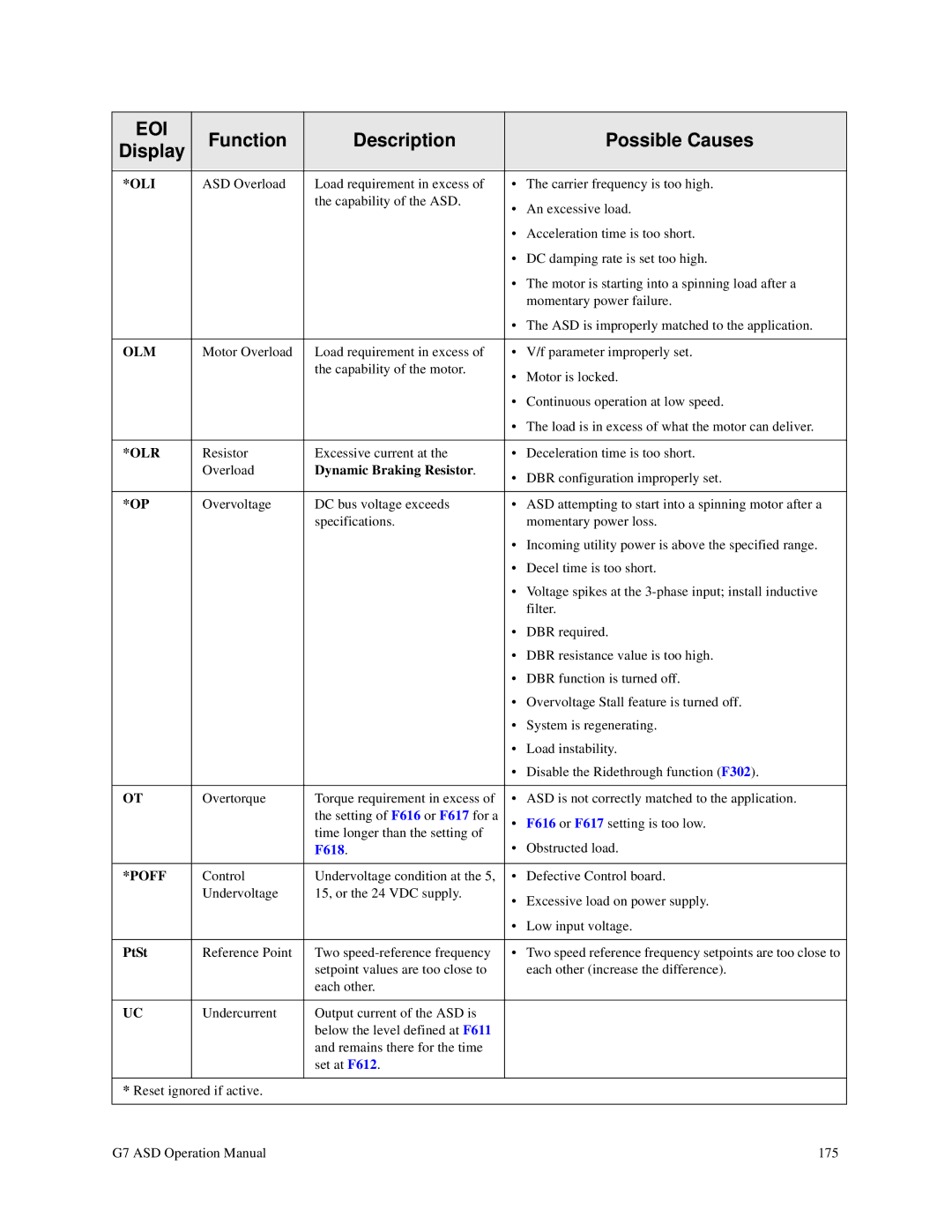

EOI | Function | Description |

| Possible Causes |

Display |

| |||

|

|

|

| |

|

|

|

|

|

*OLI | ASD Overload | Load requirement in excess of | • | The carrier frequency is too high. |

|

| the capability of the ASD. | • | An excessive load. |

|

|

| ||

|

|

| • Acceleration time is too short. | |

|

|

| • DC damping rate is set too high. | |

|

|

| • The motor is starting into a spinning load after a | |

|

|

|

| momentary power failure. |

|

|

| • The ASD is improperly matched to the application. | |

|

|

|

|

|

OLM | Motor Overload | Load requirement in excess of | • | V/f parameter improperly set. |

|

| the capability of the motor. | • | Motor is locked. |

|

|

| ||

|

|

| • Continuous operation at low speed. | |

|

|

| • The load is in excess of what the motor can deliver. | |

|

|

|

|

|

*OLR | Resistor | Excessive current at the | • | Deceleration time is too short. |

| Overload | Dynamic Braking Resistor. | • DBR configuration improperly set. | |

|

|

| ||

|

|

|

|

|

*OP | Overvoltage | DC bus voltage exceeds | • | ASD attempting to start into a spinning motor after a |

|

| specifications. |

| momentary power loss. |

|

|

| • Incoming utility power is above the specified range. | |

|

|

| • Decel time is too short. | |

|

|

| • Voltage spikes at the | |

|

|

|

| filter. |

|

|

| • | DBR required. |

|

|

| • DBR resistance value is too high. | |

|

|

| • DBR function is turned off. | |

|

|

| • Overvoltage Stall feature is turned off. | |

|

|

| • | System is regenerating. |

|

|

| • | Load instability. |

|

|

| • Disable the Ridethrough function (F302). | |

|

|

|

|

|

OT | Overtorque | Torque requirement in excess of | • | ASD is not correctly matched to the application. |

|

| the setting of F616 or F617 for a | • | F616 or F617 setting is too low. |

|

| time longer than the setting of |

|

|

|

| F618. | • | Obstructed load. |

|

|

|

|

|

*POFF | Control | Undervoltage condition at the 5, | • | Defective Control board. |

| Undervoltage | 15, or the 24 VDC supply. | • Excessive load on power supply. | |

|

|

| ||

|

|

| • | Low input voltage. |

|

|

|

|

|

PtSt | Reference Point | Two | • | Two speed reference frequency setpoints are too close to |

|

| setpoint values are too close to |

| each other (increase the difference). |

|

| each other. |

|

|

|

|

|

|

|

UC | Undercurrent | Output current of the ASD is |

|

|

|

| below the level defined at F611 |

|

|

|

| and remains there for the time |

|

|

|

| set at F612. |

|

|

|

|

|

|

|

* Reset ignored if active. |

|

|

| |

|

|

|

|

|

G7 ASD Operation Manual | 175 |