Controller Link Units

Controller Link Units

Page

Omron

Omron Product References

Unit Versions

Unit Version Notation on Products

Confirming Unit Versions with Support Software

Unit Versions and Manufacturing Dates/Lot Numbers

Using the Unit Version Labels

Unit Version Notation

Function Support by Unit Version

Viii

Table of Contents

Data Links 105

Appendices

Xii

About this Manual

Name Contents Cat. No Suffixes omitted

Xiv

Read and Understand this Manual

Application Considerations

Disclaimers

Xviii

Precautions

General Precautions

Safety Precautions

Intended Audience

Operating Environment Precautions

Operating Environment Precautions

Applications Precautions

Xxiii

Conformance to EC Directives

EMC Directives

Low Voltage Directive

Section

Section

What Is the Controller Link?

Wired System

Overview

Branch Wiring

Long-distance Wiring

Converting Part of the Transmission Line to Optical Fiber

CS1W-CLK12-V1 CVM1-CLK12

Token Ring Mode

Connecting Repeater Units Using GI Optical Fiber Cable

Token Bus Mode

Data Links

Message Service

Automatic Setting

Manual Setting

Error Log

Or the message service function

Status Area

Specifications

Features

Features of Twisted-pair Cable

Features of Optical Fiber Cable

Compatible with Different Node Configurations

Improved Error Handling

Flexible Inter-network Connections

Up to 62 nodes can be connected

Features and Functions of Version-1 Models

Total length of wired networks can be extended

Devices can be modularized

System Configuration

Specifications and Configurations

Branch Wiring

Maximum Configuration of 62 Nodes

General Specifications

Items Specifications

Communications Specifications

PCF type GI type

Within 1 segment See Entire network

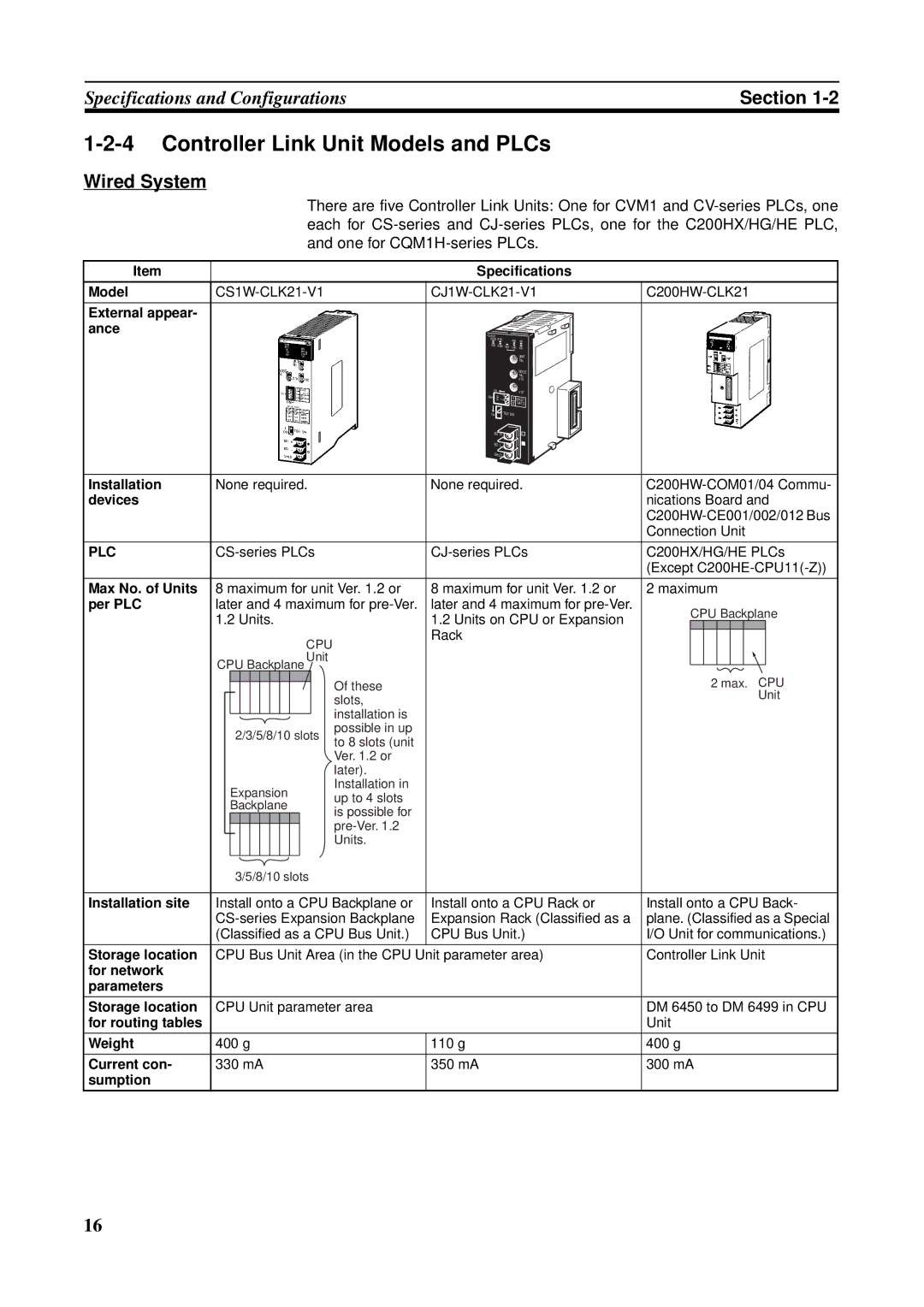

Controller Link Unit Models and PLCs

Wired System

Units per PLC

External Appearance Installation

Tables Weight

Max No.

