Operating manual

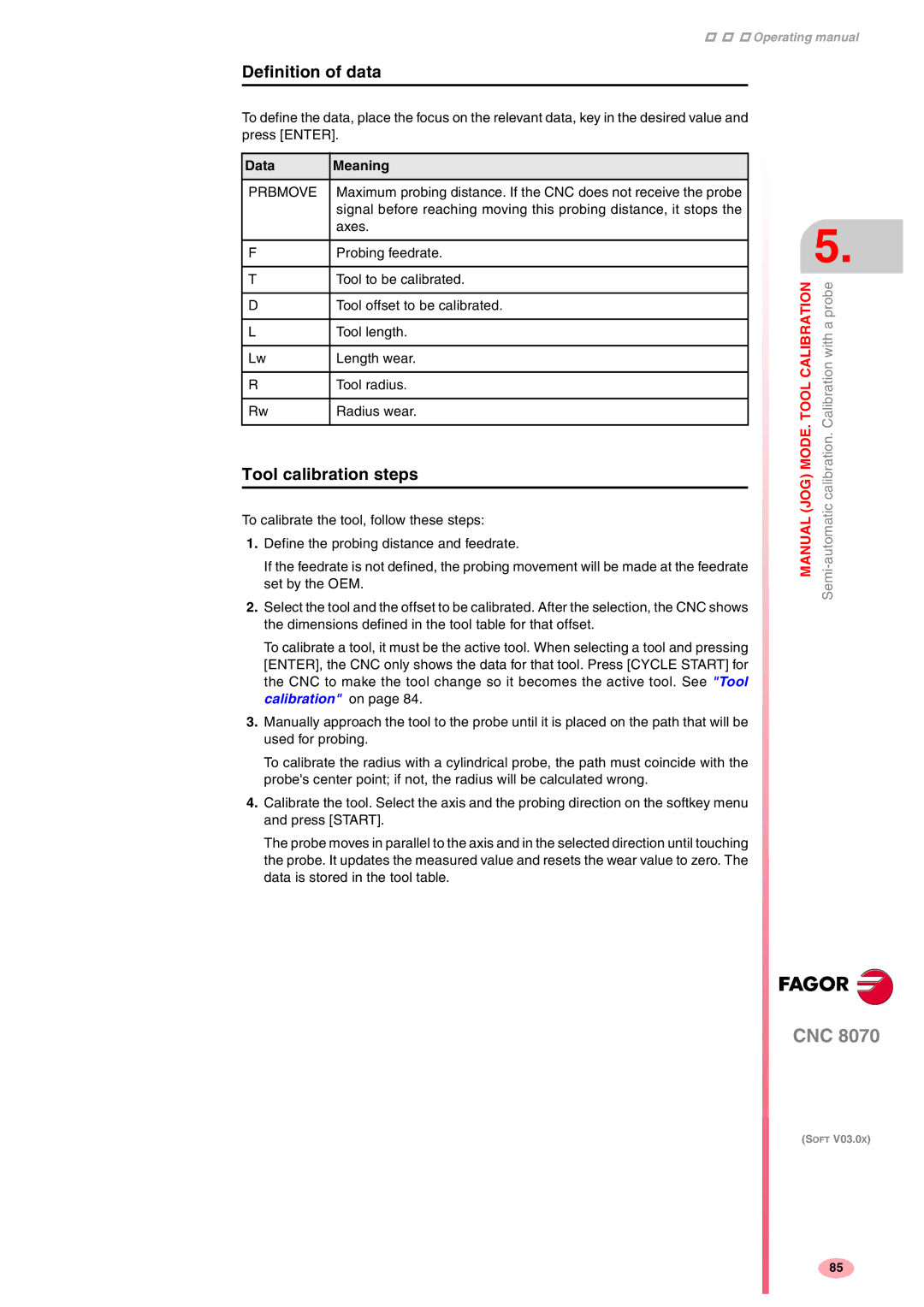

Definition of data

To define the data, place the focus on the relevant data, key in the desired value and press [ENTER].

Data | Meaning |

|

|

PRBMOVE | Maximum probing distance. If the CNC does not receive the probe |

| signal before reaching moving this probing distance, it stops the |

| axes. |

|

|

F | Probing feedrate. |

|

|

T | Tool to be calibrated. |

|

|

D | Tool offset to be calibrated. |

|

|

L | Tool length. |

|

|

Lw | Length wear. |

|

|

R | Tool radius. |

|

|

Rw | Radius wear. |

|

|

Tool calibration steps

To calibrate the tool, follow these steps:

1.Define the probing distance and feedrate.

If the feedrate is not defined, the probing movement will be made at the feedrate set by the OEM.

2.Select the tool and the offset to be calibrated. After the selection, the CNC shows the dimensions defined in the tool table for that offset.

To calibrate a tool, it must be the active tool. When selecting a tool and pressing [ENTER], the CNC only shows the data for that tool. Press [CYCLE START] for the CNC to make the tool change so it becomes the active tool. See "Tool calibration" on page 84.

3.Manually approach the tool to the probe until it is placed on the path that will be used for probing.

To calibrate the radius with a cylindrical probe, the path must coincide with the probe's center point; if not, the radius will be calculated wrong.

4.Calibrate the tool. Select the axis and the probing direction on the softkey menu and press [START].

The probe moves in parallel to the axis and in the selected direction until touching the probe. It updates the measured value and resets the wear value to zero. The data is stored in the tool table.

5.

MANUAL (JOG) MODE. TOOL CALIBRATION |

CNC 8070

(SOFT V03.0X)

85