Section 2 |

| |

|

|

|

NOTE: Using the <F1> key (Totalizer clear command) also clears all channel totalizers plus the overflow register described in the last paragraph.

Assigning Relay 1 and 2 Functions

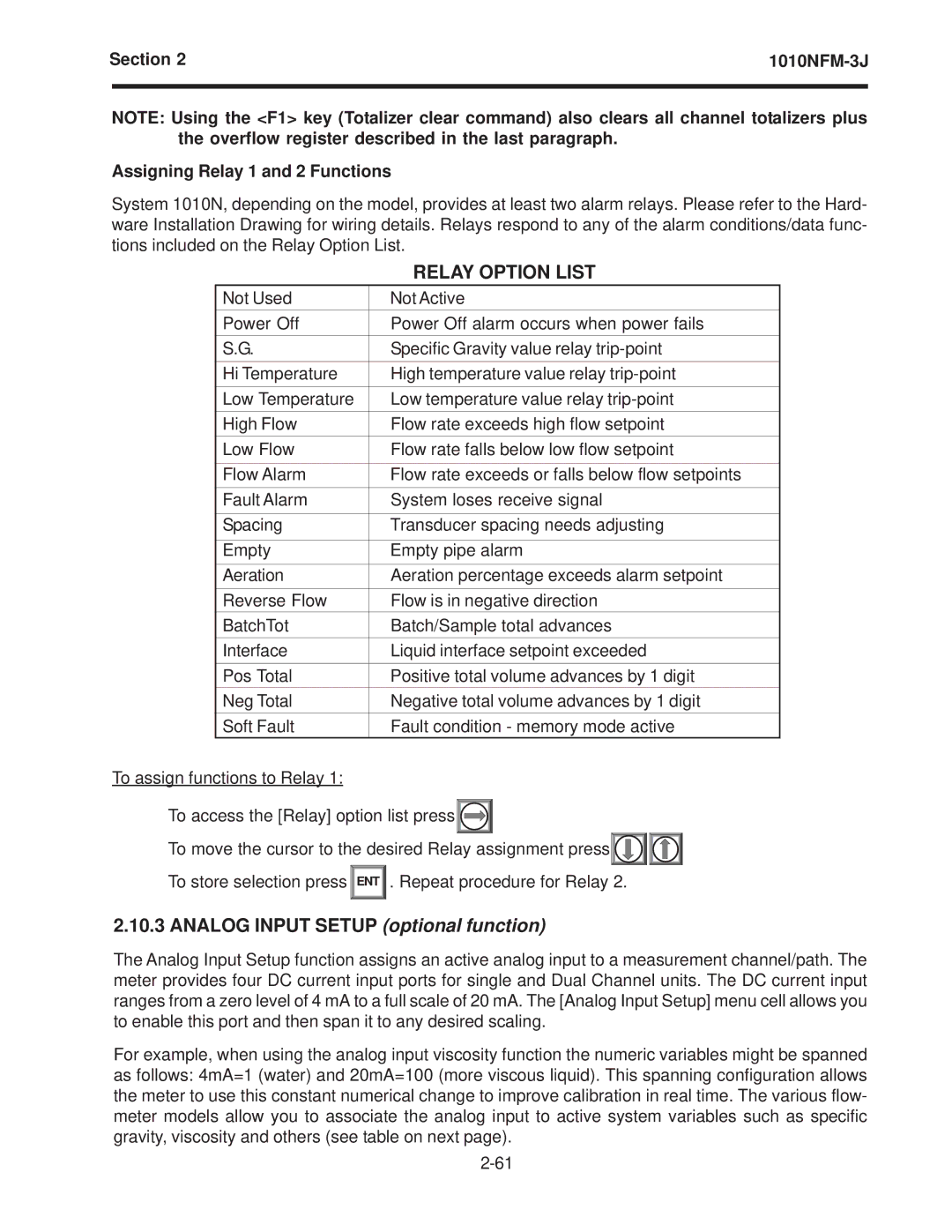

System 1010N, depending on the model, provides at least two alarm relays. Please refer to the Hard- ware Installation Drawing for wiring details. Relays respond to any of the alarm conditions/data func- tions included on the Relay Option List.

| RELAY OPTION LIST | |

Not Used | Not Active | |

Power Off | Power Off alarm occurs when power fails | |

S.G. | Specific Gravity value relay | |

|

|

|

Hi Temperature | High temperature value relay | |

|

|

|

Low Temperature | Low temperature value relay | |

High Flow | Flow rate exceeds high flow setpoint | |

Low Flow | Flow rate falls below low flow setpoint | |

|

|

|

Flow Alarm | Flow rate exceeds or falls below flow setpoints | |

Fault Alarm | System loses receive signal | |

|

|

|

Spacing | Transducer spacing needs adjusting | |

|

|

|

Empty | Empty pipe alarm | |

Aeration | Aeration percentage exceeds alarm setpoint |

|

|

| |

Reverse Flow | Flow is in negative direction | |

BatchTot | Batch/Sample total advances |

|

Interface | Liquid interface setpoint exceeded | |

Pos Total | Positive total volume advances by 1 digit |

|

Neg Total | Negative total volume advances by 1 digit | |

Soft Fault | Fault condition - memory mode active | |

To assign functions to Relay 1:

To access the [Relay] option list press![]()

![]()

![]()

To move the cursor to the desired Relay assignment press ![]()

![]()

![]()

![]()

![]()

![]()

To store selection press![]() ENT

ENT ![]() . Repeat procedure for Relay 2.

. Repeat procedure for Relay 2.

2.10.3ANALOG INPUT SETUP (optional function)

The Analog Input Setup function assigns an active analog input to a measurement channel/path. The meter provides four DC current input ports for single and Dual Channel units. The DC current input ranges from a zero level of 4 mA to a full scale of 20 mA. The [Analog Input Setup] menu cell allows you to enable this port and then span it to any desired scaling.

For example, when using the analog input viscosity function the numeric variables might be spanned as follows: 4mA=1 (water) and 20mA=100 (more viscous liquid). This spanning configuration allows the meter to use this constant numerical change to improve calibration in real time. The various flow- meter models allow you to associate the analog input to active system variables such as specific gravity, viscosity and others (see table on next page).