Xerox WorkCentre C226 User Guide

Trademark information

Warranty

Table of contents Introduction

Xerox WorkCentre C226 User Guide

Before Using the Product

Managing the Machine

Before Making Copies

Peripheral Devices

Convenient Copy Functions

Basic Procedure for Making Copies

Basic Printing Procedures

Machine Maintenance for Copying

Setting the Printer Driver Properties

Xerox WorkCentre C226 User Guide Vii

Web Pages in the Printer

Printer Configuration Settings

Printing from the Operation Panel

Key Operator Programs

Appendix

Troubleshooting

Sending an Image

Condition Setting Screen of Scanner Mode

Scanning Settings

Before Using the FAX Feature

Specifications

Basic Operations

Transmission Using F-Codes

Advanced Transmission Methods

Xii Xerox WorkCentre C226 User Guide

Xerox WorkCentre C226 User Guide Xiii

Convenient Methods of Use

Programming

Xiv Xerox WorkCentre C226 User Guide

Safety Notes

Maintenance

Operator Accessible Areas

Cleaning Your Product

Electrical Supply

Do These

Operational Safety Information

Disconnect Device

Xerox WorkCentre C226 User Guide Xvii

Ozone Safety Information

Maintenance Information

For Consumables

Do Not Do These

Xerox WorkCentre C226 User Guide Xix

Product Safety Certification

Radio Frequency Emissions

CE Mark

FAX Send Header Requirements

Xerox WorkCentre C226 User Guide Xxi

Data Coupler Information

Xxii Xerox WorkCentre C226 User Guide

Canada

Europe

Xerox WorkCentre C226 User Guide Xxiii

USA Energy Star

Canada Environmental Choice

Xxiv Xerox WorkCentre C226 User Guide

Europe Energy

Xerox WorkCentre C226 User Guide Xxv

Xxvi Xerox WorkCentre C226 User Guide

Other countries

Installation Requirements

Before Using the Product

General Information

If the machine has been placed on a stand/1-Tray Unit

Installation Requirements

Moving this machine

If the machine is to be left unused for a long time

Introduction

Introduction

Meaning of R in original and paper size indications

Original and paper sizes

Main Features

Main Features

Auto power shut-off mode

Energy saving features

Preheat mode

Exterior

Part Names and Functions

Part Names and Functions

Operation panel

Unit

Stand/1-Tray

Tray Unit

Duplex Bypass/ See Inverter Unit and exit tray

Interior

Part names and functions of peripheral devices

Other optional equipment

Operation panel

Ready indicator Data indicator

Start key

Settings key

Start key Clear ALL key

Touch panel

Using the touch panel

Beep tone

Selection of function

Copier feature

Paper Empty in the job status display

Auditing Mode

Account counter is enabled only for the colour copy mode

Using the machine when the auditing mode is enabled

Auditing Mode

Ready To Copy Please See Your Key Operator For Assistance

When the copy job is finished, press the key ACC.#-C key

Loading Paper

Managing the Machine

Loading paper in Paper Tray

Loading Paper

Changing the paper size in Paper Tray

Loading paper in the Bypass Tray

General Information

Tray, close the paper cover as shown

When loading paper in the Bypass Tray or closing

Printing onto envelopes or postcards

Setting envelopes or postcards

Loading postcards

Loading envelopes

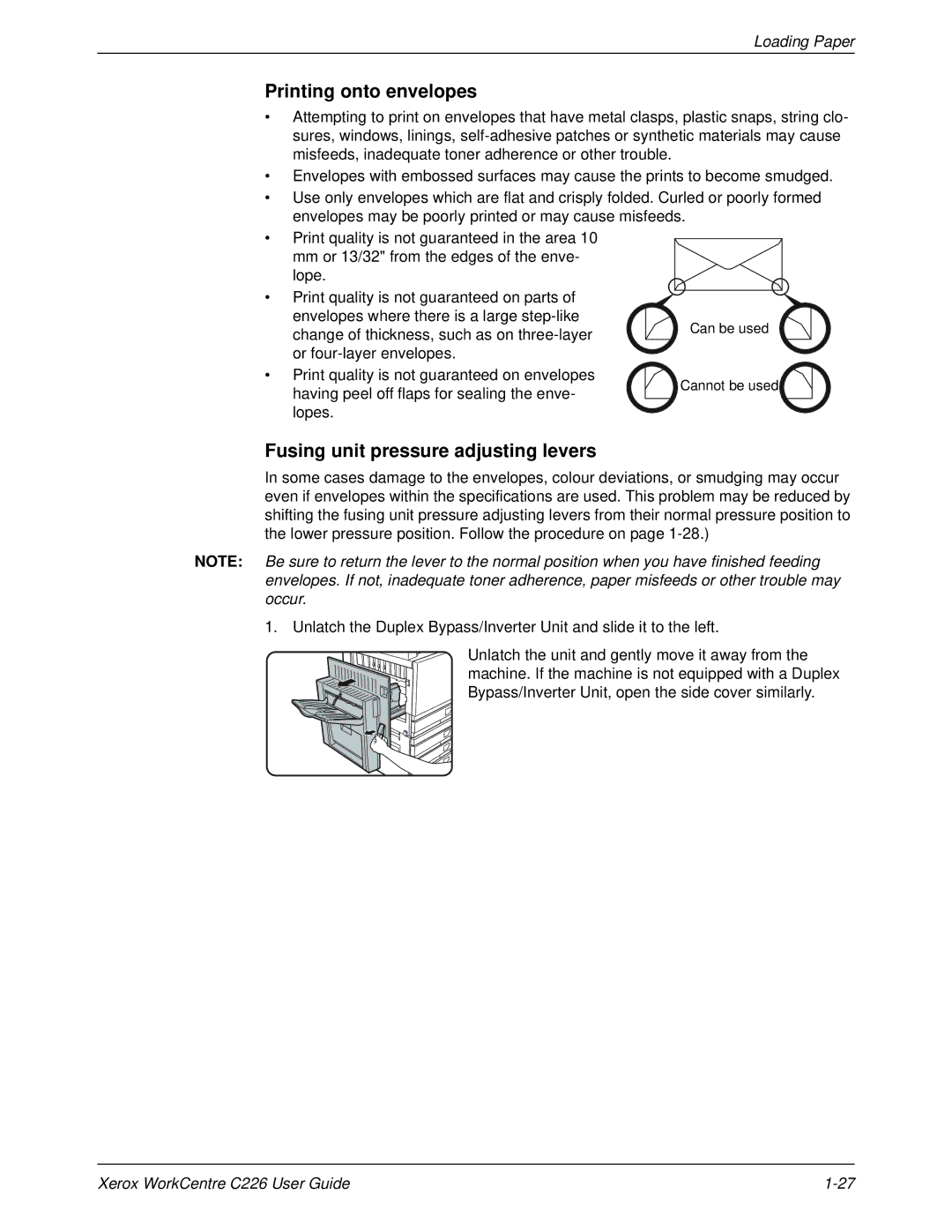

Printing onto envelopes

Fusing unit pressure adjusting levers

Upper tray / middle tray / lower tray

Loading paper in the stand/1-Tray Unit/3-Tray Unit

Loading paper in the Duplex Module/2-Tray Unit

Specifications stand/1-Tray Unit/3-Tray Unit

Upper tray

Middle and lower paper trays

Specifications for paper trays

Specifications Duplex Module/2-Tray Unit

Tray No

Paper in AB system Paper in inch system

More information on plain paper

More information on special media that can be used

Paper tray selection screen will appear

Setting the paper type except the Bypass Tray

Paper that can be used for automatic two-sided printing

Touch the OK key to complete the setting

Setting the paper size when an extra size is loaded

Setting the paper type and paper size in the Bypass Tray

Heavy Paper1 106g/m2 200g/m2

Clock adjust

Custom Settings

Total count

Display contrast

Receive mode

Tray settings

