Initial Slot

Line Program Mode Card VMI

Memory Block 4B9 VMI Initialize 2 Assignment

MOD1 SLOT?

1000 mS Disconnect Time = 500 mS. + 200 mS. x M

Digit Duration = 60 mS. x M + 50mS.xM Default 110 mS Pause

Card Interface Slot Assignment

Memory Block 4Cl

Etiu

General Information Card Interface Slot Assignment

2A1,4C2

Interface Busy Module

Memory Block 4C2 Interface Slot Busy OUT Assignment

U L E

Enters new module and slot number

Interface Slot Busy OUT Assignment

Type TRK

Dial Tone INE TYPETRK.GZ Delay

Select

TYP Trunk GROUP?

2E1,3C2,4Cl

General Information TLI Line Type Assignment

2AlO,ZBlO

2Cl-2C3,2C6

TRK-G2

Memory Block 4E2 TLI Dial Tone Assignment

Dial

ASS Trunk GROUP?

QFJ

General Information TLI Dial Tone Assignment

Code Trunk GROUP?

Memory Block 4E3 TLI Digit ADD /DELETE Code Assignment

TLI Programming

ADD

14E1.4E2 12A10,2BlO

General Information TLI Digit ADD / Delete Code Assignment

TLl

Block 4E4 TLI I Initialized Values

TLI

ALI ZEI Trunk

4El-4E3 2A10,2BlO 2Cl-2C3,2C6 2E1,4E5-4ElO

Defaults

4E4

General Information TLI I Initialize Values

TRUNKGROUP1

F Line Program Mode TLI ALI

Memory Block 4E5 TLI II Initialized Values

TLl INITIALIZE2

Guide to

Feature PR-OGRAMMING

TLI II Initialize Values

Example Trunk Group

Memory Block 4E6 TLI Initialized Values

INITIALIZE3 Trunk GROUP4 I I NI TI ALI ZE3 TRUNKGROUP?

General Information TLI Ill Initialize Values

4E6

SLOT? ALI ZE4

Memory Block 4E7 TLI-IV Initialized Values

Programmi

ALI ZE4

Uoo 0010 00113 100

4E7

Initialized Values

LINEsurroNS-l- Function

ALI ZE5

Line Program Mode Programmi

Memory Block 4E8 TLI-V Initialized Values

ZE5

Function

4E8

General Information TLI V Initialized Values

4El-4E7 2A10,ZBlO ‘ZCl-2C3,2C6 2E1,4E9,4ElO

Hunt Tandem Port Asgn

Port to Hunt Group

Tandem Port Asgn

EXT300

LE2,4Cl 2A10,2BlO 4El-4E8 2Cl-2C3,2C6 2E1,4ElO

4E9

General Information -TANDEM Port to Hunt Group Assignment

Hunt Tandem Port Asgn TRK

Line Program Mode Programmi Tandem Hunt Asgn

Tandem Hunt Asgn

II General Information -TRUNK Group to Tandem Hunt Group

4ElO

START???

Memory Block 5A Station

RI NG DAY

Copy

General Information Station Copy Assignment

Guide TOI Feature Programming

CPU Initial Clear Data

Memory Block 5Bl- CPU Initial

History

14JAN22-88

ROM

General Information CPU Initial History

CPU Initial

31JAN04-88

SYS Prog Check

SYS Prog Check Error

Memory Block 5B2 System Program Check

OFF-LINE Program

ROM 128~

General Information System PR0GRA.M Check

Program no

ROM 00 ROM 02,03,04,05,06 ROM 06,07,08

Xxx

Memory Block 5B3 Interface Slot Check

OFF-LINEX.Xx

MOD SLOT5

General Information Interface Slot Check

5B3

Terminal Check

Error Count

Terminal Check DSS? Error Count

Memory Block 5B4 Terminal Check

General Information Terminal Check

5B4

MODULE1 SLOT?

Memory Block 5B5 SOFTWARE/HARDWARE Slot Status

Status

MODULE? Slot

TLI

General Information SOFTWARE/HARDWARE Slot Status

KEY Function

Spkr

S3,CH2 Xxx Hyyy

OFF Line Program Mode MAINTENANCE1 T E RM Status TEL???