CS/CJ-series Controller Link Unit Models

Unit Ver .2 Pre-Ver .2 Without -V1 suffix Suffix

Name Model Current consumption Number Per Unit a Units

Repeater Units when Required

Devices for Connection

Communications Cables

Name Model Remarks

Relay Terminal Blocks

Programming Devices

Programming Device for the PLC

Programming External Model Applicable PLCs Device

Controller Link Support Software Version

Using an Independent Computer

EV2 HG/HE, CVM1

Software External Model Applicable PLCs Remarks

CX-Programmer

Controller Link Support Software Menu Overview

Software External Model Applicable PLCs

When Operating on Personal Computer as Peripheral Software

When Operating on Personal Computer Connected as a Node

Selection of Communications Functions

Basic Procedures

Preparations C200HX/HG/HE and CQM1H-series PLCs

CVM1, CV-series, and CS/CJ-series PLCs

Application Precautions

C200HX/HG/HE PLC

Communications error type Data link areas

Section

Section

Basic Procedures

Manually Setting Data Links

Data Links Procedures

Set the data link mode

AR 0700 operating level #0

Automatically Setting Data Links

Start the data links

CS/CJ Series Word 0 of DM30000 + 100 ⋅

CV-series PLCs Console Only

Gramming Console

Section

CX-Programmer version 3.2 or higher

To 1 Type

CS/CJ Series Word 0 of DM30000 + 100 ⋅ N

Chain Type

Create the I/O tables

Message Service Procedure

Register routing tables if using inter-network connections

Contents Remarks

Create the user program

Section

Installation and Wiring

CS-series Controller Link Units

Component Names and Functions

Name Color Status Meaning

Wired Unit Indicators

CJ-series Controller Link Units

Dimensions Unit mm

For details, refer to 9-1 Troubleshooting Using Indicators

Component Names and Functions

3 C200HX/HG/HE Controller Link Unit

Node address switches Refer to p

Yellow Lit Data reception Receive Not lit No data reception

4 CVM1 and CV-series Controller Link Unit

Unit number switches Refer to p

34.5

5 CQM1H-series Controller Link Unit

Wire-to-Wire Repeater Unit

Dimensions Unit mm

Repeater Unit Indicators

Wire-to-Optical H-PCF Repeater Unit

Wire-to-Optical GI Repeater Unit

Unit Installation

C200HX/HG/HE PLCs

Installing One Controller Link Unit

Installing Two Controller Link Units

Mounting Controller Link Units

Installing with Another Communications Unit

Installing with a PC Card Unit

CVM1 and CV-series PLCs

Expansion CPU Rack

CS-series PLCs

CPU Rack

CJ-series PLCs

Mum current of 4.6 a 5 V and maximum power of 30 W

Mounting a Repeater Unit

CQM1H-series PLCs

Screw-mounting a Repeater Unit

Mounting a Repeater Unit on DIN Track

DIN Track

End Plate PFP-M 2 Plates required per Repeater Unit

Wiring

Communications Cables

Communications Cables

Connecting the Shield Line

Terminal Block Connections

Not Unit a Relay Terminal Block

Using a Relay Terminal Block

Connecting the Communications Cables

Apply vinyl tape or a heat-shrinking tube

Do not pull on a communication cable

Power Supply Wiring

Mark Signal name Line color

Repeater Units

Laying Optical Cable CS1W-RPT02/03 Only

Power Supply Specifications

Mounting bracket Tension member Terminal

Optical Fiber Cables Indoor Use Only

Name Specifications Model

Name Model Specifications

Optical Bus or Optical Ring System H-PCF Cable

Name Model Specifications Manufacturer

Optical Fiber Cables with Connectors Indoor Use Only

Optical Fiber Cable Accessories

Specifications Length Model

CS1W-RPT03 GI

Optical Fiber Cables

50/125 ∝m AGF Cable

Minimum Standard Maximum Unit Conditions

Connectors

Constructing Networks with Repeater Units

62.5/125 ∝m AGF Cable

Segments

Specifications within Remarks Each segment

Branch Wiring 2-stage Repeater Unit Connection

Number of Repeater Units

Examples of Correct Repeater Unit Connections

More than 2 Stages of Repeater Units

Long-distance Wiring 2-stage Repeater Unit Connection

Examples of Incorrect Repeater Unit Connections

Partial Optical Conversion 2-stage Repeater Unit Connection

Branch Wiring

Long-distance Wiring

Terminating Resistance

Partial Conversion to Optical Fiber

Section

Preparations for Communications

CS-series Controller Link Units

Overview

Unit Number

Node Addresses

Baud Rates

Pins Baud rate Maximum Transmission distance

Default setting is 2 Mbps, 500 m

Bottom switch Terminating resistance

CJ-series Controller Link Units

Setting range Nodes 01 to 32 default is

Setting range Nodes To F default is

Node

Baud Rates

C200HX/HG/HE PLC

C200HX/HG/HE Controller Link Units

Baud Rate and Operating Level

Always leave pin 3 OFF

Operating Level

Level Pin

Baud Rate Pins 1

Setting the Operating

Baud Rates and Operating Levels

Pin Operating level Node

Node Addresses

Setting Baud Rates

Always keep pins 3 and 4 set to OFF

CVM1 and CV-series Controller Link Units

Unit

Set the following pins for the baud rate setting DIP switch

Switch Baud rate Maximum Transmission distance Pin

Switch at the front Terminating resistance

Pin Sion dis Tance

Setting Baud Rate

Switch Terminating Nodes Resistance

CQM1H-series Controller Link Units

101

Repeater Units

Terminating Resistance Switch for SL2

Wire-to-Wire Repeater Unit

Wire-to Repeater

Terminating Resistance Switch for SL1

Switch Terminating resistance

Data Links

Manually Setting Data Links

What Are Data Links?