Fax data forward

Keyboard select

Detailed descriptions for program settings start on

Operation procedure common to all custom settings

More information on setting procedures

Total count

About the settings

Tray settings

Clock adjust

Display contrast

List print

Toner

Replacing the Toner Cartridges

Remove the protective material from the new toner cartridge

Replacing the Toner Cartridges

General Information

Proper storage

Storing Supplies

Storing Supplies

Supply and Consumables

Misfeed Removal

Misfeed in the paper feed area

Misfeed Removal Guidance

Misfeed in Tray

Misfeed Removal

Misfeed in the Bypass Tray

Transport area

Misfeed in the transport area, fusing area, and exit area

Upper exit tray

Fusing area

Models without the Duplex Bypass/Inverter Unit

Misfeed Removal

Misfeed in the stand/1-Tray Unit

Misfeed in the 3-Tray Unit

General Information

Misfeed in the upper or lower tray

Problem Check Solution or cause

Problem Check Solution or cause

Troubleshooting

Problem Check Solution or cause

Saddle Stitch Finisher

Peripheral Devices

Part names and functions

Saddle Stitch Finisher

Using the Saddle Stitch Finisher

Remove the empty staple box

Staple cartridge replacement and staple jam removal

Staple cartridge replacement

General Information

Staple jam removal

Remove the staple box

Saddle Stitch Finisher

Push the Saddle Stitch Finisher back against the main unit

Open the top cover

Misfeed in the Saddle Stitch Finisher

General Information

Saddle Stitch Finisher

Check the list below before calling for service

Troubleshooting Saddle Stitch Finisher problems

Problem Check Solution or cause

Top binding

Stapling position quick reference guide for duplex output

Relation between print image and saddle stitch

Part name

High Capacity Feeder

Loading paper in the High Capacity Feeder

Top cover

High Capacity Feeder

Misfeed in the High Capacity Feeder

General Information

High Capacity Feeder

General Information Xerox WorkCentre C226 User Guide

Part Names and Functions The Dadf

Before Making Copies

Copier Operation

Touch Panel main screen of copy mode

Dadf

Acceptable originals

Size and weight of acceptable originals

Setting Originals

When using the Dadf

Adjust the original guides to the size of the originals

How to place the original

When using the document glass

Setting Originals

Operator programs

Original size detection function

Example

Standard original setting orientation

Automatic copy image rotation rotation copying

Selecting the Original Size

Selecting the Original Size

Using the Dadf Using the document glass

Storing or deleting an original size

Storing, Deleting, and Using Original Sizes

Touch the Original tab Touch the Custom Size key

Touch the STORE/DELETE key

Enter X and then touch the key to enter Y. a width

Storing, Deleting, and Using Original Sizes

64 to 432 mm can be entered in X, and a length

To 297 mm can be entered in Y

Touch the OK key Stored original size is called up

Using a Stored Original Size

Normal Copying

Basic Procedure for Making Copies

Copying from the Dadf

Sided copies of 1-sided originals

A4 Plain B4 Recycled A3 Plain

Normal Copying

Copy mode output restrictions

Normal Copying

About the offset function

Copy output sort and group

Touch Offset Touch OK

Automatic two-sided copying from the Dadf

Selecting the output tray

Turning on the offset function

Selected

Following two-sided modes can be

Set an original on the document glass pages 2-4 to

Copying from the document glass

How to place the original

Normal Copying

Automatic two-sided copying from the document glass

Example TEXT/PRTD.PHOTO key is selected

Exposure Adjustments

Exposure Adjustments

Normally this setting is selected. When

Original type Contents of the original

Exposure is automatically adjusted to

Obtain the best image quality. When a

Making a copy of a copy

Automatic selection auto image

Reduction/Enlargement/Zoom

Reduction/Enlargement/Zoom

100

Manual selection

Menu

To return the ratio to 100%

Touch the X key

XY Zoom

64%

Special Papers

Special Papers

Colour adjustment menu

