F242 | F251 | |

|

|

|

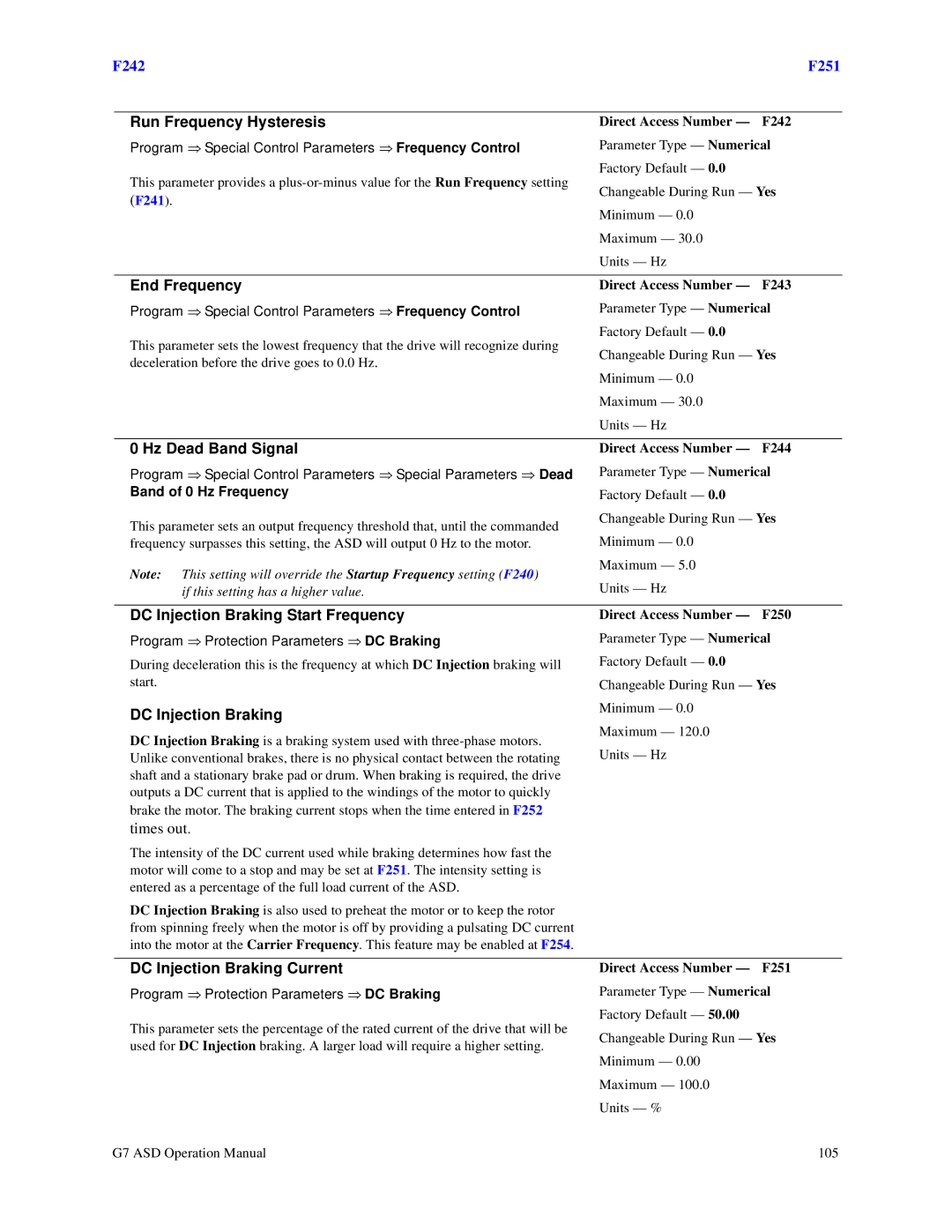

| Run Frequency Hysteresis | Direct Access Number — F242 |

| Program ⇒ Special Control Parameters ⇒ Frequency Control | Parameter Type — Numerical |

| This parameter provides a | Factory Default — 0.0 |

| Changeable During Run — Yes | |

| (F241). | |

| Minimum — 0.0 | |

|

| |

|

| Maximum — 30.0 |

|

| Units — Hz |

End Frequency

Program ⇒ Special Control Parameters ⇒ Frequency Control

This parameter sets the lowest frequency that the drive will recognize during deceleration before the drive goes to 0.0 Hz.

Direct Access Number — F243

Parameter Type — Numerical

Factory Default — 0.0

Changeable During Run — Yes

Minimum — 0.0

Maximum — 30.0

Units — Hz

0 Hz Dead Band Signal | Direct Access Number — | F244 |

Program ⇒ Special Control Parameters ⇒ Special Parameters ⇒ Dead | Parameter Type — Numerical | |

Band of 0 Hz Frequency | Factory Default — 0.0 |

|

This parameter sets an output frequency threshold that, until the commanded | Changeable During Run — Yes | |

|

| |

frequency surpasses this setting, the ASD will output 0 Hz to the motor. | Minimum — 0.0 |

|

Note: This setting will override the Startup Frequency setting (F240) | Maximum — 5.0 |

|

Units — Hz |

| |

if this setting has a higher value. |

| |

|

|

|

DC Injection Braking Start Frequency | Direct Access Number — | F250 |

Program ⇒ Protection Parameters ⇒ DC Braking | Parameter Type — Numerical | |

During deceleration this is the frequency at which DC Injection braking will | Factory Default — 0.0 |

|

start. | Changeable During Run — Yes | |

DC Injection Braking | Minimum — 0.0 |

|

|

| |

DC Injection Braking is a braking system used with | Maximum — 120.0 |

|

Units — Hz |

| |

Unlike conventional brakes, there is no physical contact between the rotating |

| |

shaft and a stationary brake pad or drum. When braking is required, the drive |

|

|

outputs a DC current that is applied to the windings of the motor to quickly |

|

|

brake the motor. The braking current stops when the time entered in F252 |

|

|

times out. |

|

|

The intensity of the DC current used while braking determines how fast the |

|

|

motor will come to a stop and may be set at F251. The intensity setting is |

|

|

entered as a percentage of the full load current of the ASD. |

|

|

DC Injection Braking is also used to preheat the motor or to keep the rotor |

|

|

from spinning freely when the motor is off by providing a pulsating DC current |

|

|

into the motor at the Carrier Frequency. This feature may be enabled at F254. |

|

|

|

|

|

DC Injection Braking Current | Direct Access Number — | F251 |

Program ⇒ Protection Parameters ⇒ DC Braking | Parameter Type — Numerical | |

| Factory Default — 50.00 |

|

This parameter sets the percentage of the rated current of the drive that will be

used for DC Injection braking. A larger load will require a higher setting.

Changeable During Run — Yes

Minimum — 0.00

Maximum — 100.0

Units — %

G7 ASD Operation Manual | 105 |