CS/CJ-series Controller Link Unit Functions by Unit Version

Offsets

Easy Setting

Automatic Setting Data Links with 1N Allocations

Automatically Setting Data Links with Equality Layout

Type Model

Offsetting Image

Using Offsets

Data Link Specifications

Communications error type Data link area

Description

Manual setting Automatic setting

Differences between Manual and Automatic Setting

Selecting Manual or Automatic Setting

Setting Data Links

Transferring from a Programming Device

Manual Setting

CS/CJ-series PLCs

Data Link Table Specifications

Setting item Setting range

Transferring from a Computer Node

116

C200HX/HG/HE PLCs

118

Used. Refer to 5-4 Checking Data Link Status for details

CVM1 and CV-series PLCs

CQM1H-series PLCs

121

W307 for information on the Controller Link Support Board

Precautions

Data link start word 1 + Total number of send/receive

Words in area ≤ 247 IR Area

Data Link Area Structure

Manual Setting Examples

Device Information Settings

SAMPLE1.CLK Same Allocation to All Nodes

124

SAMPLE2.CLK Different Allocations to Each Node

Device Information Setting

SAMPLE3.CLK Creating Data Link Groups within a Network

Device Information Setting Data Link Tables

Only area 2 is used in this example

SAMPLE4.CLK Receiving Only Part of Send Data and Offsets

Automatic Setting

CS/CJ-series Startup Node

Automatic Setting, Equality Layout

Automatic Setting, 1N

Allocations

Between master and slave nodes

Equality Layout

Setting Range for Automatic Setting

133

1N Allocation, Common Type

Features of Common Type 1N Allocation

135

136

137

1N Allocations, 1 to 1 Type

Features of 1 to 1 Type 1N Allocation

139

140

1N Allocation, Chain Type

Features of Chain Type 1N Allocation

142

143

144

C200HX/HG/HE Startup Node

Settings

146

CVM1 or CV-series Startup Node

148

149

CQM1H-series Startup Node

DM Parameter Area

Automatic Setting Example

Settings for Equality Layout

Link areas that are created as a result

Data Link Areas Created

DM Parameter Setting Example for 1N Allocation, Common Type

Automatically Set Data Links

Starting and Stopping Data Links

Data Link Areas

Manually Set Data Links

Using a Programming Device or the User Program

CS/CJ-series Start Bit

C200HX/HG/HE Start Bit

Using Fins Commands

Checking Data Link Status

LED Indicators

Check the Link and M/A indicators on the front of the unit

Name Color Status Contents

157

Following shows an example of a remaining receive area

Name Function

Data Link Status Storage Format CS/CJ Series Only

Data link status storage area is set as follows

Only status for nodes 1 to 6 are saved

Matic settings

Specification

Checking by Manipulating Bit/Word Status

Error Detection Program Example

Programming Examples for Processing Data when Errors Occur

Processing Data Only when Data Links Are Operating Normally

Data Link Example Communications Error at Node

Writing 0000 in the Data Link Area when Errors Occur

164

Message Service

Introduction

CS/CJ-series PLCs

Send and Recv

168

@SEND90

C200HX/HG/HE PLCs

170

171

CIO

Timer/counters numbers 0 to 2047 can send and receive data

Word for data reception at the destination node, N