Memory Block 5B6 SOFTWARE/HARDWARE Terminal

Xxx Hyyy

Decrements terminal number

586

General Information SOFTWARE/HARDWARE Terminal Status

1E2

SYS Data

OFF-LINE Program Mode

MAINTENANCE2

Memory Block 5Cl- System Data Last Change

OI3I 11121JIAINj2121 LlAI-1014j

System Data Last Change

Address

Memory Block 5C2 Data Dump

000000

400000

Xxyy

General Information Data Dump

Addressdata

This page Intentionally Left Blank

Section Function Timer Chart

Timing Value

Function Timer Chart Contd

Contd

Timing Value Timer

350

300-260

3E9

Section CODE/CALL Restriction

3E8

Digit Disconnect station

OCC Other Common Carrier Code Parameter

Step Second digit dialed

Digit Allow

Table is allow

Any Digit Allow User To dial Another digit Next

Step 5th Digit

Station System Deny Disconnect 300-265

New Found Table found

Is allow Allow user Free dialing System

Allow user Free dialing Is deny

300-266

E2, Ll-L8 on

1+ Dial Area

Direct Dial Area MB 3E2, Ll-L8 OFF

Other Common Carrier Access

MB 3E1, Puerto Rico Type Dialing

Special Code Override Table

Jobspecificationsheets Tableofcontents

JOB Specification Sheets Table of Contents

JOB Specification Sheets

Entry

JOB SJ?lWlFlCATION Instructions

For

Extension Assignment

Assignments

IL3

Being Assigned Extension Number Assignment of DSS Buttons

JOB Specification Instructions for

Attendant Associated

300-277

Blocks lC-1, -3

DSS Button Assignments

For EDE-30

Extension Number Each

Memory Block lC-2 BLF Feature to Telephone Assignment

ETE-16D- Multiline Terminal With BLF Feature

Description Entry

Module

Block lC-2 BLF Feature to Telephone Assignment

Memory

Extension Number XXX or

For Memory Blocks lC-5, -6, -7

Itemdescription

UJ5 iSYJ!iLlF‘lLA’l’lUN 1N S’l’K. U C‘l’lUN

300

Entry

Itemdescription

300-283

LD-2

JOB Specification Instructions for Memory Block

Data Service

Block lD-2 Data Service Assignment

UP to 16 Digits / CHARACTERS, #, *, l- 9, Pause

L8Z-OOC

Iin

Circuit Number From the CO

Description Assigning Third Programming

Allow Prime Line Pickup in the System

Separate Single Digits O-9 EKW

Trunk Tenant

Maximum Number of Digits That a Station can

Dial When Using a TIE Line Station Being Assigned

300-291

VMI extension number

JOB Specification Instructions for

Memory Blocks

Memory Block 2BlO is located on

2RR

Memory Blocks 2B-3, -4, -7, -8 and 2C-5 DIT/ANA

Assignments

Modem Pool and SLT to VMI

\/FOR TIwNI&R~~P

Specification Instructions For Memory Blocks 2C-7

Relay Assignments

JOB

NG Control

1NOTE 48 Virtual Extensions Are Available

For Assignment

Extension

Memory Block 2C-10 Virtual

Timing Required For Each FE URE

300-298

SEC

Memory Blocks 2D-1, -2 & -3 SYSl fi,M Time Base Assignments

SEC

2D-3

ANY Unused Code Pattern

‘NEW Feature

1NONE

Memory Block 2E-1 System Access Codes

None

Inone

NEW Feature ANY Unused Access Code Desired

Speed

Memory Blocks 3A-2, -3, -4, and 3C-1

Memory Blocks 3A-2, -3, -4, and 3C-1

Centrex Ringing Station Hunting

Specification

For Memory

3B-1 6, -7

3B-8

3B-5

3B-7

Rejection of First Digit Dialed

When Puerto

Type of Dialing Available in the Area

Dialing Methods Used for Toll Calling

Memory Block

3E 1, -2, -3, -4,

Blocks

System Rest

Description

3E5

3E6

3E7

3E5

Timing of CO / PBX Hook Flash from

Dtmf or DP

Memory Blocks 4B-1 and -2 CO1 Initialized

YES or no

JOB Specification

Hook Flash Start Time

L-3

ESI-EB Data and Second Voice Path Assignment Memory Block

SLI

CO1 Group

VMI Initialize

CNF-E

TLI-EB

M--w

Memory Block

4C-1 Card Interface Slot Assignment

Module Number

Description Entry

300

Description

Memory Blocks 4E-4, -5, and -6 TLI Initialized Values

40 ms. 180 ms 60 ms. 760 ms

TLI Initialized Values

Descriptionentry

Page

Chapter Station Operation

Chapter Station Operation

Consultation Hold Broker’s Call

General

Sample LCD Indications

1 idol I ILlI Iniei I I

I I I I I I I I I I IS1210 1101 I4151 Io~cITI lslsl 1~1~11

1 IElXh’l ILlI INlEl 1 1

Ifiri

1i’

