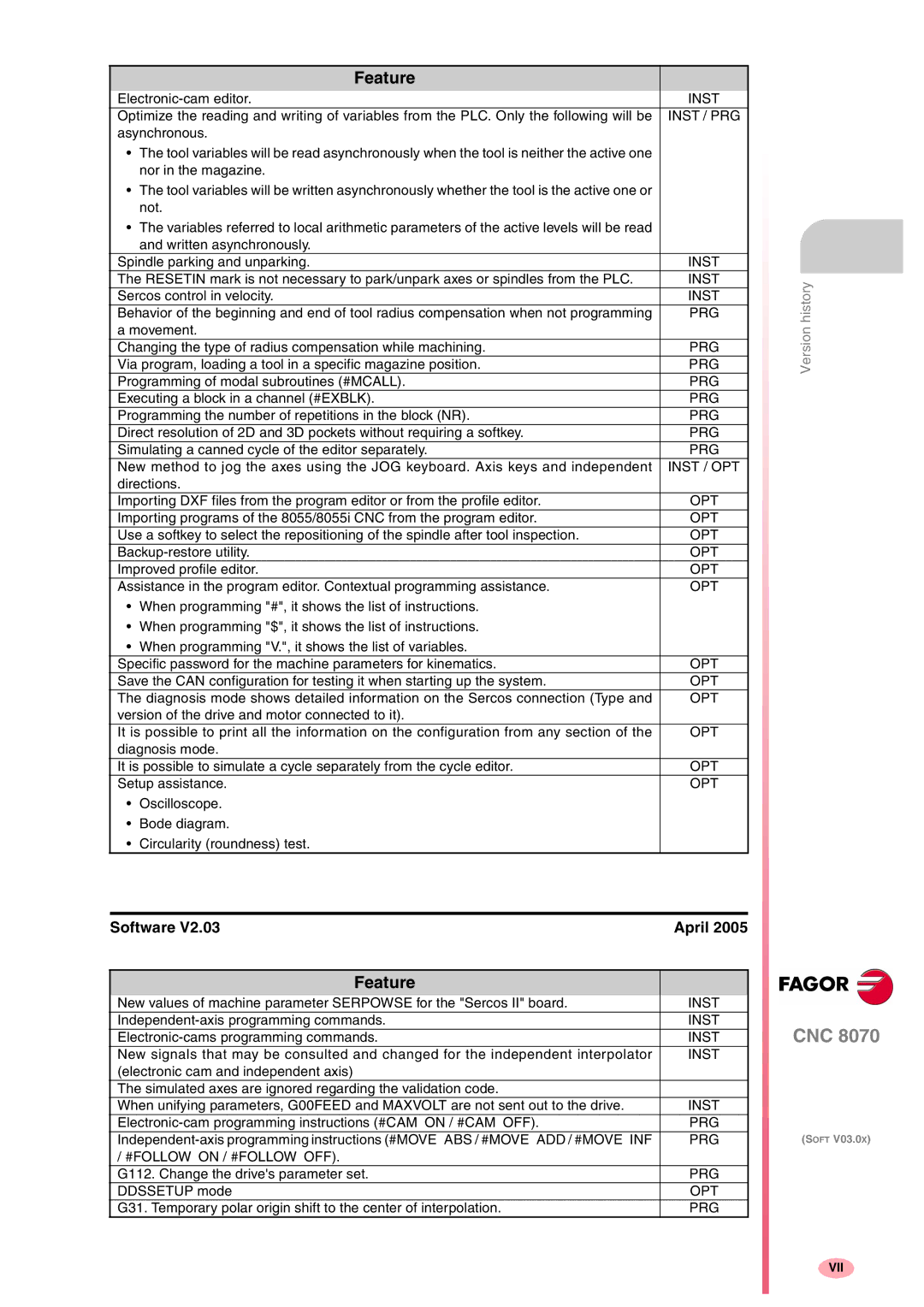

| Feature |

|

| |

INST |

| |||

Optimize the reading and writing of variables from the PLC. Only the following will be | INST / PRG |

| ||

asynchronous. |

|

| ||

• The tool variables will be read asynchronously when the tool is neither the active one |

|

| ||

| nor in the magazine. |

|

| |

• The tool variables will be written asynchronously whether the tool is the active one or |

|

| ||

| not. |

|

| |

• | The variables referred to local arithmetic parameters of the active levels will be read |

|

| |

| and written asynchronously. |

|

| |

Spindle parking and unparking. | INST |

| ||

The RESETIN mark is not necessary to park/unpark axes or spindles from the PLC. | INST | history | ||

Sercos control in velocity. | INST | |||

| ||||

Behavior of the beginning and end of tool radius compensation when not programming | PRG |

| ||

a movement. |

| Version | ||

Changing the type of radius compensation while machining. | PRG | |||

| ||||

Via program, loading a tool in a specific magazine position. | PRG |

| ||

Programming of modal subroutines (#MCALL). | PRG |

| ||

Executing a block in a channel (#EXBLK). | PRG |

| ||

Programming the number of repetitions in the block (NR). | PRG |

| ||

Direct resolution of 2D and 3D pockets without requiring a softkey. | PRG |

| ||

Simulating a canned cycle of the editor separately. | PRG |

| ||

New method to jog the axes using the JOG keyboard. Axis keys and independent | INST / OPT |

| ||

directions. |

|

| ||

Importing DXF files from the program editor or from the profile editor. | OPT |

| ||

Importing programs of the 8055/8055i CNC from the program editor. | OPT |

| ||

Use a softkey to select the repositioning of the spindle after tool inspection. | OPT |

| ||

OPT |

| |||

Improved profile editor. | OPT |

| ||

Assistance in the program editor. Contextual programming assistance. | OPT |

| ||

• | When programming "#", it shows the list of instructions. |

|

| |

• | When programming "$", it shows the list of instructions. |

|

| |

• | When programming "V.", it shows the list of variables. |

|

| |

Specific password for the machine parameters for kinematics. | OPT |

| ||

Save the CAN configuration for testing it when starting up the system. | OPT |

| ||

The diagnosis mode shows detailed information on the Sercos connection (Type and | OPT |

| ||

version of the drive and motor connected to it). |

|

| ||

It is possible to print all the information on the configuration from any section of the | OPT |

| ||

diagnosis mode. |

|

| ||

It is possible to simulate a cycle separately from the cycle editor. | OPT |

| ||

Setup assistance. | OPT |

| ||

• | Oscilloscope. |

|

| |

• | Bode diagram. |

|

| |

• | Circularity (roundness) test. |

|

| |

Software V2.03April 2005

Feature |

|

|

New values of machine parameter SERPOWSE for the "Sercos II" board. | INST |

|

INST | CNC 8070 | |

INST | ||

New signals that may be consulted and changed for the independent interpolator | INST |

|

(electronic cam and independent axis) |

|

|

The simulated axes are ignored regarding the validation code. |

|

|

When unifying parameters, G00FEED and MAXVOLT are not sent out to the drive. | INST |

|

PRG |

| |

PRG | (SOFT V03.0X) | |

/ #FOLLOW ON / #FOLLOW OFF). |

|

|

G112. Change the drive's parameter set. | PRG |

|

DDSSETUP mode | OPT |

|

G31. Temporary polar origin shift to the center of interpolation. | PRG |

|

VII