Section CVM1 and CV-series PLCs

174

CQM1H-series PLCs

176

177

178

179

180

181

Cmnd

Beginning word for storing response data

Type of command Code

Example Commands for CVM1, CV-series and CS/CJ-series PLCs

Area Range

Send/Receive Data Areas

CVM1-CPU11/21

Area Range CV500, CVM1-CPU01

Selecting Communications Instructions

Read/write

Com

Tents

Puter Or CV

Message Service Specifications

Using the Message Service

Name Address Contents Word Bit

SEND/RECV Flags

CVM1, and CV-series PLCs

Name Operating Address Contents Level

Name Address Contents

Network Status

Example

Word Bits Contents

SEND/RECV Flag Operations

Communications Instruction Response Codes

CS/CJ-series, CVM1,

C200HX/HG/HE

CQM1H-series PLC

Response Codes

C200HX/HG/HE PLCs CS/CJ-series, CVM1, and CV-series PLCs

Simultaneous Execution of Communications Instructions

On the next

PLC Programming Examples

195

196

197

198

Fins Commands and Responses

Fins Communications Service

Sending and Receiving Fins Commands and Responses

Execution result

Applicable Units for Fins Commands

Command Codes

Any parameters must follow the command code

Response Block

Commands and Responses for Controller Link Units

Command Codes

Command Block

Model

Response Block For C200HX/HG/HE, CVM1, and CV-series PLCs

For CS/CJ-series and CQM1H-series PLCs

Parameters

Wired/Optical response

Reads the Controller Link Unit’s controller status

Unit. Always set to 00 Hex

204

Corresponding to the node address

Network Status Read

0 0 0 0

Hex 32 nodes

Default value 32 nodes

Reads the data link operational status

Ified as a 2-byte 4-digit hexadecimal number as follows

208

One was sent is returned

Data that was sent by the command

Response gives the number of records actually read

Reads the PLC’s error log

Broadcasts test data to all nodes in a specified network

Hexadecimal decimal 0 to

Configuration of each error record is as follows

Error LOG Clear

Memory Area Designations

Command PLC mode Name Code

Memory Area Code

Specified for CQM1H-series PLCs

Word/Bit Addresses

Each word/bit address specifies a specific bit or word

Flag or Bit Status One Byte

Data Configuration

Word Contents or PV Two Bytes

Parameters Memory area code command The data area to read

Parameters Memory area code command The data area to write

Memory Areas

Memory area Data No. Code Bytes

Memory area designations

Sequence starting from the beginning address

Program Area Write

Stop

Data command The data to be written

02 Hex Monitor mode 04 Hex RUN mode

8 RUN

Meaning Unit Hex

Area data response As follows

Command Block Response Block

Reads the status of the Controller

0 0

Value Day

Clock Read

Parameters Range

Parameters Error reset code command Set to Ffff Hex

Memory area Data

Value Function

Response

Designations for memory area designations

Area Data type Memory area Number Code Bytes

Configuration

Response Codes

IR, SR, LR, HR, and AR Areas

Relay Errors

Network Relay Errors

Exist

Response Codes and Troubleshooting

To some cause such as a routing table error

CPU Unit

228

229

230

231

232

Network Interconnections

What is Network Interconnection?