Sample LED Indications

I I I I I I I I I I I I

IDI1 ITI IClAlLlLl 1 1 1

I I I I I I I I I I I I I ’

101~1~112181

I I I I I I I I I I I I I 1101I4161 IoIcITI lzlsl Ifiri

I I I I I I I I I I I I

1101 I5121 101~1~1 12181 Ifiri

I lclol I IL II Iwei I I

Prime Line

I Idol I ILlI WI I I

Land 1x1

Tie Lines & did

ITI Iiei ILI Iinie

IoIcITI 121.81 Ifirii

Page

01-l

Sample LED Indications Sample LCD Indications

Iliw

LIKIW~I

L I lslTlElVlEl 111317 1101

Handsfree Call

1101 I4151 101~1~1 lzlsl 1~1~11

1101 I4151 101~1~1 12181 Ifirii

101~1~1 12181 1~1~11

Ilo1 I4151 101~1~112181IFIRII

Eiliaip

1101I

1101

I I I I I I I I I I

I I I I I I I I

LIA P S ElDt 1 I 10151lo 2 I 01 4 5 ~OC~T 12181 Ifir

IJ-ZUBYZ

Ifirii

Ifiri I I I I I I

Ifirii I I I I I I

IOC

Sample LED Indications

I I I I I I I I I I I I

IO C

I I I I I I I I I

I IEIxITI 1~11IWI I I I 1101I4151 101~1~1lzlsl Ifirii

~c~o~N~F~E~R~E~N~c~EI I

I I I I I I I I I I I I I llol I4151 101~1~112181 1~1~11

John

FRI

Ilo1 I4151 IoIcITI InIsI 1~1~11

Depress Hold key and hang up

Icnf LED flashes ANS LED lights

Sample LED Indications Sample LCD Indications

I I I

161

IOlClTl

Pl LED’s gooff 400 ‘/ ’

1101 I4151 IOlClTl 12181 k’lRl1 400

IOlCtTl

Iext green LED lights IEIxITI 1101 I4151

Lf03l IFlRi

1 1 1 1 1 1 1 i 1 1 Li’ol I4151 101~1~1 12181 1~1~11

1101 I4151 101~1~1 Is181 1~1~1I

1 1 lJlIblMlYl l t

I IEIxITI 1~11 INlEI I I

1101 I4151 IoIcITI 12181 Ifir

1 1 IJIItilMlYI I I

1101I4151 IoIcITI 12181 1~1~1I

I2181

Sample LCD Indications

Ifirii

Lslsl

1101 I4151 101~1~1 12181 1~1~11

1 t lSlTlElVlEl 1 1 1101 I4151 101~1~1 lzlsl 1~1~11 400

Ifiri

I4151

1101

I I I I I I I I I I I I

Ifir

CNF

Ipiairiki Inib RI I? I I

Isie

ElEXT green LED lights

Green LED lights

I I IsITIEIvIEI I I 111317 llol I4151 IOlClTl Isisi IFlRlI

1101 I4151 ~oIcITI 12181 1~1~11

CO/PBX

Ifiri

1101 I4151 101~1~1 Msl Ifirii 400

I I I I I I I I I I

BhJISIfl 1 1 1 1 1 1 1 1 111317’