Special Modes

Convenient Copy Functions

Special Modes

Inserts key

Touch the Special Modes tab

Common operation procedure for using the special functions

Screen

To set the margin shift function

Margin shift

Touch the key for the desired special mode. Example

About the steps that follow

Touch the Margin Shift key on the Special Modes screen

Set the shift amount as needed and touch the lower OK key

Screen to indicate that the function is turned on

Erase

Dual page copy

Touch the Dual page Copy key on the Special Modes screen

When copying book originals

This function can be used to reduce a larger sized origi

Centring

Nal image and centre it on a copy of smaller paper size

As well as centre a smaller original onto a larger sized

Insert sheets must be the same size A4 or A4R

Transparency film with insert sheets

2 x 11 or 8-1/2 x 11R as the transpar

Ency film

Auto

Copying onto a cover

Covers

Touch the Covers key on the Special Modes screen

Not copying onto a cover

See pages 2-13through

Select cover placement

Reverse

Touch the key to switch to the second Special Modes screen

Originals with large black areas which use a large amount

Consumption

Colour Adjustments Menu

Colour Adjustments Menu

Key to weaken the colour

RGB Adjust

Select a colour from R RED, G GREEN, and B Blue

Sharpness

Suppress background

Colour balance

About the steps that follow

Brightness

Brightness setting screen will appear

Adjust the brightness

Intensity

Intensity setting screen will appear

Adjust the intensity

Single Produces copies with a selected single colour

Image Edit Menu

Image Edit Menu

Select the desired colour

Single colour

Touch the Mirror Image key on the Image Edit menu screen

Mirror image

Photo Repeat

See pages 2-21through

Multi shot

On the copy

Touch the Multi Shot key on the Image Edit menu screen

Lines are added around the borders of the images

A3 11 x 17 Full-bleed

Touch the A3 FULL-BLEED key on the Image Edit menu screen

Overlap of sections of image

Multi-page enlargement

Inch system

About the steps that follow

Pamphlet copy icon , etc. will also appear

Pamphlet copy

Upper left corner of the screen to indicate that the func

Tion is turned on

When using the document glass

When using the Dadf

Job Program Memory

Job Program Memory

Storing a job program

Number of copies cannot be stored

Recalling a job program

Make all copier selections to be stored

Deleting a stored job program

CEL key is touched, the screen in will return but

Played in to exit the job program mode

Program will not be deleted. If no other programs are

To be deleted, touch the Exit key on the screen dis

Interrupting a Copy Run

Interrupting a Copy Run

Copier Operation

Removing an Original Misfeed

Machine Maintenance for Copying

Removing a misfed original from the Dadf

Removing an Original Misfeed

Check location C

Check location B

User Maintenance for copying

User Maintenance for copying

Cleaning the Original Scanning Area

Printed Photo

Problem Check Solution or cause

Setting the Printer Drivers

Basic Printing Procedures

Change the settings using the printer properties

Windows 95 / 98 / Me

Printer Operation

Selecting a Color Mode setting

Windows NT4.0 / 2000 / XP / Server

Setting the Printer Drivers

Using the Help file to view explanations of the settings

Opening Help in Windows

Click Help to display

Printing in black and white

Setting the Printer Drivers

Printer Operation

Automatic switching between colour and black and white

Printer Operation

Setting the Printer Drivers

Printing in colour

Setting the Printer Drivers

Printing using optional peripheral equipment

Setting the Printer Drivers

Printer Operation

Selecting Printing Functions

Setting the Printer Driver Properties

Selecting Printing Functions

Colour mode display

Frequently used settings

Copies

Collate

Up Pamphlet

Document Style

Tiled Pamphlet

Up Printing

User Settings

Border

Save

Auto Job Control review

Configure settings for staple or punch finishing

Finishing

Binding Edge

Staple

Staple sort mode

Saddle stitch function

Top left

Stapling positions

Offset mode