Interconnecting Controller Link Networks

Interconnecting Different Types of Networks

235

Remote Programming and Monitoring

Local Networks

Sysmac Support Software and CV Support Software

Sysmac Support Software or CV Support Software

Remote Controller Link Networks

CX-Programmer Programming Device

Other Remote Networks

Local Network Table

Routing Tables

Creating Routing Tables

Appropriate Unit according to the routing tables

Network end network not directly connected to the local PLC

Setting Routing Tables

Created

Relay Network Table

Routing Table Setting Procedure

Editing Local Network Tables

Local network

Saving Routing Tables

Editing Relay Network Tables

Operating level 0 DM Operating level 1 DM

Connecting to the PLC

Routing Table Enable Bit C200HX/HG/HE and CQM1H-series Only

Transferring Routing Tables

PCs

Example Routing Table Settings

Routing Tables on PLC

Nodes

246

Communications Timing

Data Transmissions over the Network

Communications Mechanism

Setting the Polling and Polled Nodes

No. of Polled Nodes per Communications Cycle

Network Parameters

Active Data Links

Network parameter Setting Default Range Value

Communications Cycle Time

Specifying Network Parameters

Communications conditions are as follows

Instruction When sent When received

Inactive Data Links

Calculation Example

Bytes

Being issued

Data Link I/O Response Time

Data Exchange Timing

CS/CJ-series PLCs, CVM1

Synchronous Mode

Data Processing Time

Under Asynchronous

Calculation Example

Time Case

257

258

259

260

261

Minimum Response Time

Maximum Response Time

CVM1 and CV-series PLCs Under Asynchronous Operation

264

Data Transmission Time

Message Delay Times

1 CS/CJ-series, CVM1, and CV-series PLCs

Data Processing Time see

Transmission Processing

Link Service Processing Source and Destination Nodes

Transmission Delay Time

Link Servicing Interval Source and Destination Nodes

Number of words transferred ⋅ 0.00075 + 1.3 ms

That transmits event frames before the Send command is sent

Maximum Delay Time

Reception Processing

268

269

Responses Number of words transferred ⋅ 0.00125 ms + 2.3 ms

2 C200HX/HG/HE and CQM1H-series PLCs

SEND90

Responses Number of words transferred ⋅ 0.00125 ms + 3 ms

RECV98 Instruction

272

273

274

Troubleshooting and Maintenance

CS-series Unit

Troubleshooting Using Indicators

Troubleshooting with RUN, ERC, ERH and INS Indicators

1 CS/CJ-series Controller Link Units

277

278

Started

Troubleshooting with LNK and M/A Indicators

Using the following table

Data Link Cannot be

Stopped

Troubleshooting of Other Errors

Node Cannot Participate

Data Link

Problem Status Cause and remedy

Configuring a Network with 33 Nodes or More

282

2 C200HX/HG/HE and CQM1H-series Controller Link Units

Configuring a Network with 32 Nodes or Less

284

285

286

CVM1 and CV-series Controller Link Units

288

289

290

291

Status Area and Troubleshooting

Troubleshooting with the PWR Indicator

Troubleshooting with the T/R1 and T/R2 Indicators

Status Area

Error Information CIO 1500 + 25 x Unit No

294

Bit Status and Error Processing

Data Link Status

Bit status Probable cause Probable remedy

296

Other Status

Refer to 7-4 Setting Rout

Stopping Data Links

Terminating Resistance Status CIO 1500 + 25 ⋅ Unit No. +

2 C200HX/HG/HE Controller Link Units

Duplicate Operating Levels/Refresh Error AR

Routing Table Error/Unit Restart Bits AR

Service Time AR 16, AR

Polling Node Address, Startup Node Address SR 238, SR

Data Link Status SR 239 to SR 241, SR 243 to SR

Operating Level Status SR

Data Link Status First Data Link Status Word + 0 to +

Troubleshooting with Status Flags

302