1101 I4151 IoIcITI Mel Ifirii

I I I I I I I I I I 1101 I4151 IoIcITI Mel Ifirii

1101I4151 lolcl~l 12181 1~1~11

Jioi

101~1~112181

I I I

Iciailil

ITI

I I I I

IoIcITI Ifirii

~oIcITI

Ilol

IoIcITI

Iext 1EXT

BlUlSlYl 1 1 1 1 1 1 1 1

I I I I I I I I I I I

1 1

BbJlSlYl 1 1 1 1 1 1 1 1

1 IElXtTl ILlI IN/El 1 1

Aicicioiuiniti IcIoIDIEI I?1

CO/PBX green LED is lit steady

ElLlAlPlSlElDl I lOlOl 1101 l415l

Lslsl ~1~11

12181 ~1~1 Lll2l3l4lSl6 Ilo1

Ilii

INlEl

LClOlDlEl

Irieipieiaiti

1 IClOl 1 ILlI INhI 1 1

Depress line key programmed for Do Not Red LED lights steady

111111111111111

1101 I4151 IoIcITI lzlsl 1~1~11

~11 INlEl

Isieit

Llol I4151 IoIcITI 12181 1~1~1

Fiwidi IAILILI. I 1~101~1 Isieit

1101 I4151 101~1~1 lslsl 1~1~11

FlWlDl IAlLlLl 1113171+ 1101 I4151 IoIcITI 12181 1~1~11

I I I I I

1101 IoIcITI 12181

1101 I4151 IOlClTl 12161 IFlRlI 400-65

II417

1113171+

1101 L4151

IAlC

ElCNF LED flutters Icnf LED goes off 400

ISPlDj

SPD RIK

Sipidi I I Itiriki Mcbl I

111

IAlCl91

I I I I I I I I I I I I I 110’1 I4151 101~1~1 l2l8l Ifirii

SkIDI I 1 lTlRlKl IAlCbi I

111111111111111

1101 l45l

Itiriki

Aici

IFI

Itiriki

IoIcITI Lslsl

Sample LCD Indications I I I I I I I I I I I I

IFI

PiRIOIGIRIAIMl ISlPlDl l?l?l

IMIuIsIIIcI Inibiri I?I I

1 IElXlTI ILlI Inpi I 1

1101 I4151 101~1~1 lzlsl 1~1~1I

JlL‘

1101 l4151 lOlClTl 12181 lFlRl1

Depress the DSS key programmed for calculator function

SlPlDl

IAIcI

Input 123

LCD during

Calculation, do not continue making entries

Addition

‘ND-20292

ND-20282

Ioiciti

I IEIxITI 1~11ppl 1 l 1 1101 14151 IoIcITI 12181 1~1~1

Iiiiiiiiiii

Ill

Ifir NE’W

I I I I I I

LlK11161 lVl lMlAlIlLl l

IV! Imiai

Imiaiiili

OCT

4151

ZUZYa

Isitieiviei

ITIoI

Diaitiai IP Iaitihi

OCT FRI Steve

Viei

FIR11

Steve

Inigi Datja

Not Ready

CAL

Inigi

TIO

Ilii Iniei

Diaitiai Ipiaitihi

Fjrii

IsITIEIvIEI

Diaitiai

IsITIEIvIEI

CIT

T ElV El 1 1 3

Ill3

Mmyi Data

MM’YI NOT’READY

IPI!$HI

M red LEDs flash IDR red LED flashes IDR green LED lights

TEXT-lLED goes off

~A~T~A

Steve Data END

I I Isl I Ivl I I I I1

I I IsITIEIvIEI I I I1

Data END

OCT FRI Data Path to END

I I IsITIEIvIEI I I I1 1317. ilo 14151 Io~c~T\ lep3l 1~1~11

I I IsITIEIvIEI

~A~TA~ Ipiaitihi

400-96

END

Steve

OCT

Data Steve

Octi FRI

EIV

CIT

OCT FRI Steve Data Path Busy VIE

Data Ressrve

IsITIEIvIEI

1101 14151 olc TI 12 81 1~1~11

EVE

Ifir

WA1 Tiiing

Sample LCD Indications Xiti Inie

