F314 |

|

| F320 | |

|

|

| ||

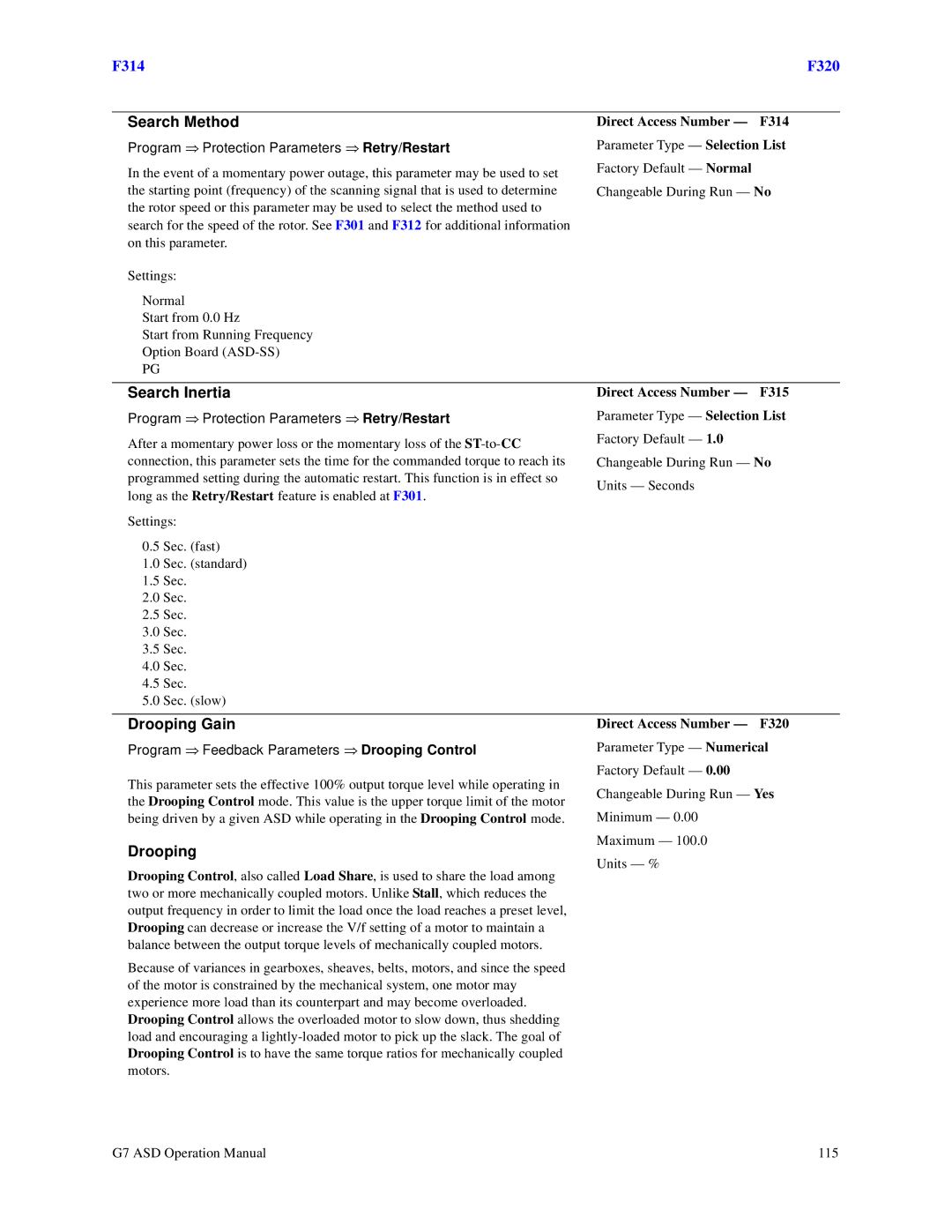

Search Method | Direct Access Number — | F314 | ||

Program ⇒ Protection Parameters ⇒ Retry/Restart | Parameter Type — Selection List | |||

In the event of a momentary power outage, this parameter may be used to set | Factory Default — Normal |

| ||

|

| |||

the starting point (frequency) of the scanning signal that is used to determine | Changeable During Run — No | |||

the rotor speed or this parameter may be used to select the method used to |

|

| ||

search for the speed of the rotor. See F301 and F312 for additional information |

|

| ||

on this parameter. |

|

| ||

Settings: |

|

| ||

Normal |

|

| ||

Start from 0.0 Hz |

|

| ||

Start from Running Frequency |

|

| ||

Option Board |

|

| ||

PG |

|

|

| |

|

|

| ||

Search Inertia | Direct Access Number — | F315 | ||

Program ⇒ Protection Parameters ⇒ Retry/Restart | Parameter Type — Selection List | |||

After a momentary power loss or the momentary loss of the | Factory Default — 1.0 |

| ||

|

| |||

connection, this parameter sets the time for the commanded torque to reach its | Changeable During Run — No | |||

programmed setting during the automatic restart. This function is in effect so | Units — Seconds |

| ||

long as the Retry/Restart feature is enabled at F301. |

| |||

|

| |||

Settings: |

|

| ||

0.5 | Sec. (fast) |

|

| |

1.0 | Sec. (standard) |

|

| |

1.5 | Sec. |

|

| |

2.0 | Sec. |

|

| |

2.5 | Sec. |

|

| |

3.0 | Sec. |

|

| |

3.5 | Sec. |

|

| |

4.0 | Sec. |

|

| |

4.5 | Sec. |

|

| |

5.0 | Sec. (slow) |

|

| |

|

|

| ||

Drooping Gain | Direct Access Number — | F320 | ||

Program ⇒ Feedback Parameters ⇒ Drooping Control | Parameter Type — Numerical | |||

This parameter sets the effective 100% output torque level while operating in | Factory Default — 0.00 |

| ||

Changeable During Run — Yes | ||||

the Drooping Control mode. This value is the upper torque limit of the motor | ||||

|

| |||

being driven by a given ASD while operating in the Drooping Control mode. | Minimum — 0.00 |

| ||

Maximum — 100.0

Drooping

Units — %

Drooping Control, also called Load Share, is used to share the load among two or more mechanically coupled motors. Unlike Stall, which reduces the output frequency in order to limit the load once the load reaches a preset level, Drooping can decrease or increase the V/f setting of a motor to maintain a balance between the output torque levels of mechanically coupled motors.

Because of variances in gearboxes, sheaves, belts, motors, and since the speed of the motor is constrained by the mechanical system, one motor may experience more load than its counterpart and may become overloaded. Drooping Control allows the overloaded motor to slow down, thus shedding load and encouraging a

G7 ASD Operation Manual | 115 |