Hole punching only if a Hole Punch Module is installed

Punch

No Offset

Hold After Print

Retention Normal Print

Hold Before Print

Proof Print

Notify Job End

Defaults

PIN 5-digit identification number

User Name

Default Job ID

Account Number

Job Name

Paper settings

Always Use This ID

Paper Size

Correct Wrong

Custom

Fit To Paper Size

Fit To

Paper Source

Paper Selection

Paper Type

Tray Status

PCL5c

Advanced settings

Transparency Inserts

Image Quality

Select 300 dpi or 600 dpi Default setting 600 dpi

Resolution Settings

Graphics Mode

Margin Shift

PostScript

Job Compression

Compress Options

Bitmap Compression

See the explanation for Overlays on

Watermark settings

Size

Text

Angle

Edit Fonts

Original Type

Color settings

Table of document type previews

Preview of document type

This shows a preview of the document type selected

Color Mode

Print Priority

Use this item to adjust the brightness and contrast

All Text to Black

Image

Color Balance

Contrast

Saturation

Red Strength

Environment required for accessing Web pages

Printer Configuration Through the Network

Accessing Web pages and displaying help

Web Pages in the Printer

Printer Configuration Through the Network

Destination

Items and outline of menu frame of Web pages

System Information Image Send Management

Password

Device Setup

Sender

Network Scanning

Network Setup

Printer Configuration Settings

Making Configuration Settings

Making Configuration Settings

Paper Select Condition Settings

Default paper size

Default settings

Default output tray

Copies

Default paper type

PCL settings

PCL symbol set setting

PCL font settings

Hold Job List

Printing from the Operation Panel

Hold Job List

Key operator program list

Key Operator Programs

Key operator program list

Initialize and/or store settings

Program name

Auto colour calibration

Touch the Printer Settings key

Procedure for using key operator programs

Procedure for using key operator programs

Level

Key operator program menu

Default settings

Description of Setting Programs

Printer settings

Interface settings

Timeout

Network settings

IP address setting

Enable TCP/IP

Enable EtherTalk

Colour adjustments

Enable NetBEUI

Reset the NIC

Restore factory defaults

Initialize and/or store settings

Restore configuration

Store current configuration

Troubleshooting

Degrees with Respect to paper

Paper type Keys

Touch the Printer Test page key

Checking the IP address

Cancel key

Screen and printing begins. To cancel printing, touch

Appendix

Disabling of notice page printing

Print area of this product is shown below

Print Area

Print Area

PCL symbol set

Symbol set

Printer Operation Xerox WorkCentre C226 User Guide

Options required to use the network scanner function

Network Scanner Operation

About the Network Scanner Function

About the Network Scanner Function

Accessing Web Pages

Web

About the Web

About the Web

Enable scanner delivery methods Enable Scanner Delivery to

Basic Settings for Network Scanning

Enabling user authentication Advanced Setup

Network Scanning Setup screen

Basic Settings for Network Scanning

Mail Server and DNS Server Settings

Smtp Setup Description

Description

DNS Setup Description

Setting Up Destination Information

Storing destinations for Scan to E-mail

Setting Up Destination Information

Drop down list

Check box for Frequently-Used

Storing destinations for Scan to FTP

Description

Storing Groups Scan to E-mail

Editing and deleting programmed transmission destinations

Storing Sender Information Scan to E-mail

Storing a Custom Directory

Storing a Custom Directory

Editing and deleting programmed senders information

Protecting Information Programmed in the Web Page Passwords

Condition Setting Screen of Scanner Mode

Protecting Information Programmed in the Web Page Passwords

Condition setting screen

Display

Mode and fax mode

Key

Mail Destination Management

Address directory screen

Key Index keys

Switching keys

Search key

Basic Transmission Method

Sending an Image

Basic Transmission Method

Up to 20 senders can be stored using the Web page.