AIL Wiaii Inig

AIT

DIA T a

Lw4DlYl Ill311

I I I I

I I

MODEM/2

Sample LCD Indications EIX

OCT FRI RIE Rieserved

I I I I I I I I I I I I

I I I I I I I I I I Ill410

I I I I I I I I I 1

EIM2

1ANS

Sample LCD Indications DIA

OIN

I I-I I I I’I II I‘I~I

I I I I I I I I I I

I I I I I I I I I

1101 14151 Ioc~T~ 12181 1~1~11

DepressDTkey

Red LED lights IDT redLEDgoesoff

DblTlAl iElNlDl I t 1 I 1113tl

Ii I I I I I I I I I I I I

Datia

Bold

Sample LCD Indications DIA TIA Onto M/ODEM,2

I I I I I I I I I I

Llol 14151 ~oIc~TI 1218 1~1~11

I lclol I I,LI Iinie I I

I I I I I I I I I I

Busy Elapsed OCT FRI

RIESERVEDMODEM2 Data Error

OCT FRI Elapsed

FRI OCT Elapsed

400-112

Eiliaipisieidi

Green LED on the CO Add-On Module lights

1161 I4151 IoIcITI 12181 Ifiri 1511

LOjOl I317

Eiliaip

LOClTl

Iliiiniei

1 ICI01 1 ILlI INId 1 1 1 1101 I4151 IoIcITI 12181 Ifiri

I2181

IoIcITI

Firi

1101 I4151 IoIcITI 12181 Ifirii

Ioct

Not S T AIL/L

OCT Busy OUT

I I I I I I I I I I I

DepressPrimary extensionline key

Lift handsetor depressSPKR key to receive dial tone

See Sections 420.1.2,420.1.3 and 420.1.4 of this manual

I I I I I I I1

IoIcITI 12181 1~1~11

IoIcITI Lalsl

I I I I I I I I

I I I

11~1~1IzIoINIEI I II IPIAIGIE- 1101I4151 101~1~1I2181 1~1~11

DSS red LED lights

Depress DSS key on the DSS/BLF

III Ipiaigie

Lift handset Idss red LED lights

Message Waiting ToSet

1101 I4151 IoIcITI 12181 Ifir

INI1 IGlHb’l IMlOlDlEl ISlEIT

~EIxITI

Iliiiniei

I 1~11 Igihiti I I I

1101 I4151 101~1~112181IFIRI

INT red LED goes off Primary

Red LED is lit steady Red LED goes off

1101I4151 101~1~1lslsl Ifirii

Iiii

Ifir

Iciodei ICI

Ifir I I

IEIxITI l~l~l~l~l I I Llol I4151 IoIcITI 12181 1~1~11

IEIxITI ~L~INIEI 1 1

FlWlDI IAlLlLl 1113171+

I IEIxITI

1101 I4151 IoIcITI

FlWlDl lAbILl 111317ld 1101 I4151 lolcl~l 12181 1~1~11

Depress primary extension line key Lift handset

SYSSPD??

SIPIDI

IAIcI ?I

LSlYlSlSlPlDl

Sipidi 1415 I Itiriki I~Ic1713 ~1~67~5~3~7~0~0~0~ 1 1 1 1

CNF LED goes off CNF LED flutters

Il‘ol I4151 IoIcITI lzlsl 1~1~11 PIR OlGjRAlM lSPlD ?I?

PIR Oigiriaim SlYlS Sipid ? ?

ID a YI

ID AYI

DEC set by line key

Llol I4151 lOlClTl 12181 IFlRlI 400-136

ND-20292 IHAPTER 4 April

Nioi

Sample LED

Icnf LED

Icnf

I I I I I I I

IAIcIcI~o~u~NIT

LOl 14151 lOlClTl j281 lFRlI

Pirio

Depressdesiredline key Green LEDs light

Day Mode

Night Mode

LED flutters PIRIOIGIRIAjMj LSPlDl ? I?