303

3 CVM1 and CV-series Controller Link Units

Error Information CIO 1500 + 25 ⋅ Unit No

Data Link Status CIO 1500 + 25 ⋅ Unit No. + 7 to +

306

307

4 CQM1H-series Controller Link Units

Error Information IR

Data Link Status IR 91 to IR

Polling Node Address, Startup Node Address IR

Network Participation Status IR 192 and IR

Local Data Link Participation Status IR

310

311

Terminating Resistance Status IR

Routing Tabless and reset

Error Log

Error Log Table

Error Log Table Configuration

1st byte 2nd byte

Error Codes

Tents of the errors

Time Information

315

Response block

Command block

317

318

319

Clearing an Error Log

Reading and Clearing Error Logs

Error Status

Reading an Error Log

Error message Troubleshooting

Example Display of Error List

322

Tools and Equipment Need for Inspection

Cleaning and Inspection

Cleaning

Inspection

Word Unit

Handling Precautions

Replacing the Unit

Bit address Unit

Resetting Network Parameters

Setting the Unit after Replacement

326

3.. . Turn off all nodes in the Controller Link Network

Using the Controller Link Support Software

Not Using the Controller Link Support software

C200HX/HG/HE and CQM1H-series Controller Link Units

CS/CJ-series, CVM1, and CV-series Controller Link Units

329

330

Adding Nodes and Editing Active Data Link Tables

Adding Nodes Using a Repeater Unit

Example of Adding Nodes Using a T-branch Line

Example of Adding Nodes with a Repeater Unit on One End

Precautions when Connecting Nodes Using a Repeater Unit

Procedure for Adding Nodes

Adding Nodes with a Repeater Unit at One End

System Configuration after Adding Nodes

Systems with an Existing T-branch Line

Systems Wired with an Existing Repeater Unit

Model Remarks

Operations when Changing Data Link Tables

Changing the Data Link Tables with Active Data Links

Example of Changing Data Link Table with Active Data Links

337

Procedure

339

340

341

342

Communications Cables Twisted-pair Cables

Standard Models Controller Link Units

Controller Link Support Board

Controller Link Support Software

Applicable Name Model number Applicable PLCs Computer

CX-Programmer with CX-Net

CPU Units and Programming Devices

CPU Units

Other Products Used with Controller Link Units

Page

Memory Areas

CS/CJ-series PLCs

Auxiliary Area

CIO Area CS/CJ CPU Bus Unit Area

CS/CJ CPU Bus Unit Duplication Error Flag

CS/CJ CPU Bus Unit Error, Unit Number Flags

Error Information CIO 1500 + 25 ⋅ Unit No. See

349

350

DM Area CS/CJ CPU Bus Unit Area

Common Type

Memory AreasAppendix B

Chain Type

To 1 Type

C200HX/HG/HE PLCs

SR Area

Communications Instruction Response Codes SR 237 See

Operating Level Status SR 252 See pages 189

Duplicate Operating Levels/Refresh Error AR 00 See

Routing Table Error/Unit Restart Bits AR 01 See

AR Area

DM Parameter Area

Service Time AR 16, AR 17 See

CVM1 and CV-series PLCs

CPU Bus Unit Numbers

CIO Area CPU Bus Unit Area

359

DM Area CPU Bus Unit Area

Word Bits Name Contents

CQM1H-series PLCs

Data Link Start Bit AR 07 See

Local Data Link Participation Status IR 90 See

Data Link Status IR 91 to IR 93 See pages 156

Terminating Resistance Status IR 95 See

Controller Link Status Information

PLC Setup Settings in DM Area

Automatic Data Link Parameters DM 6401 to DM 6409 See

Appearance Name Model number Remarks

Using the Relay Terminal Block

Replacing a Controller Link Unit with a Relay Terminal Block

367

Page

Numerics

Index

371

372

373

374

Revision History

Revision code Date Revised content

Pages 115, 117, 119, and 120 PC changed to PLC

Revision History

Regional Headquarters

Omron Corporation Control Devices Division H.Q

Authorized Distributor