Touch the one-touch key for the desired destination

When transmitting by Scan to E-mail

Using the Dadf

About pressing the Start key in the following procedure

Perform steps 1 through 9 of Basic Transmission Method on

Destination Input Methods

Destination address manual entry

Enter the e-mail address

Touch the E-MAIL Address key

Select where you put the destination

Select the file type and the compression mode

Destination Input Methods

Scanning in colour

Destination address entry with global address search

Touch the Search key

Enter a keyword for search

Select the destination type

You will return to the condition setting screen

Scanning and Transmitting a Two-sided Original

Scanning and Transmitting a Two-sided Original

Touch the Manual key

Scanning Settings

Manually Setting the Scanning Size

Touching the inner OK key in the step above returns

Manually Setting the Scanning Size

You to step

Selected size appears in the top half of the Original key

Change the exposure

When Auto is selected in step

Selecting the Exposure

Change the resolution

Selecting the Resolution

Selecting the Resolution

When Manual is selected in step

Selecting the File Format

Touch the desired resolution key

File format settings for black and white scanning

File format settings for colour scanning

Selecting the File Format

Remove the checkmark from the Programmed checkbox

Touch the OK key You will return to the initial screen

Cancelling an E-Mail/FTP Transmission

Touch the Direct Address key

Storing, Editing, and Deleting from the Touch Panel

Storing One-Touch Keys Only Addresses for Scan to E-mail

Touch the Individual key

Storing One-Touch Keys Only Addresses for Scan to E-mail

Touch the Name key

Touch the Initial key

Enter the e-mail address of the destination

Touch the Index key

Touch an index key

Settings for colour scanning

Check the file format and the compression mode

Compression mode LOW/MEDIUM*/HIGH

Settings for black and white scanning

Touch the one-touch key you wish to edit or delete

Editing and Deleting One-Touch Keys

Touching the Exit key returns you to the screen of on

Steps 3 through

Editing and Deleting One-Touch Keys

Following steps are for deleting a one-touch key

Touch the Delete key

Programming a Group Key

Programming a Group Key

Touch the group key you wish to edit or delete

Editing and Deleting Group Keys

Through

Editing and Deleting Group Keys

Following steps are for deleting a group key

If you wish to delete another group key, repeat steps 3, 6,

Touch the Sender Name key

Storing Sender Information

Touch the Store key

Editing and Deleting Sender Information

Editing and Deleting Sender Information

Edit or delete the sender

When touched, the letter entry screen appears

Storing a Group Index

Touch the Sending Address List Scanner key

Printing Programmed Information

Printing Programmed Information

To cancel printing, touch the Cancel key

Moiré stripe pattern appears on the scanned image

Image cannot be scanned

Scanned image is fuzzy or has smudges

Scanned image is clipped

Transmission takes a long time

Received image data cannot be opened

Recipient does not receive transmitted data

Error Code Table

If a Transmission Error Occurs

Resolution STANDARD, HIGHER, Highest

Error Code Description of the Error

Checking the IP Address

Checking the IP Address

Approx KB Tiff High G4 format Jpeg Medium compression

Important Points When Using Scan to E-Mail

Key Operator Programs

Using the Key Operator Programs

Setting Programs

Setting Programs

Network scanner settings

Initial resolution setting

Default display settings

Number of direct address keys displayed setting

Default sender set

Scan complete sound setting

Compression mode at broadcasting

Initial file format setting

Maximum size of e-mail attachments

Scanner mode timeout after last scan

Default exposure settings

Disable of address direct entry