400-142

Consecutive dialing cannot be made in the following cases

Placing a Call on Hold

Abandoning a Call a Restore handset

Step Calling

Station Hunt Originating

Procedure 400

Receiving Trunk Queue Recall

To cancel a Trunk Queue

Original call

‘-r

Calls can be transferred

ZzJz

External Zone Paging To Originate

Internal Zone Paging To Originate

To Answer Meet-Me

Alternates

Can be Routed Another

Chapter

Chapter

To Answer

Camp-On To Originate

Code

Automatic Callback To Set

Maximum number of digits for the account code is determined

Station’s

To Cancel Lift Handset

ToSet To Set Lift

All call Busy/No Answer

Signals cannot be programmed into SLT

Station lockout. ’ 400

Some voice mail systems cannot originate calls

Directory Terminal Operation General

Sample LED Indications Sample LCD Indications

Icnf LED

I I I I I I I I I I I I

I I

ND-20292 DHAPTER April

Number of Depressions Digit

400-169

I I I I

As 1 digit

Sample LED Indications

400-172

Sample LED

I Ifiwdi IAlLlLl

Maintenance

Chapter Maintenance

TP3

Tolerance Measuring

CPU-E

TP2

Section Self Diagnostics Maintenance

Section Troubleshooting Flow Charts

Chapter

Partial Operations

Flow Chart Number

500-6 500-7 500-8

Index Table Condition System Down

500-6

500

MMC

Radio Frequency Interference RFI

Test system using default program

Affected Muitiline

AlITerminalseerminals

Call Dropping

MFR-EA

MMC-E

Multiline Terminal Function Problems

500

Multiline Terminal Dial Tone Access Problems

No Dial Tone Access on SLT

Ringing Problem on SLT

500

Low Volume Problems

External Paging Problem

Smdr Output Problems No Call Accounting System

Chapter Etis

Electra MARK11

Plantronics JS-180 Jackset Connection

Page

ET1 Number

4of

ADA-E Unit installation

Sw*il

Panasonic Autodialer Connection

2of6

3of6

4of6

5of6

Autodialer

Genesis Genie Voice Mail System Connection Procedure

MDF

DTE

Electra MARK11 Dswblf CO ADD-ON Module Upgrade

2of4

3of4

EII

Dasa D-4800 Directory Dialer Connection

Knsure the correct access ptnc!l is

3of

DUnplug Llna Co14

Dipswitch

ADA-E Installation

Nformation

2of8

ET1 Number MK-006 Date February

4of8

Soft3

Diskcapacitor Plastic SLEEVE4 Handset Connector

7of

8of

Handset Amplifier Connection Procedure

Page

ET1 Number MK-007 Date March

Rsr

ADA-E Unit Installation

HAYES@ 1200 Smart Modem Connection to

Procedure

Access Panel Removal

I m

ETE-GD-1

NFORMATlOt

Other Requirements

Electra MARK11

3of6

Test Procedure

5of6

Power Supply

12 on Unit

Front View of W-34X and Pin Xumbers

Nformation

Programming

Electra MARK11 System

4of

Side

Forma T/On

2of6

ET1 Number MK-011

ETE-10K-1

DIP Switch SW2

ADA-EInstallation

AEC TWO Channel Announcement Machine

2of6

Switch Setting SW1

Testing

Attendant Activation and Deactivation of Delay Announcement

‘...~

AEC TWO Channel Announcement Machin E

ETI Number MK-012A

ETI Number MK-012A

ETI Number MK-01 2A

Attendant Activation and Deactivation of Delay Announcement

ETI Number MK-012A

Testing

Conductor

System Frame Iground Connector ECR-E ETU Male

Cable DIP Switch Levers Shown Black

Announcer

Internal Jumper Plug Settings 7OF7

Page

ETI Number MK-014 Date April Description

NECAmerica Inc. Switchinq Terminals Division

Procedures

Electra MARK11

SLT SLI-EB OUT Fggnd

Test Procedures

ETI Number MK-014

Ground Starttrunk

TIN Tout RIN Rout GND

TIN Tout RIN Rout

ETI Number MK-015 Date April Description

Viking Door Phone

ETI Number MK-015

Or W-2000

Figure Handsfree Doorbox connected to COI-E/EB ETU 4OF6

TOP

5OF6

Figure Door Release connected to VMI Port

Parts Required

NECAmerica Inc. Switchins Terminals Division

SET UP Procedure

ETI Number MK-016 Date April Description

ETI Number EMK-016

Procedure

Inserting the Eprom and Adding the a Revision Label

RAC-E Unit

Adding Revision Label 2A to Outside of RAA-E Unit 4OF4

Description ETI Number MK-017 Date April

Pathfinder PHONE/DATA/FAX Switch

Site Requirements

ETI Number MK-017

References

ETI Number MK-017

To Telco

Connecting theviking FaxJack 4OF5

To TE LCO

Parts Required SMDR-E ETU

NECAmerica Inc. Switchin Terminals Division

ETI Number MK-018 Date April Description

ETI Number MK-018

SMDR-E ETU

DESCRIPTION%

Configuration

ETI Number MK-019

ETI Number MK-019

MDF

Repartee Connection Block Diagram 4OF4

ET1 Number Description Date

Dterm II Single Line Telephones

ET1 Bulletins

1OFS

Dterm

ETI Number DS-001 Date April Description

Limitations

ETI Number DS-001

TX2

Efl Number DS-001

White

TX1

ETI Number OS-001

Sofs

ETI Number DS-001

Connection of Northern Telecom

ETI Number DS-002

Companion 2 Cables

IIC3

IC3

Speakerphone Cable Exit Groove on Dterm II Telephone 5OF5

ETI Number OS-002

None Parts Required

ETI Number DS-003 Date April

ETI Number

RX2

ETI Number DS-003

RX1

ETI Number OS-003

QBI

Lackret JS-180 Cable Exit Groove on Dterm II Telephone 5OF5

ETI Number DS-003

ETI Number DS-004 Date April Description

ETI Number DS-004

Connectors

ETI Number W-004

\ &I

Page

II& l-l

TA-20 or S-l 1 Cable Exit Groove on Dterm II Telephone 6OF6

ETI Number OS-004

ETI Number DS-005 Date April Description

Connection of Audio Tape Recorder

Procedure

Stepa

ETI Number OS-005

Step

PCB Connection for Automatic Operation of Tape Recorder 4OF5

ETI Number DS-005

Cable Exit Groove

ETI Number OS-006 Date April Description

ETI Number OS-006

ETI Number DS-007 Date April Description

Connection of a Panasonic Autodialer

ETI Number DS-007

Upward Downward

Cia

Connector TX2 CONNECTOR6

ETI Number OS-007

ET1

Dtem

Series

II Telephones

ET1 Number DT-001 Date December

Switchina Terminals Division

Plantronics is-1 80 Jacket Connection

NEC America, Inc

2of

Access Panel Removal

ET1 Number DT-001 Date December

ADA-E Unit Installation 4of

To Plantronics Jackset Model

DIP Switch SW2 Setting for JS-180

ADA-E Unit

NSA-171694

ET1 Number DT-002 Date December

NEC America, Inc Switching Terminals Division

Parts Required

ET1 Number DT-002 Date December Operation

2of6

ET1 Number DT-002 Date December

ET1 Number DT-002

4of

ADA-E Unit Installation

NSA-174694

DIP Switch SW2 Setting for Autodialer

ET1 Number DT-03 Date December

Dterm Series

ET1 Number DT-003 Date December

Date December 19%

Access Panel Remova\

NSA-171694

Tone Commander TA-20 Amplifier

ADA-E Unit

ADA-E Unit

Telephone

NEC America, Inc Switching Terminals Division

DtermSERIES

Dterm Series II Terminals

ET1 Number DT-994 Date January

Procedure

ET1 Number DT-004 Date January

Testing

4of6

Access Panel Removal

TO-W Ir3To Remo

DIP SW1TC.H SW2 Settings

5of6

ET1 Number DT-004 Date January

6of6

ADA-E Installation

Reference

Northern Telecom Companion Speakerphone Connection

ETI Number DT-005

ETI Number DT-005

Access Panel Removal 4of

Companion

ADA-E Unit DIP Switch SW2 Settings

ADA-E Installation

EMK-3050.001

ADA-E Unit Stock # Phonebeam Speakerphone with IR2 adaptor

ETI Number DT-006

ETI Number DT-006

Line Cord Apply Pressure

SElTlNGS

ADA-E Unit DIP Switch SW2

ETI Number DT-006 Cable Exit Groove ETE-CD

ADA-E Installation 7of7

ADA-ER Unit

From one end of the two conductor wire Step

Testing

Access Panel Removal 4of7

Lo 0 l .J

ADA-ER Unit DIP Switch SWZ Settings

ADA-ER Installation

ADA-ER Installation

ET1 Number MK-011

4of

Settings

ETE-GD-1, ETE-16D-1, ETE-16K

Date December

Limitations

Automation Electronics Corporation

NEC America. Inc Teiminals Division

ET1 Number MK-012 Date December

Procedure

References Operation

SW4

Switch Setting SW1

Terminal Station Cable

OFF

Testing

ET1 Number MK-012 Date December