TCP/IP, UDP/IP

Specifications

Scanning margins

Scanning margins

Network Scanner Operation Xerox WorkCentre C226 User Guide

Line connection

To Use this Product Correctly as a Fax Device

For United Kingdom

For Australia

Fax power switch

Important Safety Information

Settings and programming

Lithium battery

Points to Check and Program After Installation

Before Using the FAX Feature

Make sure the fax power switch is turned on

Make sure the correct date and time have been set

Connecting an Extension Phone

Connecting an Extension Phone

Look at the Operation Panel

Look at the Operation Panel

Start

Fax Mode Condition Settings Screen

Mode

Condition settings screen

Fax Mode Condition Settings Screen

Modes

Address directory screen alphabetically ordered

Settings

Original sizes

Originals that Can Be Faxed

Scanning area of original

Automatic reduction of faxed document

Using the Document Glass

Using the Dadf

Loading a Document

Loading a Document

Original key. Check the key to make

Checking the Size of a Loaded Original

Sure that the original size has been correctly

Detected

Touch the desired original size key

Sizes that can be selected are displayed

Change the resolution

Selecting Resolution and Exposure Settings

Selecting the Resolution

Selecting Resolution and Exposure Settings

Resolution settings

Standard

Ultra fine

Exposure, touch Key. To return to auto

Selecting the Exposure

Change the exposure

Convenient Dialing Methods

Exposure settings

One-touch dialing

Group dialing

On-hook dialing

Basic Operations

Basic Procedure for Sending Faxes

Sending a Fax

Sending a Fax

Entering a Pause

If needed, adjust the resolution setting see

If needed, adjust the exposure setting see

Using the document glass

Using the Dadf

Directory screen

Refer to page 5-9 for information on using the address

Continue from of Basic Procedure for Sending Faxes

Faxing a Two-Sided Original

Storing transmission jobs memory transmission

Quick On-line

Side are booklets, and two-sided originals

That are bound at the top are tablets

Image rotation

If a transmission error occurs

If the receiving party is busy

Priority Transmission of a Stored Job

Cancelling On-Hook Dialing

Cancelling a Fax Transmission

Cancelling a Fax Transmission

Press the JOB Status key Touch the FAX JOB key

Receiving a Fax

Receiving Faxes

Number of rings

Machine will ring* and reception will automatically begin

If received data cannot be printed

Advanced Transmission Methods

Using Broadcast Transmission

Dial Ann ot b e om itted

Using Broadcast Transmission

Dial

Can be omitted

Check the destinations

Setting Up a Timer Transmission

Transmission and Reception Using the Polling Function

Polling memory

Transmission and Reception Using the Polling Function

Polling

Polling key is highlighted and the polling icon appears

Using the Polling Function

Touch the Special Modes key

Manual Polling

Using Polling Memory

Touch the Data Store key

Touch the Print Data key

Printing document data in the Public Box

Touch the Public BOX key Message screen appears

Deleting document data from the Public Box

Touch the Delete Data key

Own Number Sending

Restricting polling access polling security

Example of fax page printed out by the receiving machine

11/JUN/2004/FRI

Position of senders information

Faxing a Divided Original Dual Page Scan

Faxing a Divided Original Dual Page Scan

Outside scanned data

Press the Clear ALL key

Programming Frequently Used Operations

Selecting Dual Page Scan

Programming Frequently Used Operations

Using a Program

Transfer instruction

Program the fax number of the transfer destination

Using the Transfer Function

Transferring received data

Press the Custom Settings key Touch the FAX Data Forward key

Transmission Between Machines Supporting F-codes

Transmission Using F-Codes

Transmission Between Machines Supporting F-codes