Attendant Activation and Deactivation of Delay Announcement

AEC Dual Line Announcer Model 212 Plus

ECR-E ETU

JK3 c

JK2

Automation Electronics Corporation

ETI Number MK-012A

Revised from MK-012

Terminal Cable

SW2 OFF SW3 SW4

Switch Setting SW1

BGM

Testing

Announcement ClHANDSET

Internal Jumper Plug Settings 7OF7

Page

Dees Automatic Ground Start Unit

ETI Number MK-014

TIN OUT RIN Tout

Viking Door Phone Door Release Connections

Page

ETI Number MK-015

ETI Number MK-015

ETI Number MK-015

ETI Number MK-015

RAA-E Unit Upgrade

ETI Number EMK-016

RAC-E Unit

ETI Number EMK-016

Pathfinder PHONE/DATA/FAX Switch Connections

ETI Number MK-017

ETI Number MK-017

To Telco

To Telco Phone Jack Port Machine MODEM/ P.0.S Terminal

AlECAmerica Inc. Switchinq Terminals Division

ETI Number MK-018

SMDR-E ETU Ribbon Cable from Rear of Computer

Active Voice Repartee Voice Mail System Connection Procedure

ETI Number MK-019

ETI Number MK-019

ETI Number MK-019

ET1 Bulletins

Dterm

ETI Number DS-001

Speakerphone Cable Connection

ETI Number OS-001

Line Drawing For Completed installation 5OF5

Connection of Northern Telecom Companion 2 SP

ETI Number DS-002

ETI Number

Insulate

Sofs

Dterm

ETI Number DS-003

+ro

Insulate

ETI Number OS-003

Dterm

ETI Number DS-004

LCl8-l

DS-004

IC3

TA-20 or S-l 1 Cable Exit Groove on Dtetm II Telephone 6OF6

Dterm

ETI Number DS-005

Step

IC4

Chapter Least Cost Routing LCR

Chapter Least Cost Routing LCR

Section Equipment Identification

Chapter

Section Installation of LCR-E ETU

Installation Ofthe LCR-E ETU

Section Installation of PC-8300

Battery Backup

Printer Connection

Programming System Memory For LCR

700-10

Then p

Depress1F2 1,lF?l ,thenlF16I

LCR Program Construction

Chapter

Chapter

Route Advance Tables

Initializing the PC-8300

27 Rear Side View of the PC-8300

IBM LCR

Programming the LCR-E ETU KEY Layout and Explanation of Keys

28 Keyboard Layout Number Keys l-9

Data

Route Advance

Route

Route Modify

TE Table Modify

Other Keys Used P, #, *, INS, DEL

Code 0 8

Input of Data

+z+

At this time, any table to be down loaded can be selected

Program Loading

Areacode ? ml

Modify Display System Control Enter Menu no

WY%54

Selection of up load mode results in the menu display shown

Verify Mode

Office Code Table Verify Start w

Area Code ,,BL

Pzz7

00 00 00 00 00 00 01 01 01 00 00

With the Modify Menu in the display, depress

Route Table MODIFY*** Table no Advance

Route Table Modify

Table Modify DEL ADD ETR Code TBL02

Sample LCD Indications

Office Code Table Modify Table NO. ?

700

Enter Menu NO. c 700

Area Code f,BE Display

Daily Schedule Display Daily Schedule Table NO.?

Display Table NO. ?

Office Code Table Display

Home NPA Code Table Print OUT Start Normal END

System Data Clear

Phase Executing Normal END Abnormal END Line Trouble

Error Messages

FDD I/O

Start \ Station

NNX + No LCR

Normal Operation No LCR 1YES

1st. Priority

ADO

700-64

UzazcI I I I I I I I I I I I I I I I I I I I I I

=I=

‘700

Weekly Schedule Tables Descriptionentry

I I I

Daily Schedule Table

Daily Schedule Tables

700-72

Route Advance Tables

Route Tables

Route Tables

Office Code Tables

Chapter

700-78

SD-20292

Chapter Voice Mail Integration

Chapter

Section Programming

Parameter Minimum Maximum Default Increments Memory Block

This page Intentionally Left Blank

Page

Remote Administration Adaptor

910.2 PC-8300 Personal Computer

Tzx

LlolBLlmElllol

R&J-E Switch Setti*g

Electra Markii

PC8300 and PC-8231A Installation

General

Text Telcom

FRI Hook

#*O

LK Asgn

Pmq /-xmqpixiq

Pmqpiziq

Executing IBM Type Compatible Sofiware

Ryl \

JAN 01 MON

System Up’~PL~VD&lWN Load

System Memory UP Load /DOWN Load

Electra Mark 2 Digital KEY Telephone System

Chapter

Verify

900

Page

Page

Page

Page