This machine

Condition Settings Sub Address

Creating a Memory Box for F-Code Transmission

Code Polling Memory

How F-code polling memory works

Your machine Other machine

Scanning a document into an F-code polling memory box

Using F-Code Polling Memory

Code Polling Memory

As the scanning destination

Checking and clearing document data in a memory box

Procedure for F-Code Polling

Corpo.Tps Xerox Group

Code Confidential Transmission

Code Confidential Transmission

Code Confidential Transmission

If the print PIN is not correct, the message PIN is not

Press Start to Print DATA. appears

Relay machine your machine

Code Relay Broadcast Transmission

Code Relay Broadcast Transmission

Your machine is the relay machine

Using the F-Code Relay Broadcast Function

Using the F-Code Relay Request Function

Using an Extension Phone

Using an Extension Phone

Convenient Methods of Use

FAX key

Sending a Fax after Talking Manual Transmission

Send key

Press the Custom Settings key Touch the Receive Mode key

Using an Extension Phone to Receive a Fax

Changing the reception mode to Manual Reception

Reception mode is set to Manual Reception

When the extension phone is in Fax mode

Reception begins when the other party begins transmis- sion

Receiving a Fax After Talking Manual Reception

Using an Extension Phone

Storing, Editing, and Deleting Auto Dial Keys and Programs

Programming

Storing, Editing, and Deleting Auto Dial Keys and Programs

Storing One-Touch Keys

Corporation Fax No Mode

Passcode max digits

Use the numeric keys to enter the fax number

Transmission speed

Selections are NONE, Mode 1, Mode 2, and Mode

International correspondence mode

Editing and Deleting One-Touch Keys

Touch the one-touch key that you wish to edit or delete

If you cannot edit or delete a one-touch key

Storing a Group Key

Address Review Opqrst Uvwxyz ABC Group

Touch the group key that you wish to edit or delete

Editing and Deleting Group Keys

If you wish to delete another group key, repeat steps 2, 5,

Deleting a group key

Touch the Program Name key

Storing a Program

Special Modes

Touch the Settings key

Touch the program you wish to edit or delete

Editing and Deleting Programs

Programming, Editing, and Deleting F-Code Memory Boxes

Programming, Editing, and Deleting F-Code Memory Boxes

Programming an F-Code Memory Box

Use the numeric keys to enter a passcode max digits

Sub-address/passcode entry screen appears

Setting for F-Code Polling Memory Boxes Polling Times

Next Exit

Touching the Exit key returns you to the screen

Setting for F-Code Relay Broadcast Memory Boxes Recipient

Use the numeric keys to enter a 4-digit number

123456/987654

Editing and Deleting a Memory Box

Touch the key of the list you wish to print

Touch the Sending Address List FAX key

Entering alphabetical characters

Entering Characters

Example Xerox äÄ Touch the X key

Touch the e key, r key, o key, and x key

Touch the ä key

Entering Characters

Touch the Space key

SharpXerox ä

Screen 1/2 Screen 2/2

Entering numbers and symbols

Fax Unit

When a Transaction Report Is Printed

When a Transaction Report Is Printed

Explanation

Information appearing in the TYPE/NOTE column

Rect sub-address or other reason

Port F-code communication

Message screen Alarm Meaning of message Action Page/Guide

When an Alarm Sounds and a Warning Message Is Displayed

Viewing the Communication Activity Report

Received fax cannot Add the indicated Loading Paper on

Self-diagnosis func Turn off the power

When an Alarm Sounds and a Warning Message Is Displayed

Manual reception was Try manual recep

Open Cated cover

100 Xerox WorkCentre C226 User Guide

Problems and Solutions

Problem Check Solution

Problem Check Solution

Problems and Solutions

Fax Unit 102 Xerox WorkCentre C226 User Guide

Index

Symbols / Numerics

Index

Index

Index

Index

Index

Index

Fax 5-14,5-15

Index

PCL 3-47,3-67